General frock clamp for shaft parts

A technology for shaft parts and fixtures, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of inflexible placement, troublesome operation, single specification of clamping parts, etc., and achieves low cost and simple structure. , to solve the effect of a single specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

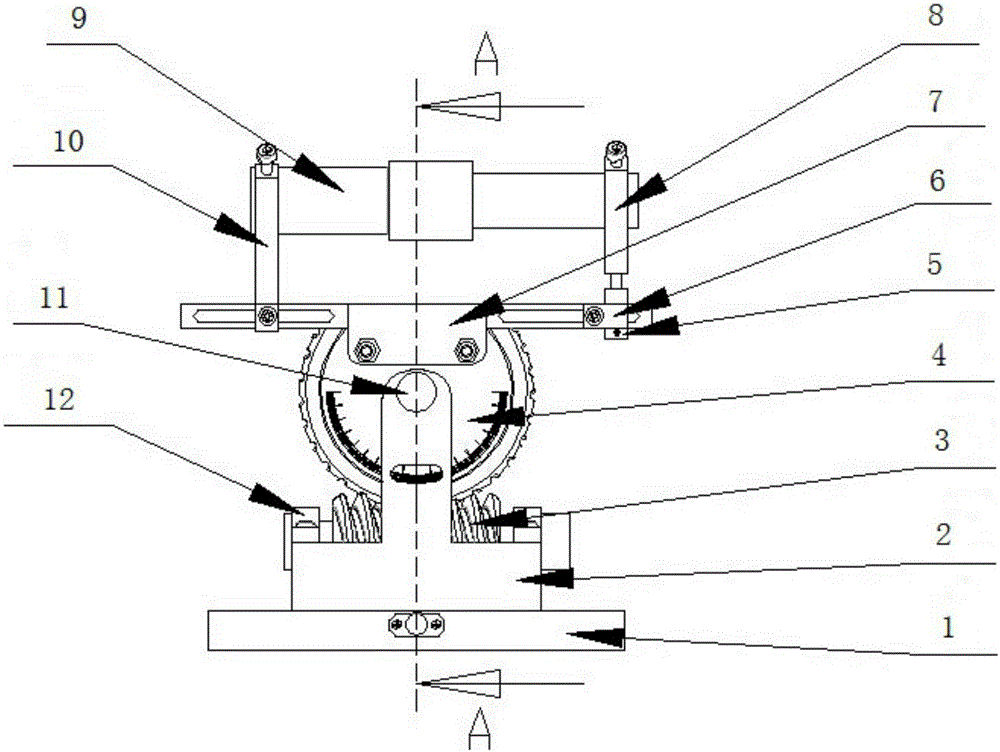

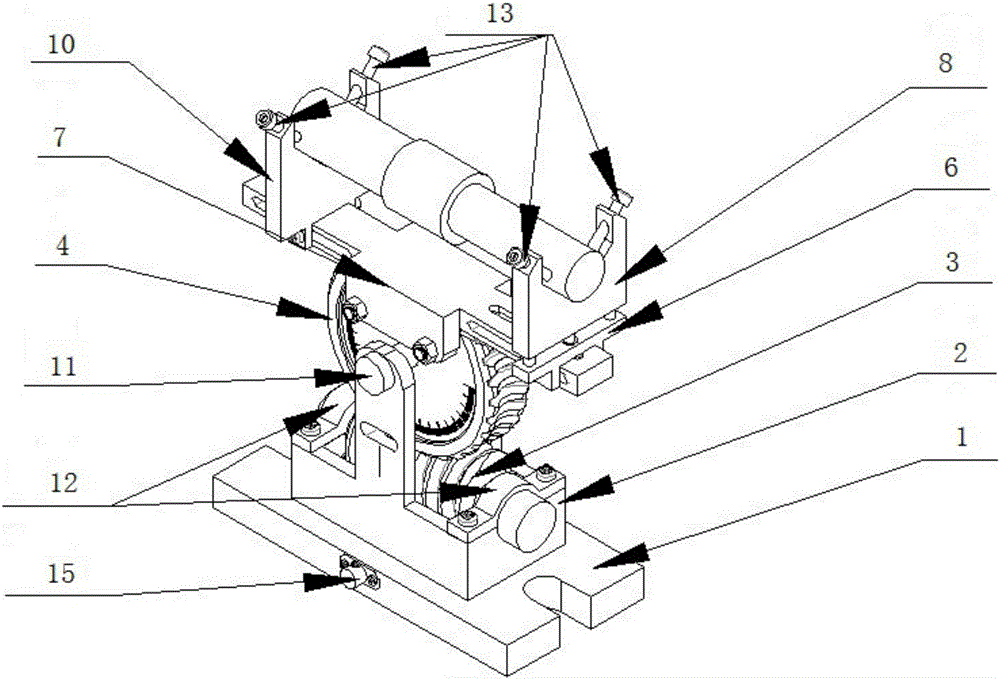

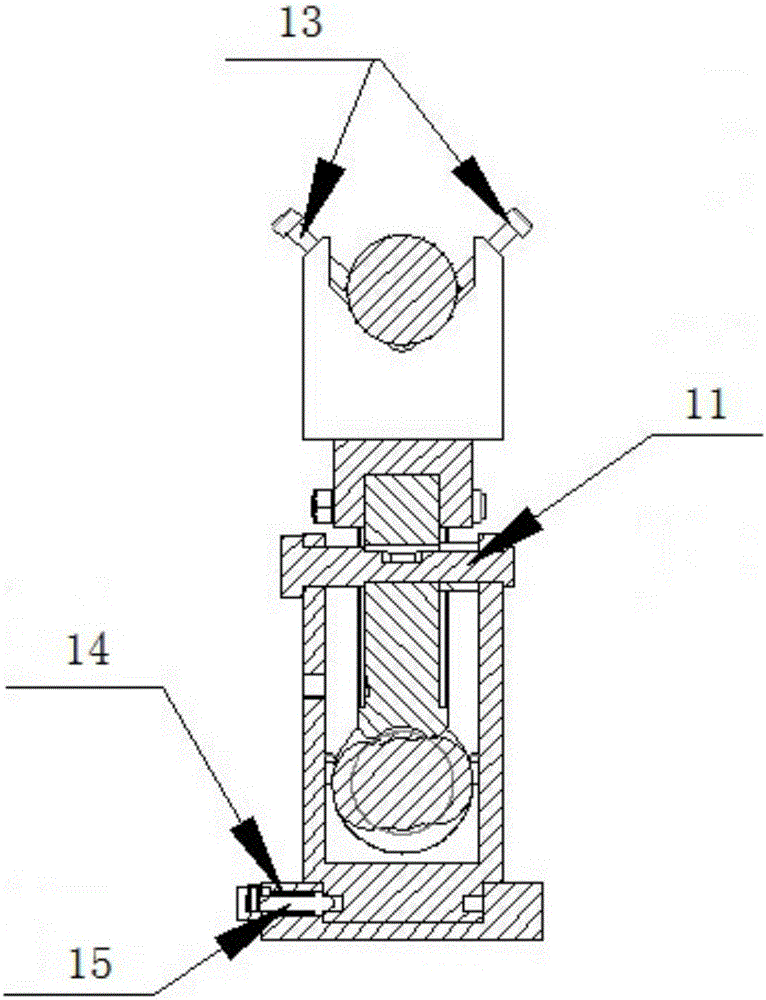

[0041] like Figure 1-2 As shown, a front view and an isometric view of a universal fixture for shaft parts according to the present invention includes a base 1 , an angle adjustment mechanism, an adjustment mechanism, a clamping mechanism and a shaft part 9 .

[0042] It should be pointed out that the angle adjustment mechanism includes a horizontal rotating part for rotating the clamping mechanism on a horizontal plane, and a vertical rotating part for rotating the clamping mechanism on a vertical plane, so The horizontal rotation part is a housing 2 with a turntable at the bottom; the vertical rotation part is a self-locking worm gear structure, and the self-locking worm gear structure includes a worm 3, a worm wheel 4, a shaft 11 and a shaft sleeve 12; the adjustment mechanism Including screw rod 5, slider 6, support slide rail 7, right V-shaped block 8 and left V-shaped block 10; the clamping mechanism includes right V-shaped block 8, left V-shaped block 10, and the The ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com