Evanescent mode foundry sand treatment device

A technology of lost foam casting and processing equipment, which is applied in the direction of casting molding equipment, cleaning/processing machinery of casting mold materials, manufacturing tools, etc., which can solve the problems of poor processing effect and low efficiency of molding sand processing, and achieve processing efficiency Low, efficient and convenient handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

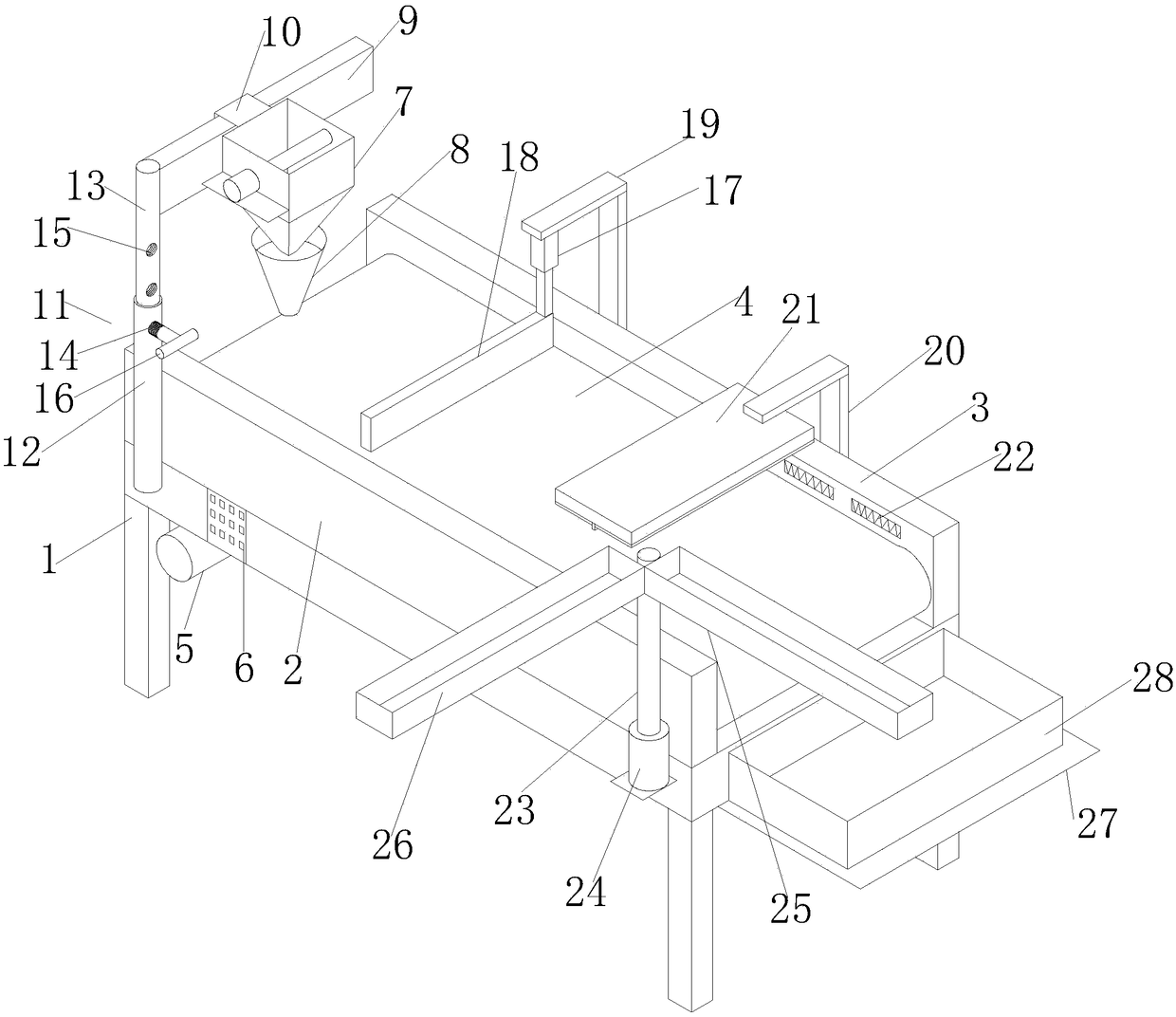

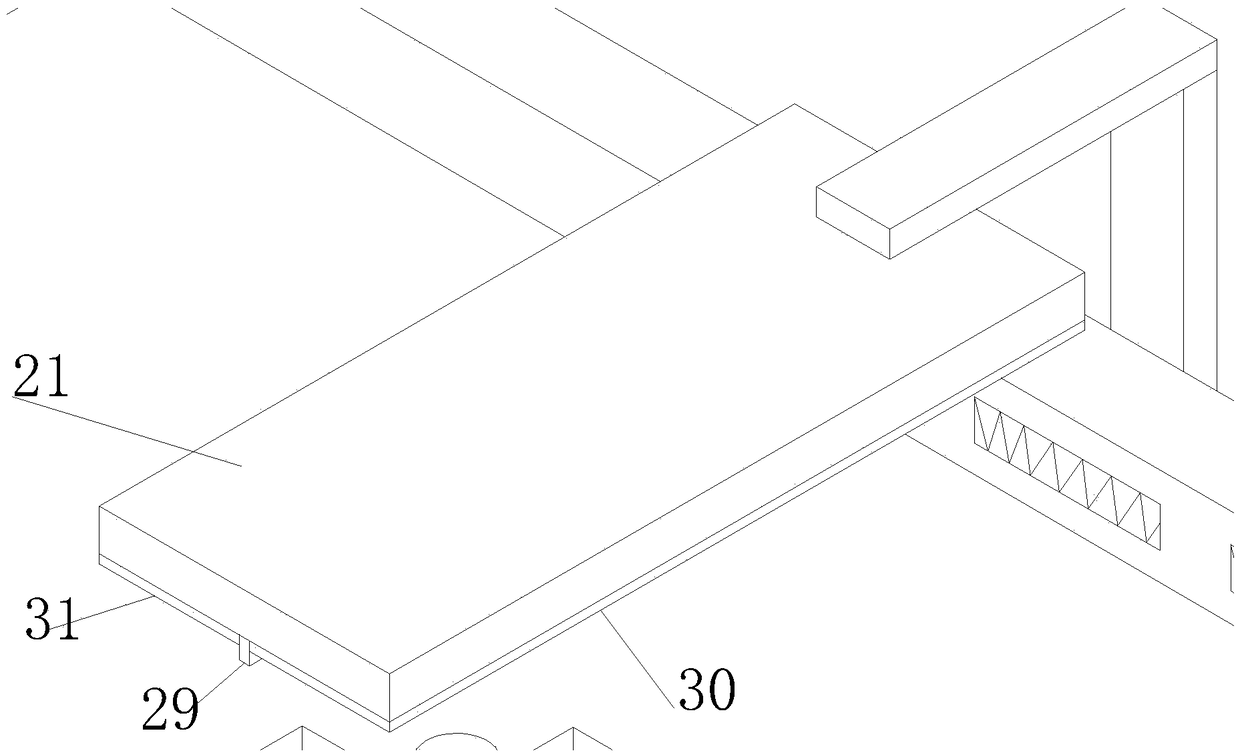

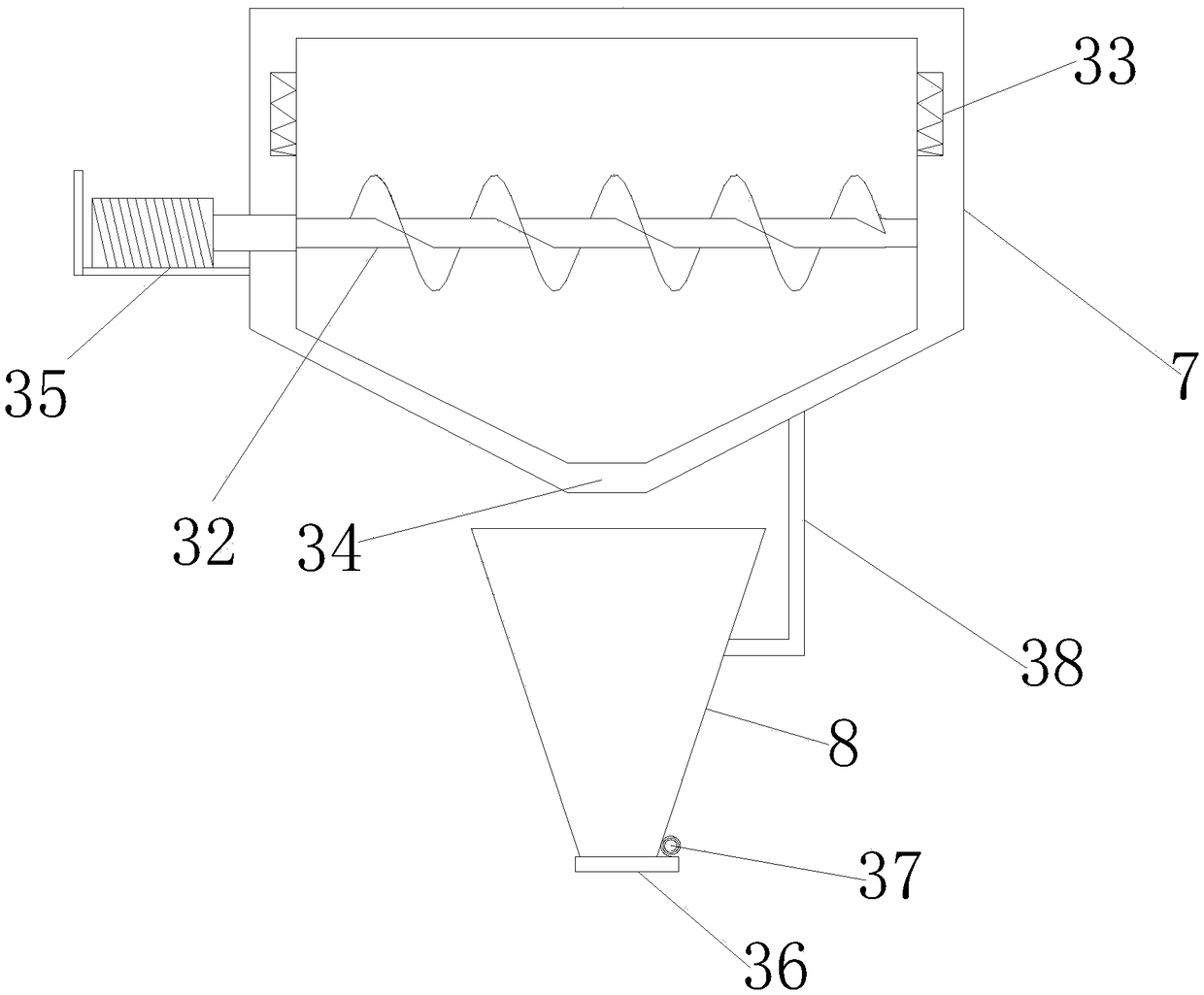

[0018] According to a lost foam casting sand processing device shown in the figure, it includes a machine platform 1, a left baffle plate 2 is provided on one end of the machine platform 1, and a right baffle plate 3 is provided at the other end, and the machine platform 1 is provided with Transmission belt 4, described transmission belt 4 links to each other with deceleration motor 5 through transmission mechanism, and described deceleration motor is arranged at the bottom of machine table 1, and described transmission belt 4 top is provided with feeding box 7, and described feeding box 7 inner wall is Hollow structure, the inner wall of the feeding box 7 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com