Circulating fluidized bed waste gas treatment device and system and waste gas treatment method

A waste gas treatment device and a technology of circulating flow, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of increasing the contact time between waste gas and adsorbent, poor waste gas effect, and low waste gas treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

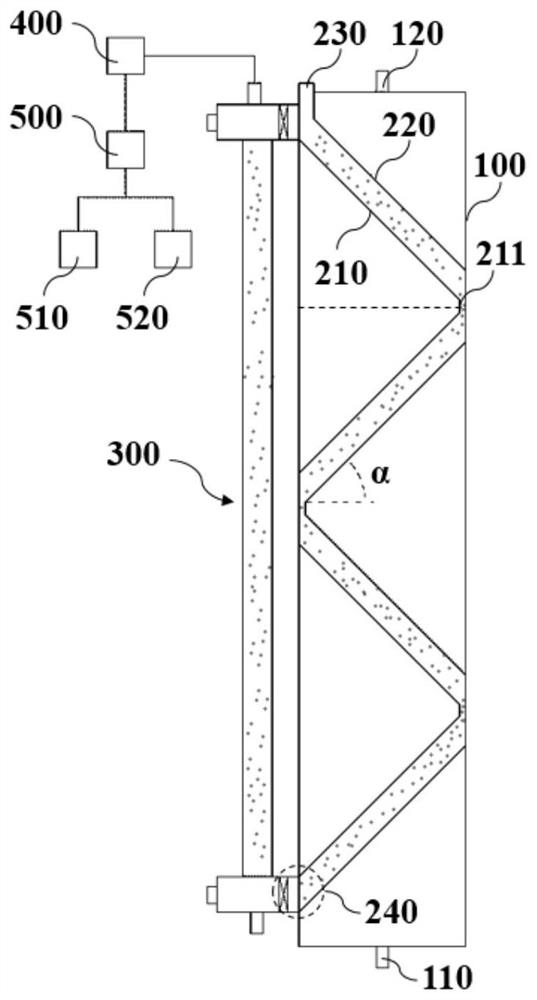

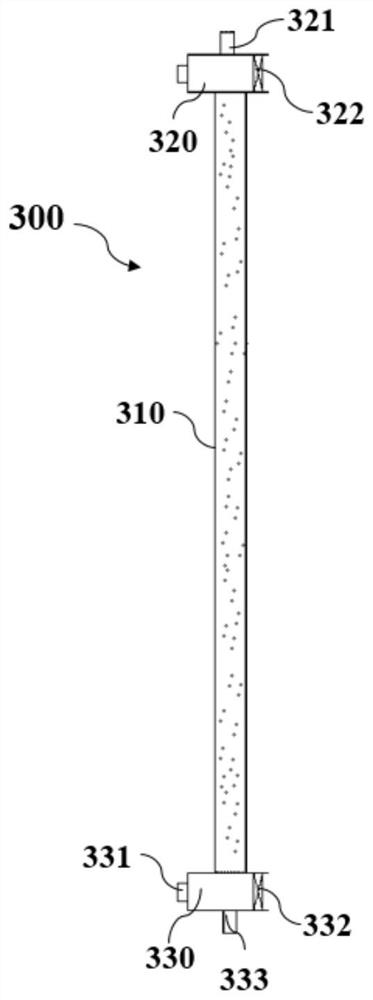

[0045] A circulating fluidized bed exhaust gas treatment device of the present invention includes an adsorption tower 100 , a fluidized plate 210 and a steam riser 300 . The bottom of the adsorption tower 100 is provided with an air inlet 110 and an adsorbent inlet 230 , and the bottom of the adsorption tower 100 is provided with a gas outlet 120 and an adsorbent outlet 240 . The diameter of the adsorption tower 100 is generally 0.6-1.2m, and the area of the inclined fluidized plate 210 is adapted to the inner diameter of the adsorption tower 100 . Further illustrate, when the adsorption tower 100 is circular, the fluidized plate 210 is generally oval, and the peripheral side of the fluidized plate 210 is connected with the inner wall of the adsorption tower 100; when the adsorption tower 100 is rectangular, the fluidized plate 210 It is generally rectangular, and the peripheral side of the fluidized plate 210 is connected to the inner wall of the adsorption tower 100 .

[...

Embodiment 2

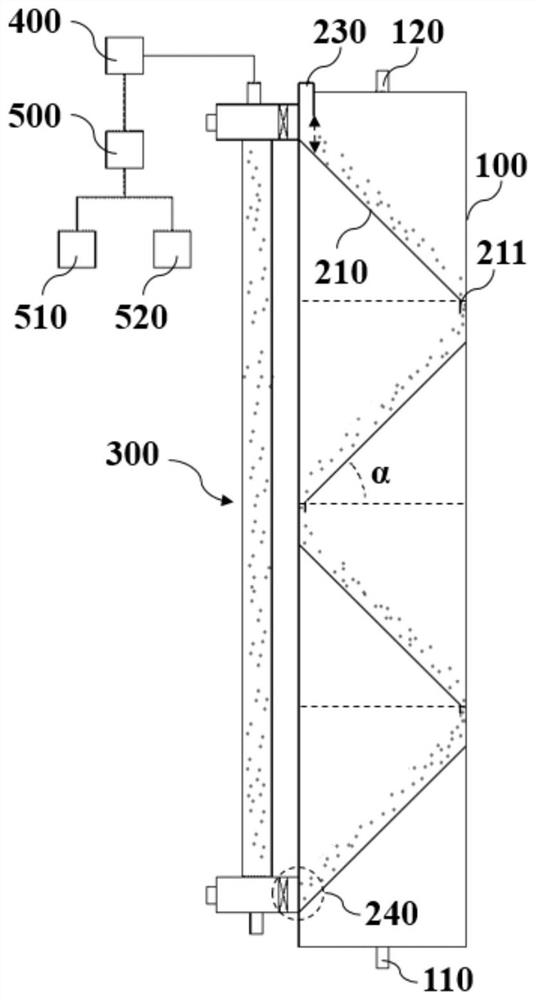

[0061] The basic content of this embodiment is the same as that of Embodiment 1, the difference is: in this embodiment, as image 3 As shown, there is no limiting plate 220 above the fluidization plate 210, the fluidization effect of this embodiment on resin is slightly worse than that of embodiment 1, and the effect of this embodiment on waste gas treatment is slightly worse than that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com