Processing method of amorphous alloy member

A technology of amorphous alloys and processing methods, which is applied in the field of amorphous alloy processing, can solve problems such as difficulty in processing amorphous alloys and difficulty in ensuring processing accuracy, and achieve the effects of shortening the production cycle, reducing processing difficulty, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

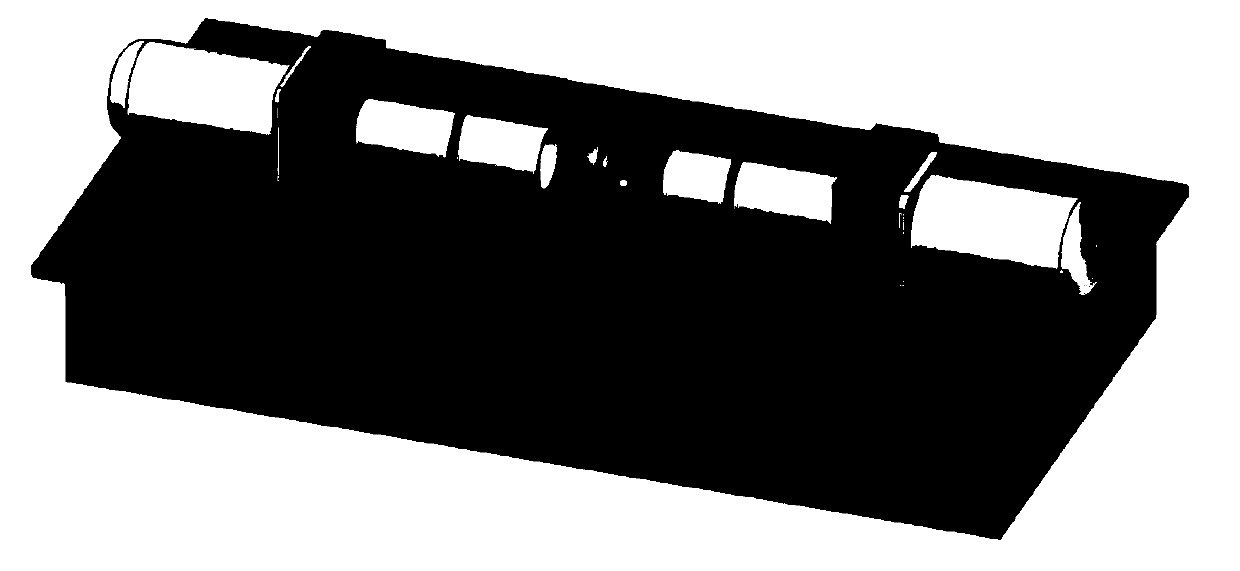

[0038] This embodiment is a processing method for removing flash of an amorphous alloy ball. During the processing, a self-made tool system is used to rub the amorphous ball at high speed, such as image 3 As shown, the self-made tool system includes a cylindrical fixed body and a cylindrical cutter, and one end of the cylindrical fixed body is set as a hemispherical concave structure, and the hemispherical concave structure is compatible with the amorphous alloy ball to be processed. Size fits. One end of the cylindrical tool is an annular blade-shaped structure, and the amorphous alloy ball to be processed is fixed through the cooperation of the hemispherical concave structure and the annular blade-shaped structure. After the amorphous alloy ball is fixed, the annular blade of the tool is closely attached to the inner edge of the flash of the amorphous alloy ball. The cylindrical fixed body can be rotated through the control of the machine tool, and can also be fixed. The ...

Embodiment 2

[0045] This embodiment is a method for processing a round hole on an amorphous alloy plate. The processing tool used in this embodiment is a hole opener. The hole opener includes a cylindrical cutter with an annular blade-like structure at the end of the cutter. During processing, the annular blade of the tool is closely attached to the circumference of the hole to be opened on the amorphous alloy plate, and an axial extrusion force F is applied.

[0046] Present embodiment process is as follows:

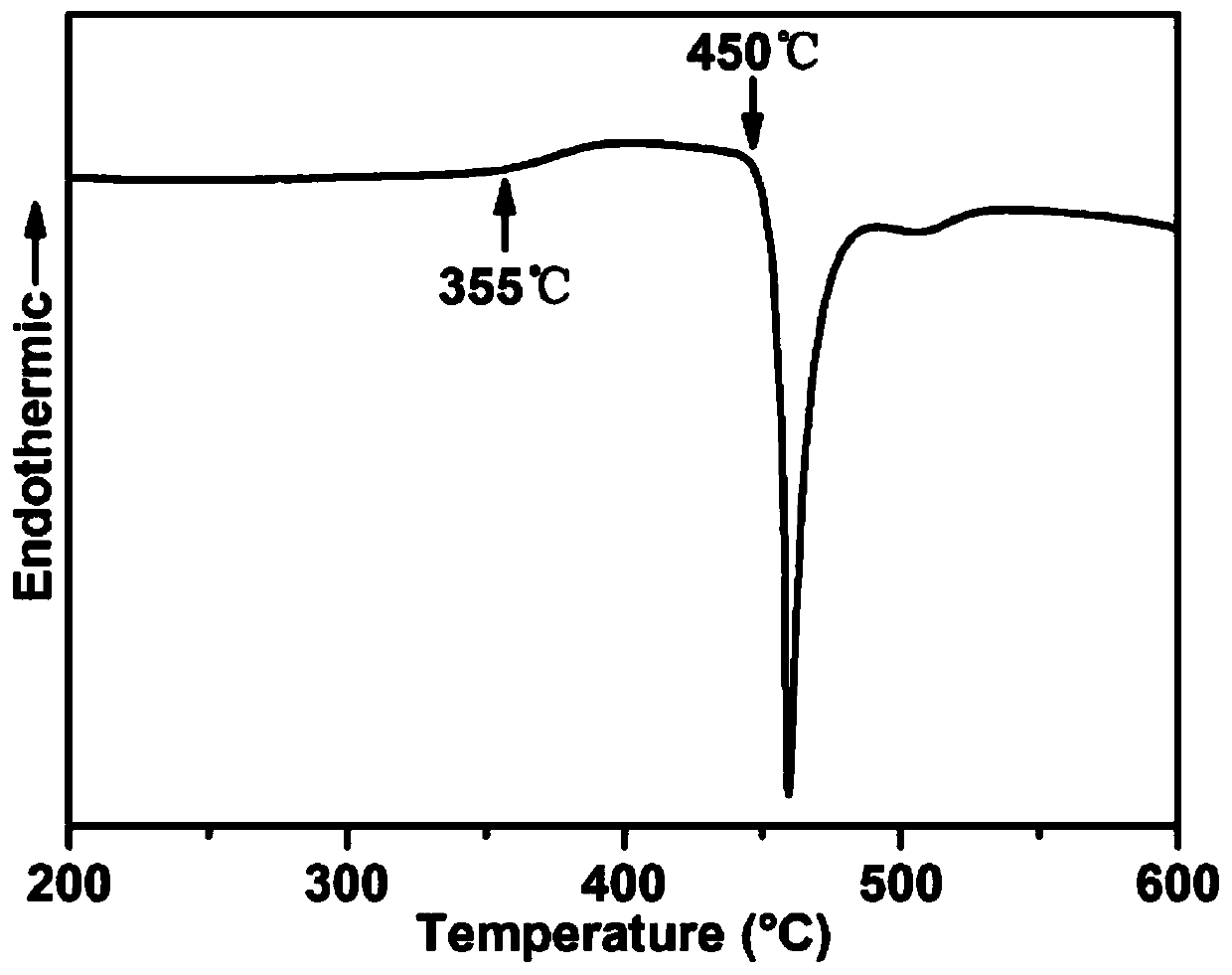

[0047] First, the thermodynamic characteristics of the amorphous alloy were characterized, and the glass transition temperature and crystallization initiation temperature of the amorphous alloy were obtained as 355°C and 450°C, respectively;

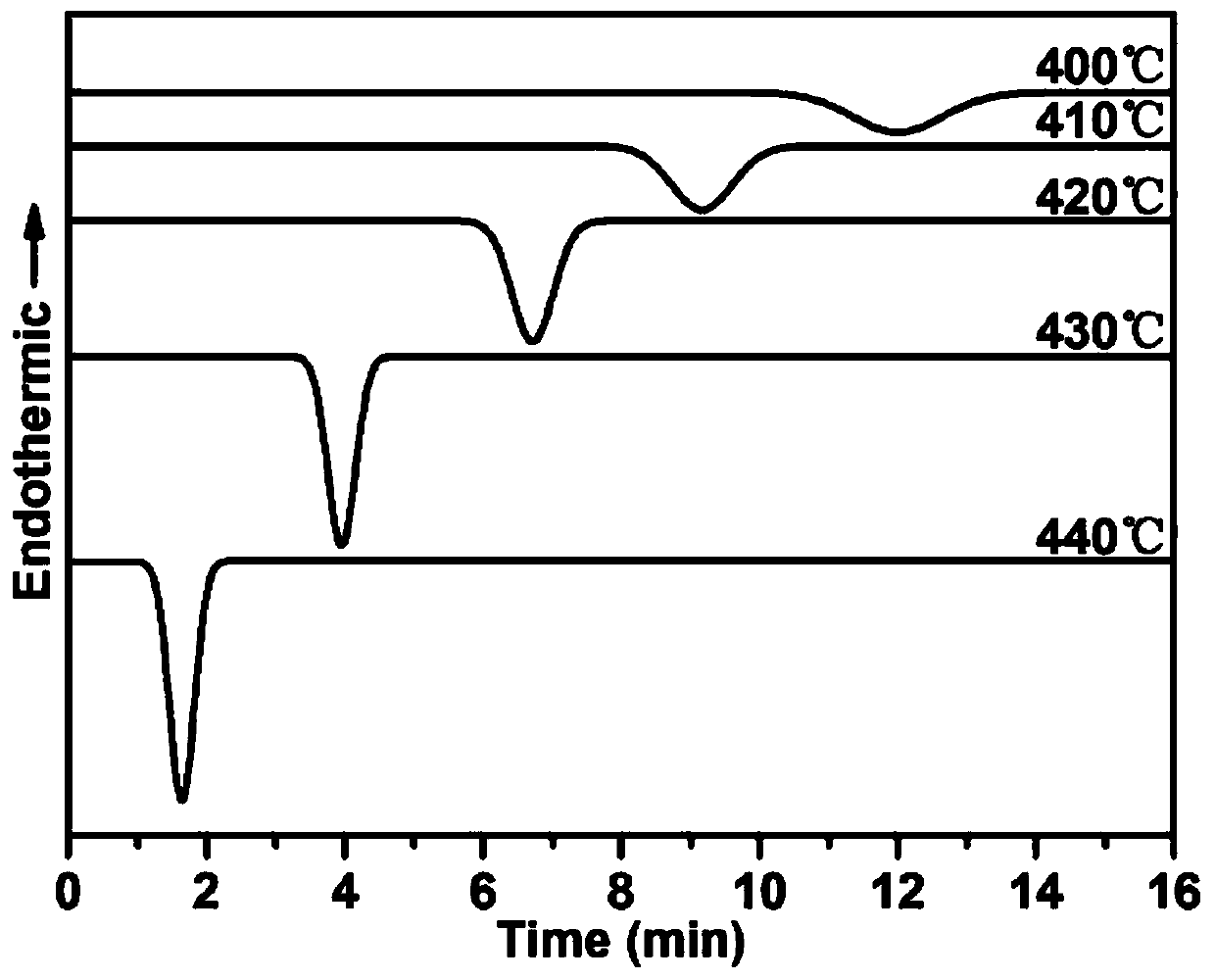

[0048] In this temperature range (355°C-450°C), conduct isothermal DSC characterization of the amorphous alloy plate, and the crystallization initiation time of the amorphous alloy is greater than 1min at 440°C;

[0049] Use the hole opener t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com