Unfolding plate blank for bent and twisted stringer

A long truss, bending and torsion technology, applied in the field of aircraft digital manufacturing, can solve the problems of unsuitable processing accuracy, high manual operation intensity, and a large number of tooling, so as to achieve the effect of improving molding consistency, improving processing efficiency, and saving tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

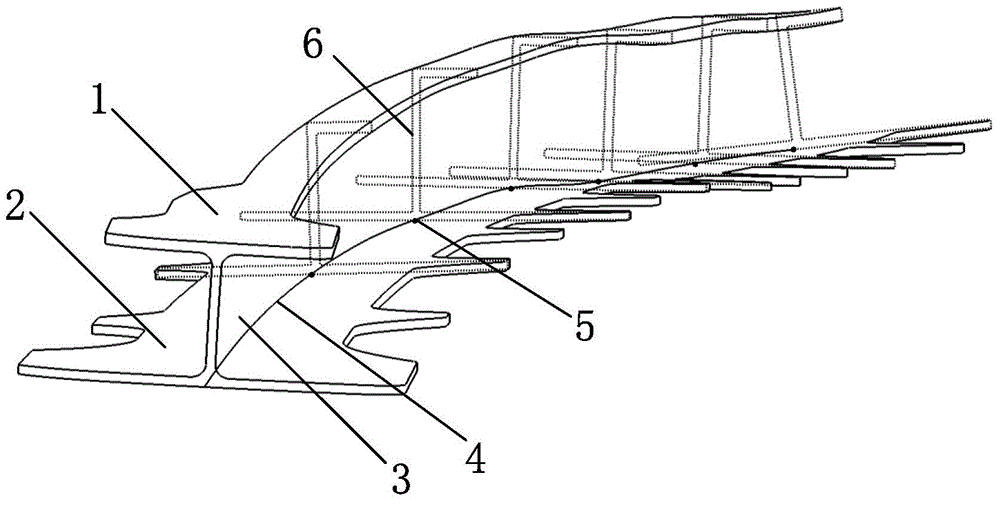

[0019] figure 1 It is a schematic design digital model of a curved and twisted long truss of an aircraft, including the upper web 1, the lower web 2, the vertical rib 3 connecting the upper and lower webs, and the reference line 4. The cumulative twist angle of vertical rib 3 along the direction of reference line 4 is 13.32°, and reference line 4 is a spatial curve.

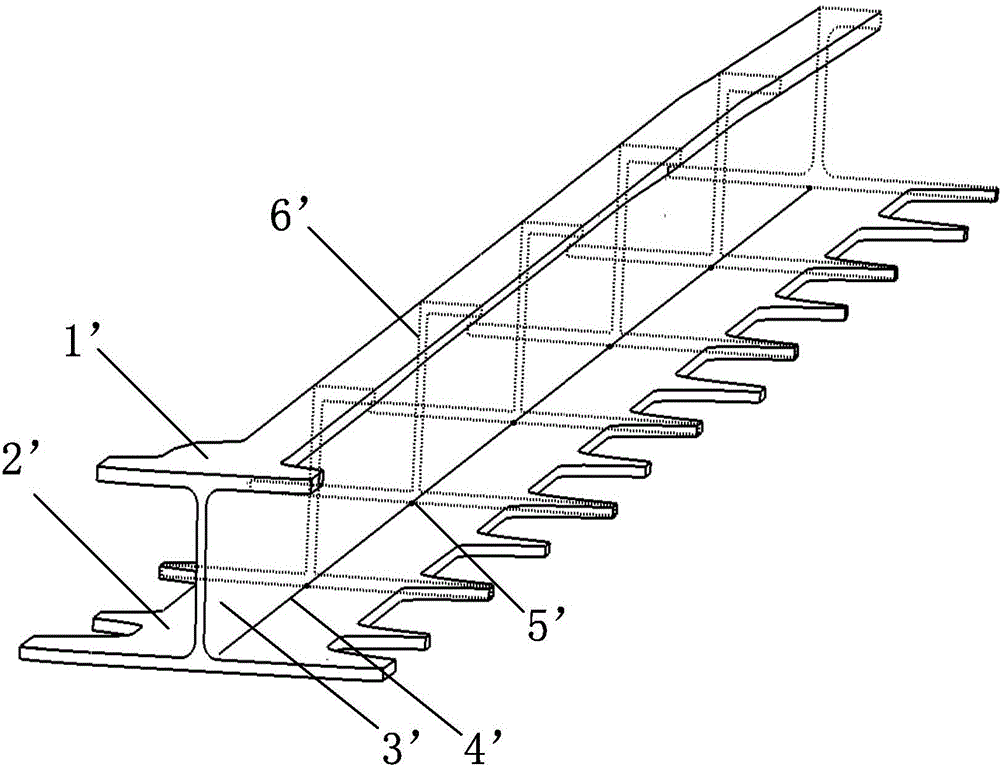

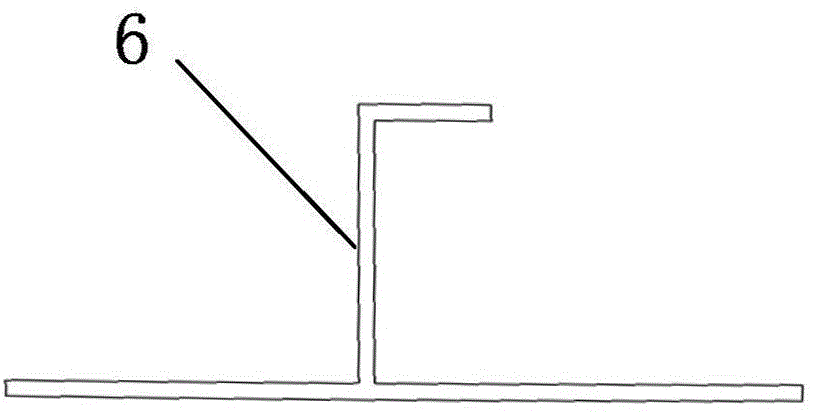

[0020] figure 2 The unfolded slab of the twisted stringer shown is given by figure 1 The shown bending and torsion truss design digital model is obtained by straightening and unfolding, corresponding to the upper web 1', the lower web 2', the vertical rib connecting the upper and lower webs 3' and the datum line 4'. The special point is that the datum line 4' is a straight line segment, and its length is equal to the datum line 4 length of the digital model of bending and torsion truss design. Such as image 3 , 4 As shown, the normal section 6' at any point 5' on the datum line 4' is the same as the normal...

Embodiment 2

[0023] Such as Figure 5 The digital model of the bent-torsion long truss design shown includes the upper web 1, the lower web 2, the vertical rib 3 connecting the upper and lower webs, and the datum line 4. The cumulative twist angle of the vertical rib 3 along the direction of the reference line 4 is 5.47°, the reference line 4 is a spatial curve, and there is a folding point 7 on the reference line 4.

[0024] Figure 6 The unfolded slab of the bent and twisted stringer with kinks shown is given by Figure 5 The shown curved and twisted long truss design with inflection point is obtained by straightening and unfolding, corresponding to the upper web 1', the lower web 2', the vertical rib connecting the upper and lower webs 3', the datum line 4' and the inflection point 7 '. The datum line 4' is a broken line composed of two straight line segments, and the included angle a' at the inflection point 11' is equal to the tangent angle a of the datum line 4 at the inflection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com