Furniture sliding rail

A sliding rail and furniture technology, applied in furniture parts, home utensils, drawers, etc., can solve the problems of easy wear and stagnation, large shaking gap, loss of limit function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

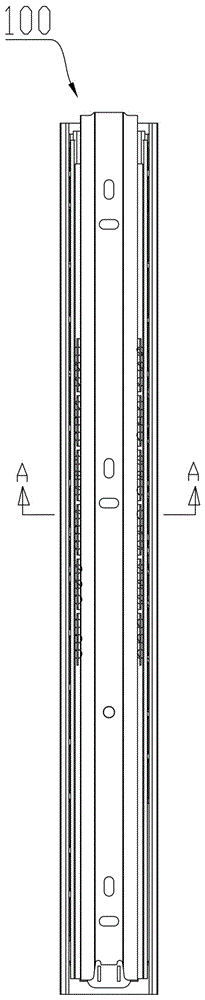

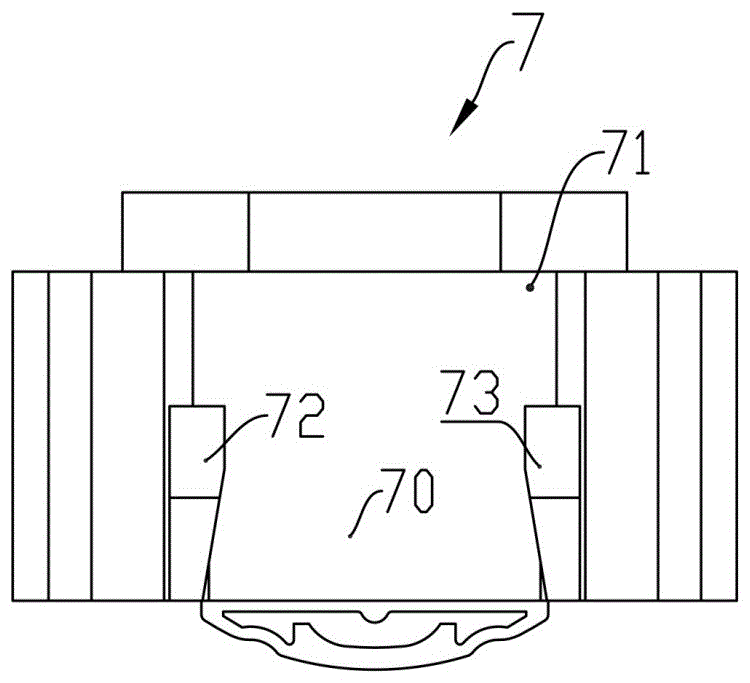

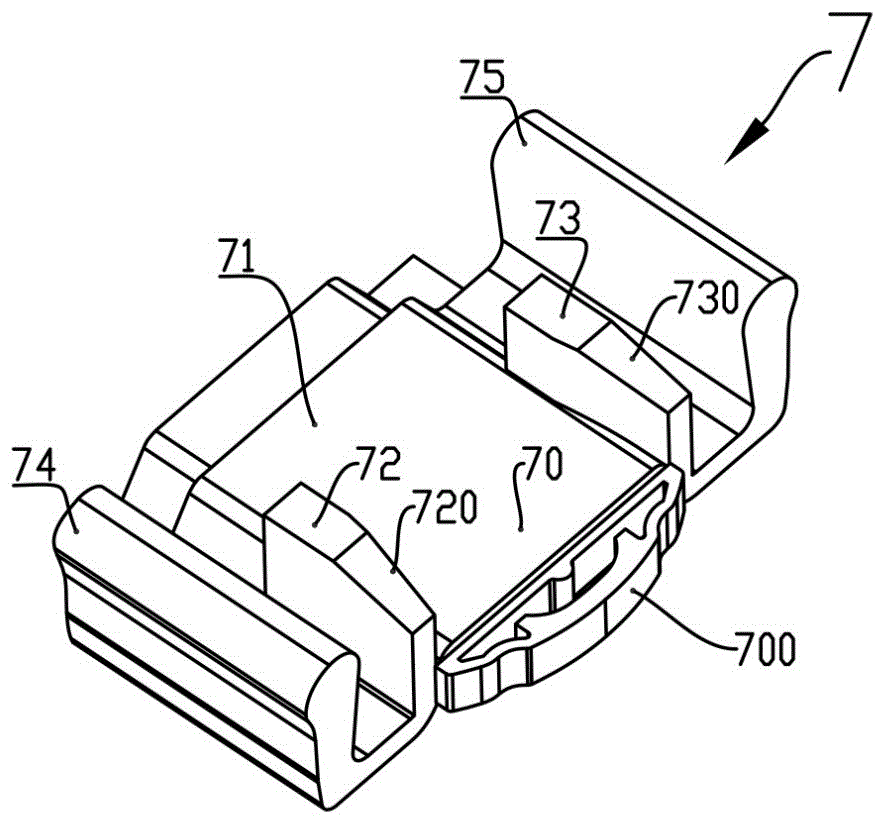

[0058] Drawer parts such as drawers and movable table boards are usually installed in furniture, and in order to provide sliding support for the drawer parts, furniture is provided between the drawer parts and the furniture. rails. Such as figure 1 and figure 2 It is a three-fold retractable furniture guide rail 100 with a new structure applying the technical solution of the present invention, including an outer rail 1 , a middle rail 2 and an inner rail 3 roughly in the shape of a U-shaped groove. The middle rail 2 is axially slidably arranged in the U-shaped groove of the outer rail 1 and the slots of the middle rail 2 and the outer rail 1 have the same orientation, and the inner rail 3 is axially slidably arranged in the U-shaped groove of the outer rail 1. In the U-shaped groove of the middle rail 2 and the notches of the middle rail 2 and the inner rail 3 are facing oppositely; and inner rail 3 sliding inwards so as to be able to limit the sliding stroke of said middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com