Brick-making dynamoelectric integrated blank-cutting method and active cut-in type blank-cutting machine

A blank-cutting machine and blank-cutting technology, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of irregularity, easy breaking of steel wires and cutting strips, and achieve the effect of reducing workload, ensuring product quality, and increasing output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

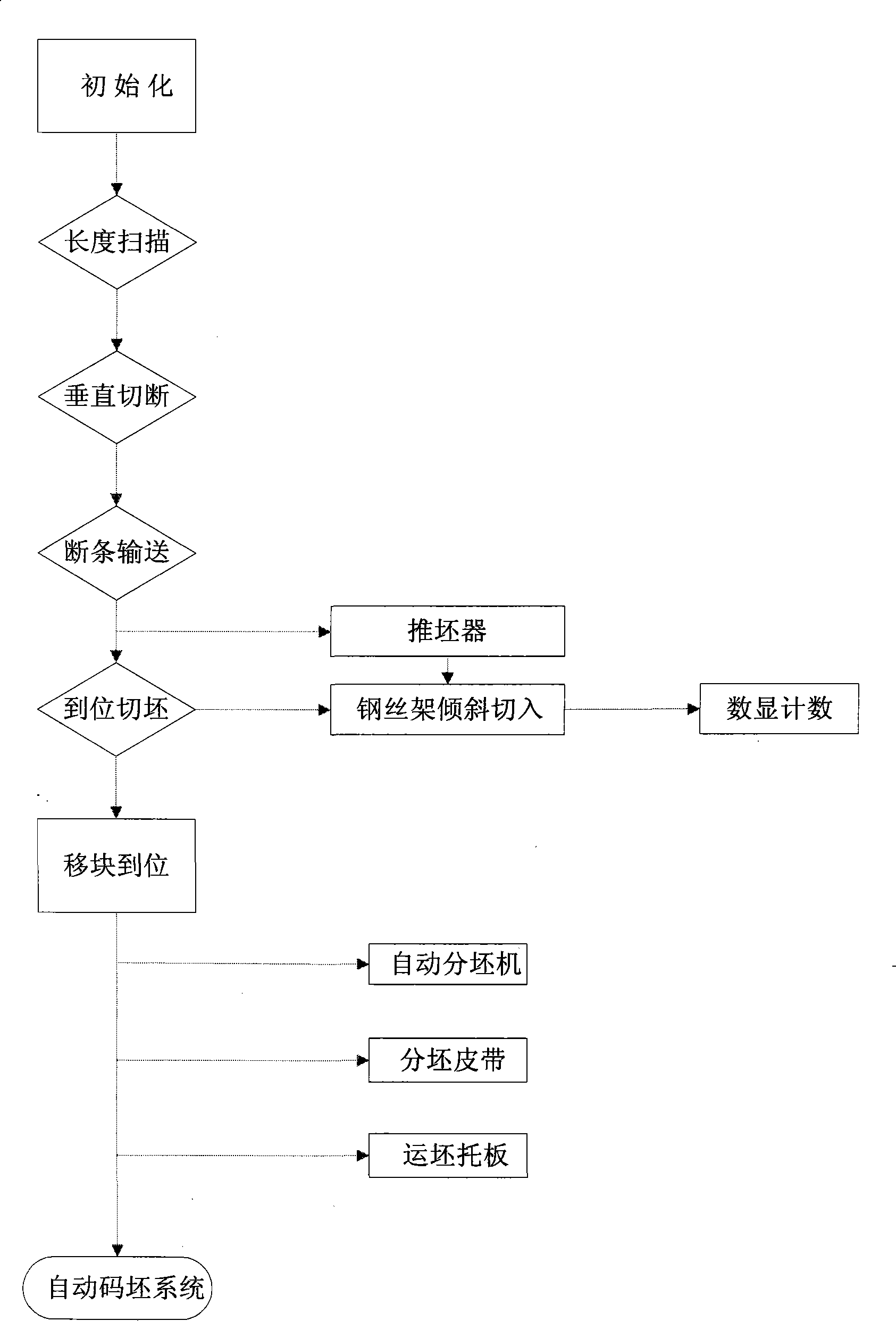

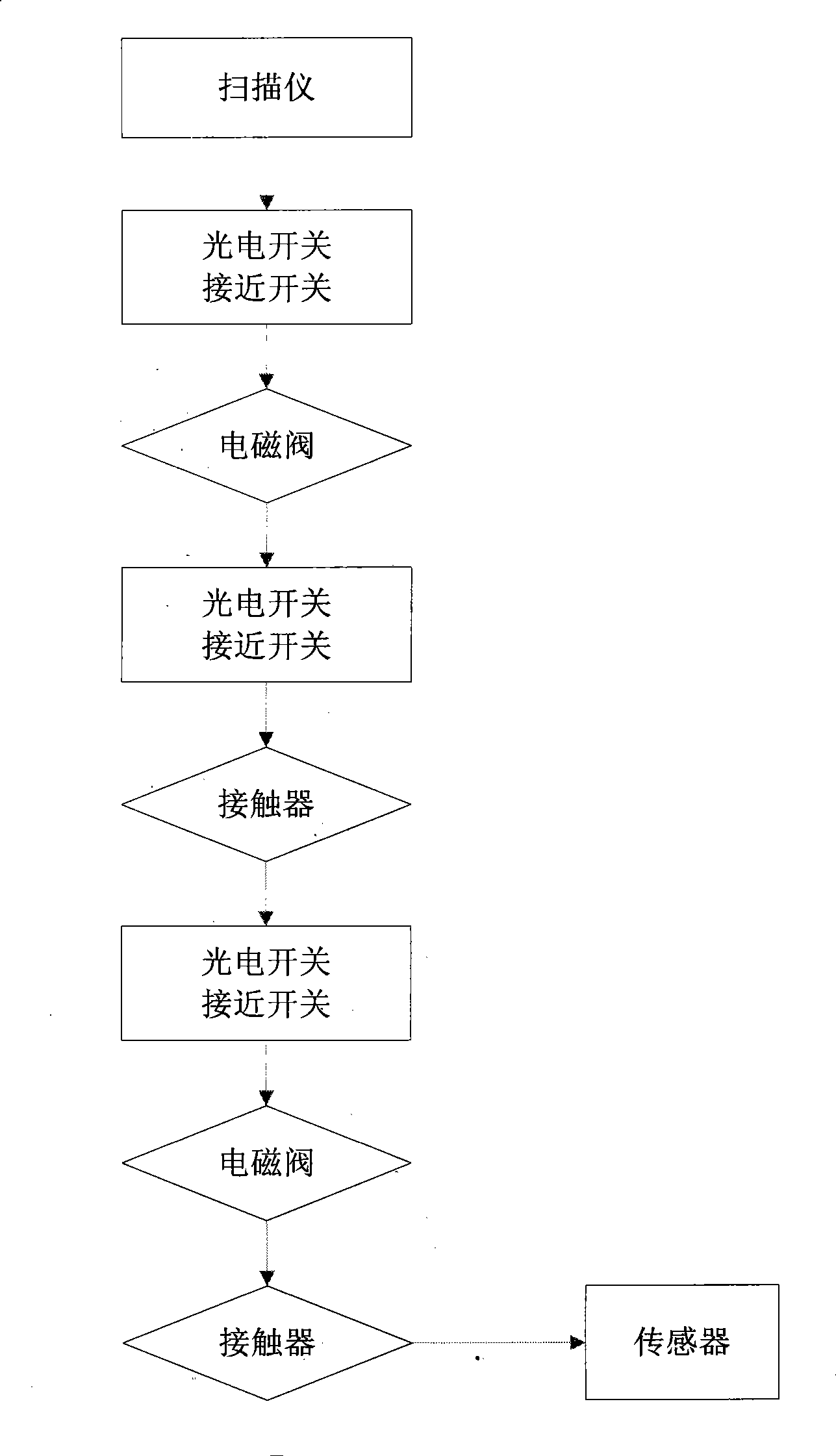

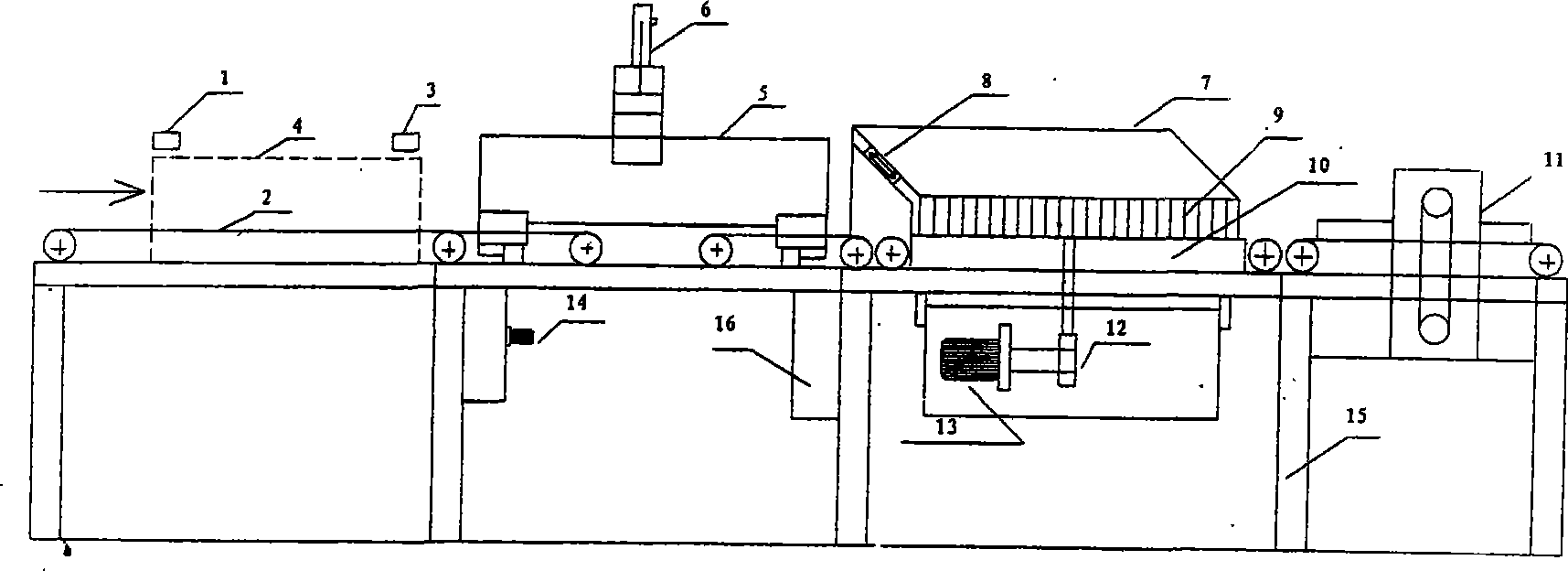

[0026] The billet cutting step of the present invention: the length of the billet extruded by the extruder port is detected by the sensor and a signal of breaking the billet is sent; after receiving the signal sent by the length determining element, the solenoid valve for cutting the billet is opened to work with the pneumatic (hydraulic) cylinder to drive the cutting The strip mechanism cuts off the billet. After the cutting mechanism finishes working, it will send out a signal, and after receiving the broken bar signal, the ring-shaped belt contactor will pull in the motor to run, and the blank will be sent to the blank cutting machine quickly. After the blank reaches the designated position of the blank cutting machine, the detection mechanism sends out a signal, and the solenoid valve of the pneumatic (oil) cylinder of the blank pusher works and the blank pusher makes a linear motion to push the blank forward. At the same time, the movable billet-cutting steel wire frame i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com