Composite lining with metal wire screen in nanometer structure and its production process

A metal wire mesh and composite lining technology, which is applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problem that the composite lining does not have large-scale industrialization and batch application, and the surface spraying process has a thin composite thickness. , complex double-liquid casting process, etc., to achieve the effect of high yield, high production efficiency and high water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation process of the above-mentioned wire mesh composite liner 1 can be realized through the following steps:

[0039] a. Directly weave the overall wire mesh with metal wire (1);

[0040] b. Cut the wire mesh (1) according to the specification and size of the composite liner, and carry out pickling treatment;

[0041] c, prepare composite filler (2);

[0042] d. Place the treated wire mesh (1) in the mould, vibrate on a three-dimensional vibration table or place it on a vulcanizer or press, and inject the composite filler (2) into the wire mesh (1) under high pressure;

[0043] e. After vibration drying, curing molding, demoulding and trimming, the metal mesh composite liner is prepared.

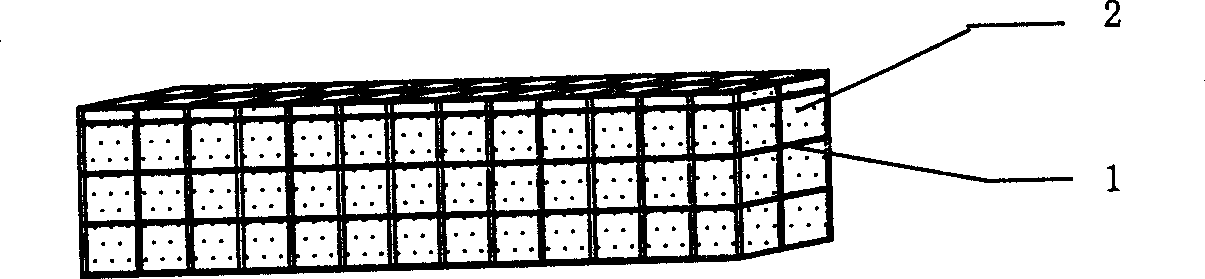

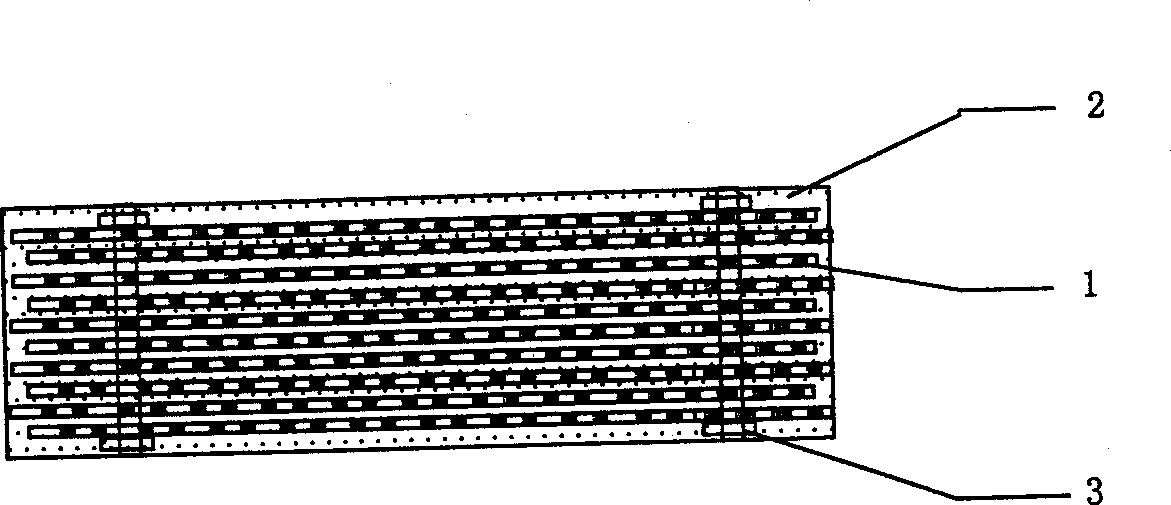

[0044] Form 2: see figure 2 . The nano-structure wire mesh composite liner 2 is composed of a wire mesh (1) and a composite filler (2), and the wire mesh (1) is composed of a single-layer wire mesh into a multi-layer wire mesh. Bolts (3) or other means are fastened as...

Embodiment 1

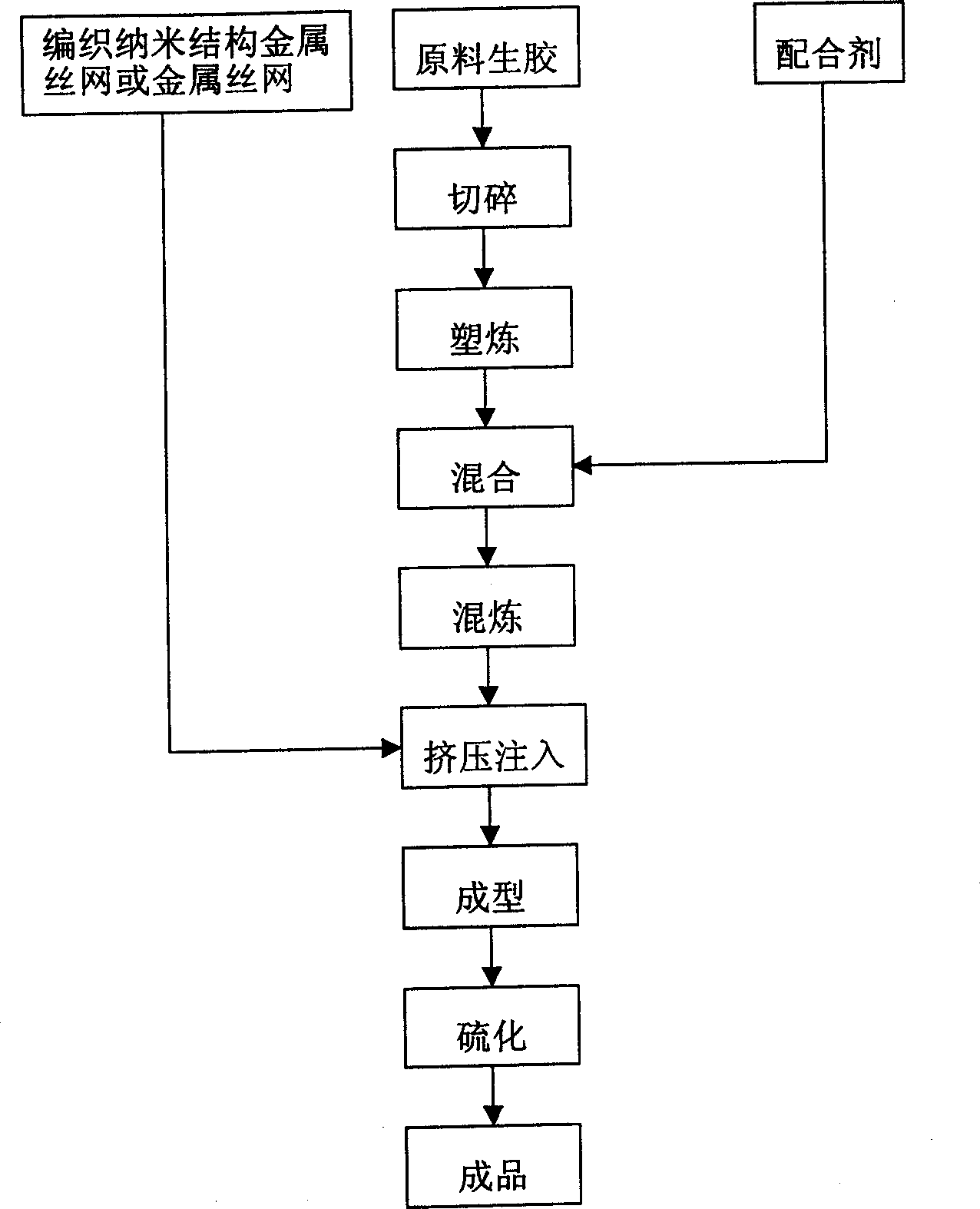

[0057] Preparation process of nanostructure wire mesh-rubber composite liner

[0058] The technological process of preparing nanostructure wire mesh-rubber composite liner, see image 3 .

[0059] a. First, weave nanostructured wire mesh 1 according to the size of the liner, and process it according to the process;

[0060] b. Preparation of composite filler-rubber raw material 2, the steps are: the raw rubber is chopped, masticated and mixed with a compounding agent (0.8-1.2% carbon black by weight), and mixed in a mixer;

[0061] c. Putting the assembled, compressed and fixed nanostructure wire mesh 1 into the mold of the vulcanizing machine;

[0062] d. Inject the kneaded raw rubber into the nanostructure wire mesh 1 under high pressure, pressurize 10-50 tons, and keep it warm at 100-120°C for 1-3 hours, the best time is 2 hours; then,

[0063] e. Carry out molding, vulcanization, demoulding and trimming to make qualified products.

Embodiment 2

[0065] Preparation process of nanostructure wire mesh-polyurethane composite lining board

[0066] The technological process of preparing nanostructure wire mesh-polyurethane composite liner, see Figure 4 .

[0067] a. First, weave nanostructured wire mesh 1 according to the size of the liner, and perform pretreatment according to the process;

[0068] b. Prepare composite filler-polyurethane filler 2, the steps are: mix oligomer polyol, chain extender, diisocyanate, etc. in a weight ratio of 7 to 9: 0.8 to 1.2: 1.5 to 2.5;

[0069] c. Put the assembled, compressed and fixed nanostructure wire mesh 1 into the mold of the vulcanizer (the mold should be preheated first, and then coated with a silicone release agent);

[0070] d. Inject the mixed slurry into the nanostructure wire mesh skeleton under high pressure, add 30-100 tons of pressure, and keep it warm at 100-120°C for 1-3 hours; then,

[0071] e. Carry out vulcanization molding and demoulding. After demoulding, perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com