Permanent-magnet surface-mounting magnetic steel assembly tool and application method thereof

A technology for assembling tooling and permanent magnet motors. It is used in electromechanical devices, manufacturing motor generators, and electrical components. It can solve the problems of poor reliability of magnetic steel assembly, ensure performance and life, reduce the impact force of magnetic steel, and avoid the impact of magnetic steel. The effect of the pole rollover phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

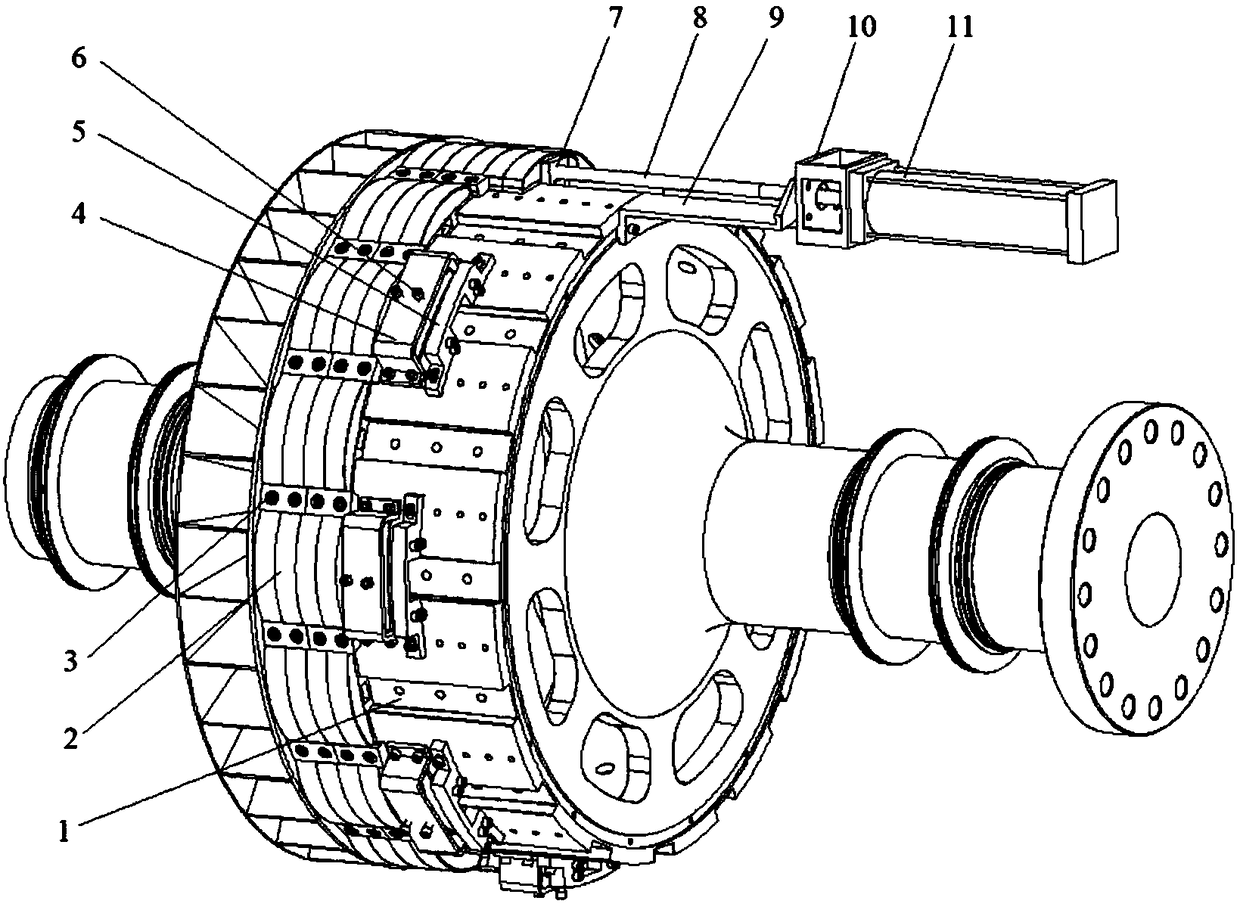

[0063] like figure 1 As shown: this embodiment discloses a surface-mounted magnetic steel assembly tool for permanent magnet motors, including: a rotor core 1 arranged on a rotor frame, a plurality of magnets that can be detachably fixed on the rotor core A steel positioning device, a plurality of magnetic steel pressing blocks 3 that can be fixedly installed on the rotor core, and a magnetic steel propulsion device that can cooperate with the rotor core 1 to push the magnetic steel block 2 to the magnetic steel installation area.

[0064] It should be noted that the rotor core 1 described here refers to the rotor core 1 in a large permanent magnet motor. Of course, the rotor core 1 described in this embodiment can also be a small or medium rotor core 1 , the same applies.

[0065] Rotor core

[0066] like figure 1 As shown: in this embodiment, the rotor core 1 is provided with a plurality of magnetic steel installation grooves on the peripheral surface.

[0067] Wherein, ...

Embodiment 2

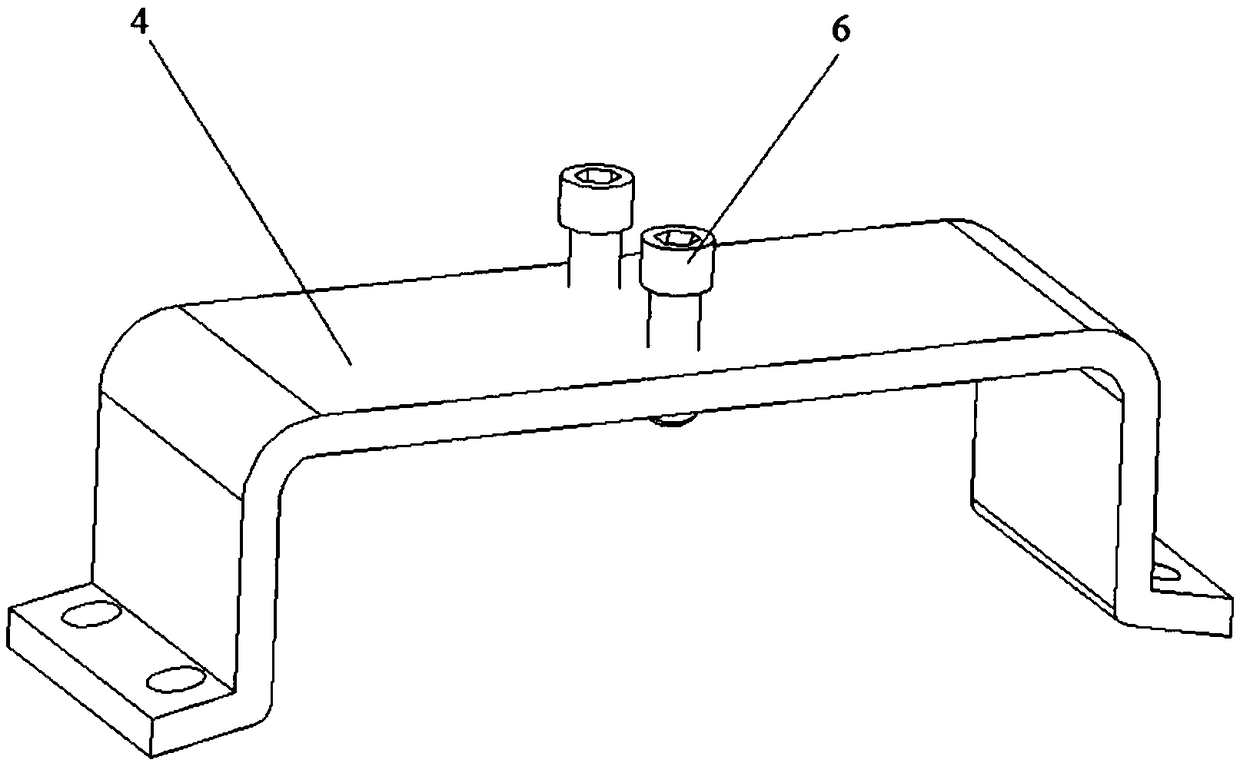

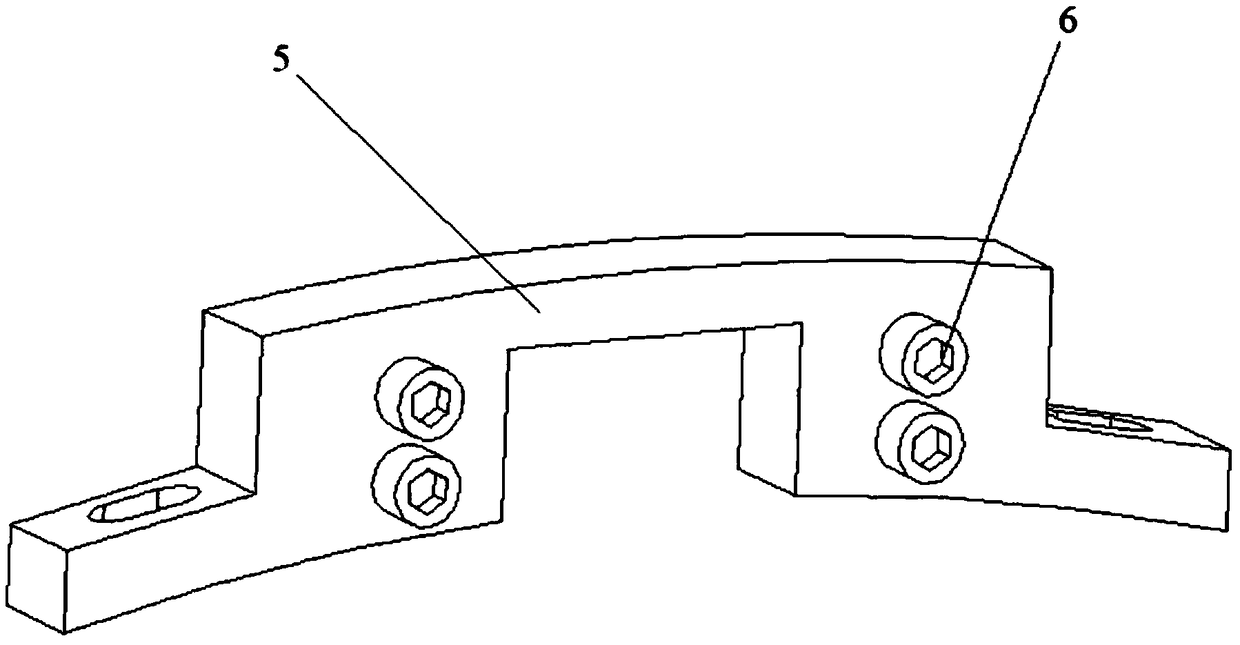

[0106]This embodiment discloses a surface-mounted magnetic steel assembly tool for a permanent magnet motor, which includes a rotor core 1, a plurality of magnetic steel blocks 2, a plurality of magnetic steel pressing blocks 3, a plurality of radial positioning blocks 4, and a plurality of shaft To the positioning block 5, a plurality of hexagon socket socket set screws 6, pads 7, push rods 8, guide plates 9, connecting brackets 10, cylinders 11.

[0107] Specifically, the rotor core 1 has a total of 16 magnetic steel installation slots; the number of motor poles is 16, and each magnetic pole is composed of 11 segmented magnetic steel blocks 2; the guide plate 9, the connecting bracket 10, and the push rod 8 are made of stainless steel Made of materials, the pad 7 is a plate made of brass, the axial positioning block 5 and the radial positioning block 4 are made of stainless steel, and the number is 8 groups respectively.

[0108] Correspondingly, a guide groove corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com