Patents

Literature

43results about How to "Guaranteed not to be damaged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

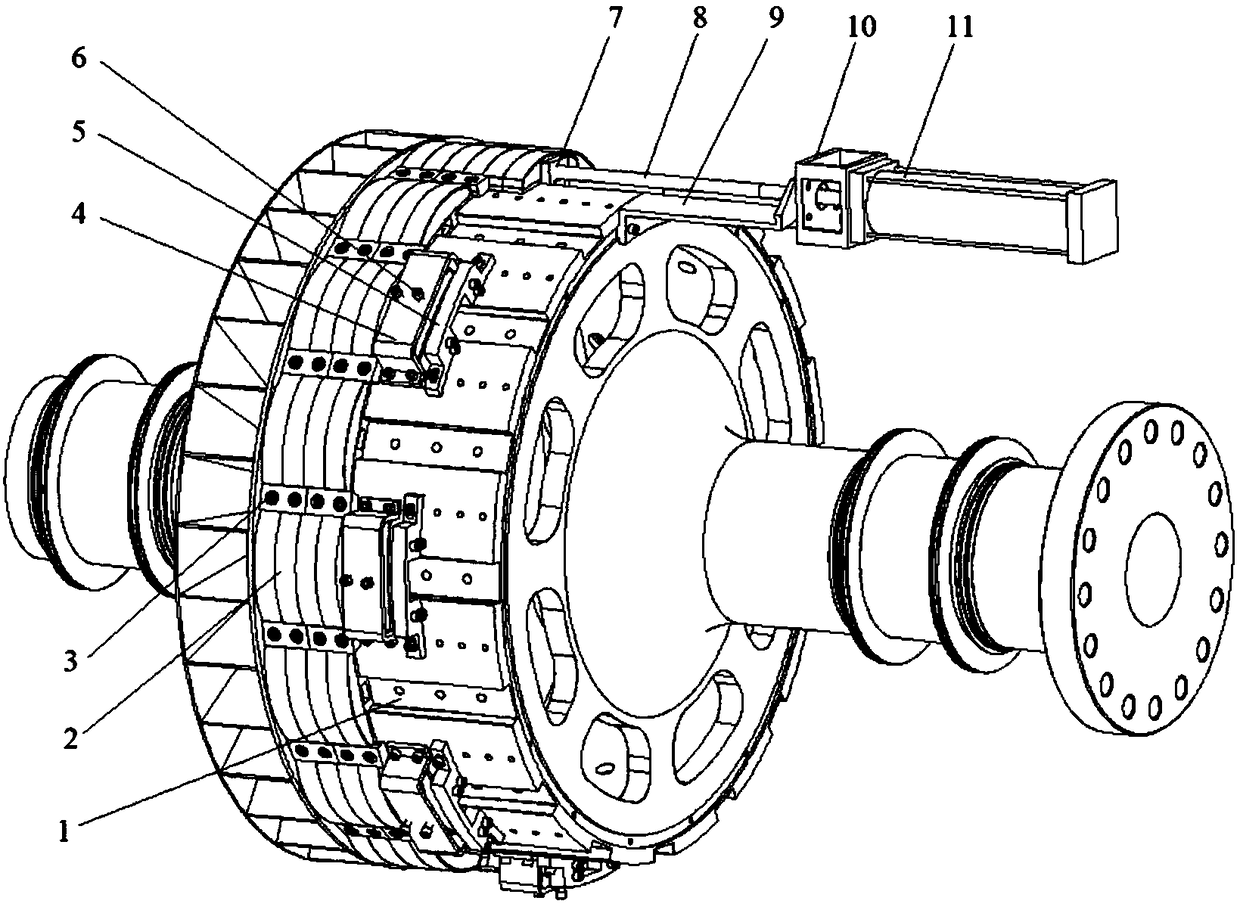

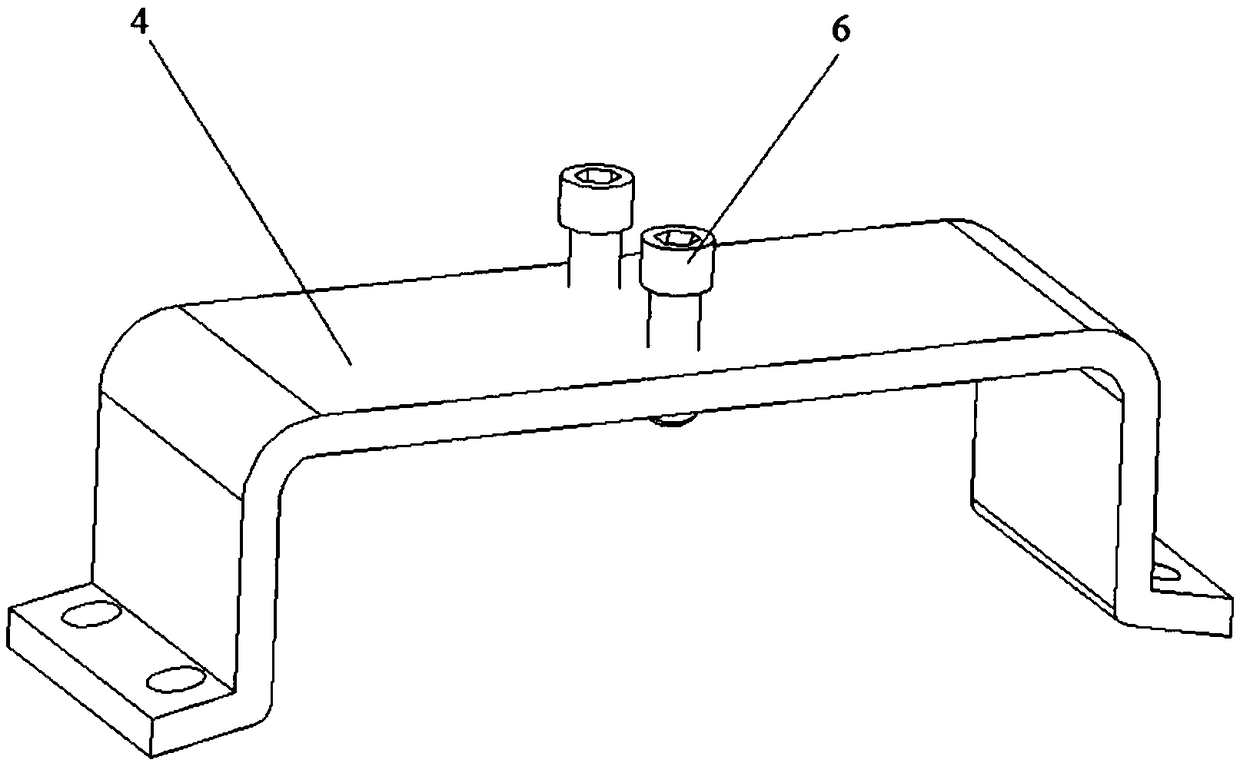

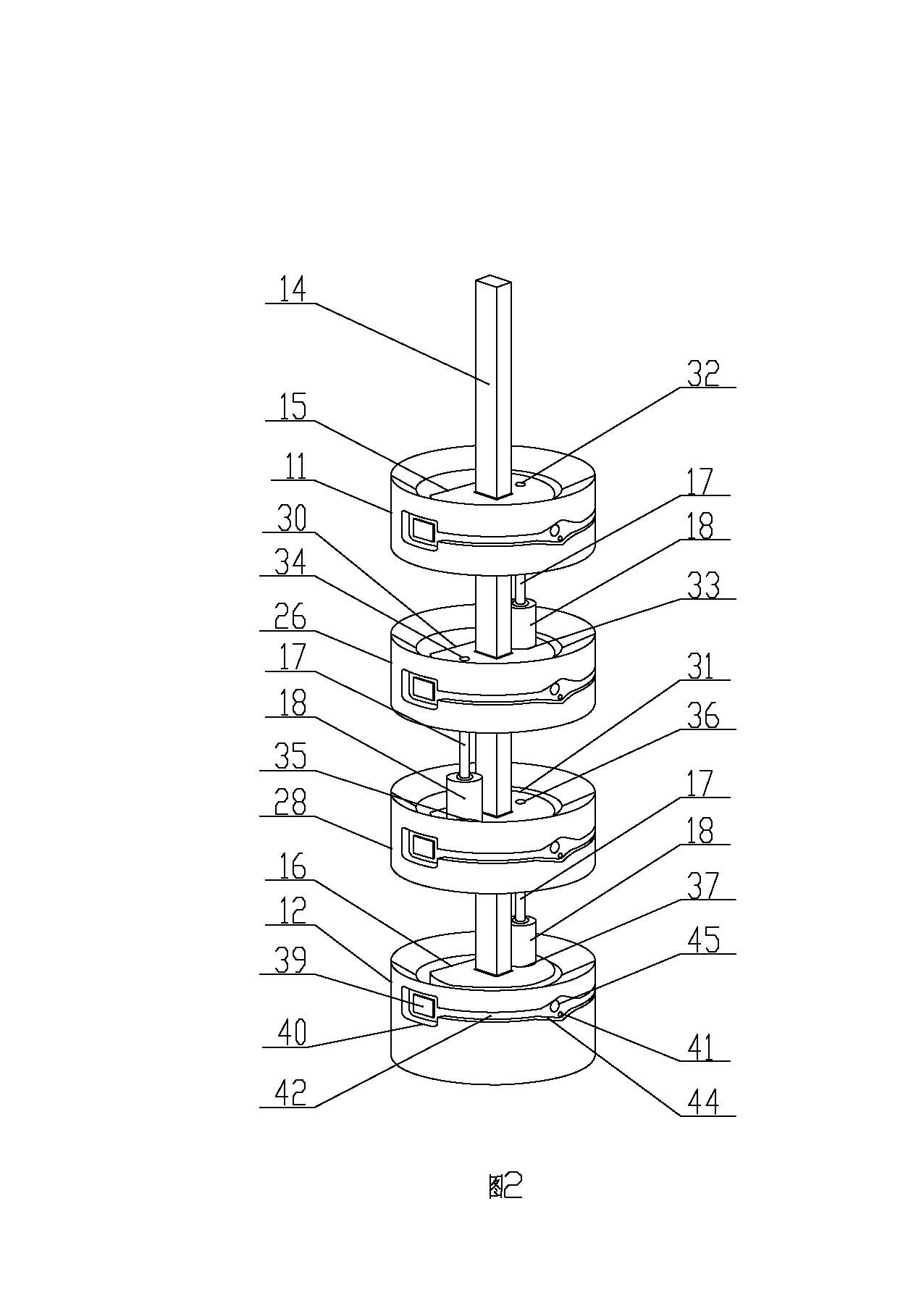

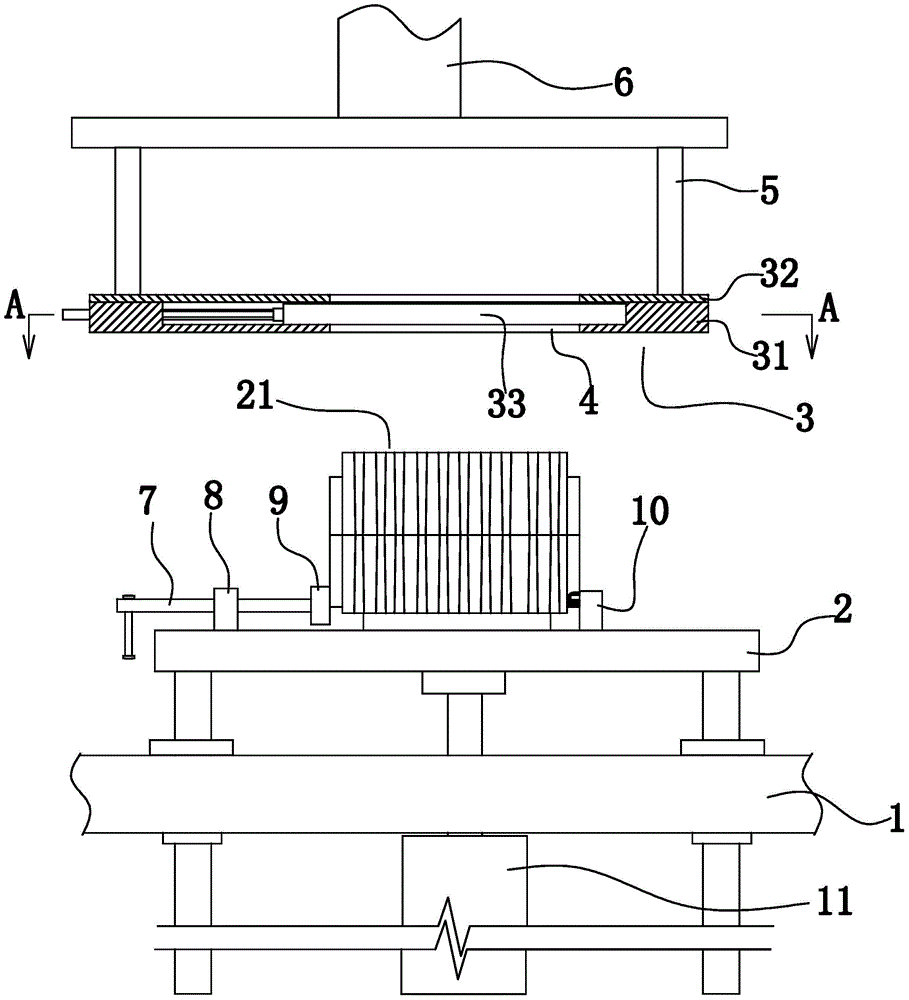

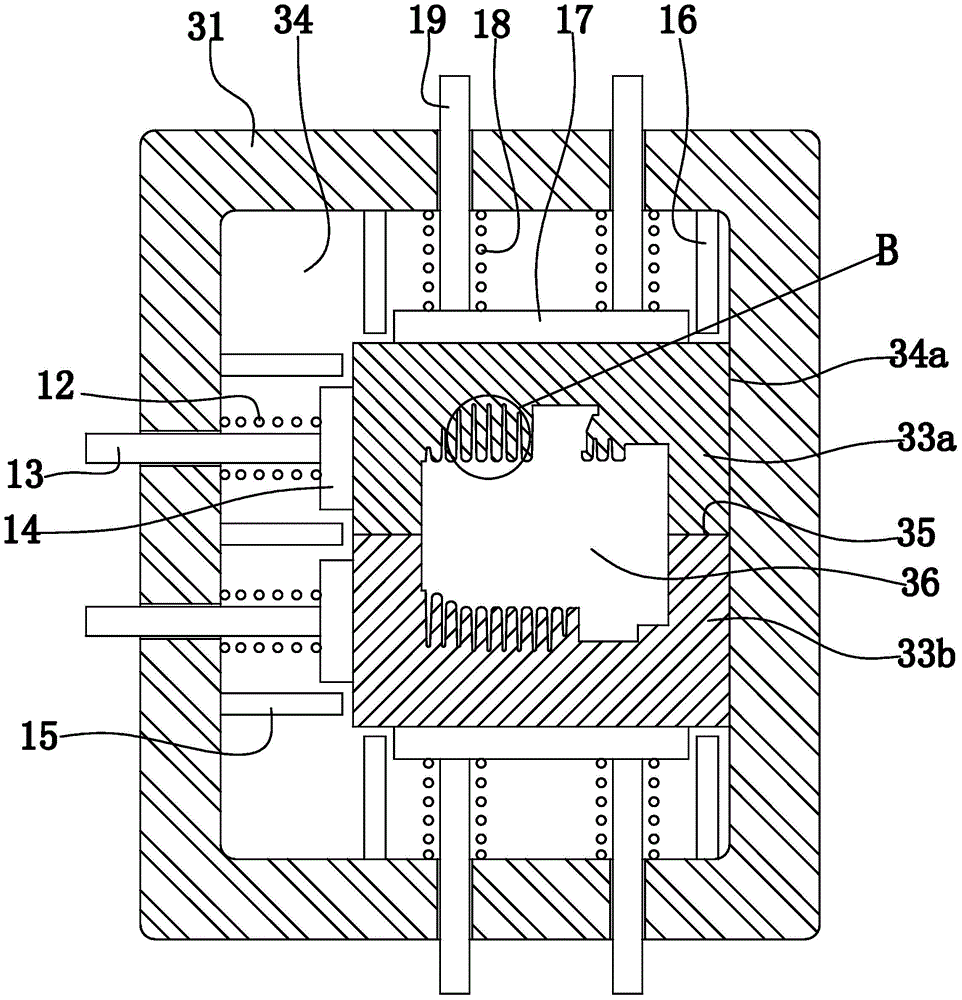

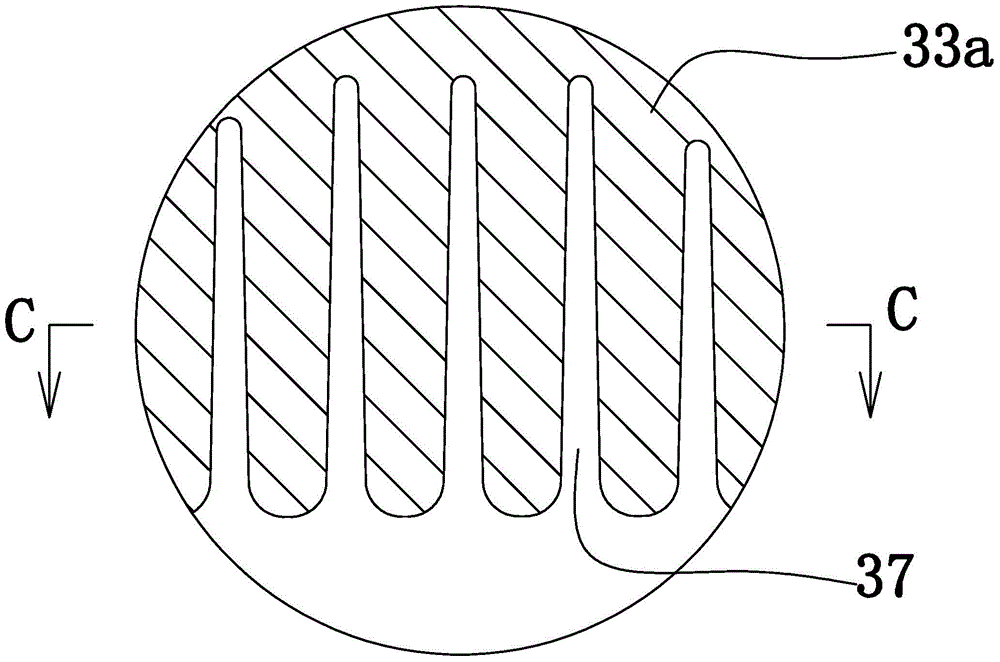

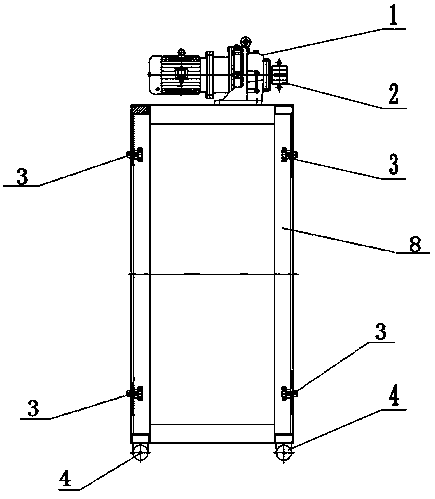

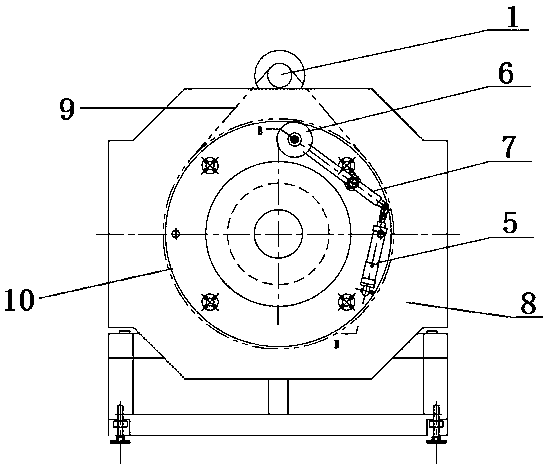

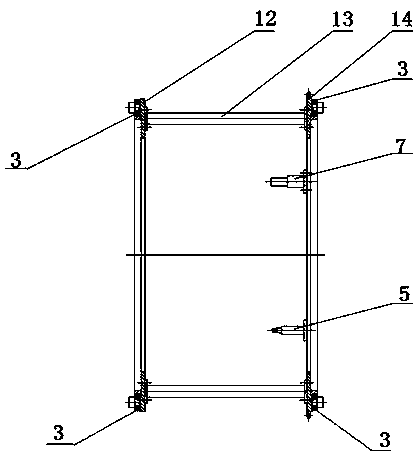

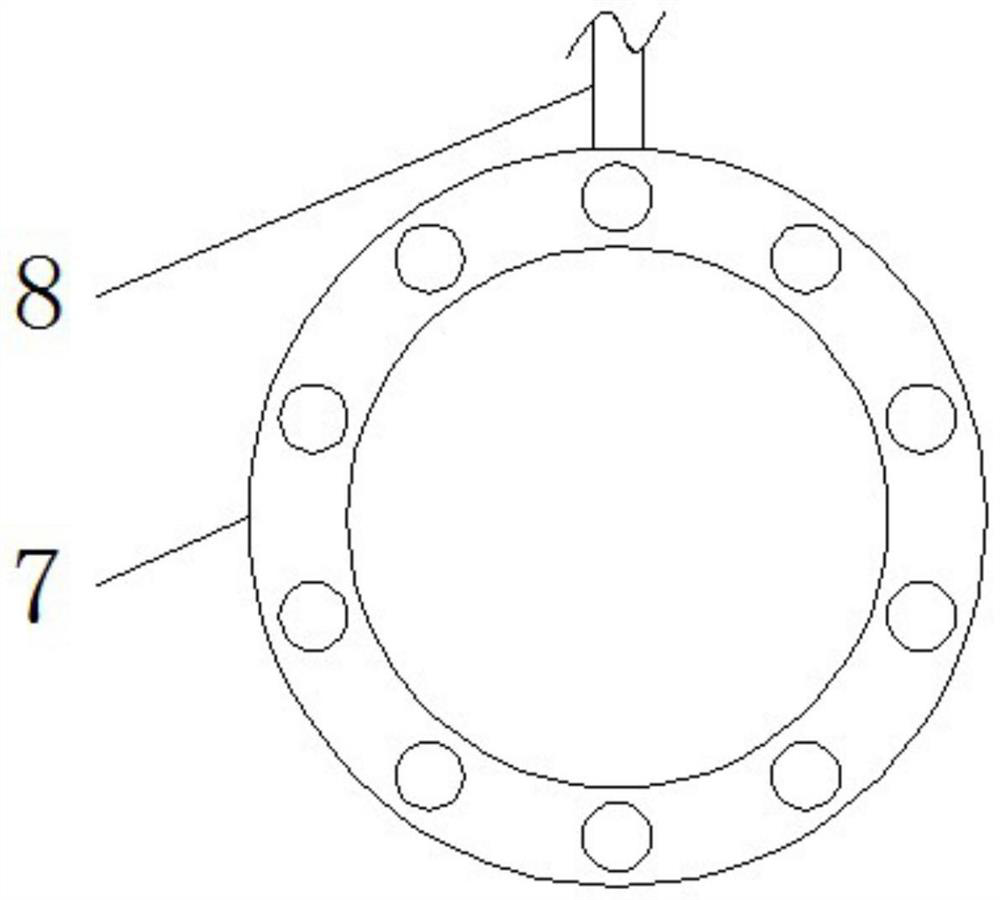

Permanent-magnet surface-mounting magnetic steel assembly tool and application method thereof

PendingCN108923600AReduce impact forceEasy to useManufacturing stator/rotor bodiesSurface mountingMagnetic poles

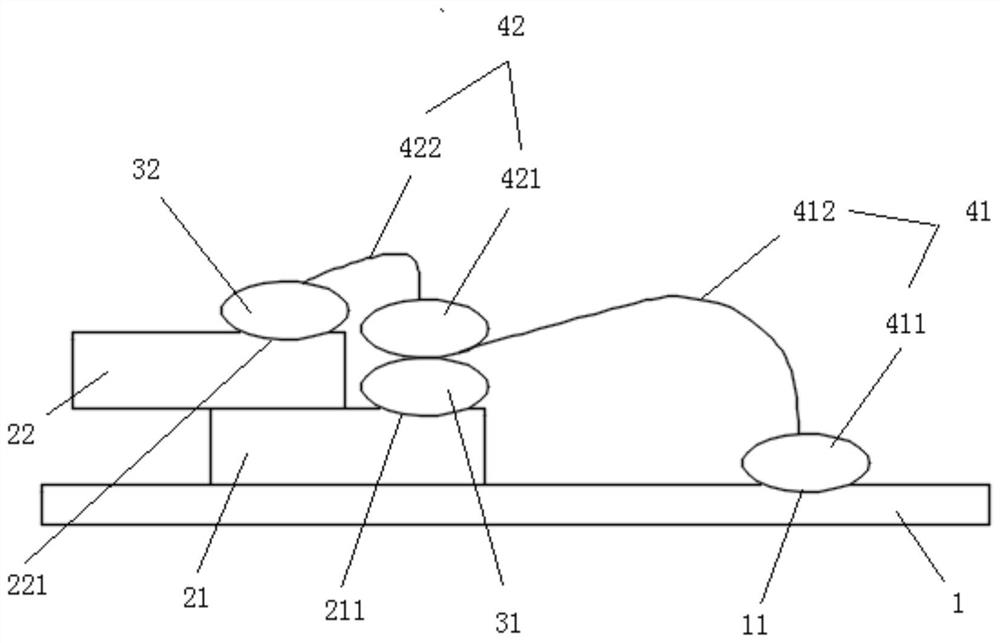

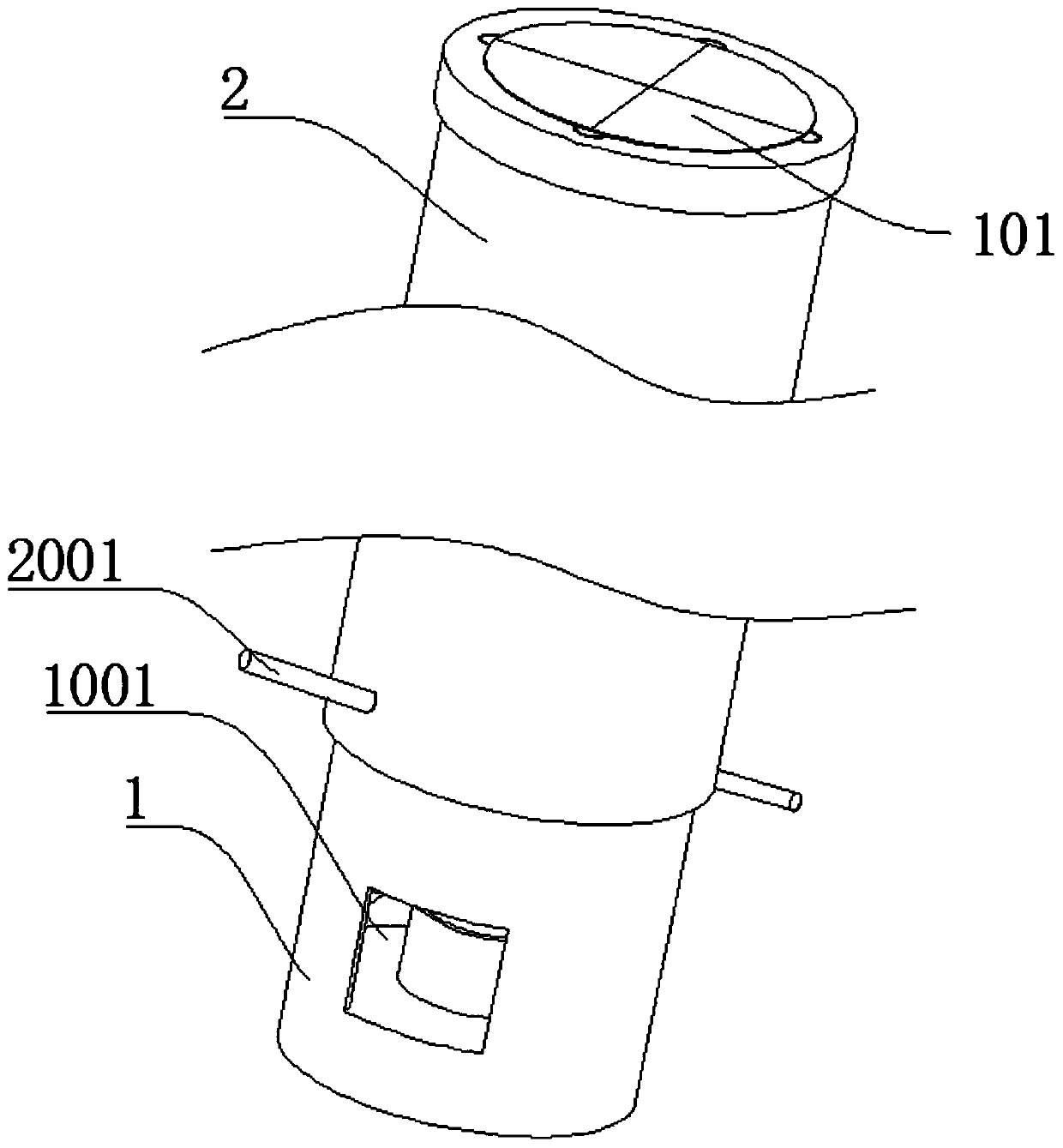

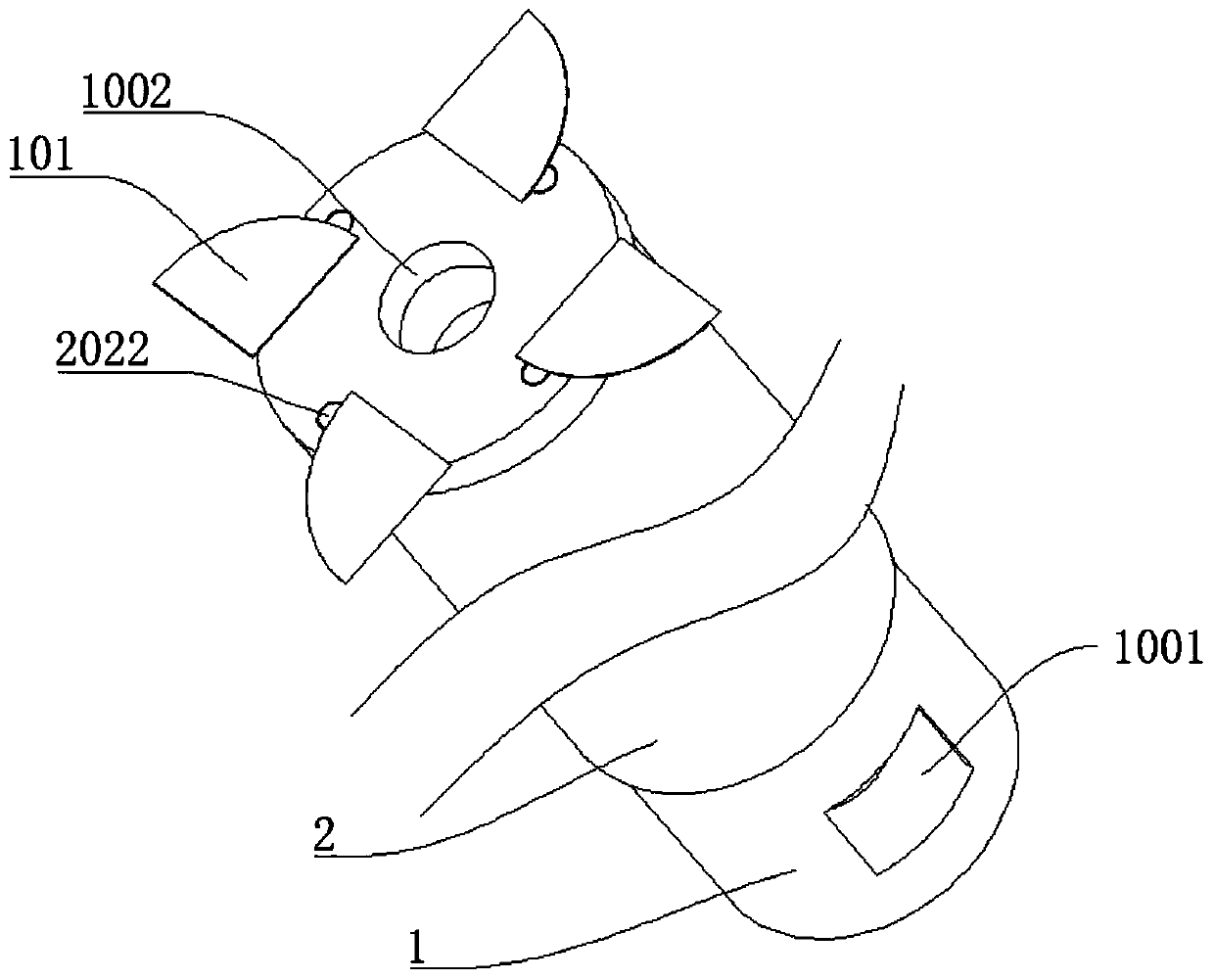

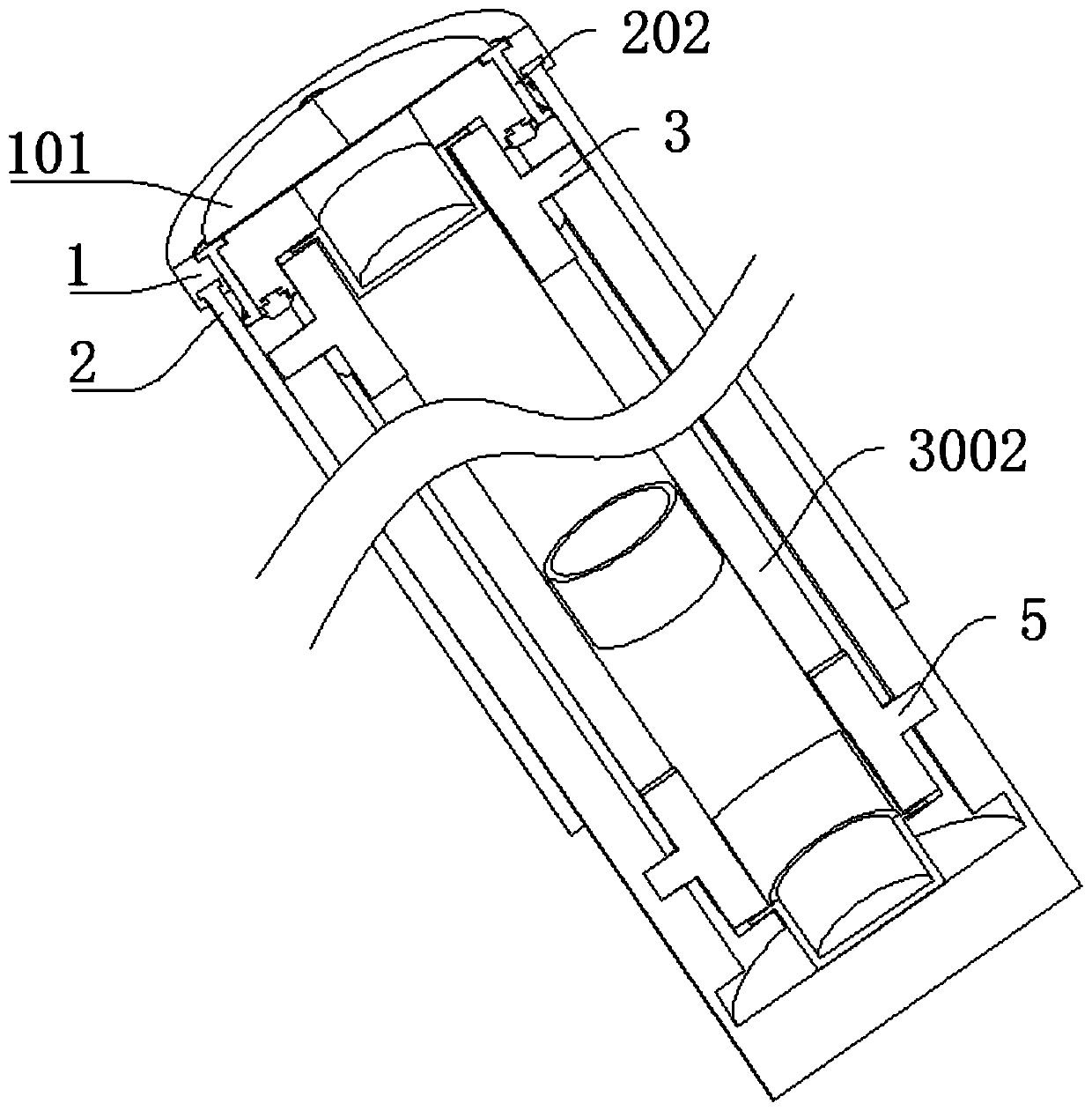

The invention belongs to the technical field of motor manufacturing, and particularly relates to a permanent-magnet surface-mounting magnetic steel assembly tool and an application method thereof. Thepermanent-magnet surface-mounting magnetic steel assembly tool comprises a rotor core, a plurality of magnetic steel positioning devices, a plurality of magnetic steel press blocks and a magnetic steel push device, wherein the rotor core is arranged on a rotor rack, the plurality of magnetic steel positioning devices can be detachably fixed on the rotor core, the plurality of magnetic steel pressblocks can be fixedly arranged on the rotor core, the magnetic steel push device can be matched with the rotor core to push a magnetic steel block to a magnetic steel installation region, a pluralityof magnetic steel installation grooves are formed in a peripheral surface of the rotor core, each magnetic steel installation groove is corresponding to a magnetic pole to be installed, and the magnetic pole to be installed comprises a plurality of magnetic steel blocks. According to the permanent-magnet motor surface-mounting magnetic steel assembly tool and the application method thereof, provided by the invention, no damage to a surface of the magnetic steel during the large-size permanent-magnet motor assembly process can be ensured, the magnetic steel collision force is reduced, so thatthe application performance and the lifetime of the motor are ensured, moreover, the magnetic steel assembly efficiency of an assembly person also can be improved, and the safety of an operator duringthe magnetic steel assembly process is ensured.

Owner:青岛海西电气有限公司

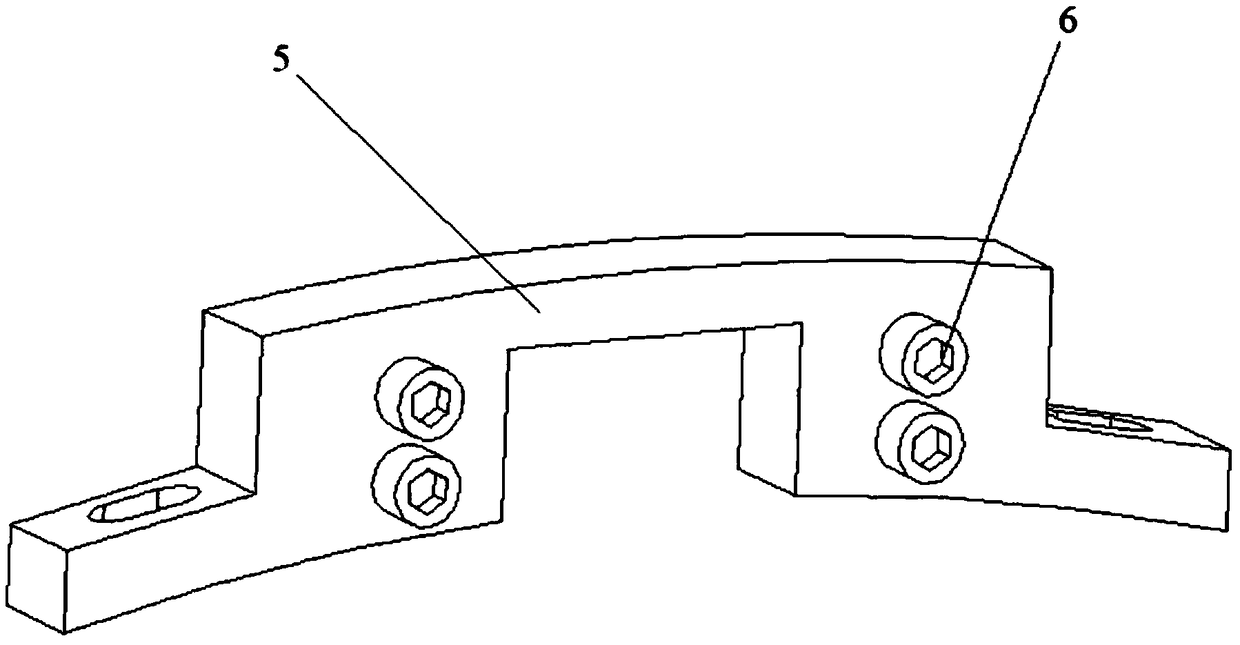

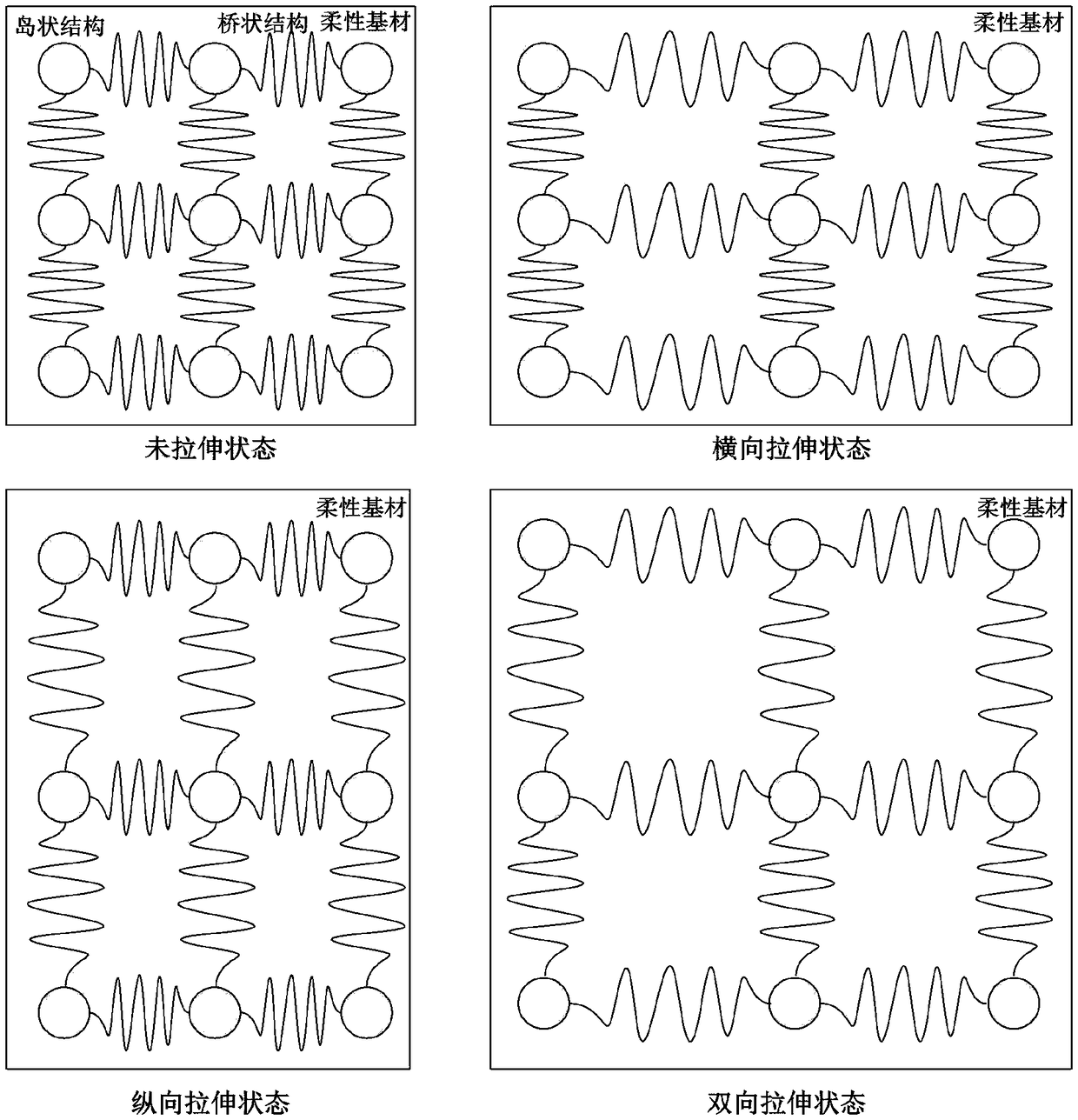

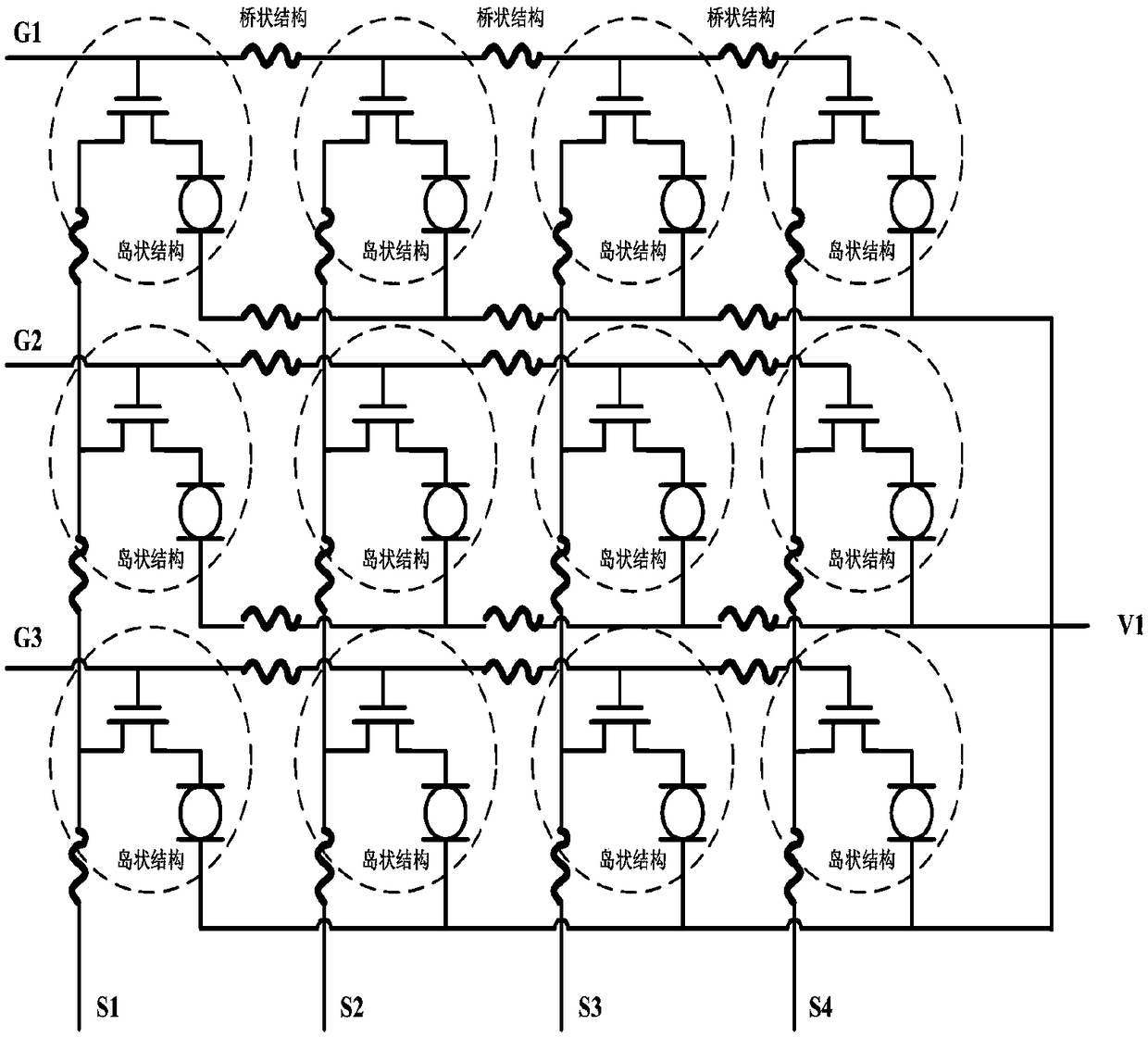

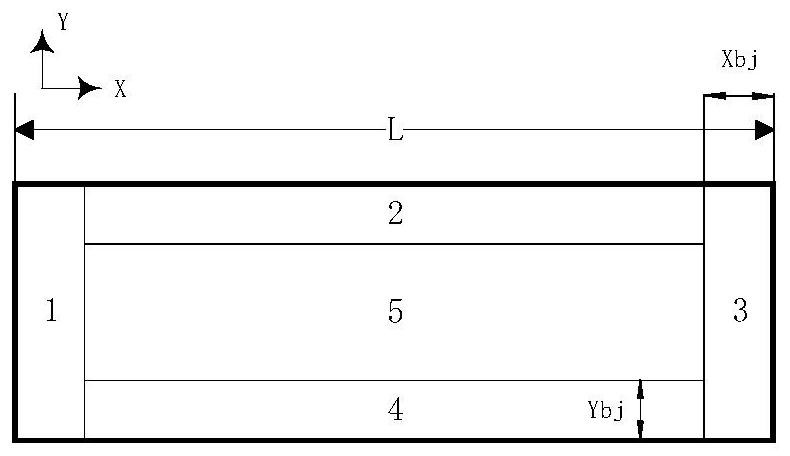

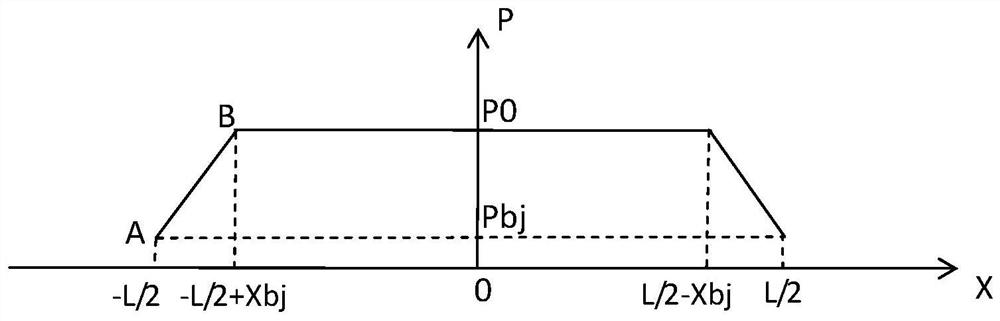

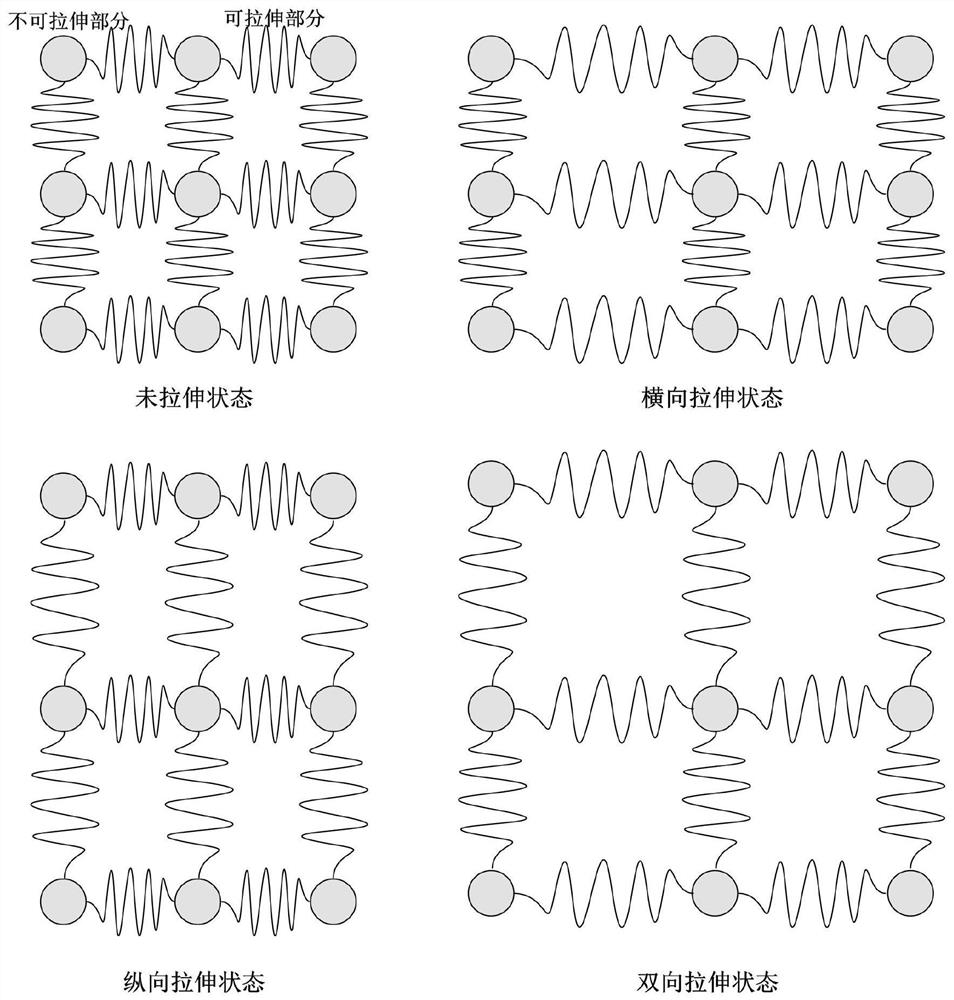

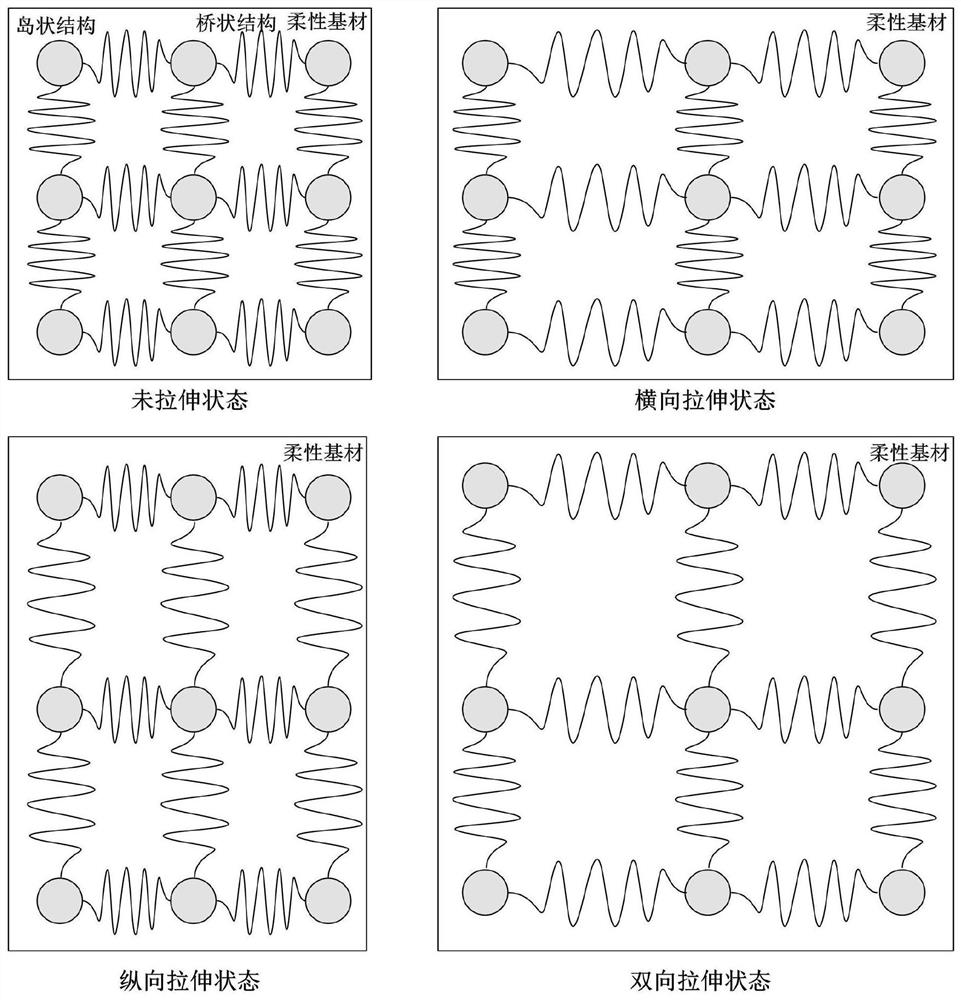

Flexible stretchable sensor

ActiveCN109341727ADoes not affect the detection functionAvoid deterioration of electrical performanceConverting sensor output electrically/magneticallyElectrical performanceSystem structure

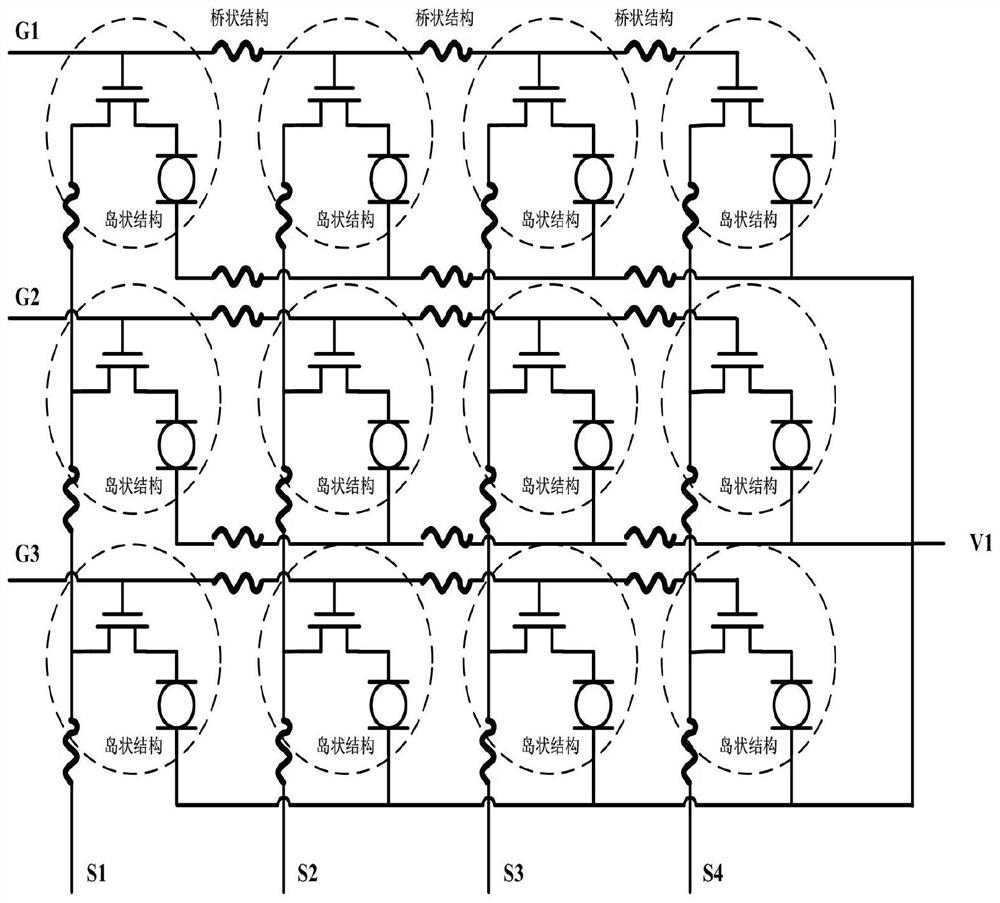

The invention relates to a flexible stretchable sensor, belongs to the technical field of sensors, and solves the problems that the existing flexible stretchable sensor is easy to be damaged, the detection result is inaccurate, and the circuit design is unreasonable. The flexible stretchable sensor disclosed in the invention comprises an M x N array formed by arranging M x N detecting units. Eachof the detecting units comprises a stretchable portion and a non-stretchable portion. A sensing module of each detecting unit is arranged in the non-stretchable portion, and is connected to the sensing modules of the adjacent detecting units by wires arranged on the stretchable portion. When the flexible stretchable sensor is used, a macroscopic stretching function is achieved by the stretchable portion without affecting the detecting function of the non-stretchable portion. According to the structural design of the non-stretchable portion, the electrical performance deterioration caused by stretching the sensing module can be avoided, and the value read by the sensor is stable and reliable. Moreover, the overall system structure size is small, the control circuit is simple, and the cost is low according to the array design.

Owner:BEIJING MECHANICAL EQUIP INST

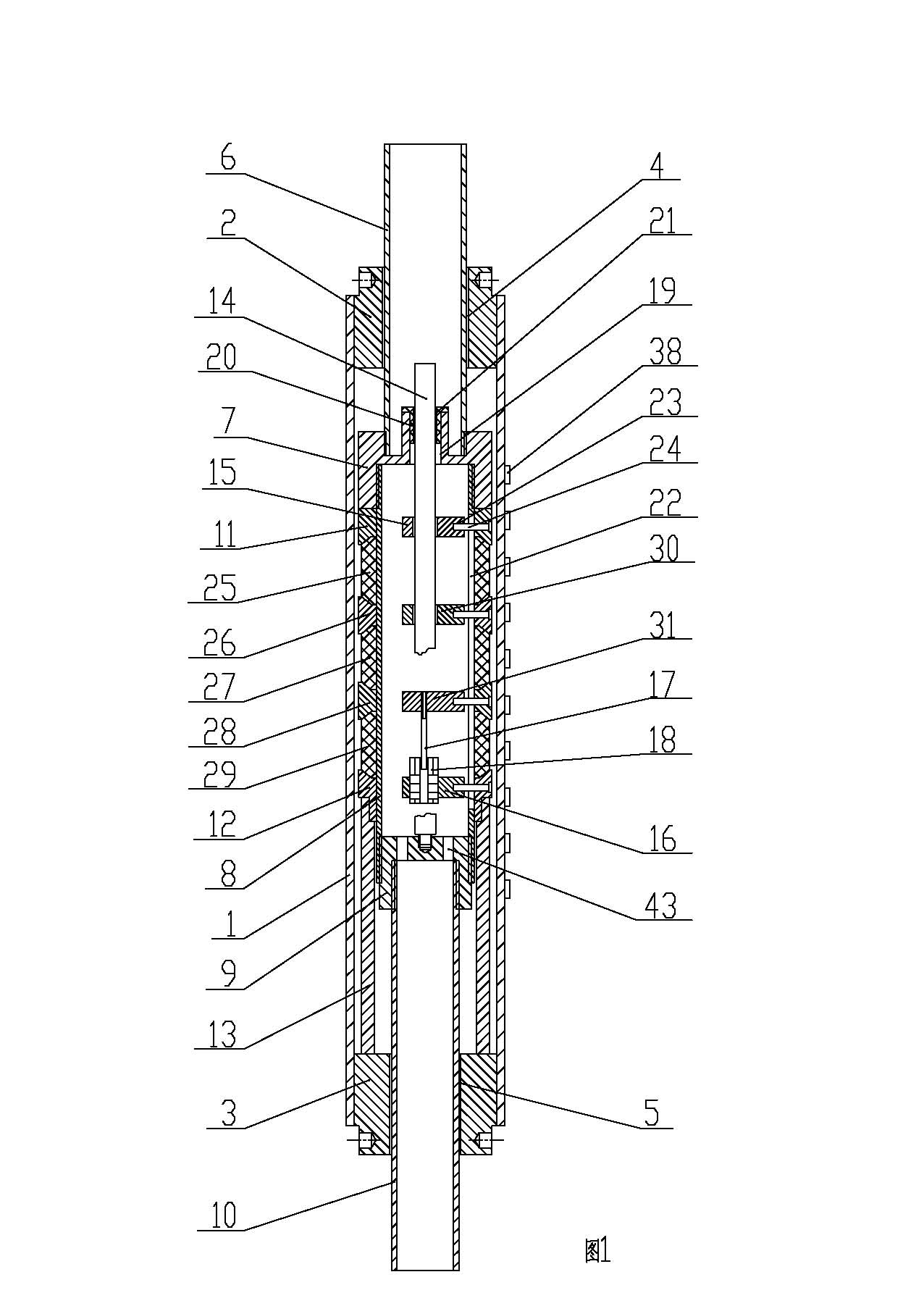

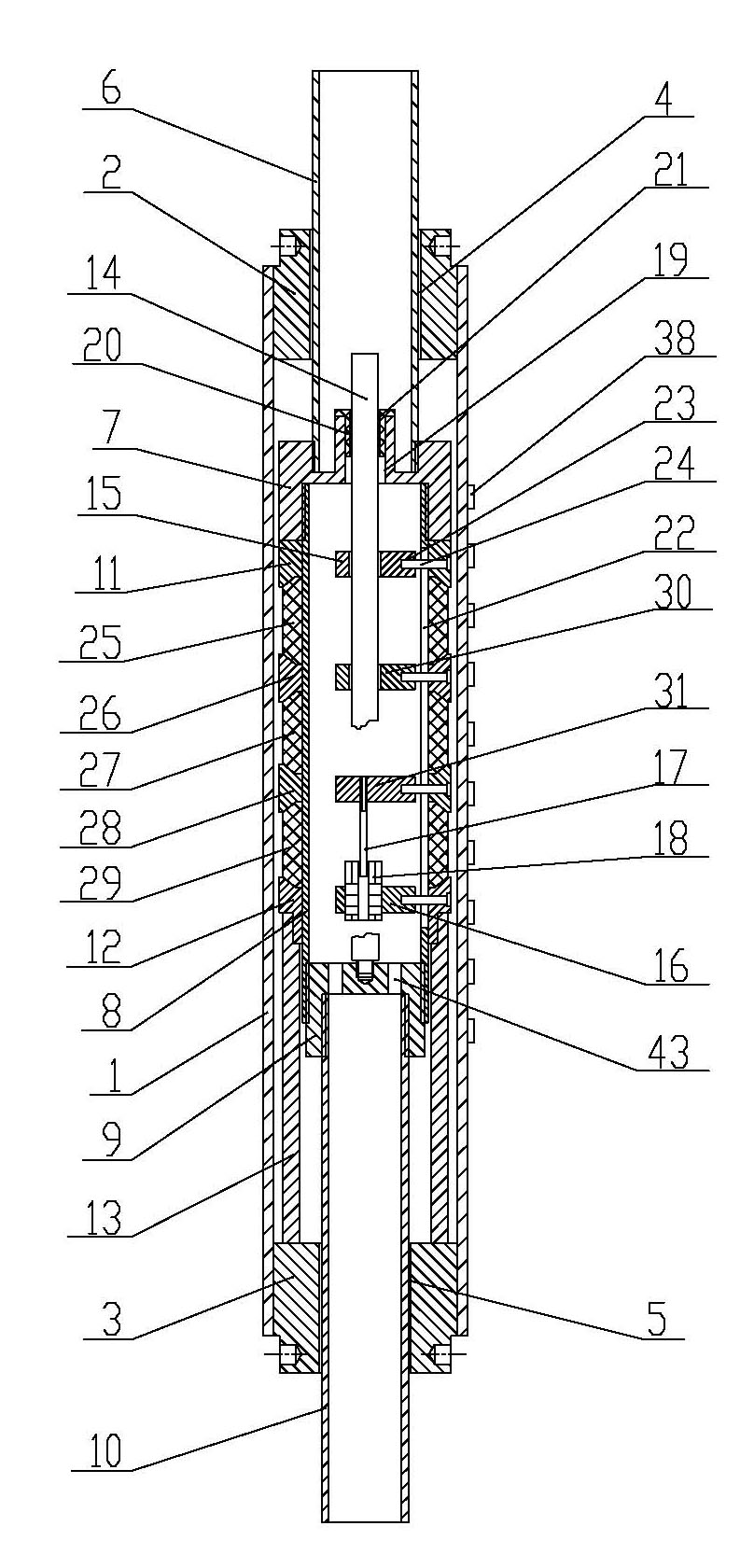

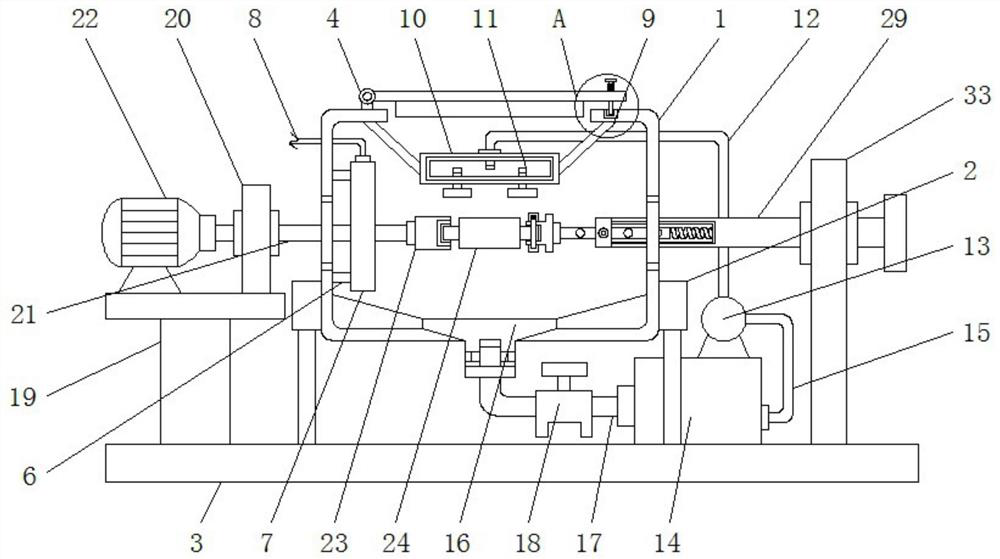

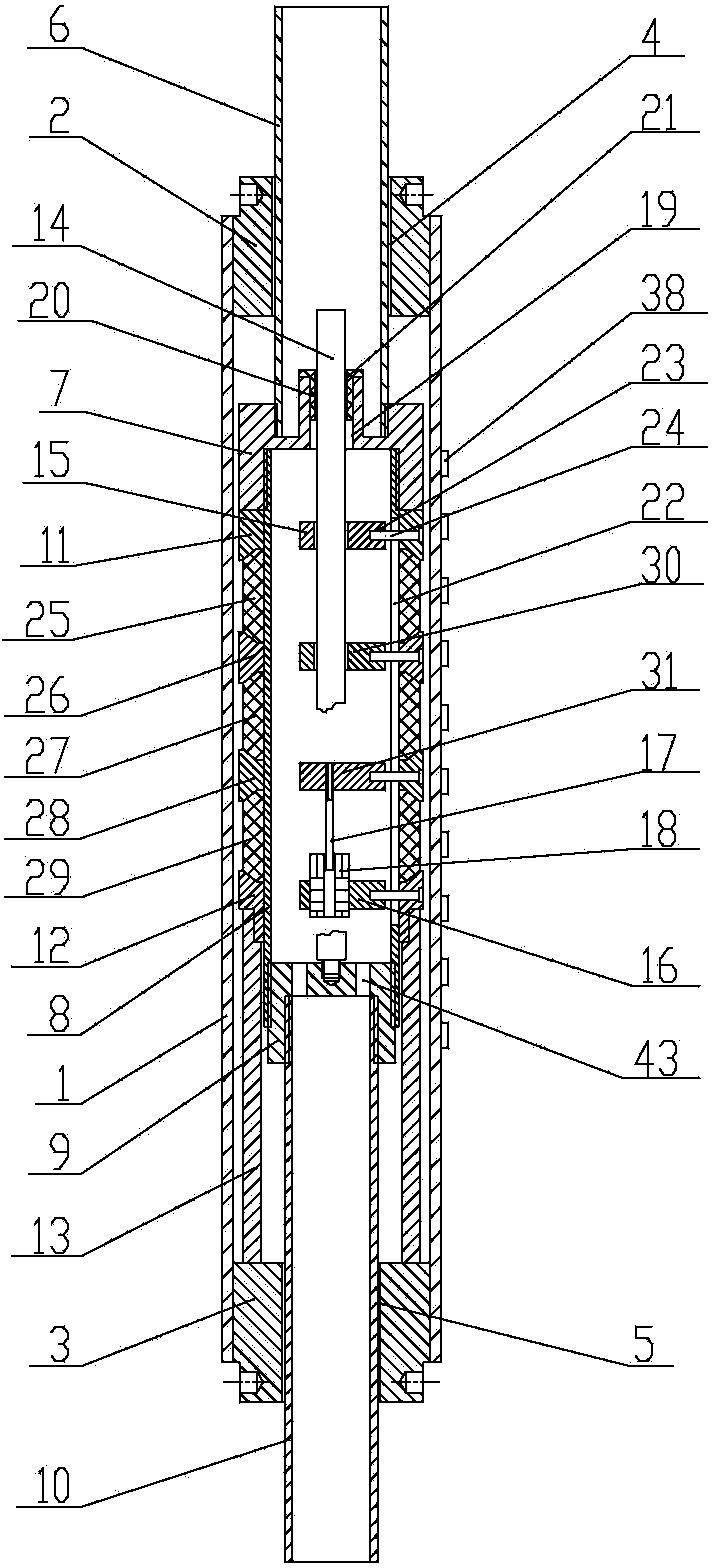

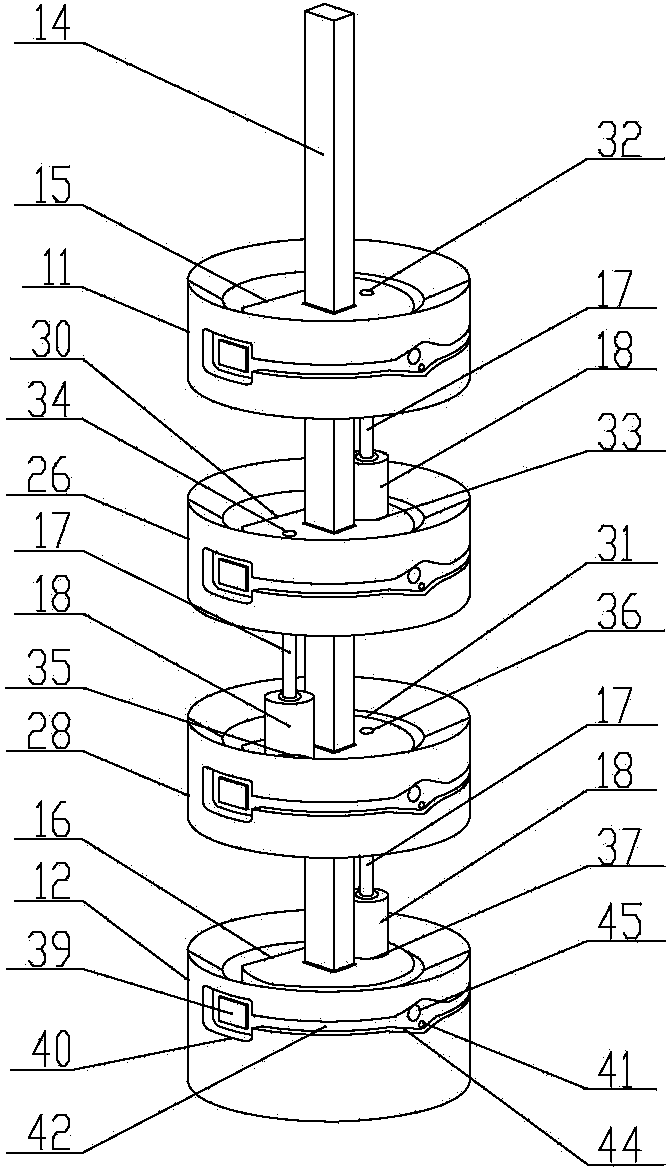

Mechanical parameter measuring device of underground compression type packer and using method thereof

ActiveCN102080514AGuaranteed not to be damagedCompact and reasonable structureMachine part testingSealing/packingRadial stressContact pressure

The invention relates to the technical field of a tool and method for mechanical parameter measuring of an underground packer rubber system for petroleum exploitation, in particular to a mechanical parameter measuring device of an underground compression type packer and a using method thereof. The mechanical parameter measuring device comprises a drivepipe, an upper head, a lower head, a packer, a radial stress sensor and an axial stress sensor; the packer with a seal element assembly is installed in the inner cavity of the drivepipe; and the exterior of the drivepipe is provided with the radial stress sensor, and the packer is provided with the axial stress sensor. The mechanical parameter measuring device provided by the invention has the advantages of reasonability and compactness, is convenient to use; and by utilizing the method provided by the invention, the parameters carried by each rubber, such as axial load, friction, compression deformation force and the contact pressure to the inner wall of the drivepipe can be measured effectively and accurately in real time in the operation of the packer, no damage to the signal output thread of each sensor can be ensured, the test cost is lowered greatly, and a reliable basis for improving the design of the packer can be provided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

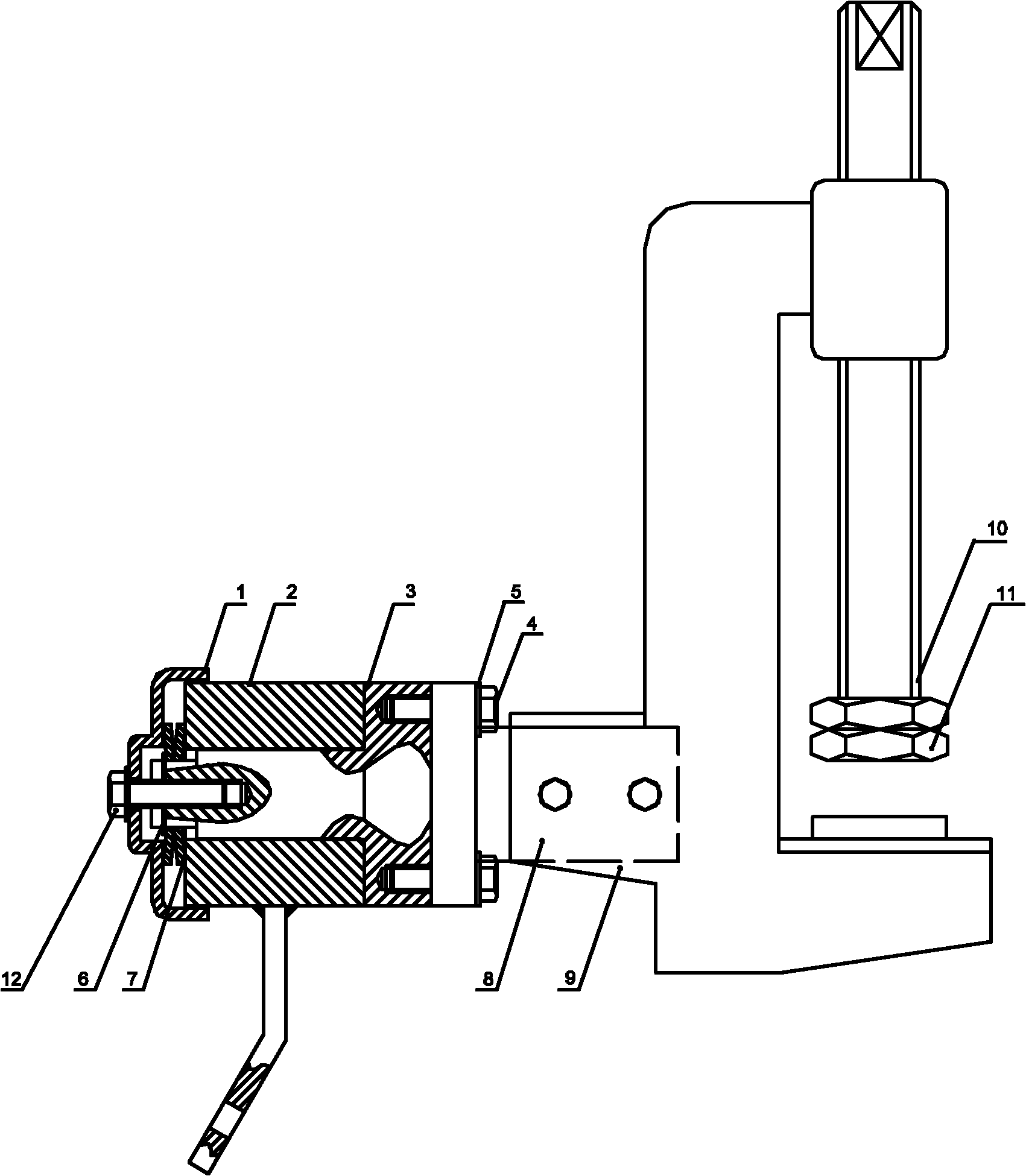

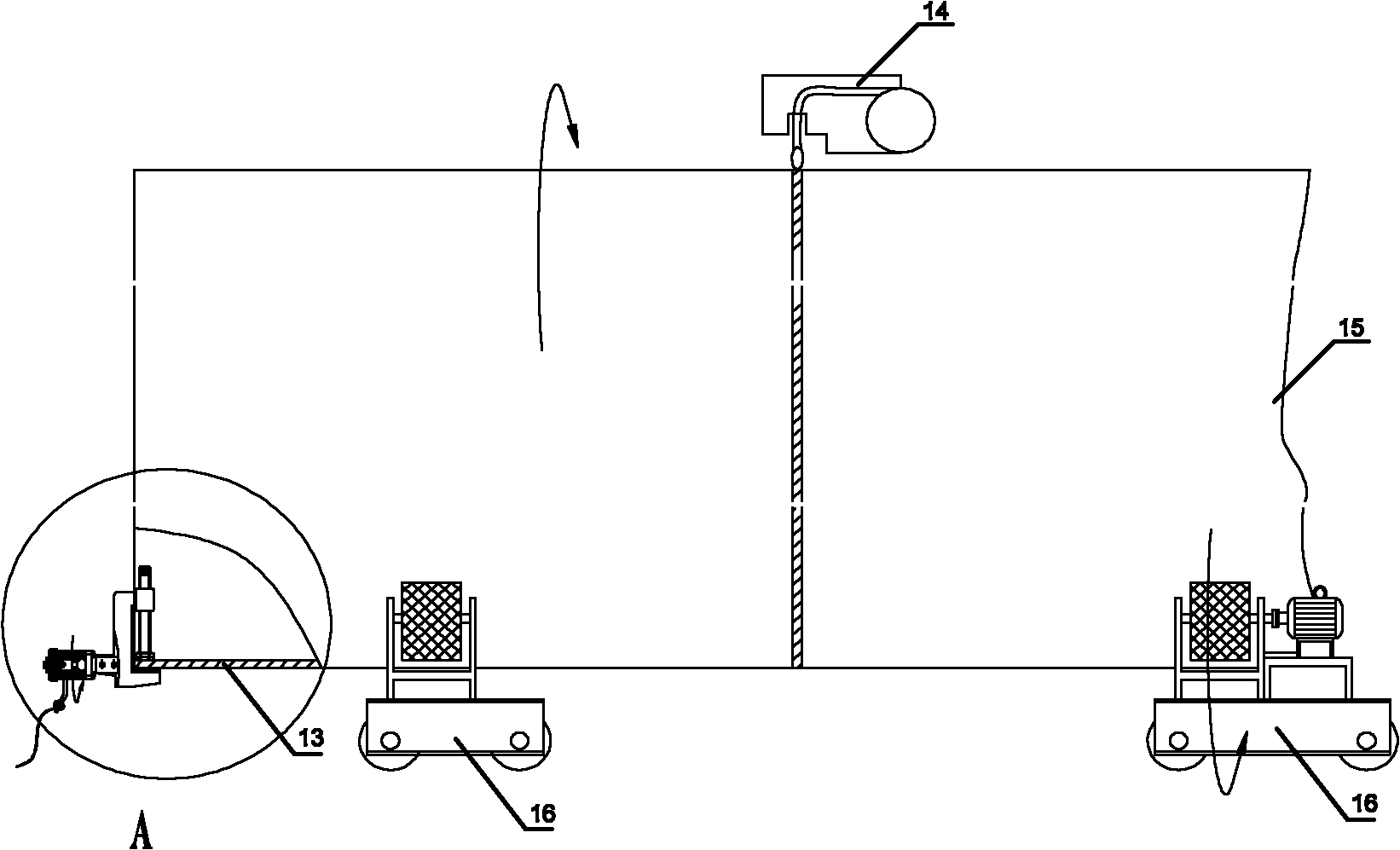

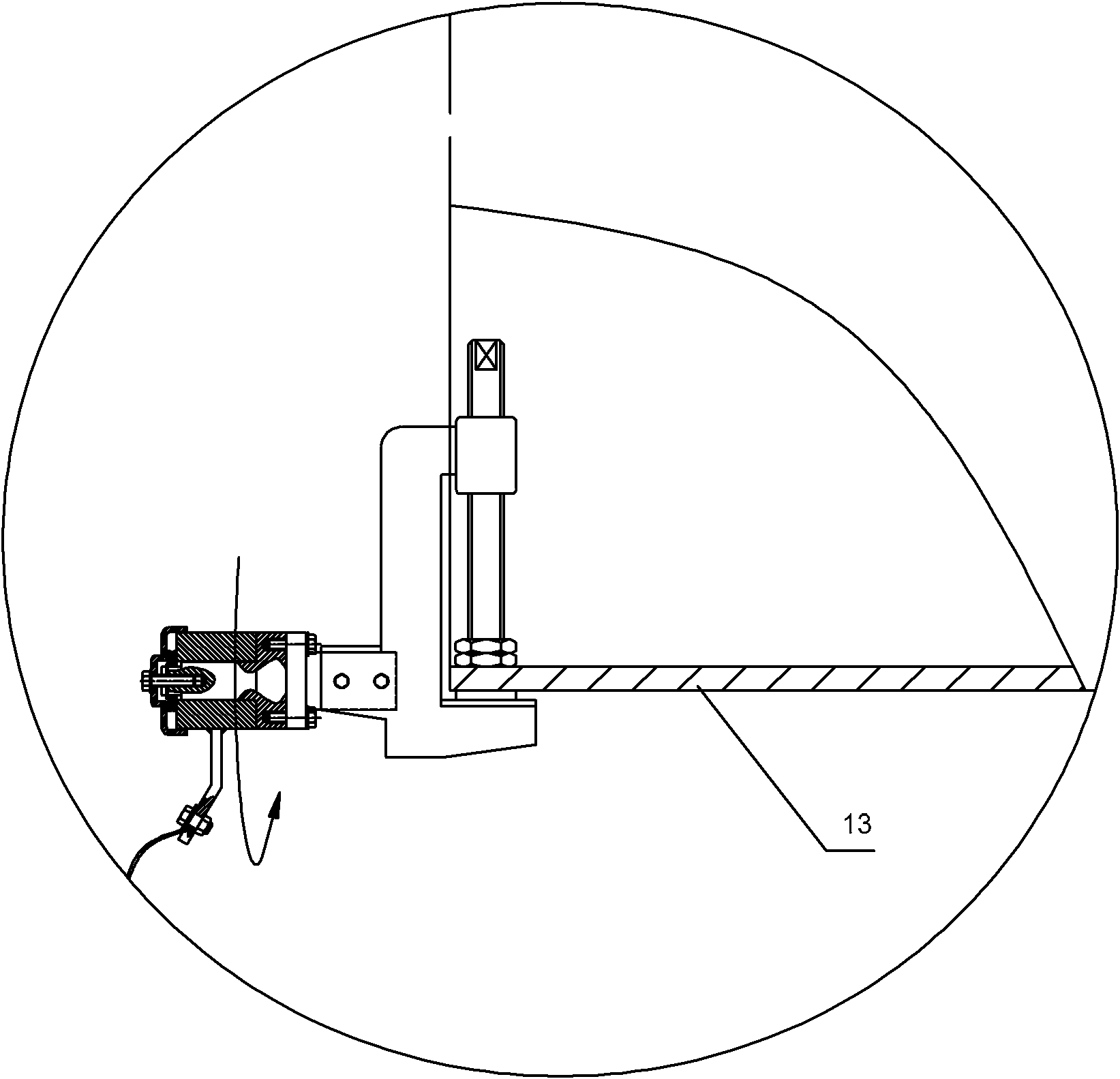

Rotating device for welding grounding wire by fixed connection with barrel body

InactiveCN102151965AAvoid distortionGuaranteed not to be damagedWelding accessoriesEngineeringCopper

The invention discloses a rotating device for welding a grounding wire by fixed connection with a barrel body. The rotating device comprises a pressing plate, a conductive copper sleeve, a conductive copper shaft, a connecting bolt, a gasket, a spring collar, a disc-shaped spring, a connecting block, a clamp body, an adjusting screw rod, a nut and a tightening bolt, wherein the pressing plate covers the conductive copper sleeve; the spring collar and the disc-shaped spring are arranged between the pressing plate and the conductive copper sleeve; the pressing plate tightly presses the disc-shaped spring and the conductive copper sleeve through the tightening bolt; one side end face of the conductive copper sleeve and one side end face of the conductive copper shaft are attached to each other tightly; the connecting bolt and the conductive copper shaft are in threaded connection; the gasket is arranged between the connecting bolt and the conductive copper shaft; the clamp body and the conductive copper shaft are fixed through the connecting block; the connecting block is arranged between the conductive copper shaft and the clamp body; the adjusting screw rod is arranged on one side of the clamp body; and the nut is positioned at the bottom end of the adjusting screw rod. By the rotating device for welding the grounding wire by fixed connection with the barrel body, the safety level during welding is increased and the welding quality is guaranteed.

Owner:SHANGHAI TAISHENG WIND POWER EQUIP

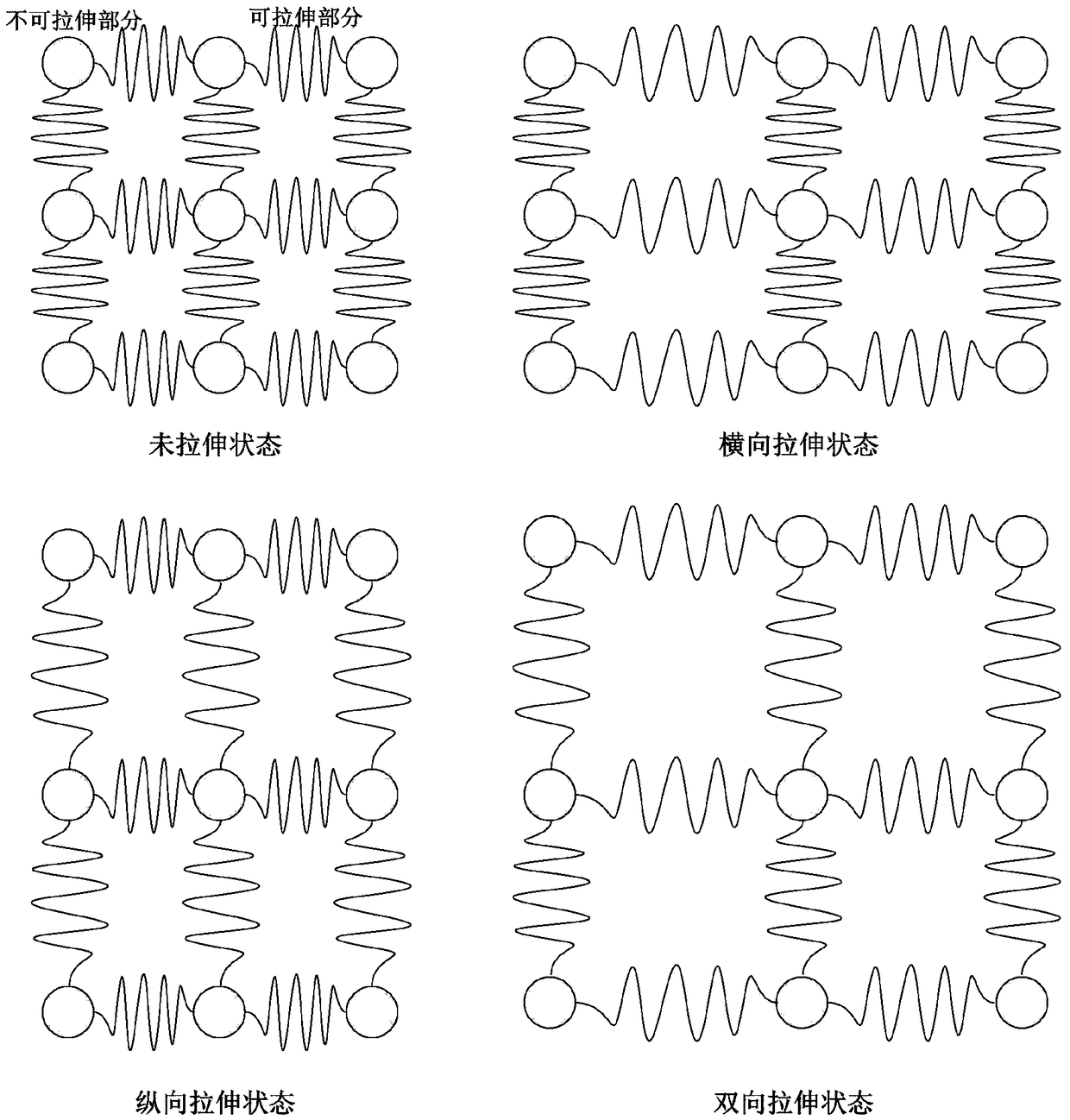

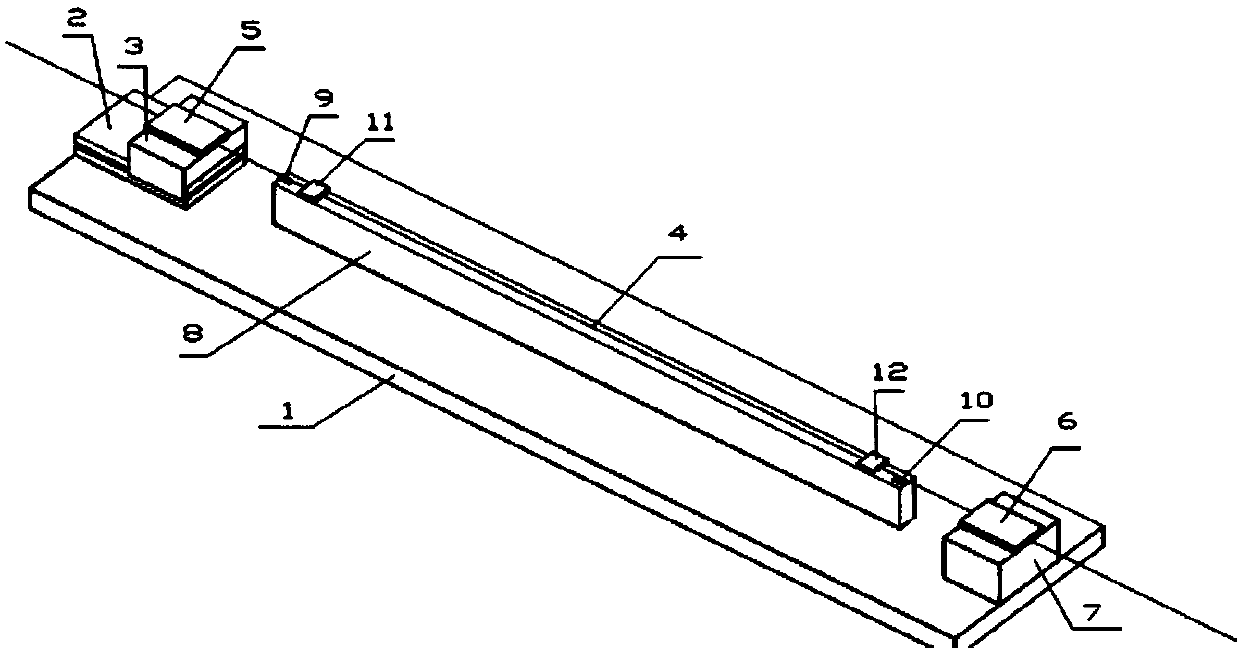

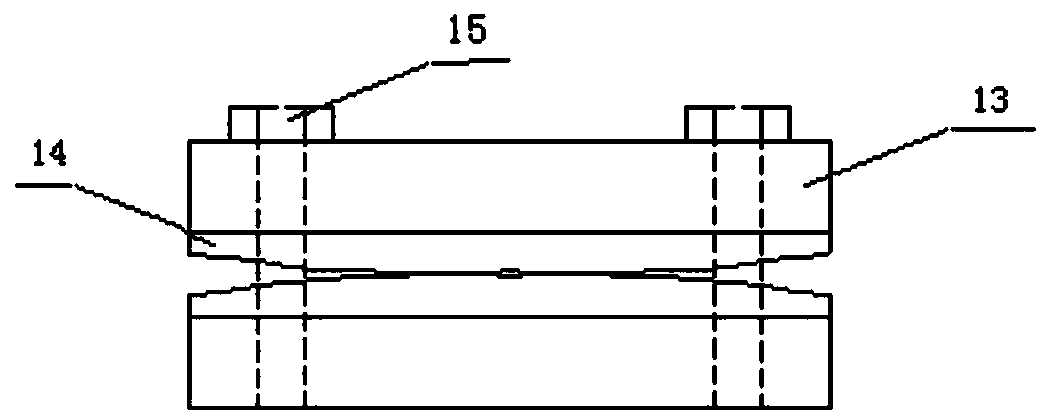

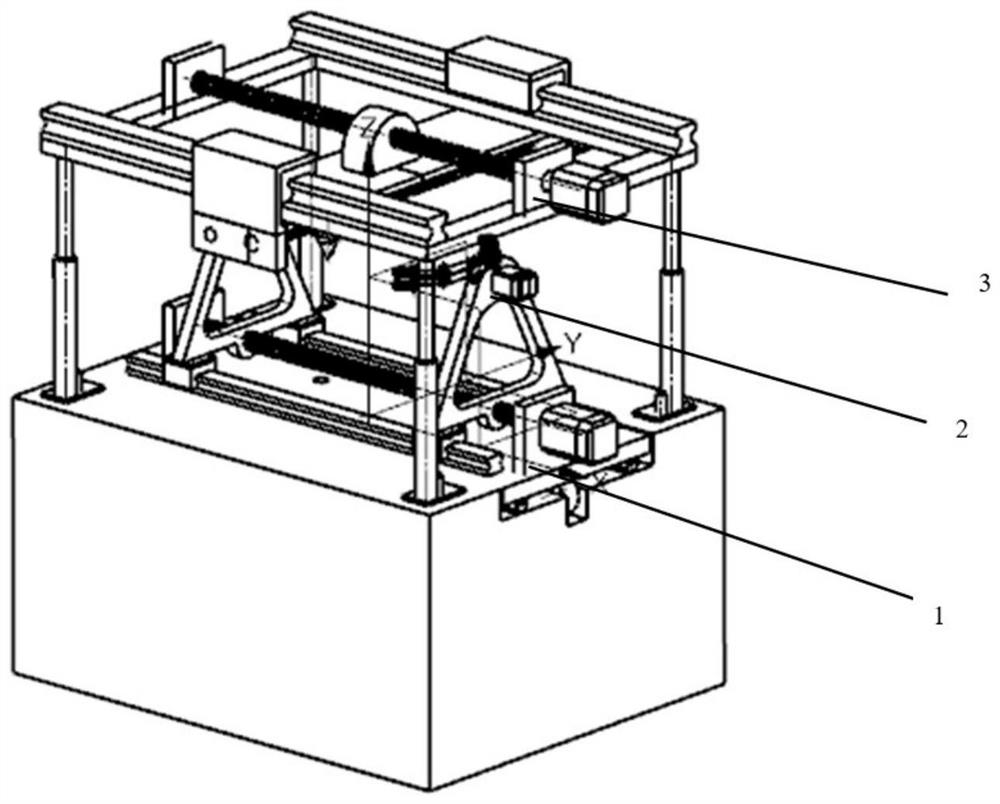

Distributed fiber strain coefficient calibration device and method

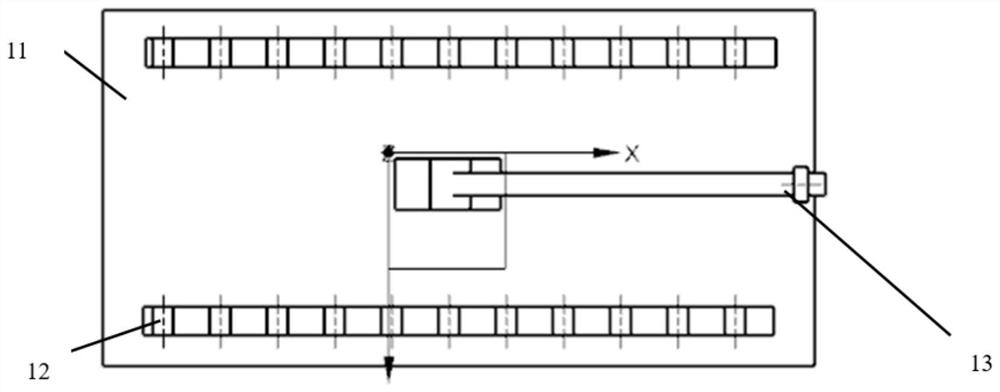

ActiveCN107941163ALarge clamping forceGuaranteed not to be damagedUsing optical meansImage resolutionFrequency shift

The invention provides a distributed fiber strain coefficient calibration device, and the device comprises an experiment table, a hydraulic stretching mechanism and a fiber clamping tool. The hydraulic stretching mechanism comprises a sliding table and a sliding block, and the sliding table is fixed on the experiment table. The fiber clamping tool comprises a first clamping tool and a second clamping tool, wherein the first clamping tool is fixed on the sliding block, and the second sliding tool is fixed on the experiment table. The device also comprises a displacement measurement mechanism, and the displacement measurement mechanism comprises a sliding rail, a first displacement meter, a second displacement meter, a first passive sliding block, and a second passive sliding block. The sliding rail is fixed on the experiment table, and two ends of the sliding rail are respectively provided with the first displacement meter and a second displacement meter in a fixed manner. The sliding rail is provided with the first passive sliding block and a second passive sliding block. When the sliding block pulls a fiber to make movement along the sliding table, the first and second passive sliding blocks make synchronous movement with a fiber. The beneficial effects of the invention are that the device solves problems that the fiber deformation measurement is not accurate and the spatial resolution affects the Brillouin frequency shift value, and the device improves the measurement accuracy of a strain coefficient.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

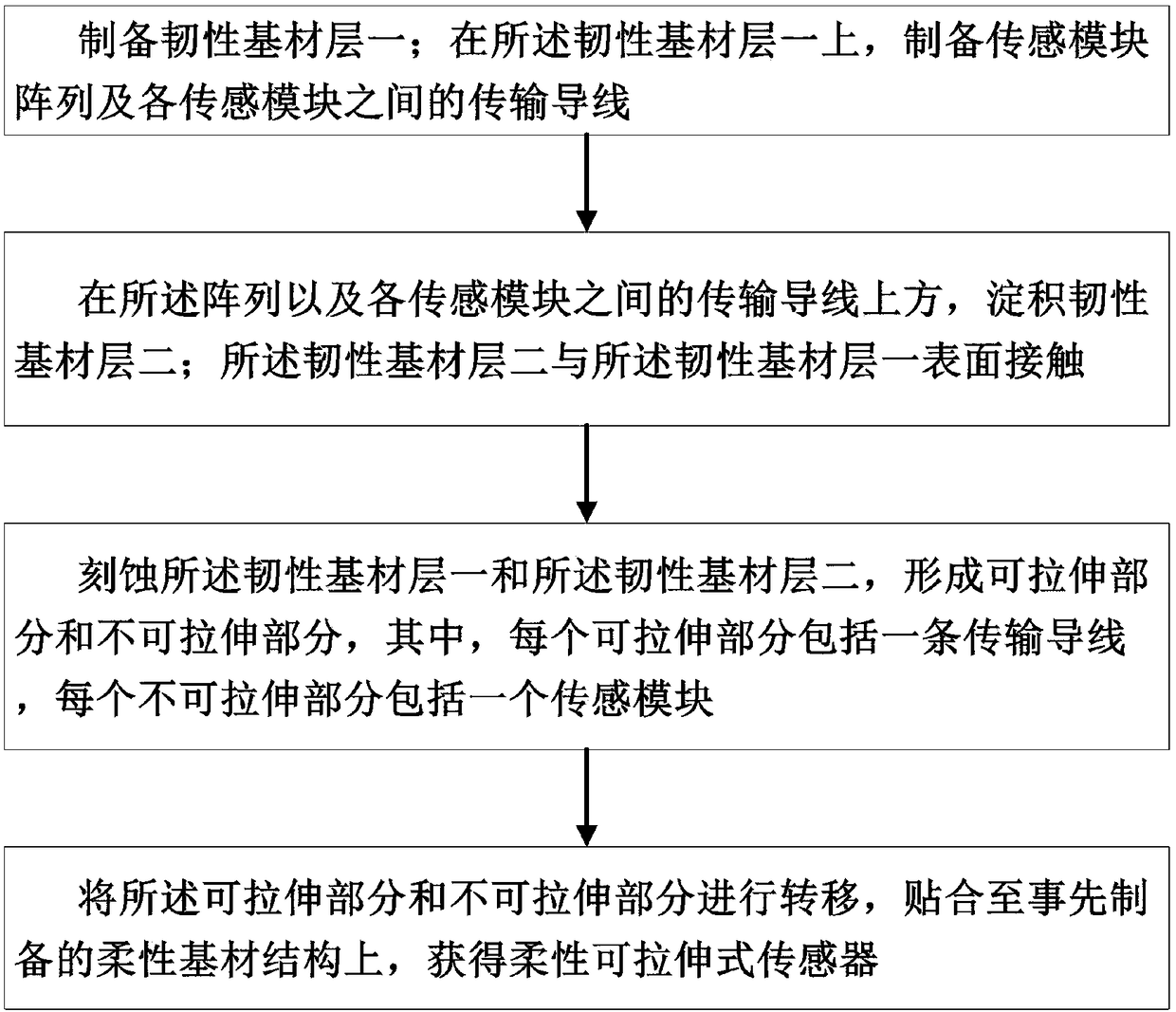

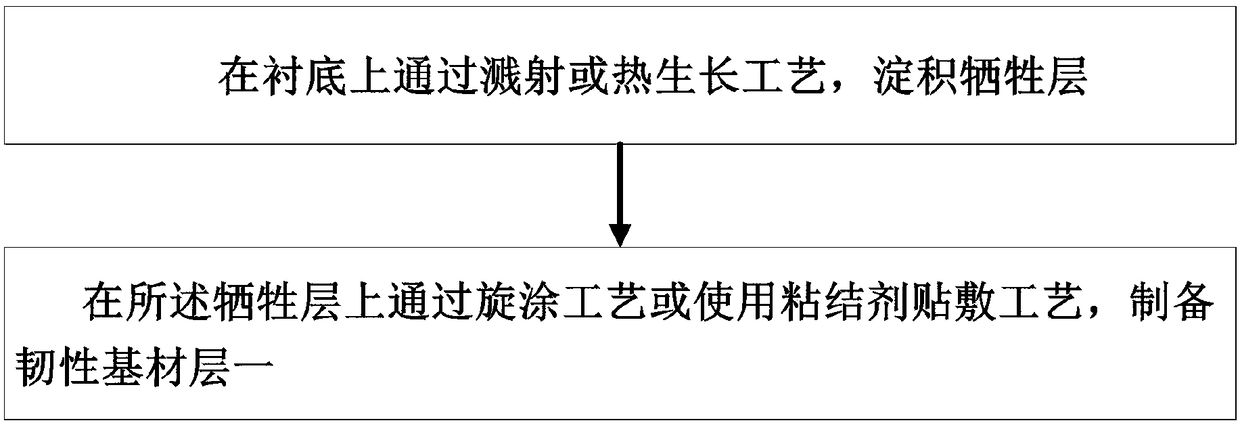

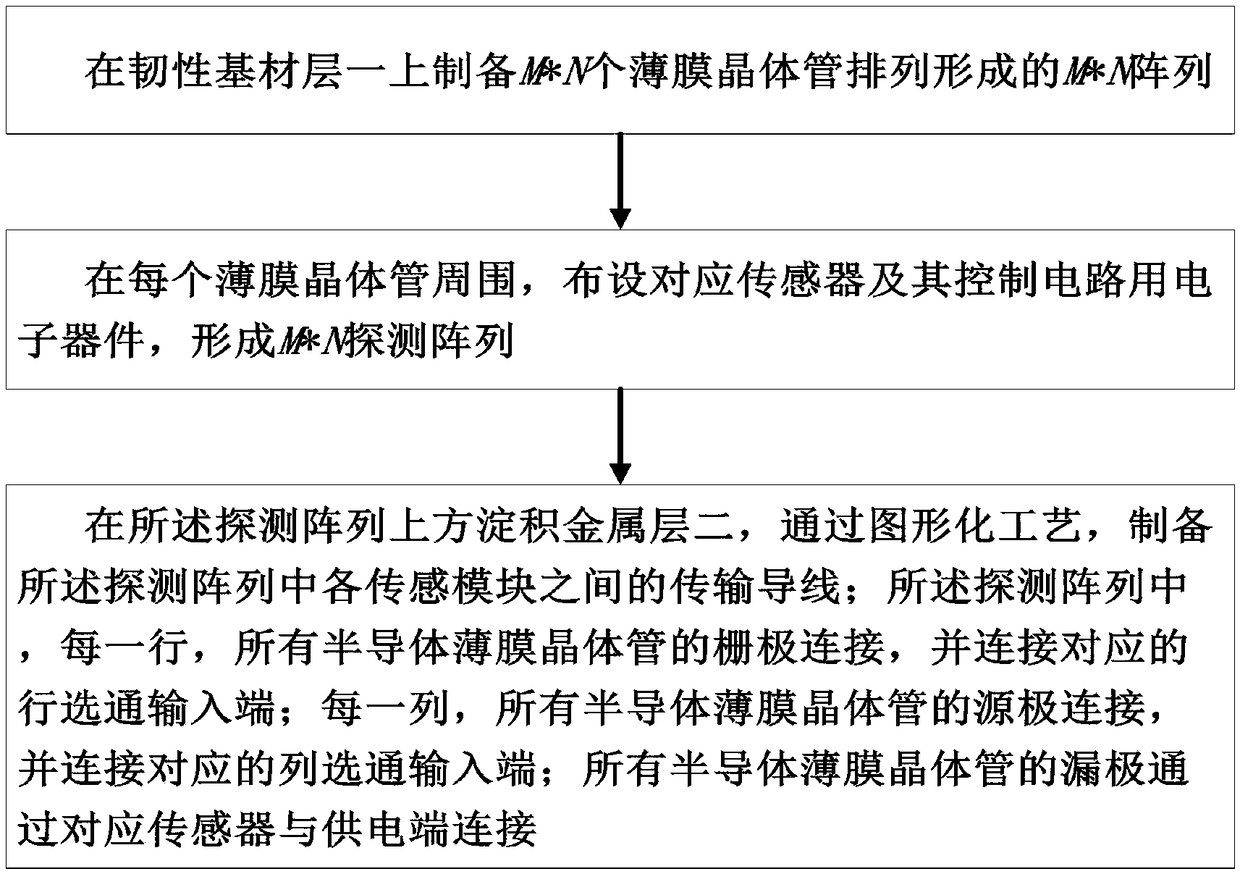

Preparation method of flexible stretchable sensor

ActiveCN109374023ADoes not affect the detection functionAvoid deterioration of electrical performanceSemiconductor/solid-state device manufacturingConverting sensor output electrically/magneticallyComputer moduleElectrical performance

The invention, which belongs to the technical field of sensor preparation, relates to a preparation method of a flexible stretchable sensor so that problems that the existing flexible stretchable sensor is easy to damage, the detection result is inaccurate, and the circuit design is unreasonable can be solved. The preparation method comprises the following steps: preparing a flexible base materiallayer I; preparing an M*N detection array formed by arranging M*N sensing modules as well as a transmission wire; preparing a stretchable portion and a non-stretchable portion of a flexible stretchable sensor; and transferring the stretchable portion and the non-stretchable portion and enabling the portions to be in contact with a pre-prepared flexible base material structure to obtain a flexiblestretchable sensor. When the flexible stretchable sensor is in use, the flexible stretchable sensor realizes the macroscopic stretching function by the stretchable portion but the detecting functionof the non-stretchable portion is not affected. On the basis of the structural design of the non-stretchable portion, the electrical performance variation of the sensing module during the stretching process is avoided and thus the number reading becomes stable, reliable, and sensitive.

Owner:BEIJING MECHANICAL EQUIP INST

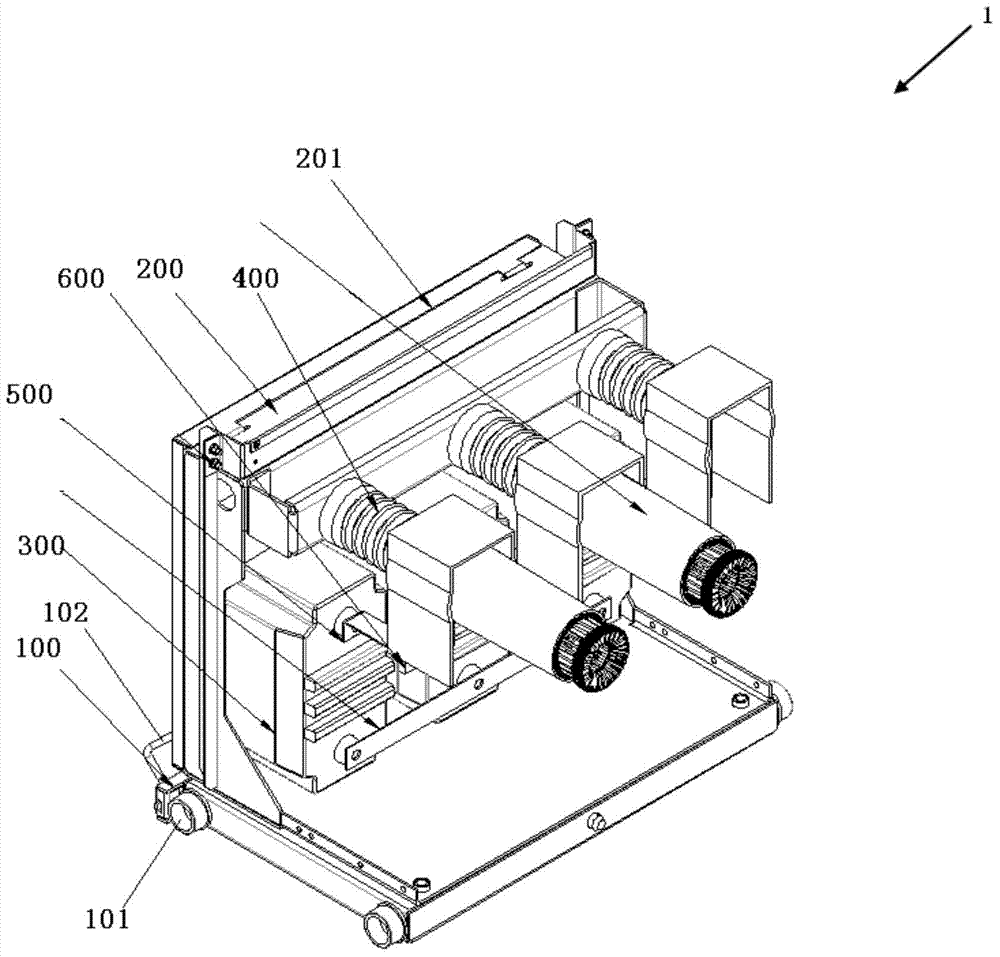

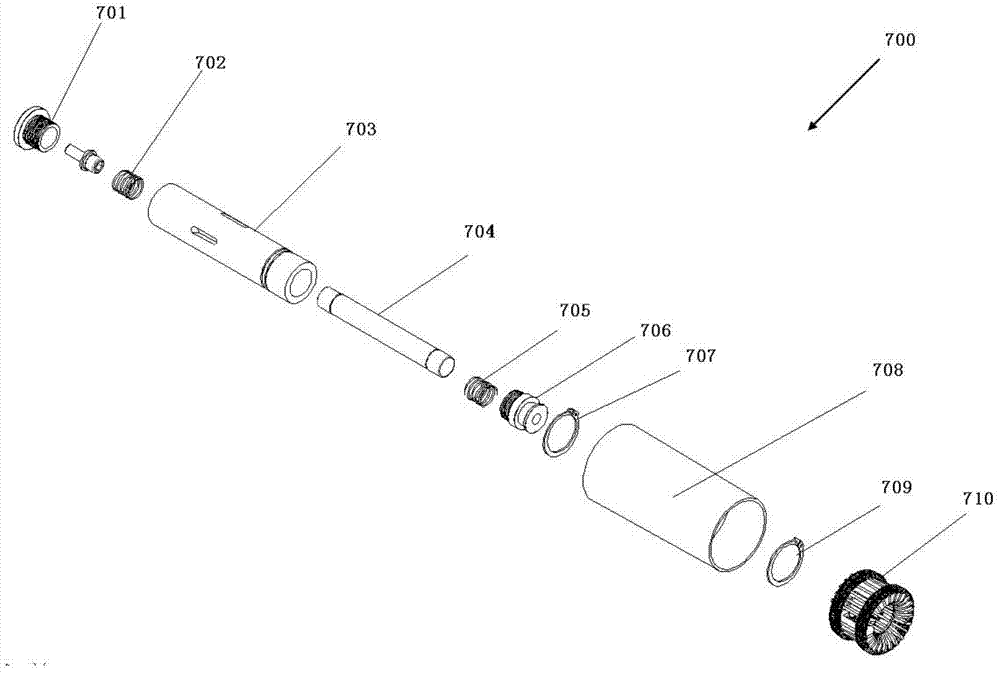

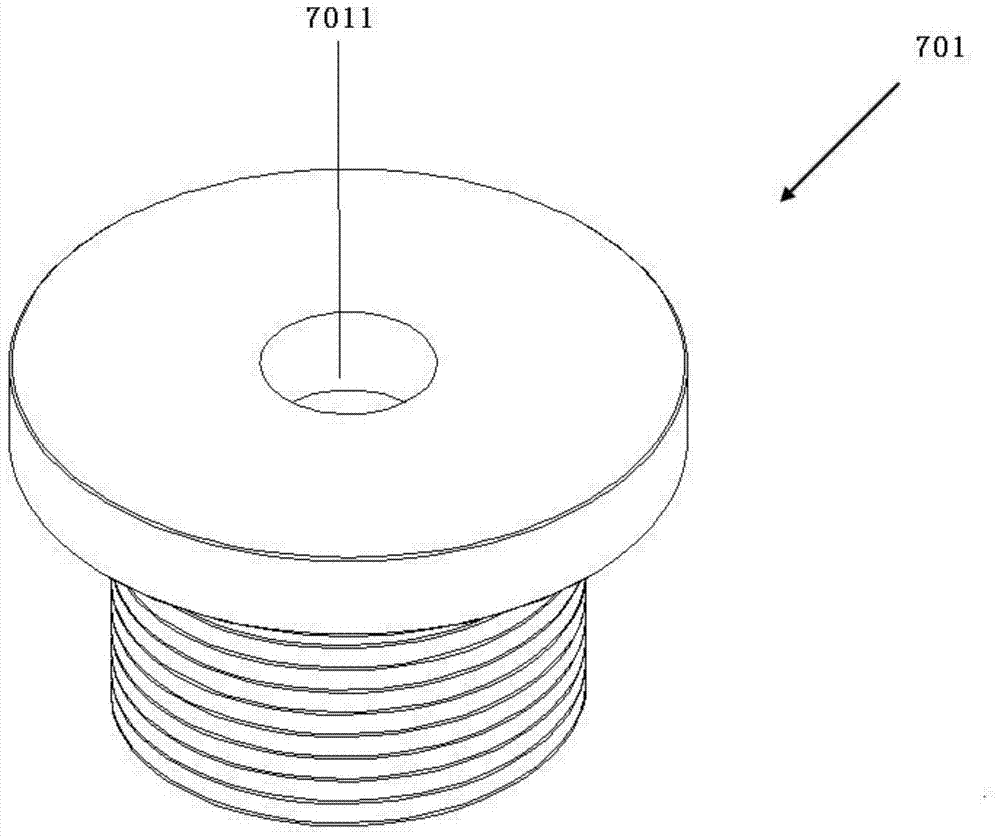

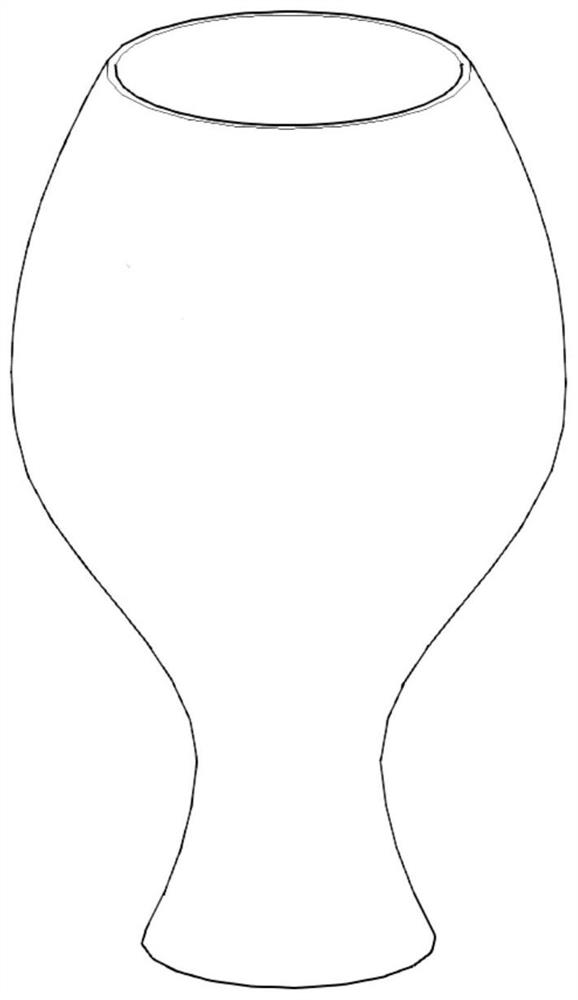

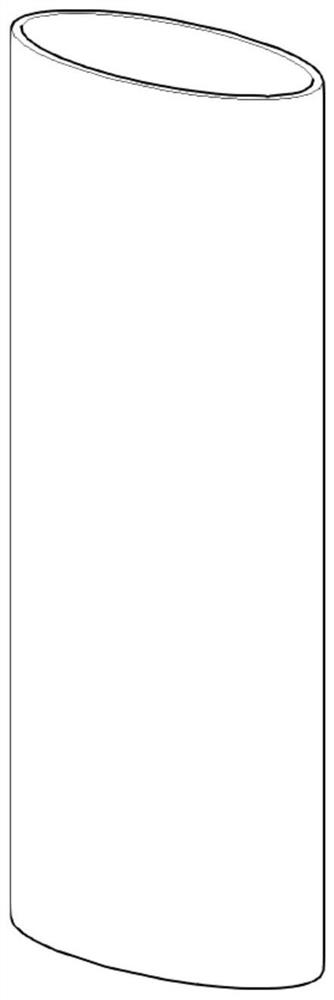

Deburring device and deburring method for cast cylinder bodies

InactiveCN104550882AGuaranteed not to be damagedSo as not to damageEngineeringMechanical engineering

The invention discloses a deburring device and a deburring method for cast cylinder bodies, and aims to provide a deburring device and method which can remove fins and burrs on the cylinder bodies thoroughly and guarantee that the cylinder bodies and a floating pressure cutting module are undamaged. The deburring device comprises a rack, a mounting platform, a floating pressure cutting device mounted over the mounting platform, a first lifting device arranged on the rack and used for lifting the mounting platform and a second lifting device used for lifting the floating pressure cutting device. A clamping tool is arranged on the mounting platform. The floating pressure cutting device comprises a floating pressure cutting module. A pressure cutting hole matched with the outer contours of the cylinder bodies is arranged in the floating pressure module. The deburring method includes: mounting one cylinder body on the mounting platform, driving the cylinder body to move upwards through the first lifting device, and enabling the joint line in the middle of the cylinder body to be located over an upper port of the pressure cutting hole; then, driving floating pressure cutting device to move upwards through the second lifting device, and thoroughly removing the fins and the burrs.

Owner:温州市马锐汽缸制造有限公司

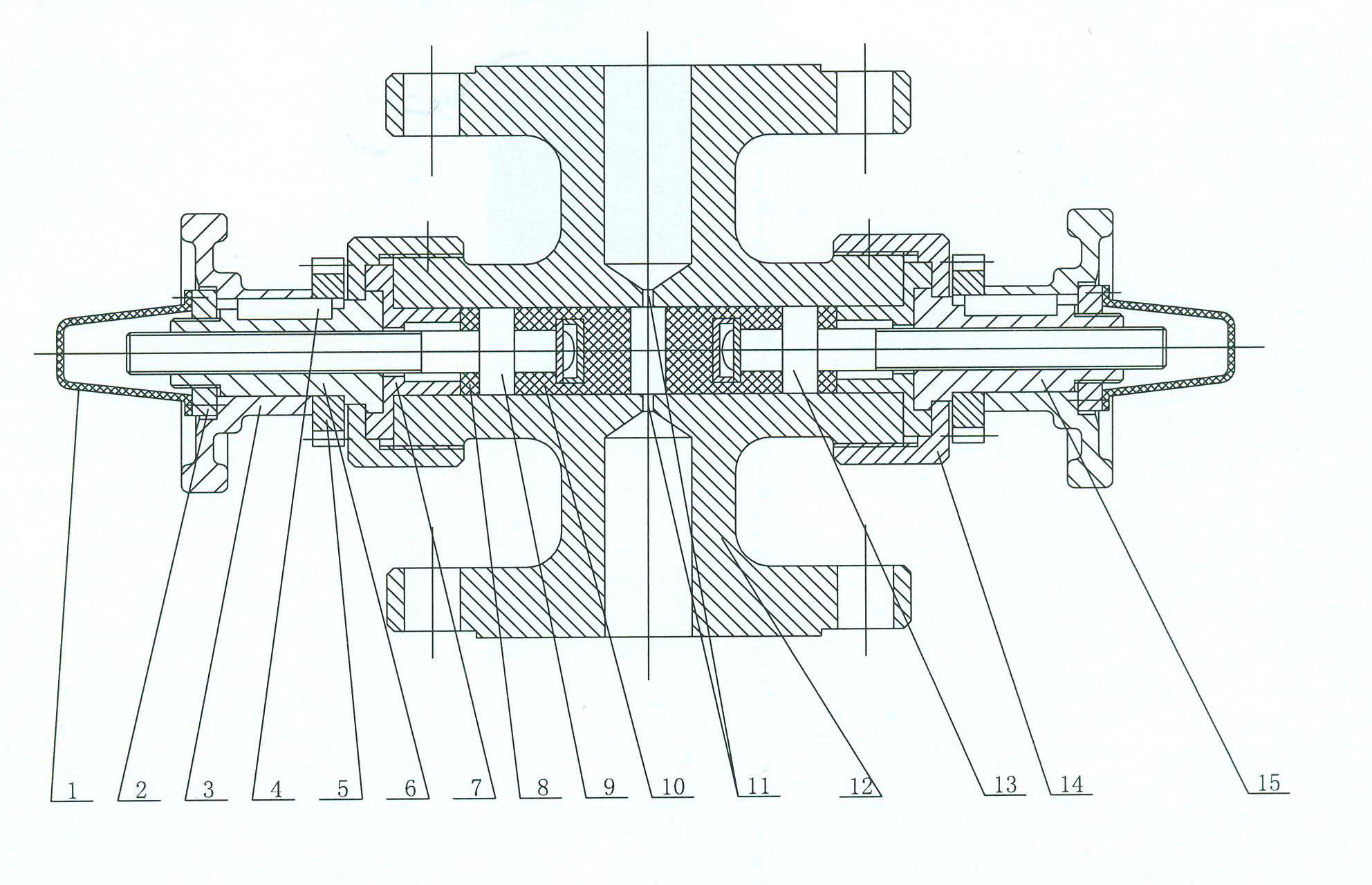

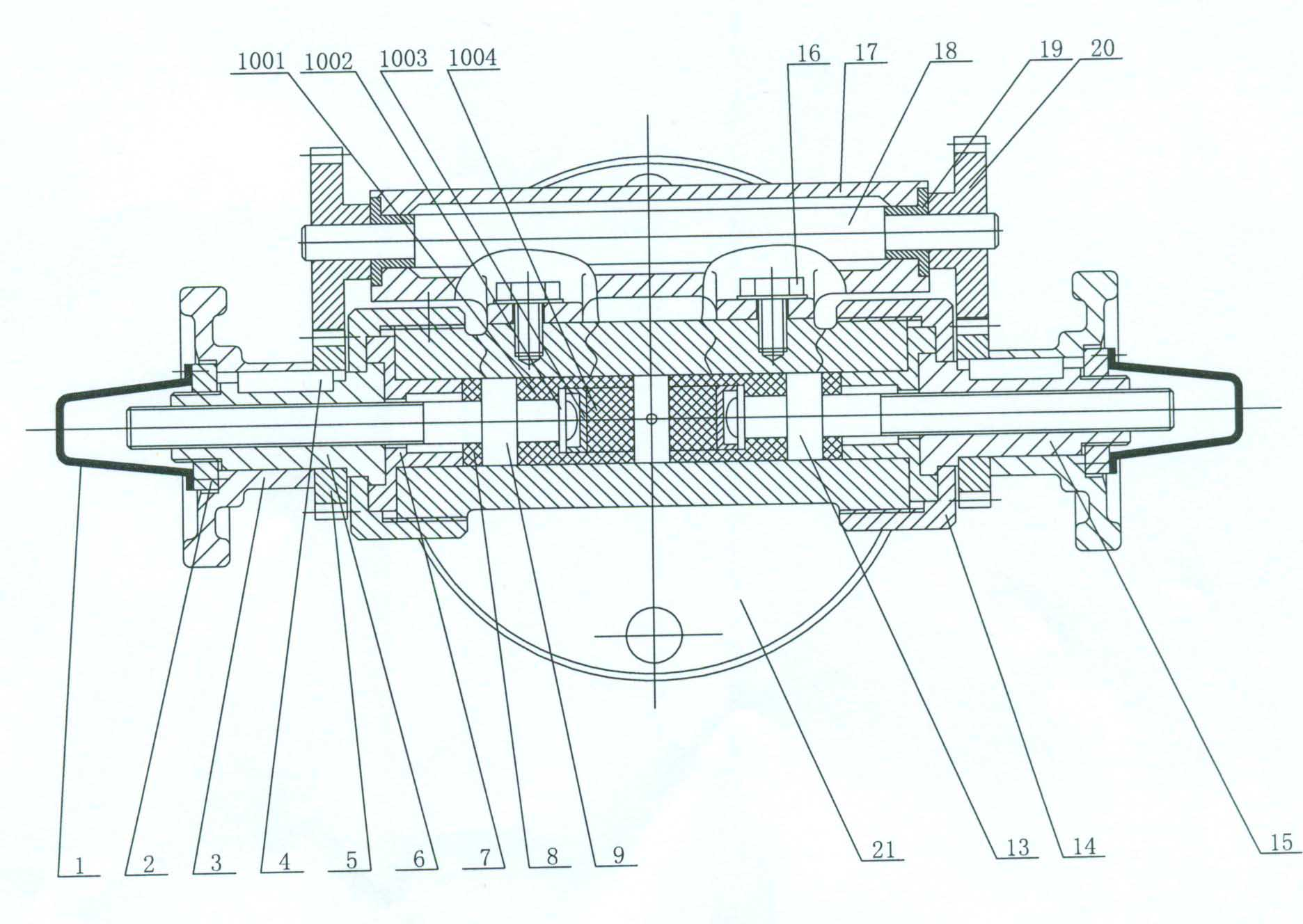

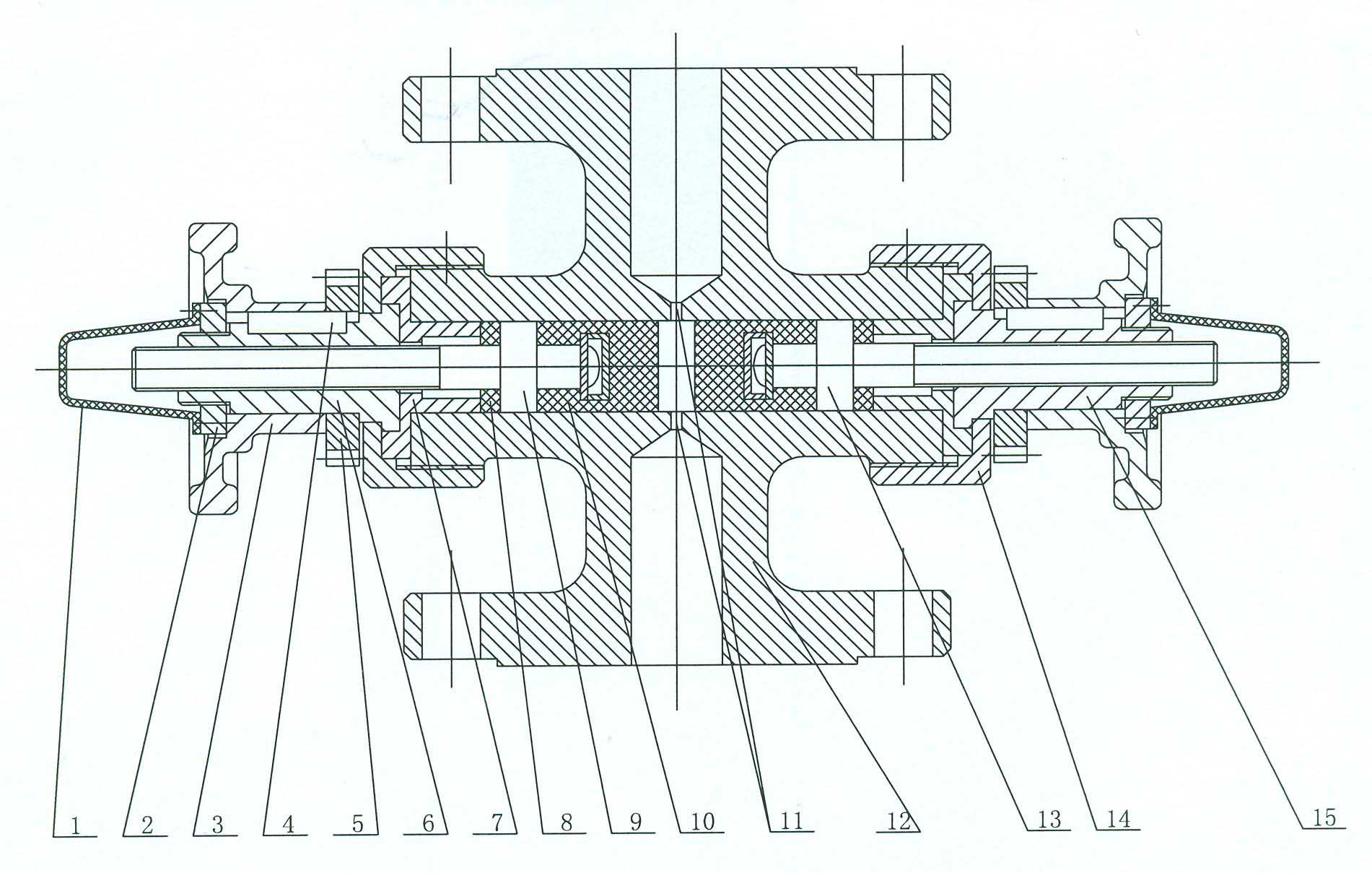

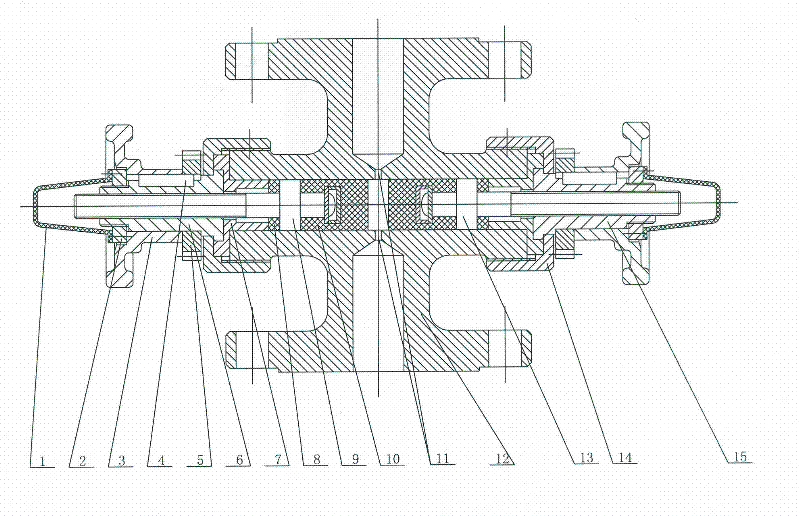

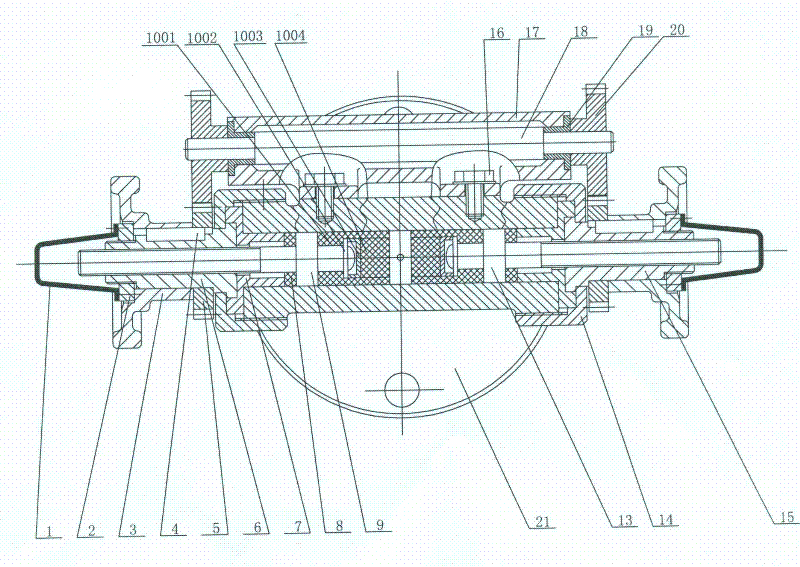

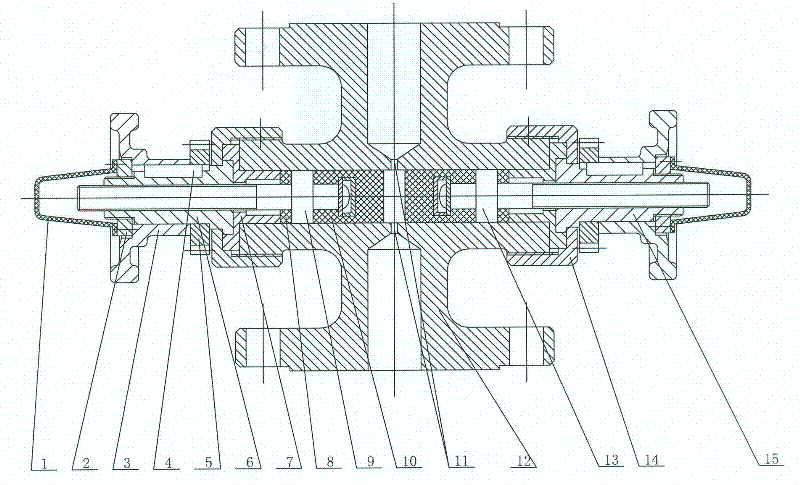

Bilateral sealing stop valve

ActiveCN102022557ARelieve pressureGuaranteed not to be damagedOperating means/releasing devices for valvesSlide valveSlider bearingDrive shaft

The invention relates to a bilateral sealing stop valve which comprises a valve body and valve elements. The stop valve adopts the technical essentials that a throttling orifice is arranged on the longitudinal central line of the valve body, and the valve elements are arranged on the transverse central line of the valve body; the valve elements are symmetrically arranged in valve element holes at two sides of the throttling orifice; the valve element hole at the front end of a valve element sealing stop is internally provided with a sealing assembly; a positioning body and a nut are sleeved outside the valve elements at two ends of the valve element holes and fixed on the valve body through a fixing press cap; a hand wheel which is clamped by a flat key and fixed by a jam nut is sleeved outside the nut, and a valve element gear is arranged outside the nut between the hand wheel and the fixing press cap; the valve body is connected with a bearing block through a bolt, and the bearing block is internally provided with a slide bearing; a transmission shaft is fixed on the bearing block through the slide bearing; and two ends of the transmission shaft are provided with a transmission shaft gear engaged with the valve element gear. The invention has the advantages of flexible and compact structure, exact and accurate sealing, good sealing quality and low manufacturing cost and is an important improvement for the safety performance of a float type liquid level metering system of a pressure container.

Owner:CHAOYANG JIAHUA ELECTRONICS

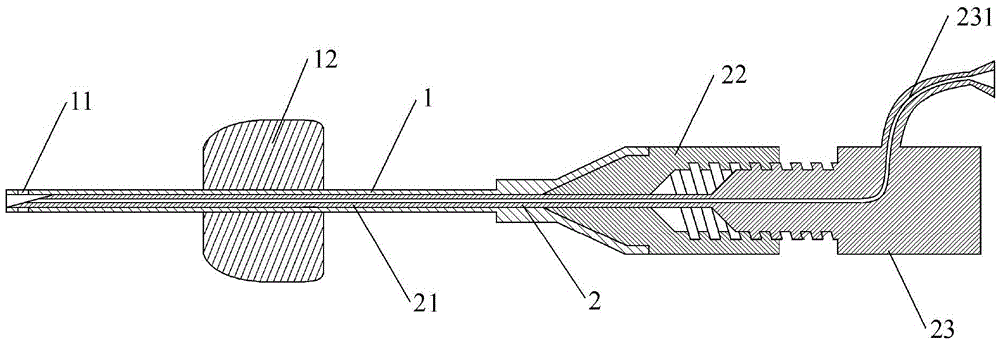

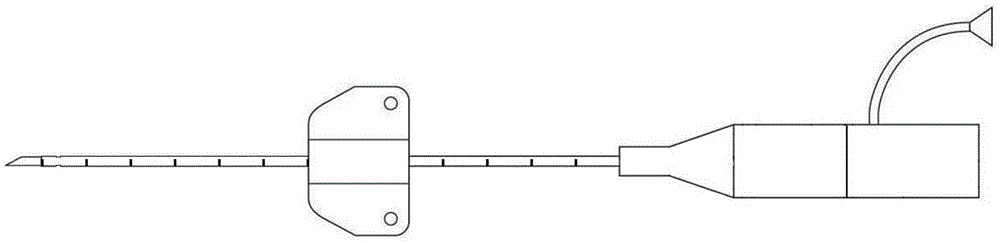

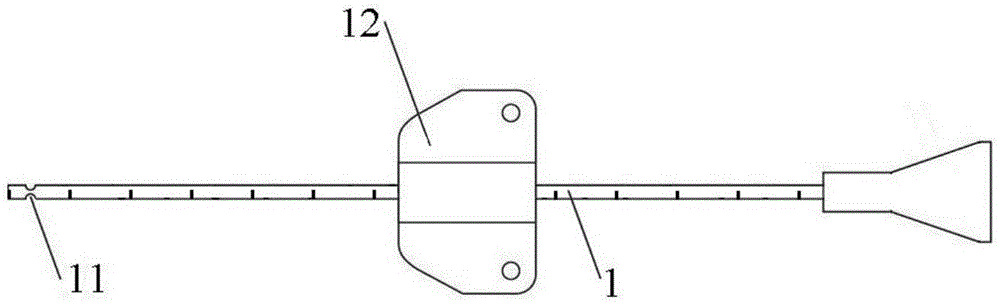

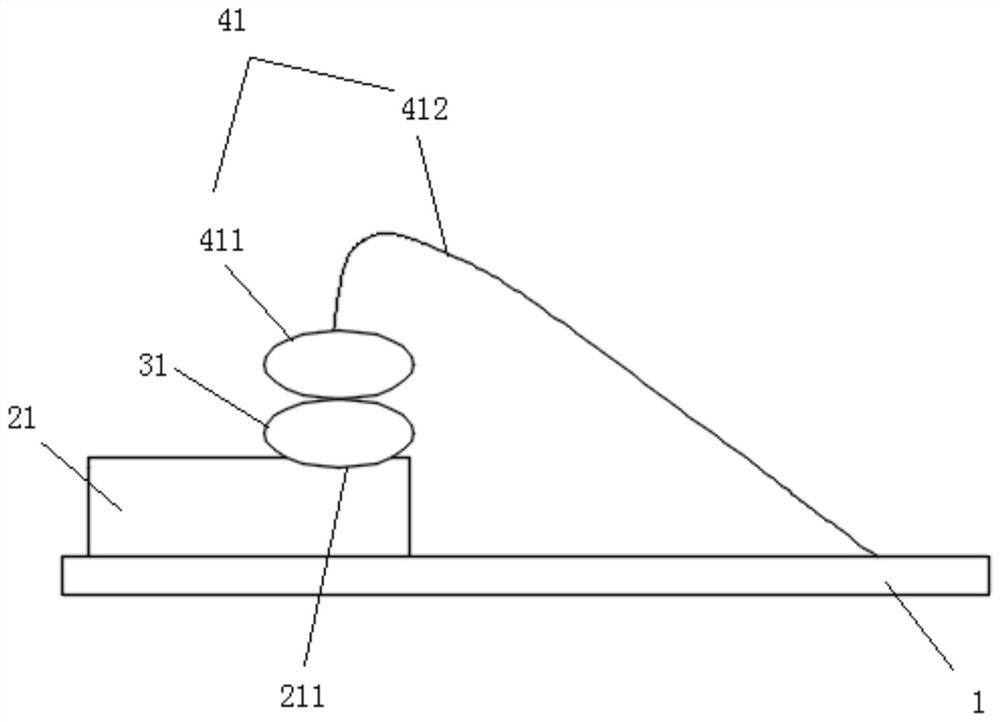

Nerve block puncture catheter needle with adjustable puncture head

ActiveCN104000639BAdjust sharpnessEasy to punctureCannulasSurgical needlesAnesthesia analgesiaNeedle catheter

The invention belongs to the technical field of medical apparatuses and instruments and provides a nerve-blocking puncture catheter needle with an adjustable puncture head. The catheter needle mainly consists of a puncture catheter and a puncture needle core. During operation, the puncture needle core is sleeved by the puncture catheter, and the sharp end of the puncture needle core extends out of a port of the puncture catheter and has sharpness. Under the ultrasonic guidance, the sharp end of the puncture needle core can return to the puncture catheter through adjustment and control when the catheter is close to the target nerve, and the catheter needle loses the sharpness but still has toughness and can continue to penetrate the fascia tissue to be close to the nerve till the catheter needle touches the nerve. Due to the fact that a needle point returns back to the catheter and loses the sharpness, the nerve is not hurt, the catheter needle reaches a target position, the puncture needle core can be directly removed, and the puncture catheter is indwelt around the nerve for future anesthesia medicine application or anesthesia analgesia treatment and other applications.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

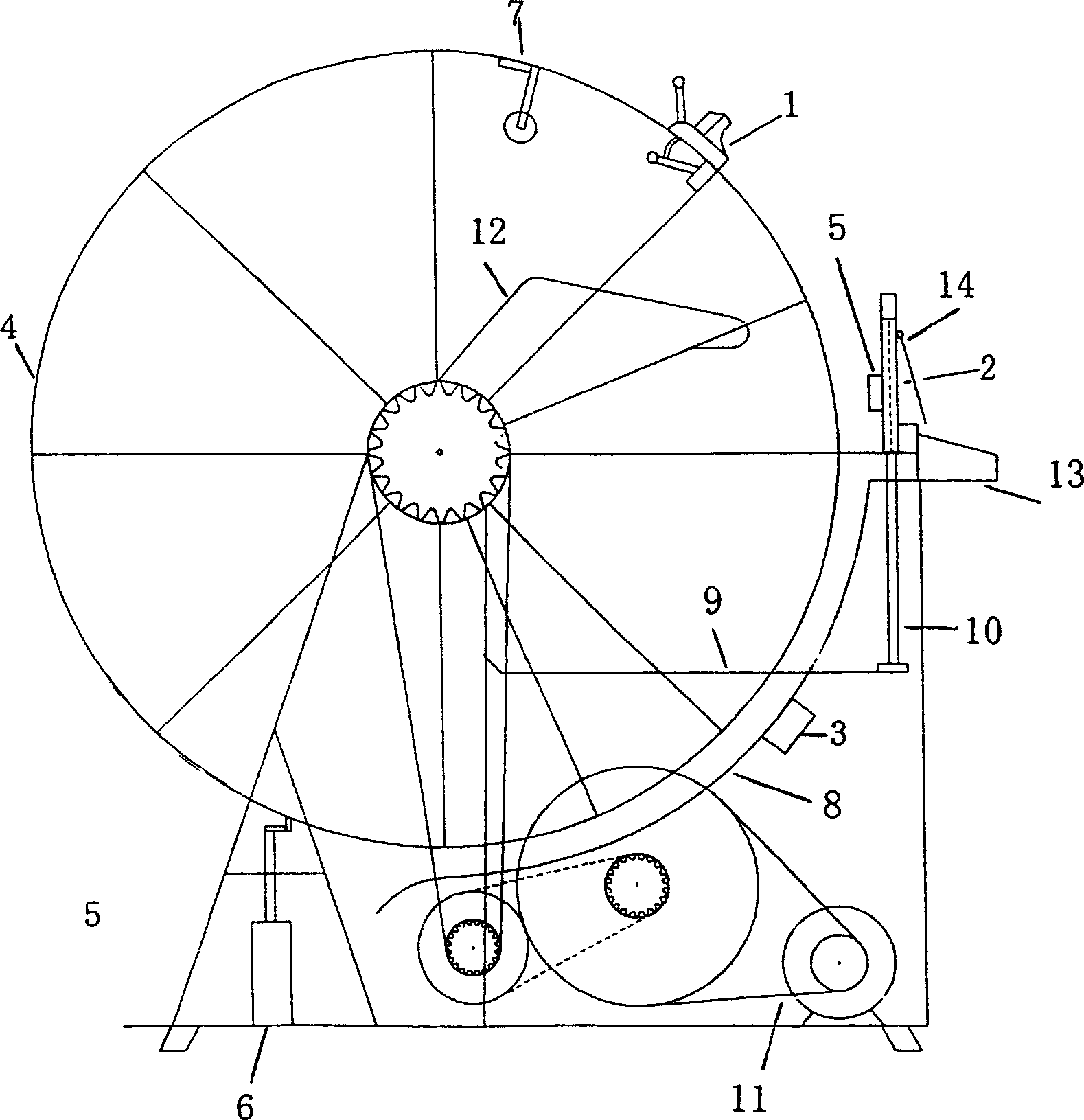

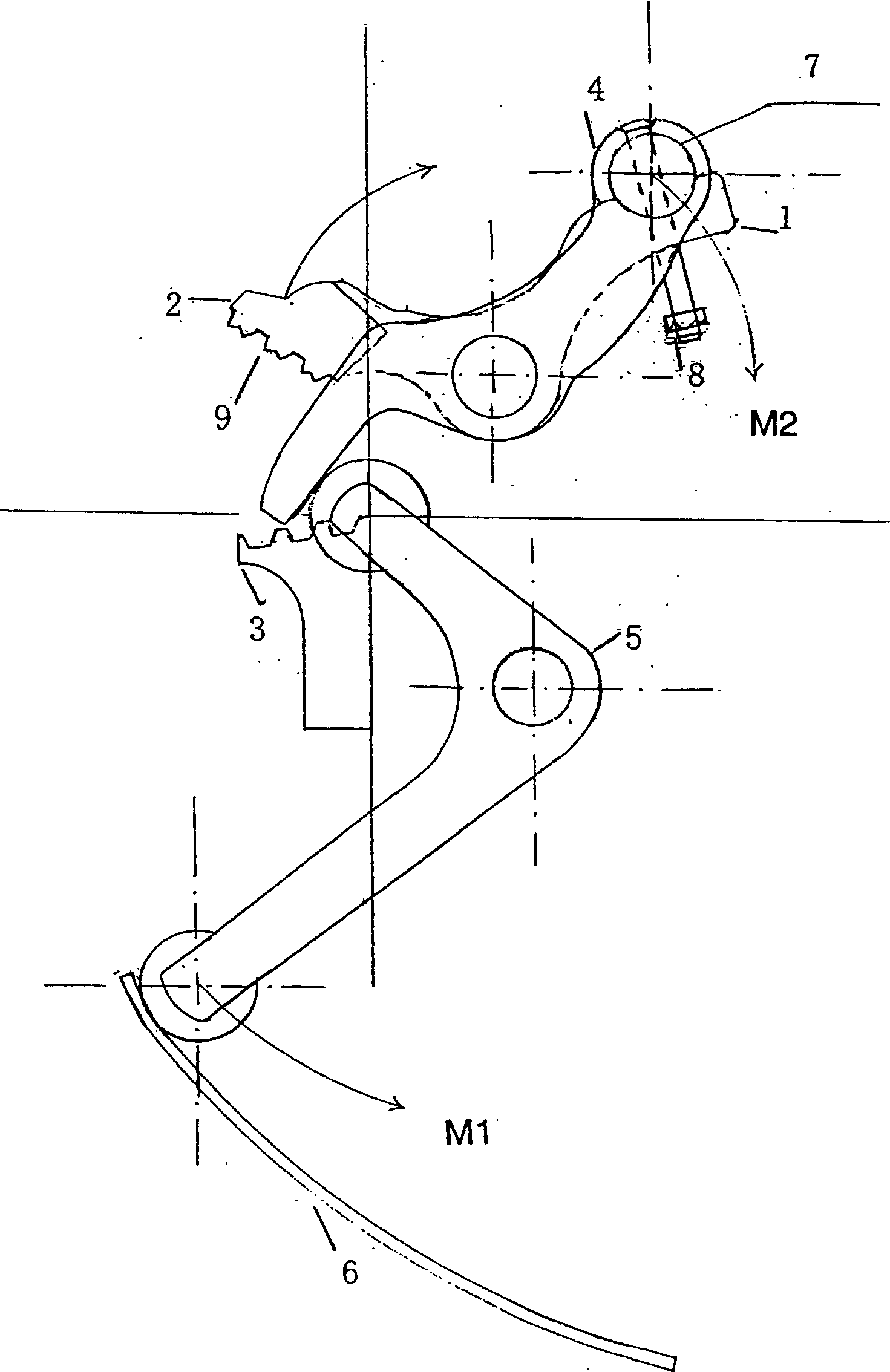

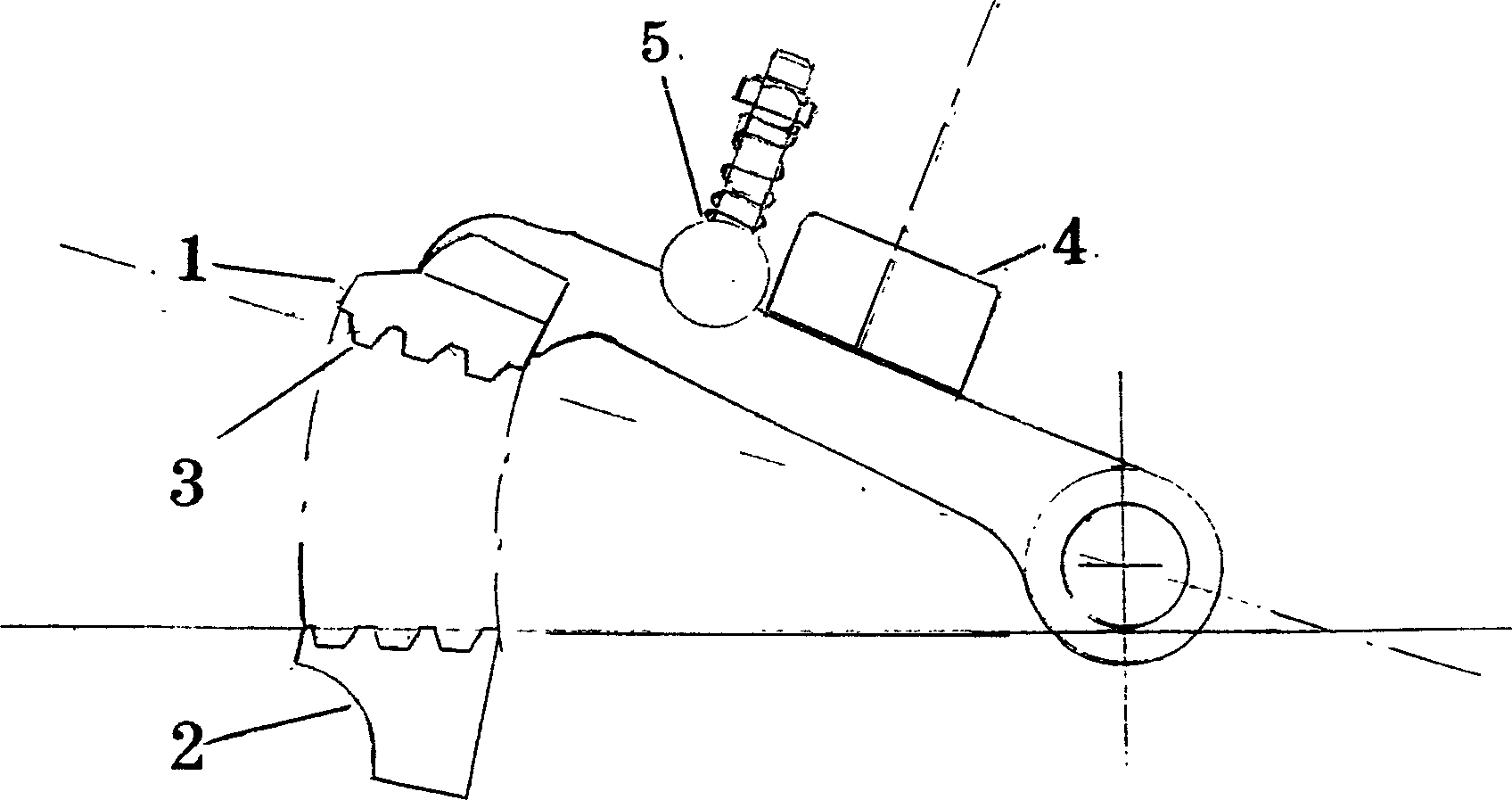

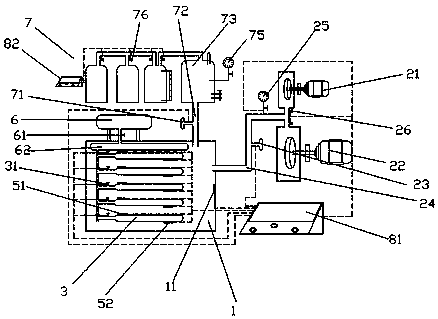

Spinning wheel type automatic scutcher

InactiveCN1635197AHigh degree of automationSimple and fast operationMechanical fibre separationAutomatic controlSelf locking

The invention discloses a spinning wheel type automatic scutcher, comprising a spinning wheel body, a manipulator that is a crocodile type canine teeth shaped adjustable self-locking type clamp, a pressing-peeling type cutter, a hemp throwing and laying mechanism, stroke electric appliances, an electromagnetic braking, guide rail striking channels, a tappet, a power transmitting means, and a feeding bench. The spinning wheel body acts as an assembled carrier, processing multifunction of transmitting, guiding and automatic controlling the crocodile type canine teeth shaped adjustable self-locking type clamp and the cutter, automatic cooperating the hemp throwing and laying mechanism, accomplishing the automatic controlling function during transmitting, pulling, guiding and laying, making the hemp body interlayer slip under the action of frictional force, strip off easily, and separate the fiber, cuticle and juice of hemp clearly. The invention has advantages of high efficiency, high output quantity, high automation, good quality of hemp fiber, short time for degumming, less drug consumed, simple operation and low energy consumption.

Owner:四川省鑫农科技有限公司

Multipurpose cleaning machine

InactiveCN102652944AConvenient lifeReduce financial burdenCleaning using liquidsWater wheelEngineering

The invention discloses a multipurpose cleaning machine, namely a machine capable of cleaning a variety of objects. The multipurpose cleaning machine consists of a cleaning barrel, a resistance fence, a layering net, a water wheel and a motor. By the multipurpose cleaning machine, a substance (such as water) used for cleaning an object to be cleaned contacts with the object to be cleaned, and a speed difference is generated between the substance (such as water) used for cleaning the object to be cleaned and the object to be cleaned, so that the object to be cleaned is impacted and then the object to be cleaned is cleaned. For stains which are difficult to be cleaned on objects such as a bowl and the like, a certain number of small objects (such as plastic balls of which the diameter is around 1 centimeter) can be added into the cleaning barrel to move together with the substance (such as water) used for cleaning the object to be cleaned, and dash against the surface of the object to be cleaned or rub against the surface of the object to be cleaned so that the object to be cleaned is cleaned.

Owner:张永生

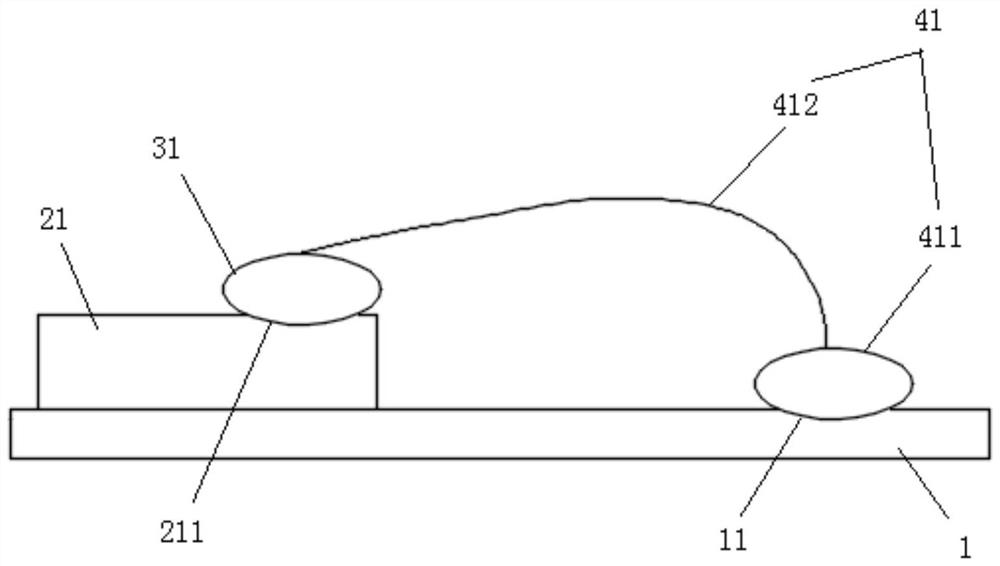

Chip welding structure and welding method

PendingCN111933605AReduce impactGuaranteed not to be damagedSemiconductor/solid-state device detailsSolid-state devicesPhysicsCopper wire

The invention relates to the field of semiconductor packaging, and discloses a chip welding structure and a welding method. The chip welding structure comprises a substrate, a first chip, a first goldwelding spot and a first copper connecting wire, wherein the first chip is arranged on the substrate, the first gold welding spot is arranged on the first chip, and the two ends of the first copper connecting wire are connected with the first chip and the substrate respectively. According to the chip welding structure, a gold welding spot is formed on the chip by using a gold wire made of a softmaterial, impact force on the chip is small, and the internal structure of the chip is not easy to damage; a copper wire is adopted to form the first copper connecting wire, the two ends of the firstcopper connecting wire are connected with the gold welding spot and the substrate respectively, so that the chip and the substrate are electrically communicated; and due to buffering of the gold welding spot, impact force on the chip during copper wire welding is effectively reduced, it is guaranteed that the chip structure is not damaged, and meanwhile, the production cost during chip packaging is reduced.

Owner:CHIPMOS TECHSHANGHAI

Contact arm of voltage transformer handcart

InactiveCN104332874ASave production spaceImprove diversion capacitySwitchgear detailsTransformerPotential transformer

The invention provides a contact arm of a voltage transformer handcart, which is characterized in that the contact arm comprises a contact arm base, an insulating contact arm body, a fuse and a contact arm head; wherein the fuse is arrange din the insulating contact arm body; and the contact arm base, the fuse and the contact arm head are successively conducted. According to the contact arm of the voltage transformer handcart according to the invention, the fuse is mounted in the insulating contact arm body, thereby saving a manufacture space, and enabling direct mounting in the voltage transformer cart without restriction by the product space. Simultaneously the contact arm of the voltage transformer handcart performs a function of protecting the voltage transformer.

Owner:SHANGHAI BAOLIN ELECTRIC GRP

Cutting device of cutting machine and control method as well as cutting machine

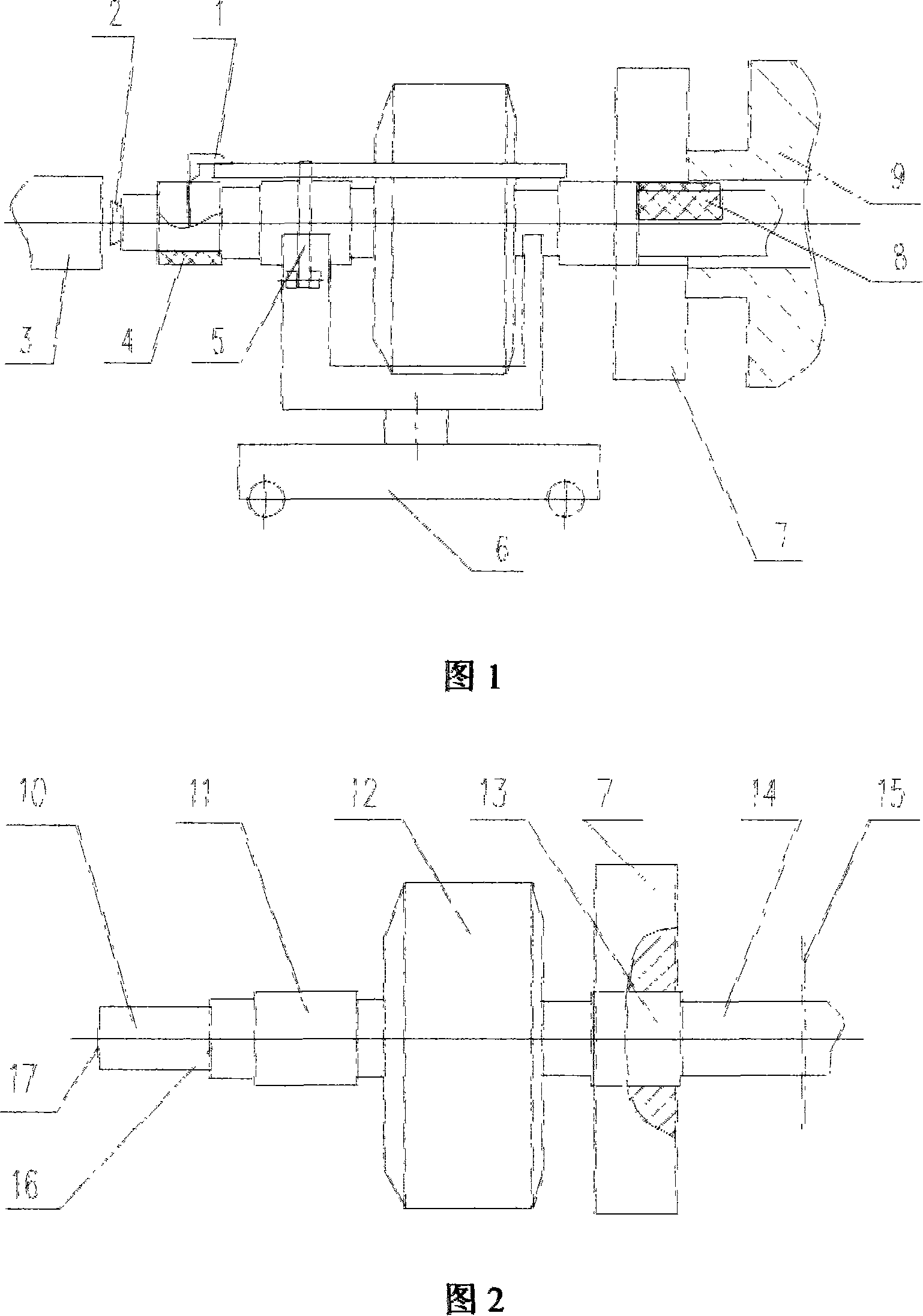

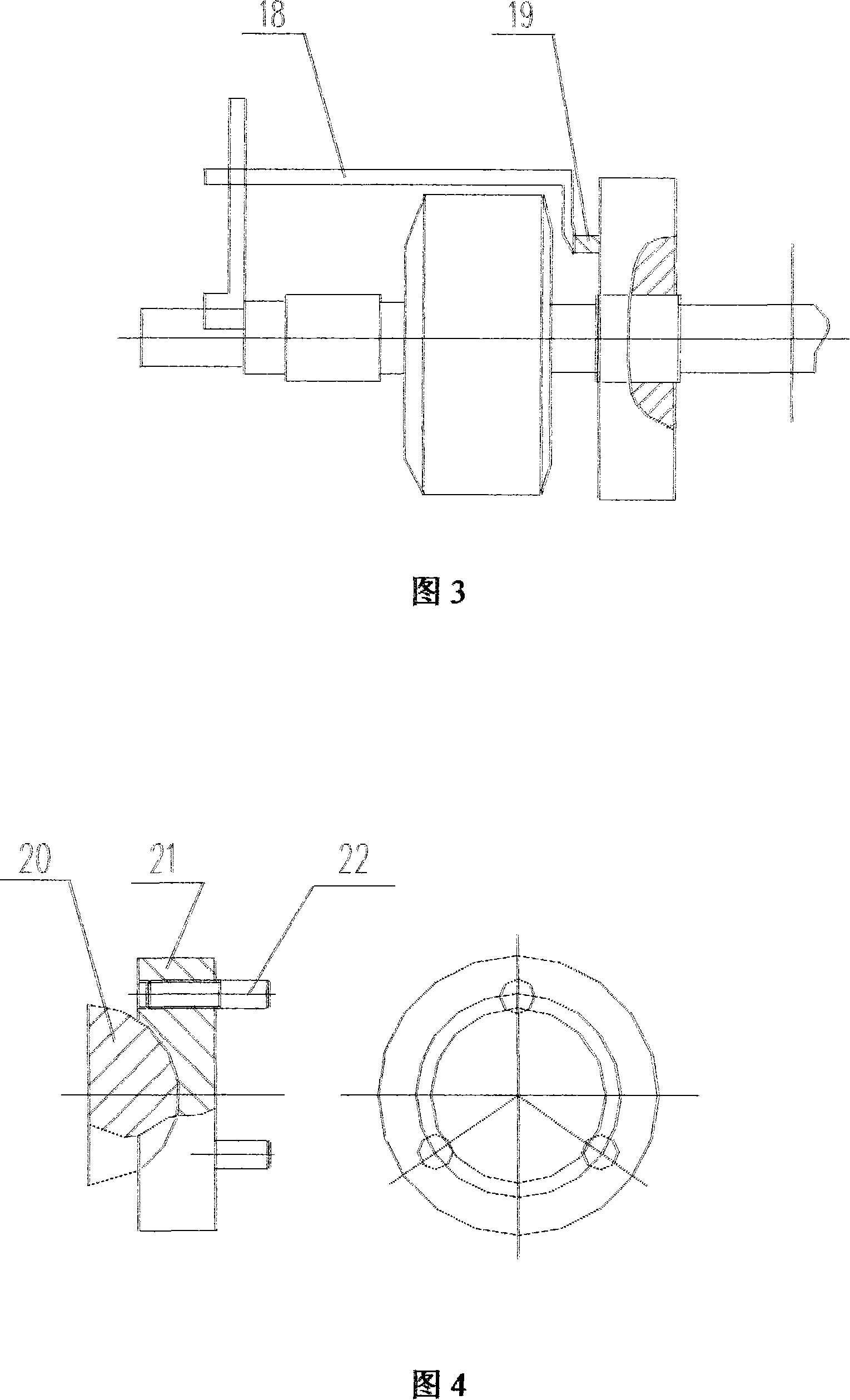

PendingCN108748352ASimple and fast operationGuaranteed not to be damagedMetal working apparatusMotor drivePropeller

The invention discloses a cutting device of a cutting machine. The cutting device comprises a rotating fixing frame, a rotating device is fixedly installed in the rotating fixing frame, the two ends of the rotating device are installed in the rotating fixing frame, and the rotating device is connected with a rotating motor, the rotating motor drives the rotating device to do rotating motion in therotating fixing frame, and the rotating device is provided with a cutter feeding device; the cutter feeding device comprises a driving motor, the driving motor is connected with a spiral propeller through a speed reducer, the spiral propeller is connected with one end of a cutting swing arm through a hinge, the spiral propeller and the cutting swing arm rotate oppositely, and a cutting blade is installed at the other end of the cutting swing arm; and a swing arm rotating shaft is arranged on the cutting swing arm, the swing arm rotating shaft serves as a supporting point, the spiral propellerdrives the cutting swing arm to control the cutter feeding and retracting actions of the cutting blade, and the two ends of the rotating fixing frame are respectively provided with tight clamping devices; and the invention further discloses a cutting control method and a cutting machine. According to the cutting device of the cutting machine and the control method as well as the cutting machine,the operation is simple and convenient, the use is wide, no cutting chips are generated, and it is guaranteed that the production site is tidy and ordered.

Owner:LAIWU ZHENGQI PLASTIC MACHINERY CO LTD

Spraying equipment for aeronautical parts

The invention relates to the technical field of space flight and aviation, and discloses spraying equipment for aeronautical parts. The spraying equipment comprises a spraying box, wherein the bottomof the side face of the spraying box is fixedly connected with the top of a base through supporting rods, a movable cover is fixedly mounted at one side of the top of the spraying box, one side of thetop of the movable cover is movably connected with the other side of the top of the spraying box through a fixing device, the side face of an inner cavity of the spraying box is fixedly connected with one side of a heating plate through connecting blocks, a power line is fixedly connected to the top of the heating plate, and the top of the inner cavity of the spraying box is fixedly connected with the side face of a conveying pipe through connecting rods. According to the spraying equipment for the aeronautical parts, through cooperation of a rotating rod, a motor, a clamping block, a fixture, an adjusting rod and a movable rod, the parts can be driven by the rotating rod to rotate in the spraying process, so that the surfaces of the parts are subjected to uniform spraying, the working intensity of operators is lowered, the spraying speed is increased, and the working efficiency of part spraying is improved.

Owner:杭州彩兔贸易有限公司

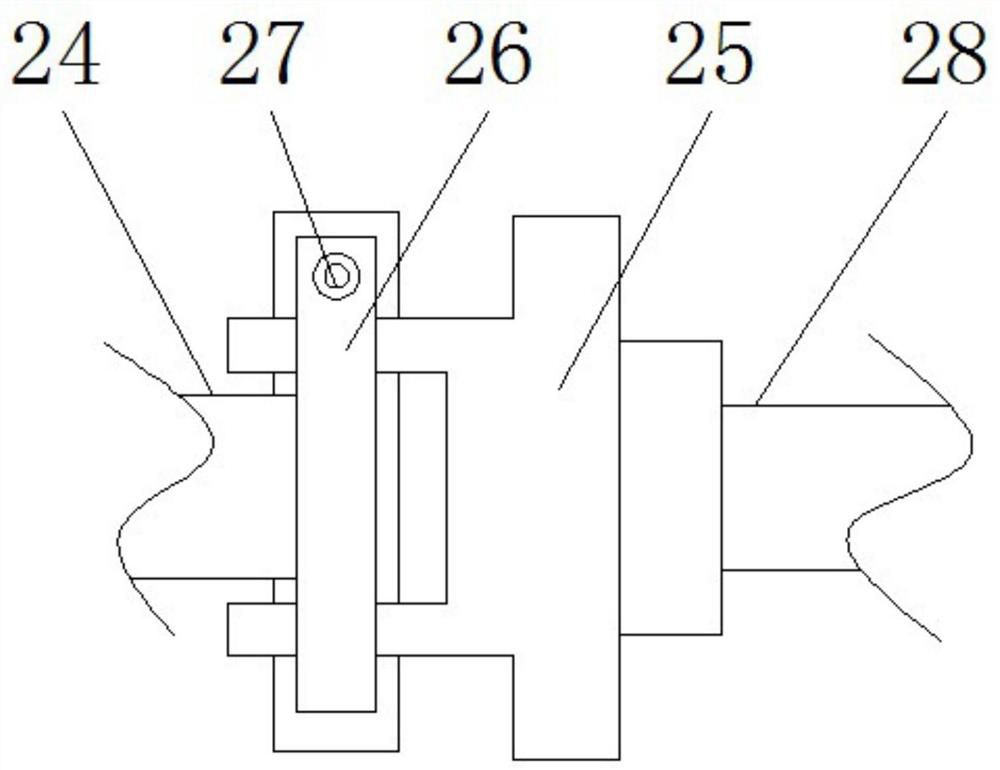

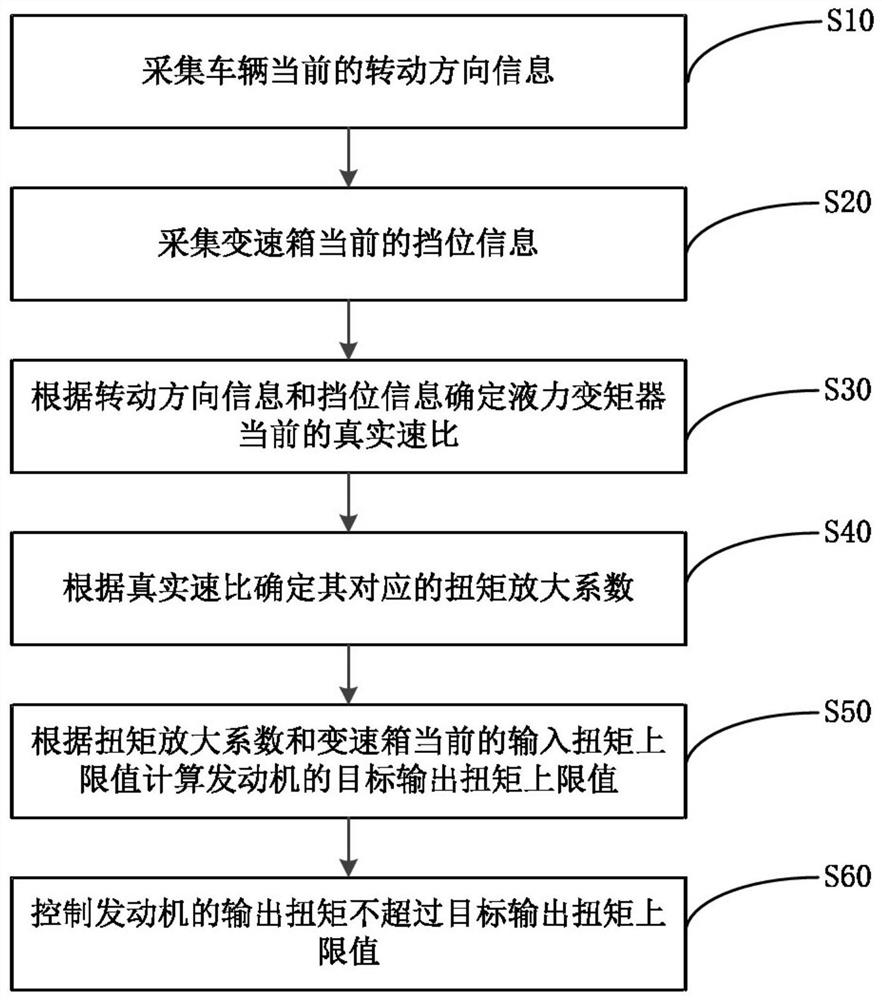

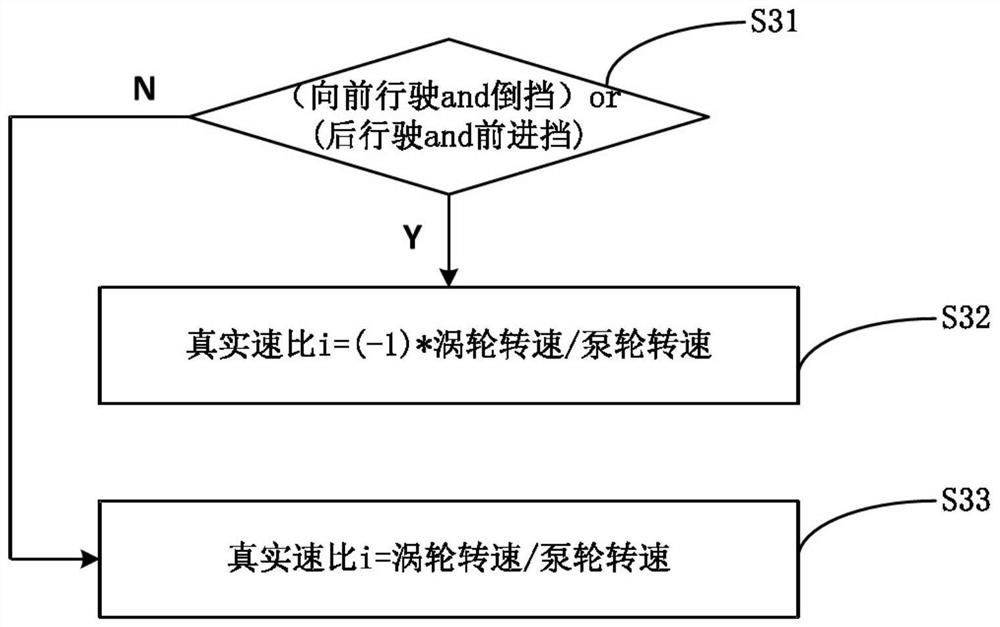

Gearbox control method and system, and vehicle

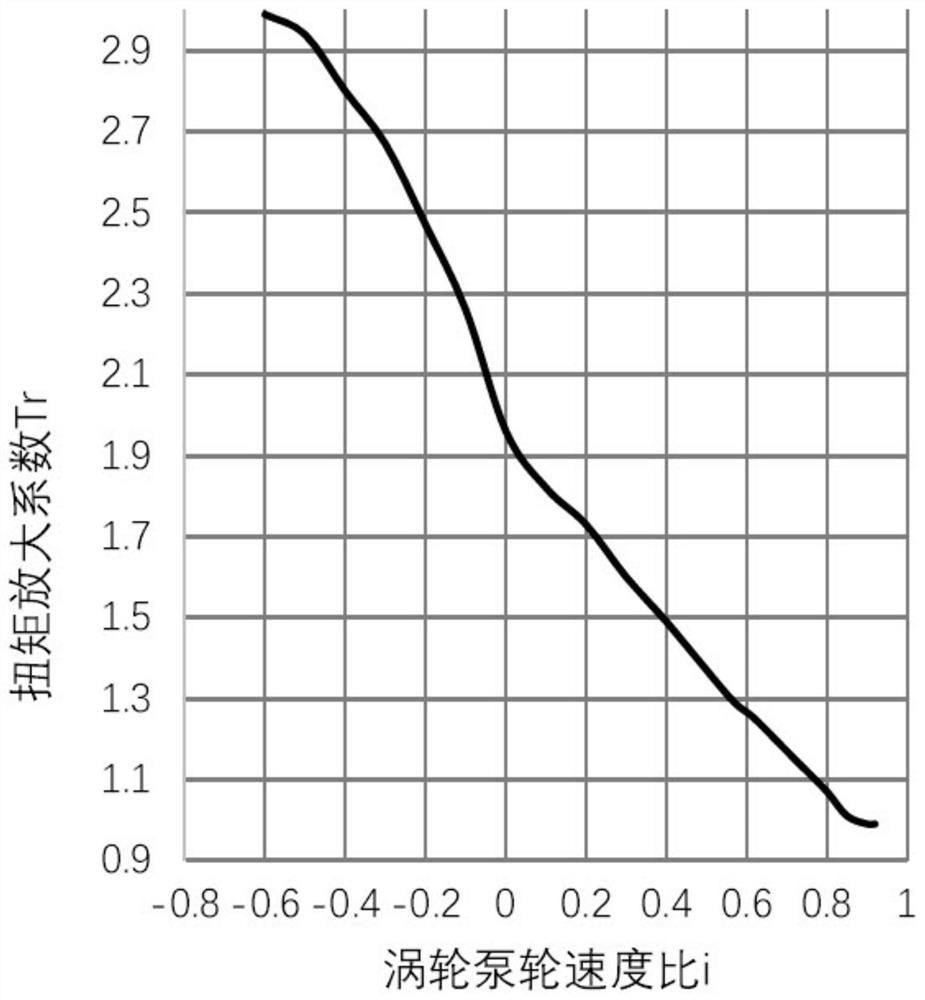

ActiveCN112901763AGuaranteed not to be damagedEnsure hardware durabilityGearing controlFluid gearingsAutomotive engineeringTorque converter

The invention provides a gearbox control method and system, and a vehicle, and belongs to the field of vehicles. The control method comprises the steps of collecting the current rotation direction information of the vehicle and the current gear information of a gearbox, wherein the rotation direction information comprises one or more of rotation direction information of wheels, rotation direction information of a pump wheel and rotation direction information of a turbine; determining the current actual speed ratio of a hydraulic torque converter according to the rotation direction information and the gear information, wherein the actual speed ratio comprises a positive speed ratio and a negative speed ratio; determining a torque amplification coefficient corresponding to the actual speed ratio according to the actual speed ratio; calculating a target output torque upper limit value of an engine according to a torque amplification coefficient and a current input torque upper limit value of the gearbox; and controlling the output torque of the engine not to exceed the upper limit value of the target output torque. According to the control method, the control system and the vehicle, the hardware durability of the gearbox under all working conditions can be ensured.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Power car wheel pair gear box side disk-braking press mounting technology

InactiveCN101125401AGuaranteed pressing efficiencyGuaranteed not to be damagedMetal working apparatusMachine pressPass rate

The present invention provides a press mounting art of moving wheel to side brake disk of gear case; the semi-transition nylon is coated on the shaft body of the gear case which is preinstalled with a brake disk and then arranged and fastened on the rotary bracket, and the shaft center is adjusted to the same level with the center of the press machine; the position nylon with reticle is arranged and fastened on the shaft diameter; a transition device is arranged at the shaft end and then positioned at the shaft end with a position pin, one end of the line set rule is closed to the face of brake disk, while the other end is placed on the position nylon with reticle; when in the press mounting, the press machine supplies press to the ball press steel which then transmits the press to the transition press steel, the press finally reaches the shaft end; when the end face of line set rule is rightly engaged with the reticle on the position nylon, the press mounting procedure is completed. Under the condition of equal cost, the present invention applies the prior common wheel to fulfill the press mounting of the press machine, thereby assuring the efficiency of press mounting and the pass rate is 100 percent after press mounting.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

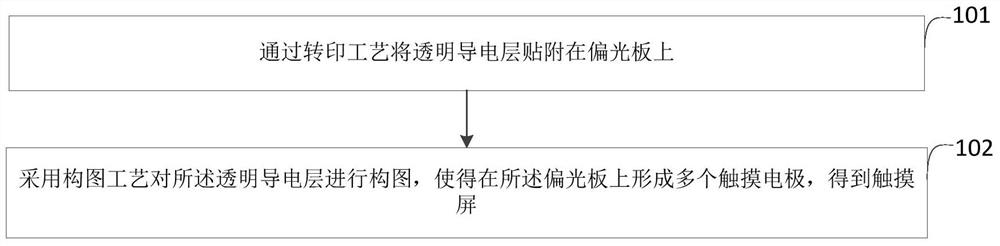

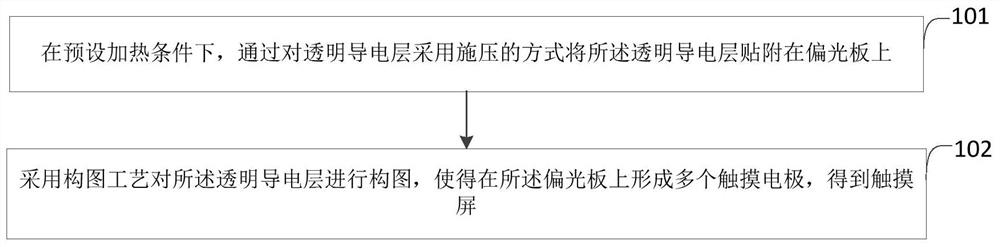

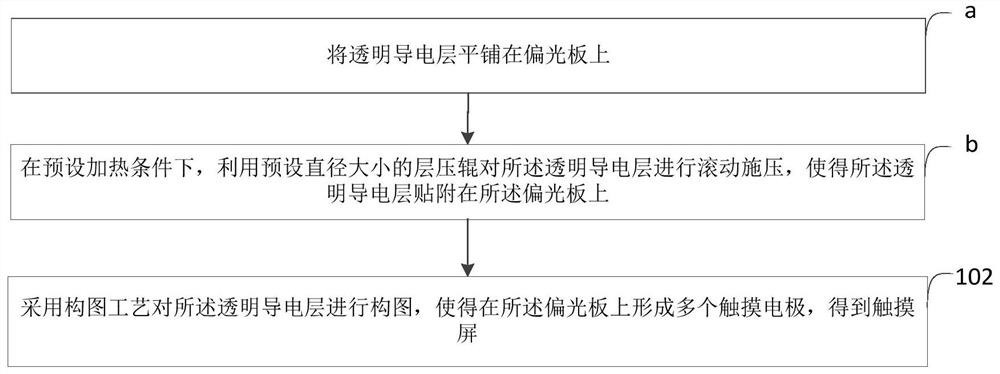

Manufacturing method of touch screen, touch screen and display substrate

ActiveCN105843453BGuaranteed not to be damagedGuaranteed damageNon-linear opticsInput/output processes for data processingEngineeringPolarizer

The invention provides a method for manufacturing a touch screen, a touch screen and a display substrate. The method for manufacturing a touch screen includes: attaching a transparent conductive layer on a polarizing plate through a transfer printing process; patterning the transparent conductive layer by using a patterning process, A plurality of touch electrodes are formed on the polarizer to obtain a touch screen. The manufacturing method of the touch screen provided by the present invention adopts the transfer printing process, so it can achieve a better adhesion effect between the touch electrodes and the polarizing plate under the premise of ensuring that the polarizing plate is not damaged.

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

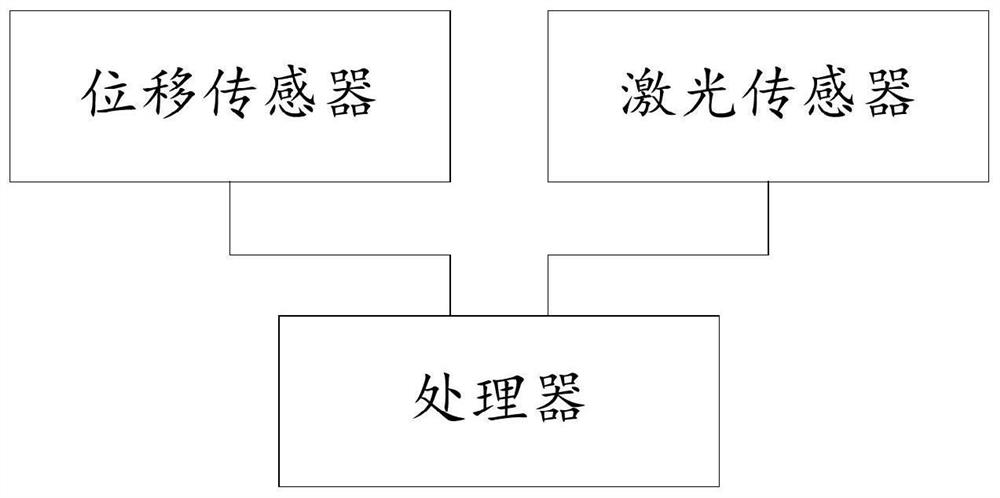

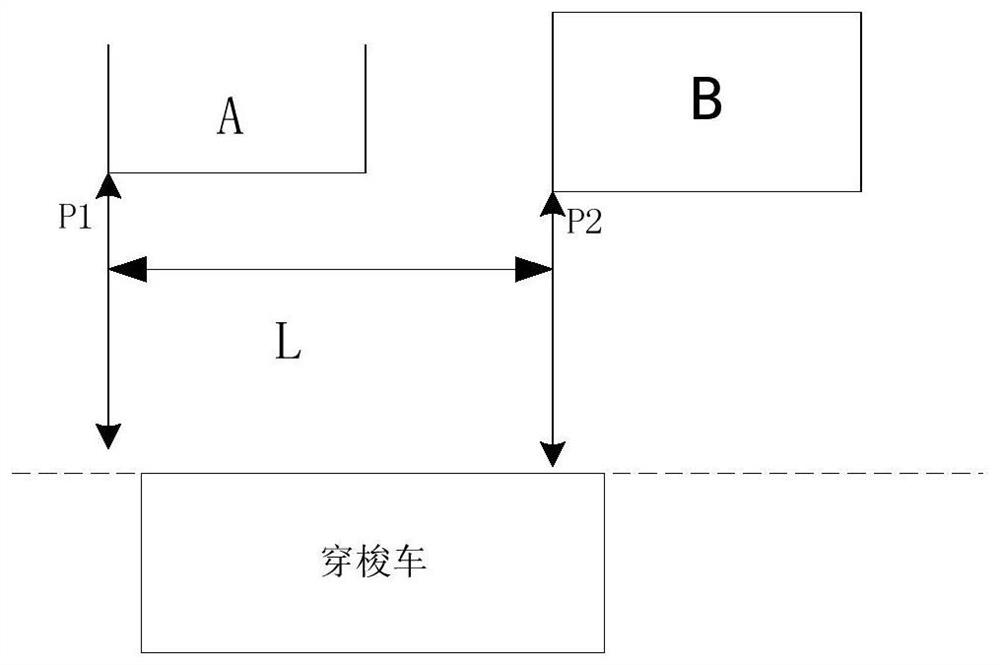

A box storage device

ActiveCN110834897BAvoid damageImprove accuracyControl devices for conveyorsMechanical conveyorsAlarm messageLaser sensor

Owner:BLUESWORD INTELLIGENT TECH CO LTD

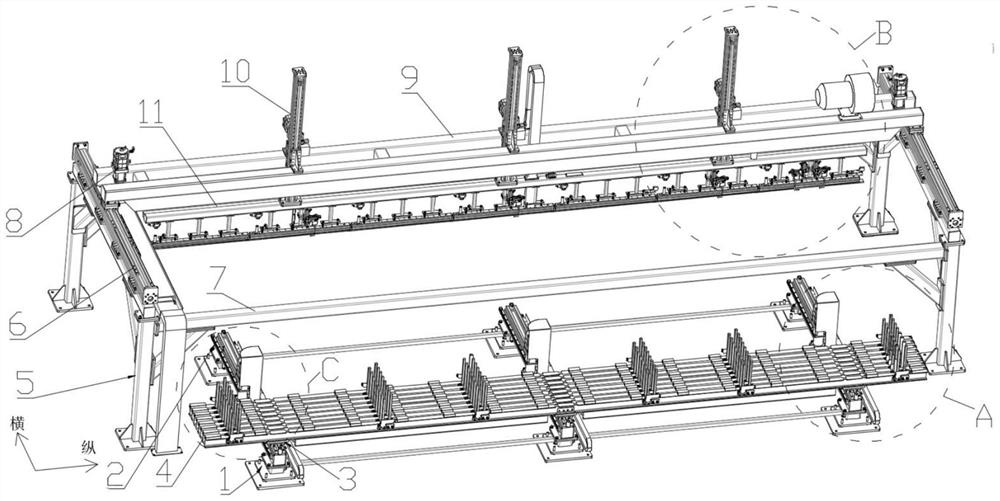

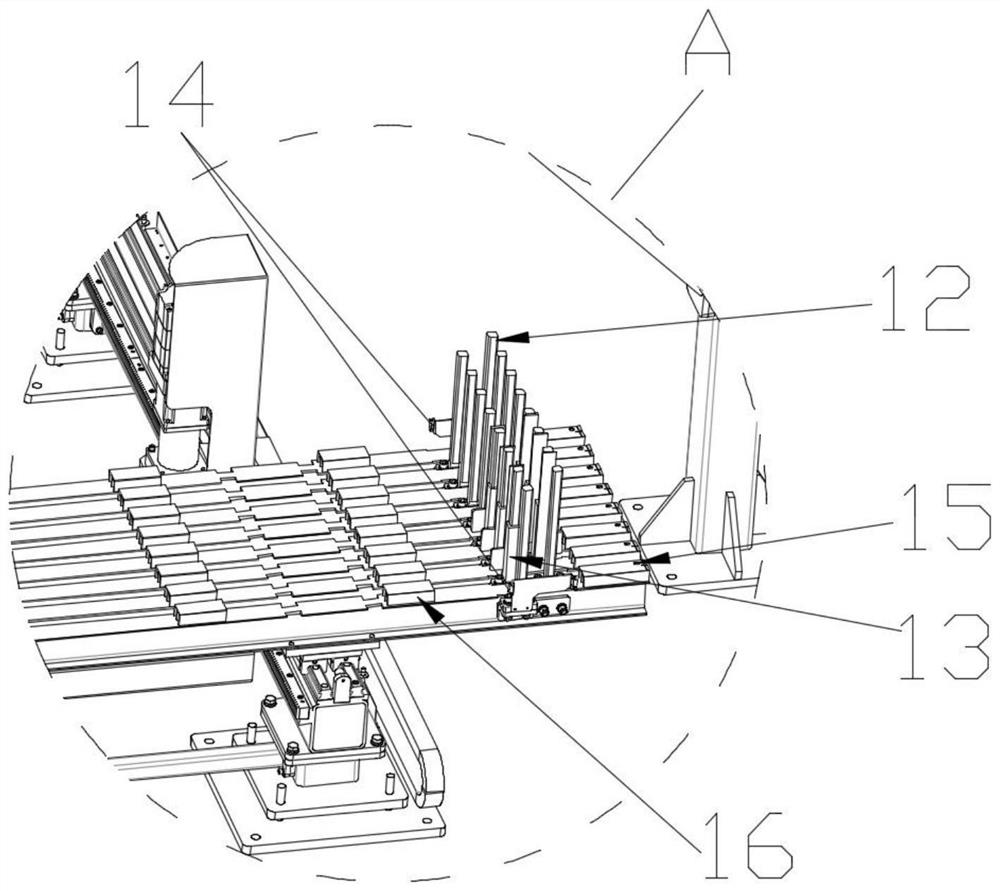

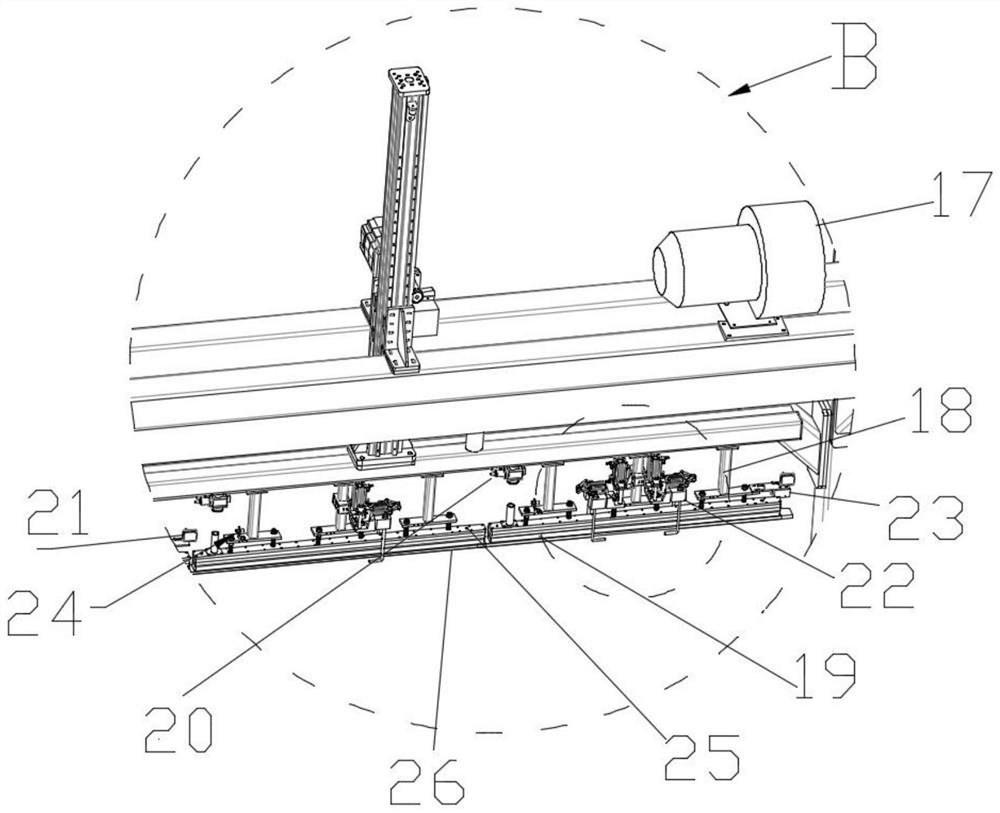

Feeding and discharging system and method for intelligent machining of copper bars

PendingCN114516519AGuaranteed not to be damagedNo dropControl devices for conveyorsProcess efficiency improvementControl engineeringStructural engineering

The invention discloses a feeding and discharging system for intelligent machining of a copper bar. The feeding and discharging system comprises a copper bar skip car, a truss manipulator body, a vacuum suction cup system and a control device. The copper bar skip car comprises a bottom supporting leg, an x-axis transverse guide rail, a skip car supporting plate and a cross beam stock bin, the bottom supporting leg stably supports the trolley, the x-axis transverse guide rail is erected on the bottom supporting leg, and the skip car supporting plate is erected on the x-axis transverse guide rail and can slide on the x-axis transverse guide rail under the driving of external force; the vacuum suction cup system comprises a fan, a vertical connecting rod, a suction cup, a valve set and a gripper assembly used for preventing a copper bar from falling off. The fan is erected on the longitudinal moving beam and connected with the longitudinal air cylinder through an air pipe. The suction cup is connected with the longitudinal air cylinder through a vertical connecting rod. The control device is used for controlling the action of the copper bar skip car, the truss manipulator body and the action part of the vacuum chuck system; automatic feeding and discharging can be achieved, the copper bars are not damaged, fall or lost, the identity of the copper bars can be traced in the whole process, and safety is high.

Owner:无锡中车时代智能装备研究院有限公司

Equipment and method for protecting and cleaning surface of hollow titanium alloy wing rudder

ActiveCN113600365ASatisfy the clampingMeet needsSpraying apparatusLaser beam welding apparatusMetallurgyTitanium alloy

The invention relates to equipment and a method for protecting and cleaning a superplastic diffusion surface of a hollow titanium alloy wing rudder. In the equipment, the specific structures of a mounting base, a centering and clamping device, a working head clamping device and a mobile platform are designed; through flexible cooperation of the components, the efficiency of spraying a protective coating before forming of the superplastic diffusion surface of the hollow titanium alloy wing rudder and the efficiency of removing a pollution layer after forming of the superplastic diffusion surface of the hollow titanium alloy wing rudder are improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Mechanical parameter measuring device of underground compression type packer and using method thereof

ActiveCN102080514BGuaranteed not to be damagedCompact and reasonable structureMachine part testingSealing/packingRadial stressContact pressure

The invention relates to the technical field of a tool and method for mechanical parameter measuring of an underground packer rubber system for petroleum exploitation, in particular to a mechanical parameter measuring device of an underground compression type packer and a using method thereof. The mechanical parameter measuring device comprises a drivepipe, an upper head, a lower head, a packer, a radial stress sensor and an axial stress sensor; the packer with a seal element assembly is installed in the inner cavity of the drivepipe; and the exterior of the drivepipe is provided with the radial stress sensor, and the packer is provided with the axial stress sensor. The mechanical parameter measuring device provided by the invention has the advantages of reasonability and compactness, is convenient to use; and by utilizing the method provided by the invention, the parameters carried by each rubber, such as axial load, friction, compression deformation force and the contact pressure to the inner wall of the drivepipe can be measured effectively and accurately in real time in the operation of the packer, no damage to the signal output thread of each sensor can be ensured, the test cost is lowered greatly, and a reliable basis for improving the design of the packer can be provided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Bilateral sealing stop valve

ActiveCN102022557BRelieve pressureGuaranteed not to be damagedOperating means/releasing devices for valvesSlide valveSlider bearingDrive shaft

The invention relates to a bilateral sealing stop valve which comprises a valve body and valve elements. The stop valve adopts the technical essentials that a throttling orifice is arranged on the longitudinal central line of the valve body, and the valve elements are arranged on the transverse central line of the valve body; the valve elements are symmetrically arranged in valve element holes attwo sides of the throttling orifice; the valve element hole at the front end of a valve element sealing stop is internally provided with a sealing assembly; a positioning body and a nut are sleeved outside the valve elements at two ends of the valve element holes and fixed on the valve body through a fixing press cap; a hand wheel which is clamped by a flat key and fixed by a jam nut is sleeved outside the nut, and a valve element gear is arranged outside the nut between the hand wheel and the fixing press cap; the valve body is connected with a bearing block through a bolt, and the bearing block is internally provided with a slide bearing; a transmission shaft is fixed on the bearing block through the slide bearing; and two ends of the transmission shaft are provided with a transmission shaft gear engaged with the valve element gear. The invention has the advantages of flexible and compact structure, exact and accurate sealing, good sealing quality and low manufacturing cost and is an important improvement for the safety performance of a float type liquid level metering system of a pressure container.

Owner:CHAOYANG JIAHUA ELECTRONICS

Method for processing and manufacturing light brick by utilizing household garbage

InactiveCN103113087BReduce manufacturing costExcellent lightweight thermal insulation functionCeramic materials productionCeramicwareBrickSlag

The invention relates to the technical field of light brick processing and in particular relates to a method for processing and manufacturing a light brick by utilizing household garbage. Low-grade diatomite is doped with high-calcium coal gangue, household garbage and other wastes, and ultramicropore light-weight high-strength sintered insulating brick is produced. Compared with the processing of common clay sintered brick and aerated concrete insulating brick, the requirements of compressive strength are met, the production cost is reduced, and the light brick has excellent light insulating performance. All raw materials come from household and industrial wastes, the treatment problems of household garbage and industrial slag removal are solved, the environmental pollution problem caused by solid wastes is solved, the cultivated land resources are protected, the solid wastes are recycled, and the building energy conservation requirements are met.

Owner:杨登云

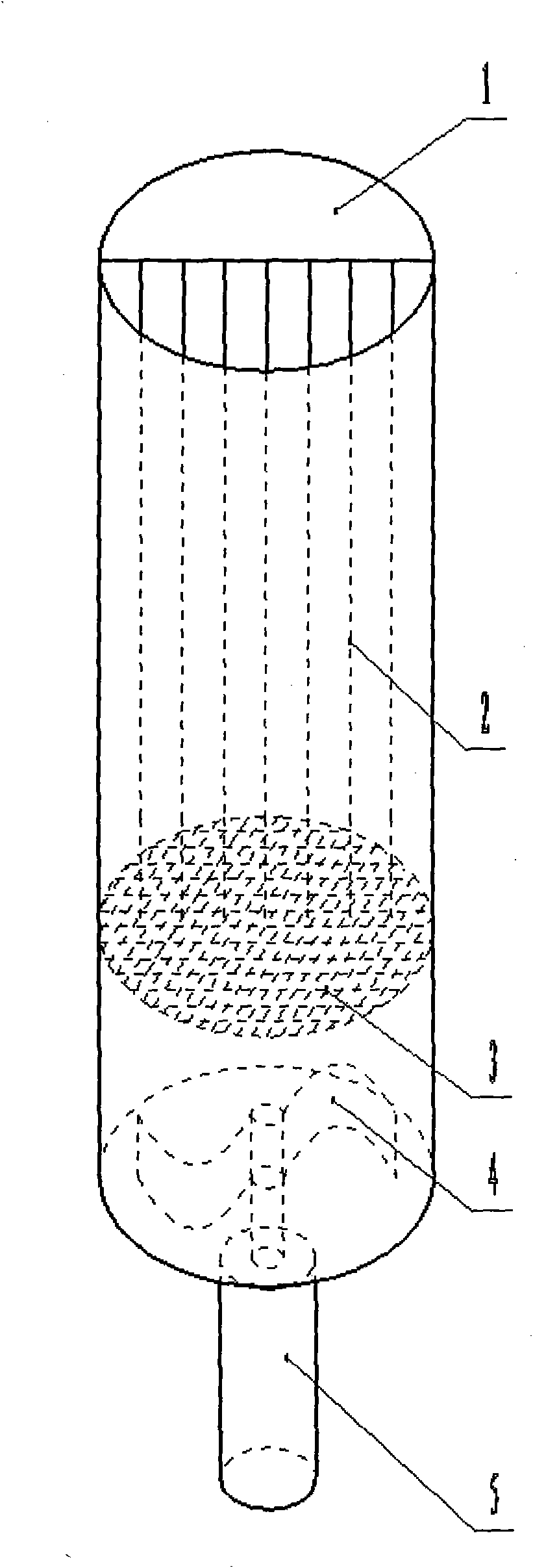

Separate-pumping separate-injection separate-heating vacuum treatment system of capacitor

InactiveCN108538649ASafe and reliable performanceEasy to operateCapacitor manufactureNitrogenTherapeutic effect

The invention provides a separate-pumping separate-injection separate-heating vacuum treatment system of a capacitor. The separate-pumping separate-injection separate-heating vacuum treatment system of a capacitor includes a vacuum cylinder, an air compressor, an intelligent display screen and a nitrogen supply apparatus, wherein the vacuum cylinder is connected with the air compressor through a pipeline with a pump out valve; at least one heat conduction pipe with an oil valve is arranged in the vacuum cylinder; an oil drum is also provided to communicate with the heat conduction pipe; temperature sensors are arranged on the heat conduction pipe; and a vacuum sensor is arranged on the inner wall of the vacuum cylinder. The separate-pumping separate-injection separate-heating vacuum treatment system of a capacitor relates to various fields, such as electromechanical integration, industrial automation, and the electronic and electric technology, provides a vacuum heat treatment system with higher safety, higher reliability, simpler operation and better treatment effect, improves the processing amount without damaging the product, can automatically charge inert gas, and can realize ideal effect of separate heating, pumping-out and uniform heating.

Owner:宁波高新区天都科技有限公司

Intelligent trash removing protection device for submersible pump

PendingCN112483475AEnsure smooth flow of waterGuaranteed not to be damagedPump componentsPump installationsStructural engineeringSludge

The invention provides an intelligent trash removing protection device for a submersible pump. A rotatable threaded conveying shaft is tightly attached and fixed along the outer wall of a cylindricalstructure body, and a trash removing brush capable of moving along the outer wall is arranged. The structures of the outer wall of the cylindrical structure body, the threaded conveying shaft and thetrash removing brush in the axial direction of the cylindrical structure body are consistent. Sludge at a water inlet of the submersible pump can be effectively cleaned away, smooth water inflow of the submersible pump is guaranteed, and therefore it is guaranteed that a water pump impeller is not damaged; the working principle is clear, the structure is simple, and maintenance and popularizationare easy; and automation and intelligence are facilitated.

Owner:CHINA CONSTR FOURTH ENG DIV INSTALLATION ENG

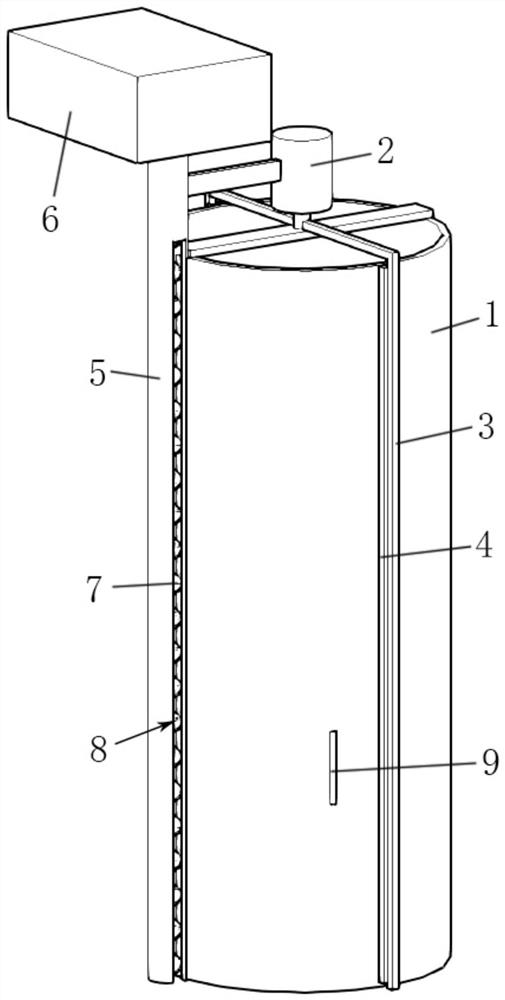

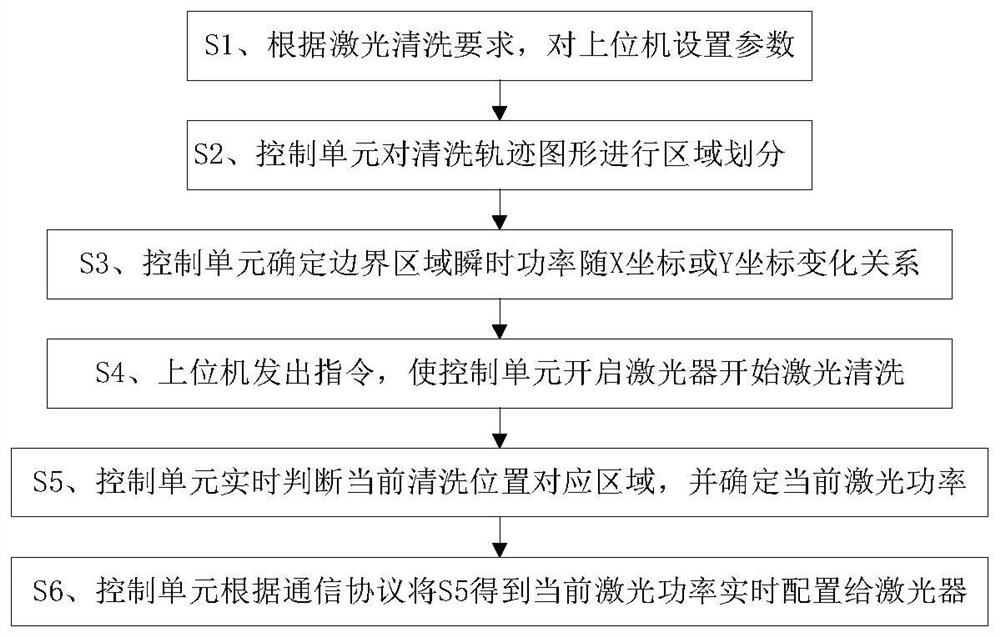

Laser cleaning method for deoxidation

ActiveCN112974411BGuaranteed not to be damagedImprove cleaning qualityProcess efficiency improvementCleaning processes and apparatusControl powerControl cell

A laser cleaning method for deoxidation, comprising the steps of: setting parameters for an upper computer according to laser cleaning requirements; a control unit dividing a cleaning track pattern into regions; The machine sends an instruction to make the control unit turn on the laser to start laser cleaning; the control unit judges the area corresponding to the current cleaning position in real time, and determines the current laser power; the control unit configures the obtained laser power to the laser according to the communication protocol. The invention can effectively realize deoxidation, improve the cleaning quality, avoid damage to the substrate, is easy to operate, can adapt to different cleaning environments, saves automation control costs, and improves cleaning efficiency. This method can be widely used in laser cleaning.

Owner:咸亨电气技术(杭州)有限公司

A flexible and stretchable sensor

ActiveCN109341727BGuaranteed not to be stretchedGuaranteed to workConverting sensor output electrically/magneticallySoftware engineeringElectrical performance

Owner:BEIJING MECHANICAL EQUIP INST

Method for isolating apoplast effector protein secreted by pathogenic bacteria from plant tissues infected with pathogenic bacteria

The present disclosure relates to a method for isolating apoplast juice from plant tissues infected with pathogenic bacteria, said apoplast juice containing effector proteins secreted by said pathogenic bacteria, the method comprising: a, placing plant tissues infected with pathogenic bacteria in Carry out infiltration treatment under vacuum in the buffer solution to obtain the plant tissue after the infiltration treatment; b. Centrifuge the plant tissue after the infiltration treatment for the first time to obtain the first centrifugate; take the first centrifugation solution for the second Sub-centrifugation to collect the second centrifugate; wherein, in the plant tissue infected with pathogenic bacteria, the pathogenic bacteria are Fusarium graminearum, Fusarium verticillium, Fusarium oxysporum, Verticillium dahliae, Anthracnose graminearum , Magnaporthe oryzae, Botrytis cinerea at least one. This method can maximize the separation of the effector proteins secreted by pathogenic bacteria and enter into the apoplast juice, which facilitates better analysis of the components and characteristics of the apoplast effector proteins secreted by pathogenic bacteria in susceptible plant tissues.

Owner:北京中农探味科技有限公司

Fruit container with control device

ActiveCN110431996APrevent fruit from fallingGuaranteed not to be damagedPicking devicesAgricultural engineeringGear tooth

Owner:长沙雾谷智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com