Distributed fiber strain coefficient calibration device and method

An optical fiber strain and calibration device technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of optical fiber strain coefficient calibration errors, small, unsuitable optical fibers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

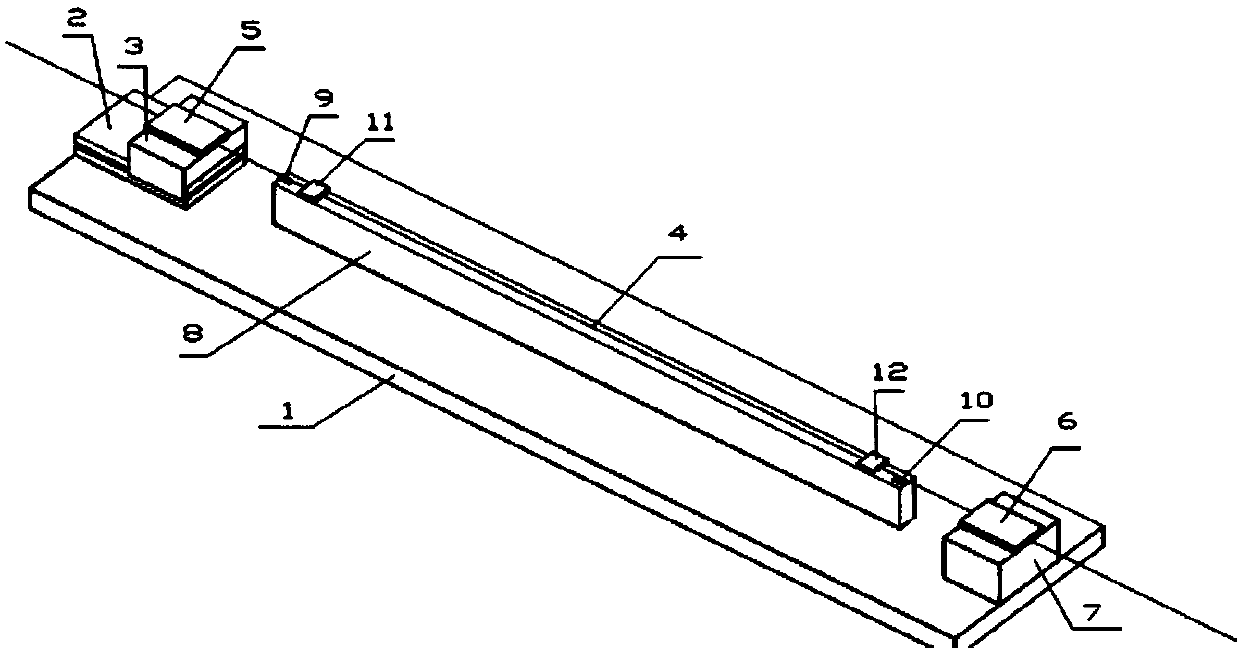

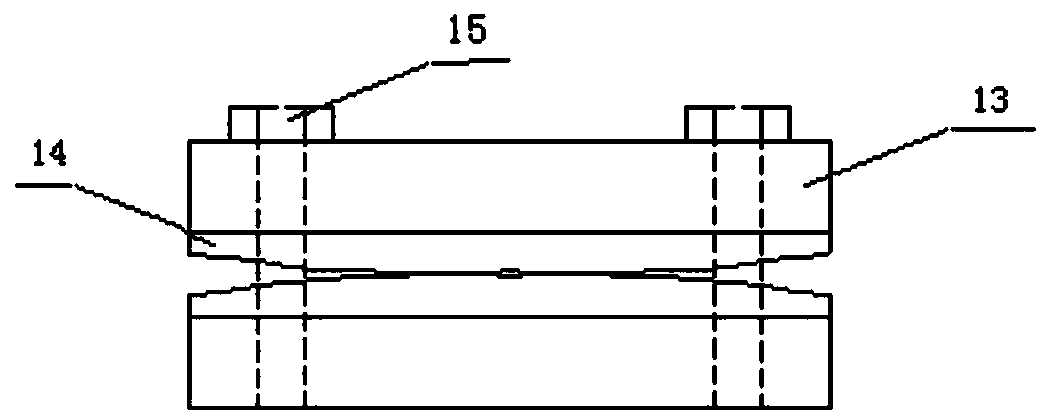

[0025] Please refer to figure 1 , the embodiment of the present invention provides a fully distributed optical fiber gauge coefficient calibration device, including a test bench 1, a hydraulic stretching mechanism and an optical fiber clamp, and the hydraulic stretching mechanism includes a lower sliding table 2 and an upper sliding block 3 , the slide table 2 is fixed on the experimental bench 1, the optical fiber clamp includes a first clamp 5 and a second clamp 6 oppositely arranged for clamping the optical fiber 4, and the first clamp includes the same two metal Block 13 and the same two rubber pads 14, the two metal blocks 13 clamp the two rubber pads 14 that fit together, after the optical fiber 4 passes between the two rubber pads 14, the two meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com