Intelligent trash removing protection device for submersible pump

A technology for protection devices and submersible pumps, applied to pump devices, parts of pumping devices for elastic fluids, pumps, etc., can solve the problem that the equipment cannot be used normally, no meaningful technical solutions are provided, and it is easy to get stuck in the sludge Conveying structure and other issues, to achieve the effect of easy maintenance and promotion, simple structure and clear working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] a. In the axial direction of the cylindrical structure, the length of the threaded delivery shaft 7 is greater than the length of the cylindrical structure.

[0034] b. In the axial direction of the cylindrical structure, the length of the cleaning brush 4 is smaller than the length of the cylindrical structure.

[0035] c. The cylindrical structure is a cylindrical structure;

[0036] d. The rotating rod 3 is driven by the driving motor 2, the rotating rod 3 is an L-shaped rod body, and the driving motor 2 is coaxial with the cylindrical structure.

Embodiment 1

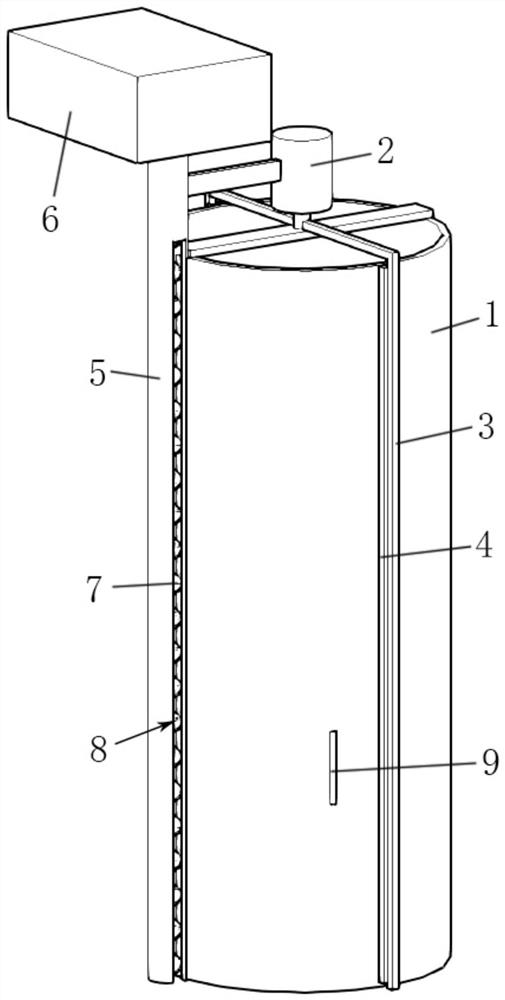

[0038] Using the above scheme, if figure 1 As shown, the protective net cover 1 is a cylindrical structure, and a drive motor 2 is arranged at the center of the top of the protective net cover 1. The output shaft of the drive motor 2 coincides with the central axis of the protective net cover 1, and the output shaft of the drive motor 2 is provided with The L-shaped rotating rod 3 and the L-shaped rotating rod 3 are attached on the outer surface of the protective net cover 1, and an electric cleaning brush 4 is arranged at the bottom of the L-shaped rotating rod 3, and the electric cleaning brush 4 is connected to the outer surface of the protective net cover 1. Surface-attached, a delivery pipe 5 is provided on one side of the protective net cover 1, a dirt collection box 6 is provided on the top of the delivery pipe 5, a threaded delivery shaft 7 is provided in the delivery pipe 5, and an opening 8 is provided at the lower part of the delivery pipe 5 The opening 8 can corres...

Embodiment 2

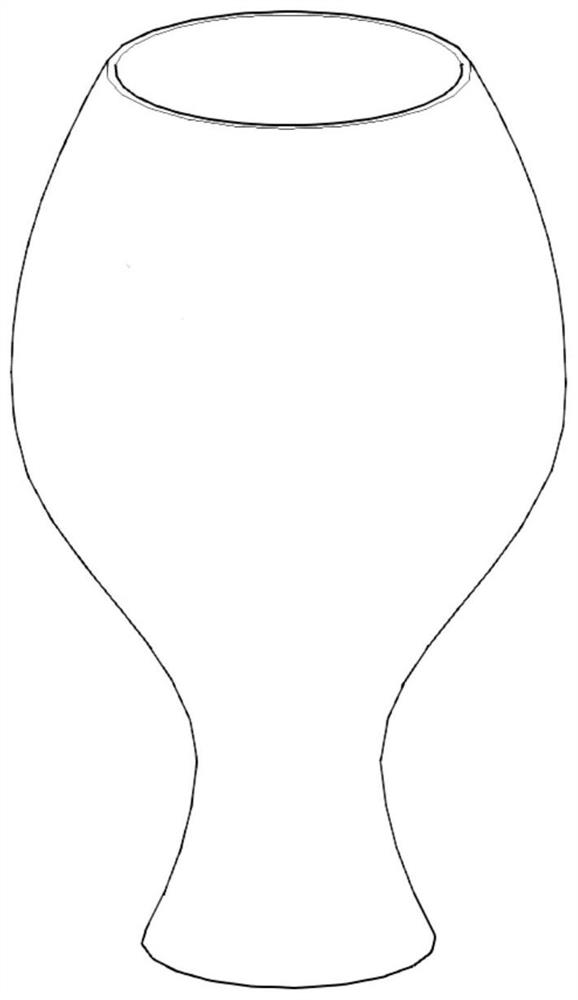

[0041] Such as figure 2 As shown, the protective net cover 1 is a cylindrical structure with unequal diameters, and other settings are the same as in Embodiment 1.

[0042] This embodiment is mainly suitable for submersible pumps that partially have raised structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com