Separate-pumping separate-injection separate-heating vacuum treatment system of capacitor

A technology of vacuum processing and capacitors, applied in the direction of capacitors, capacitor manufacturing, circuits, etc., can solve the problems of space limitation, complicated operation, inconvenient production and quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

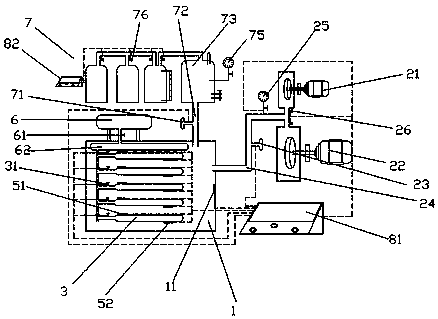

[0011] Now describe the present invention in detail in conjunction with accompanying drawing:

[0012] as attached figure 1 As shown, a capacitor single-pumping single-injection separate heating vacuum processing system includes a vacuum cylinder 1 and an air compressor 2, wherein the vacuum cylinder 1 and the air compressor 2 are connected through a pipeline 24 with an evacuation valve 23, and the pipeline 24 is provided with a first pressure gauge 25, wherein the air compressor 2 includes two parallel connected first air compressors 21 and second air compressors 22, and these two compressors are respectively connected to the pipeline 24 and respectively Correspondingly, a vacuum valve 26 is provided, and a vacuum sensor 11 is also provided on the inner wall of the vacuum cylinder 1 .

[0013] Five heat pipes 3 with oil valves 31 are arranged in the vacuum cylinder 1, and an oil drum 4 is connected with the heat pipes 3, each

[0014] Two temperature sensors are provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com