Mechanical parameter measuring device of underground compression type packer and using method thereof

A compression packer and testing device technology, which is applied in the testing of mechanical parts, measuring devices, and testing of machine/structural parts, etc., can solve the problem that it is difficult to quantitatively determine the function of the rubber cylinder system, and reduce the cost of testing and testing. , compact structure, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0021] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

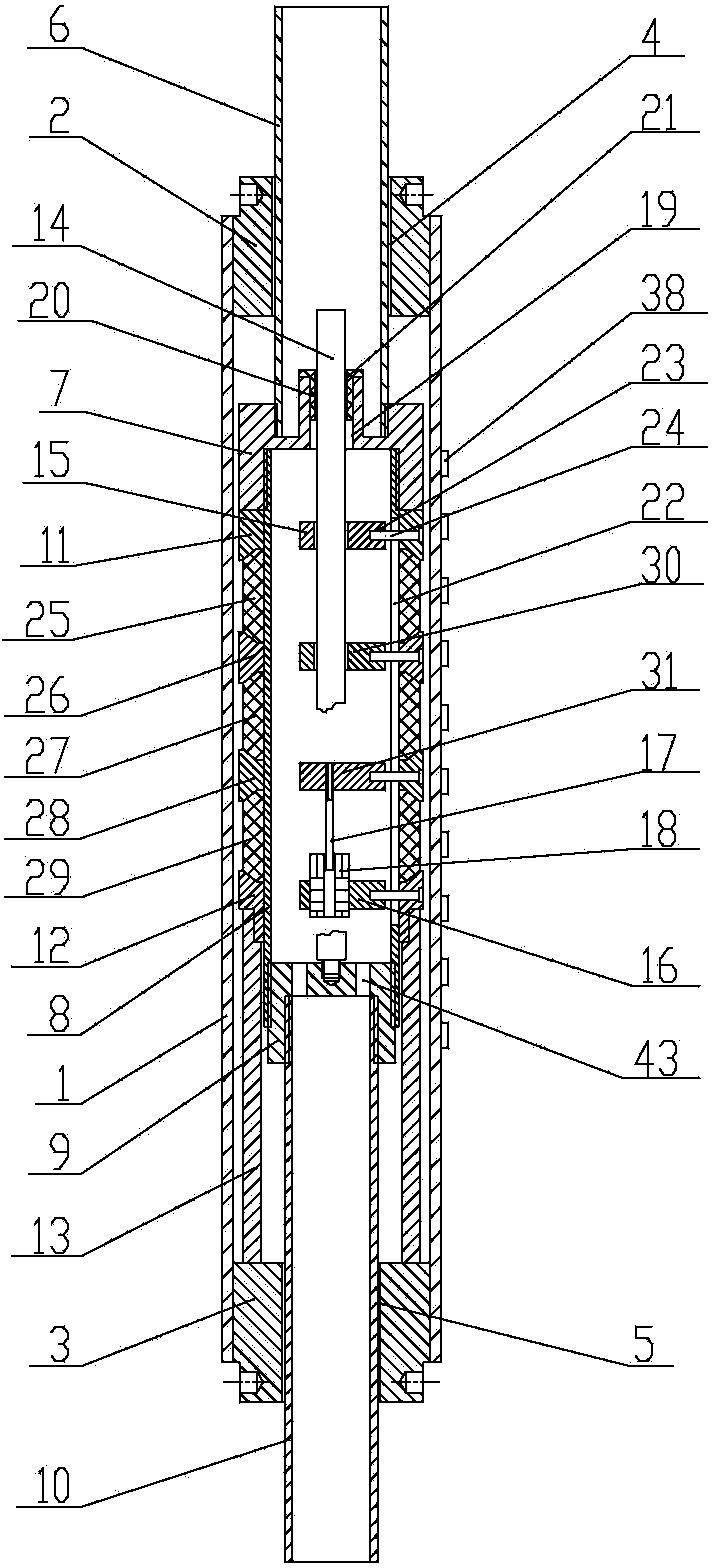

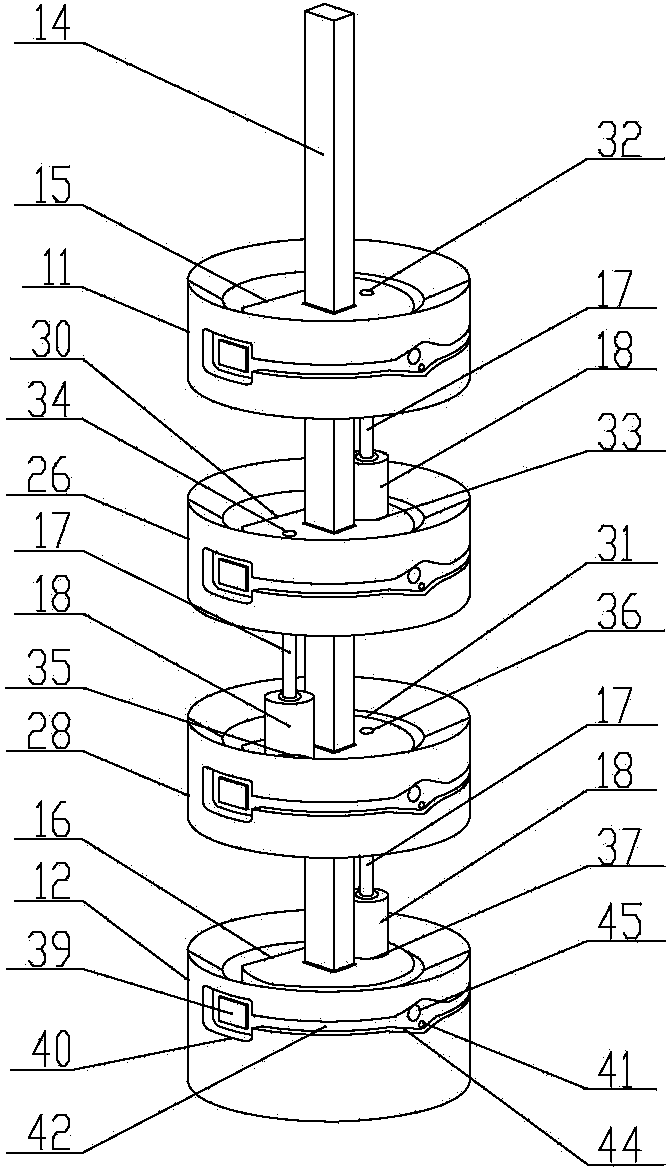

[0022] as attached figure 1 As shown, the packer downhole compression packer mechanical parameter testing device includes a casing 1, an upper head 2, a lower head 3, a packer, a radial stress sensor and an axial stress sensor; the casing 1 An upper head 2 is fixedly installed on the upper end, and a lower head 3 is fixedly installed on the lower end of the sleeve 1. The upper head 2 has an upper head hole 4 connected to the inner cavity of the sleeve 1, and the lower head 3 has a connected sleeve. 1 The lower head hole 5 of the inner cavity; the packer with the seal assembly is installed in the inner cavity of the casing 1, and the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com