Preparation method of flexible stretchable sensor

A sensor and stretchable technology, applied in the field of the preparation of flexible stretchable sensors, can solve the problems of unreasonable circuit design, inaccurate detection results, and easy damage of flexible stretchable sensors, so as to reduce the number of leads and Complexity, high sensitivity, downsizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

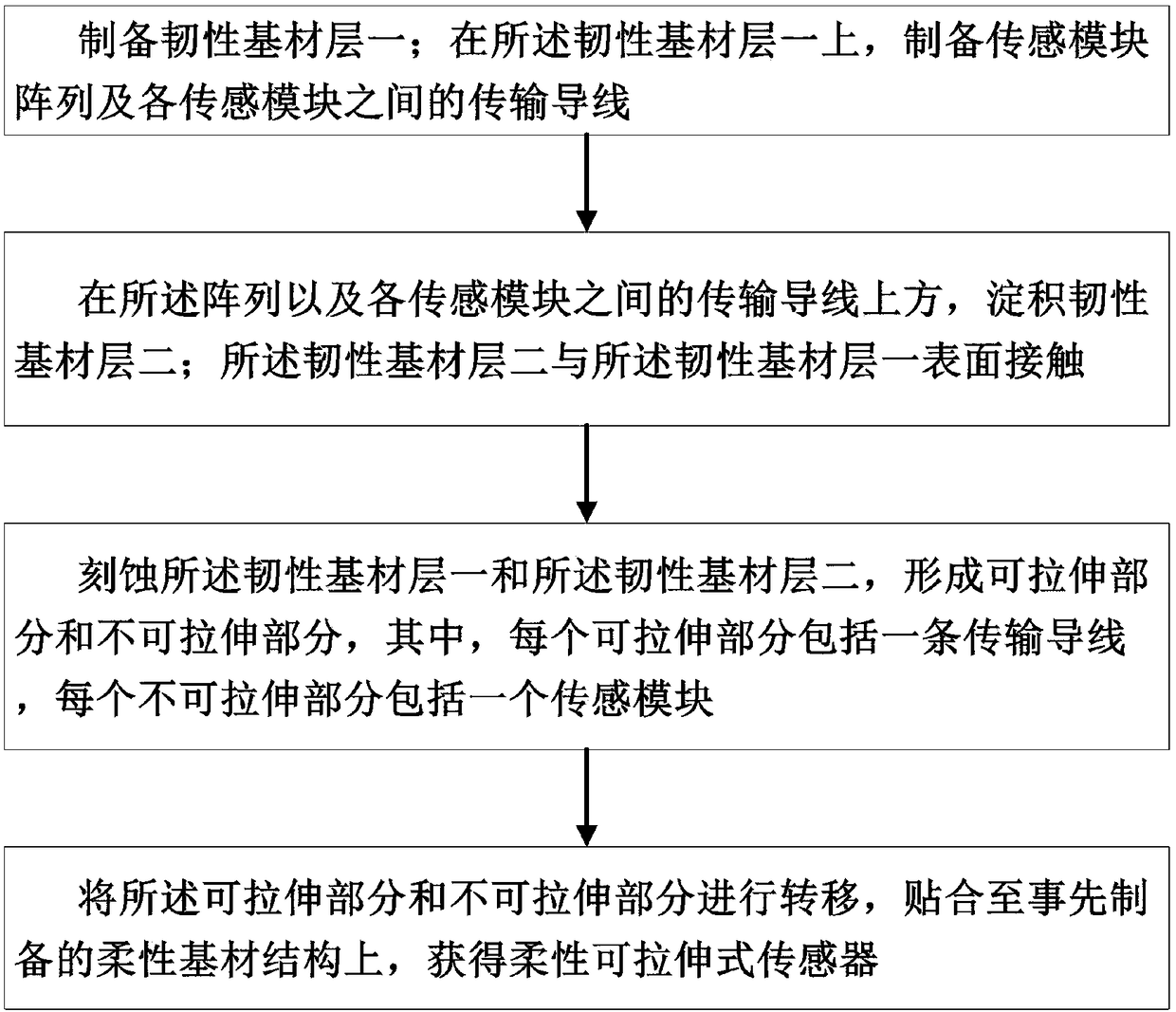

[0063] A specific embodiment of the present invention discloses a method for preparing a flexible and stretchable sensor, such as figure 1 shown, including the following steps:

[0064] S1. Prepare a first tough substrate layer, on which a sensing module array and transmission wires between the sensing modules are prepared. The transmission wire has a non-linear structure. The sensing module includes a sensor and its control circuit.

[0065] S2. Deposit a tough substrate layer two on the array and the transmission wires between the sensing modules; the tough substrate layer two is in contact with the tough substrate layer one surface and covers the entire sensing module The array and the transmission wires between the sensing modules.

[0066] S3. Etching the tough substrate layer 1 and the tough substrate layer 2 to form stretchable parts and non-stretchable parts, wherein each stretchable part includes a transmission wire, and each non-stretchable part Includes a sensin...

Embodiment 2

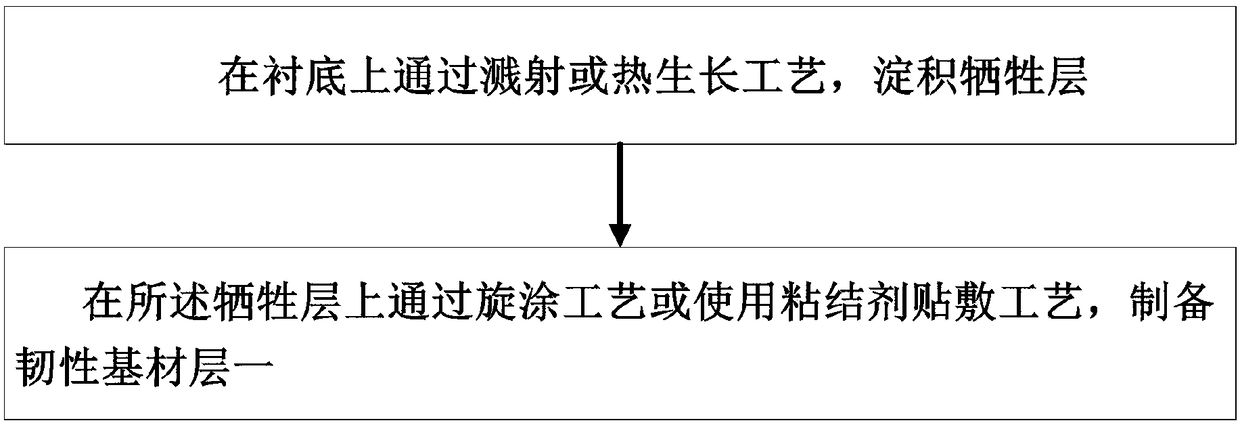

[0071] Optimizing on the basis of Example 1, such as figure 2 As shown, in step S1, the preparation of the tough substrate layer 1 can be further refined into the following steps:

[0072] S11. Deposit a sacrificial layer on the substrate by sputtering or thermal growth process. Optionally, the substrate may be a silicon wafer or a glass wafer, and the sacrificial layer may be at least one of materials such as silicon oxide, silicon nitride, and craft glue.

[0073] S12. Prepare a tough substrate layer 1 on the sacrificial layer by spin-coating or using an adhesive bonding process. Optionally, the tough base material layer—may use at least one of materials such as PI, PET, PEN, PEI, PEEK, and Paylene.

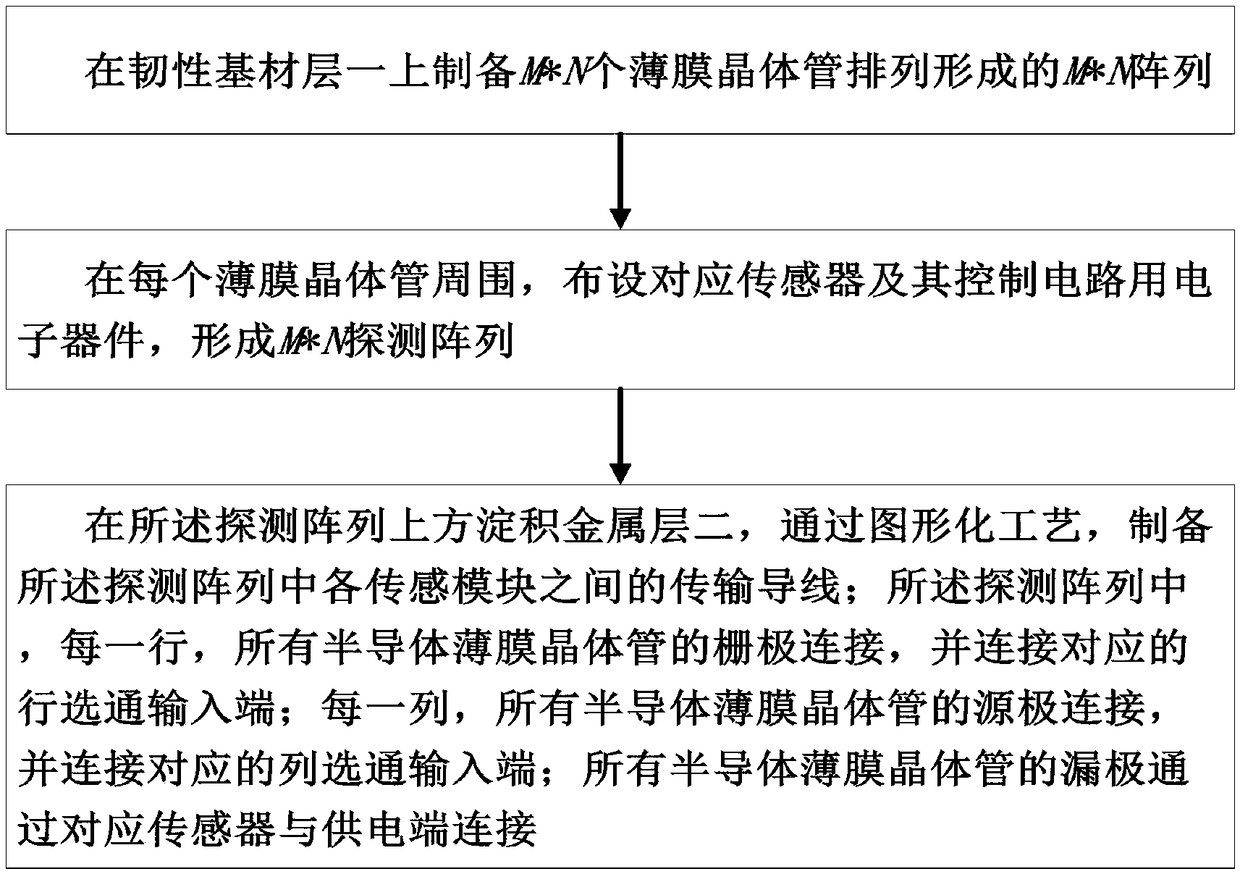

[0074] Preferably, as image 3 As shown, in step S1, the first preparation of the sensing module array and the transmission wires between the sensing modules on the tough substrate layer can be further refined into the following steps:

[0075] S13. Prepare an M×N array fo...

Embodiment 3

[0094] The flexible and stretchable sensor prepared by the preparation method described in Example 2 is as follows: Figure 5 As shown, it includes an M×N array formed by M×N detection units, such as Image 6 with Figure 7 shown. Wherein, each of the detection units includes a stretchable part and a non-stretchable part; the sensing module of each detection unit is arranged on the non-stretchable part, and the wires provided by the stretchable part and the sensing of the adjacent detection unit module connection.

[0095] The non-stretchable part is used to collect external sensing information through the sensing module after the detection unit is turned on, and convert the external sensing information into electrical signals for transmission to the processor for processing. Image 6 with Figure 7 The middle non-stretchable part shows circular structures, but is not limited to circular structures.

[0096] The stretchable part is used for stretching under the action of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com