Bilateral sealing stop valve

A shut-off valve and sealing plug technology, which is applied in the field of counter-sealed shut-off valves, can solve problems such as metering wire damage, gas leakage, safety performance, resource conservation, and environmental protection impacts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

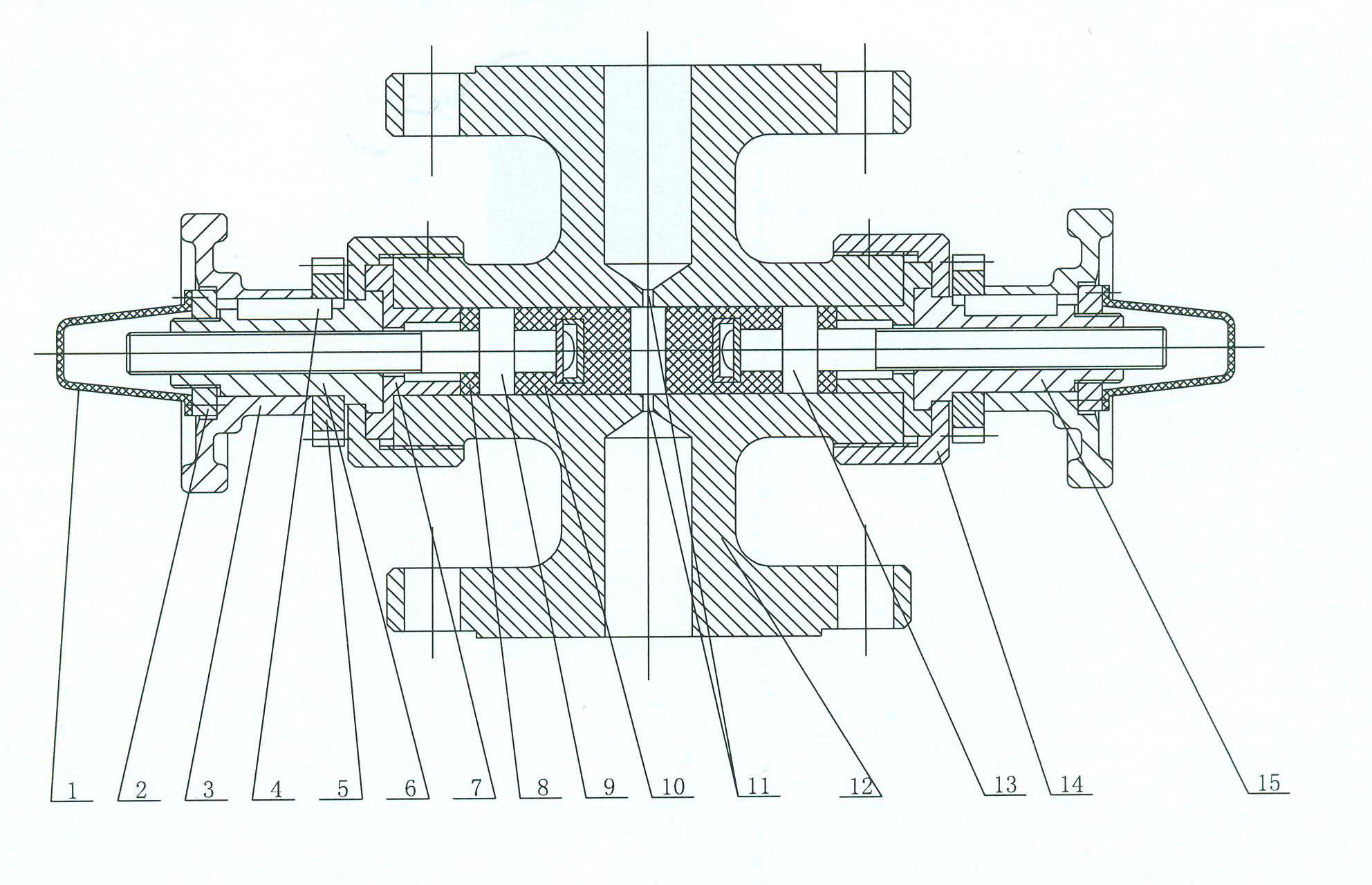

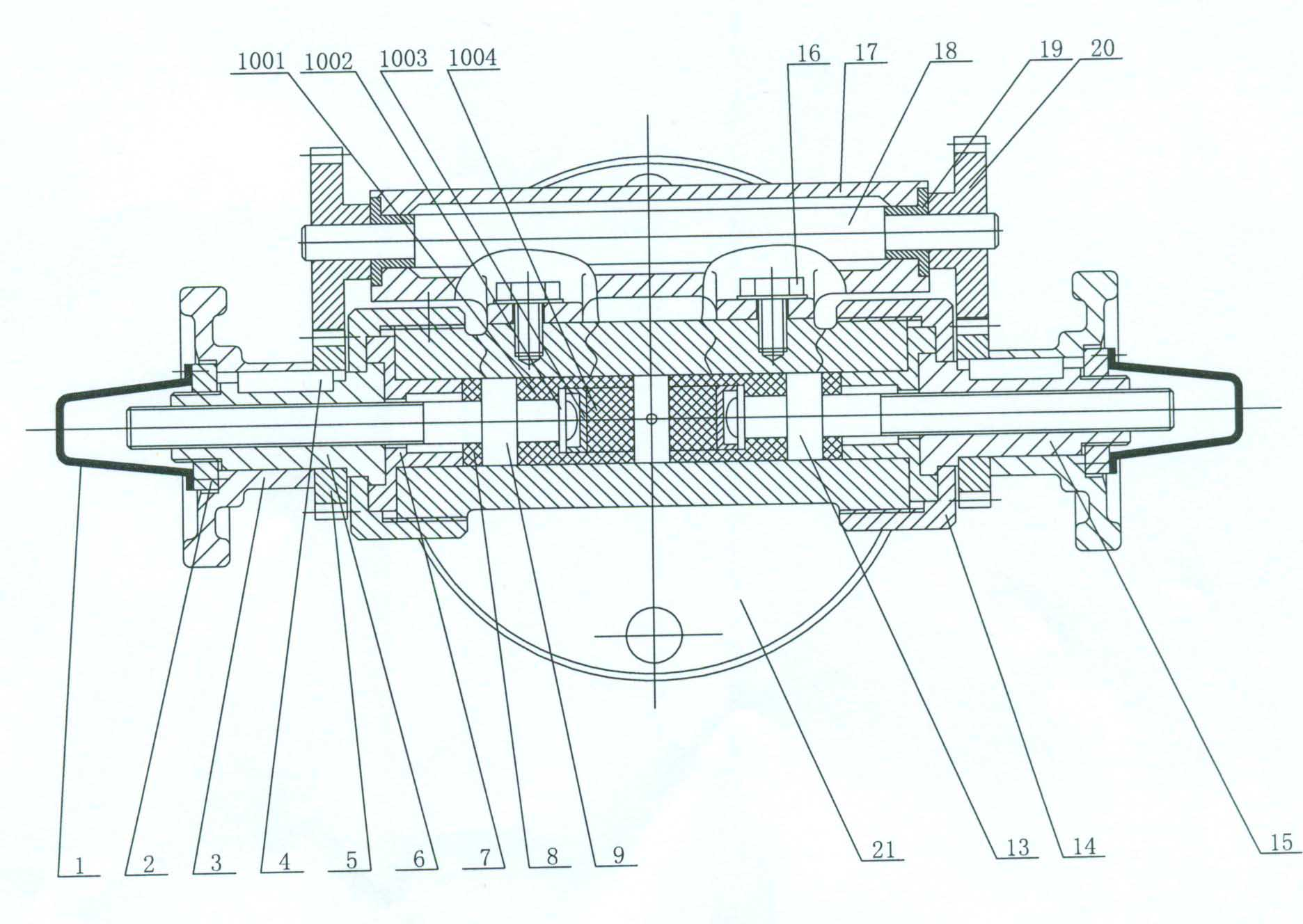

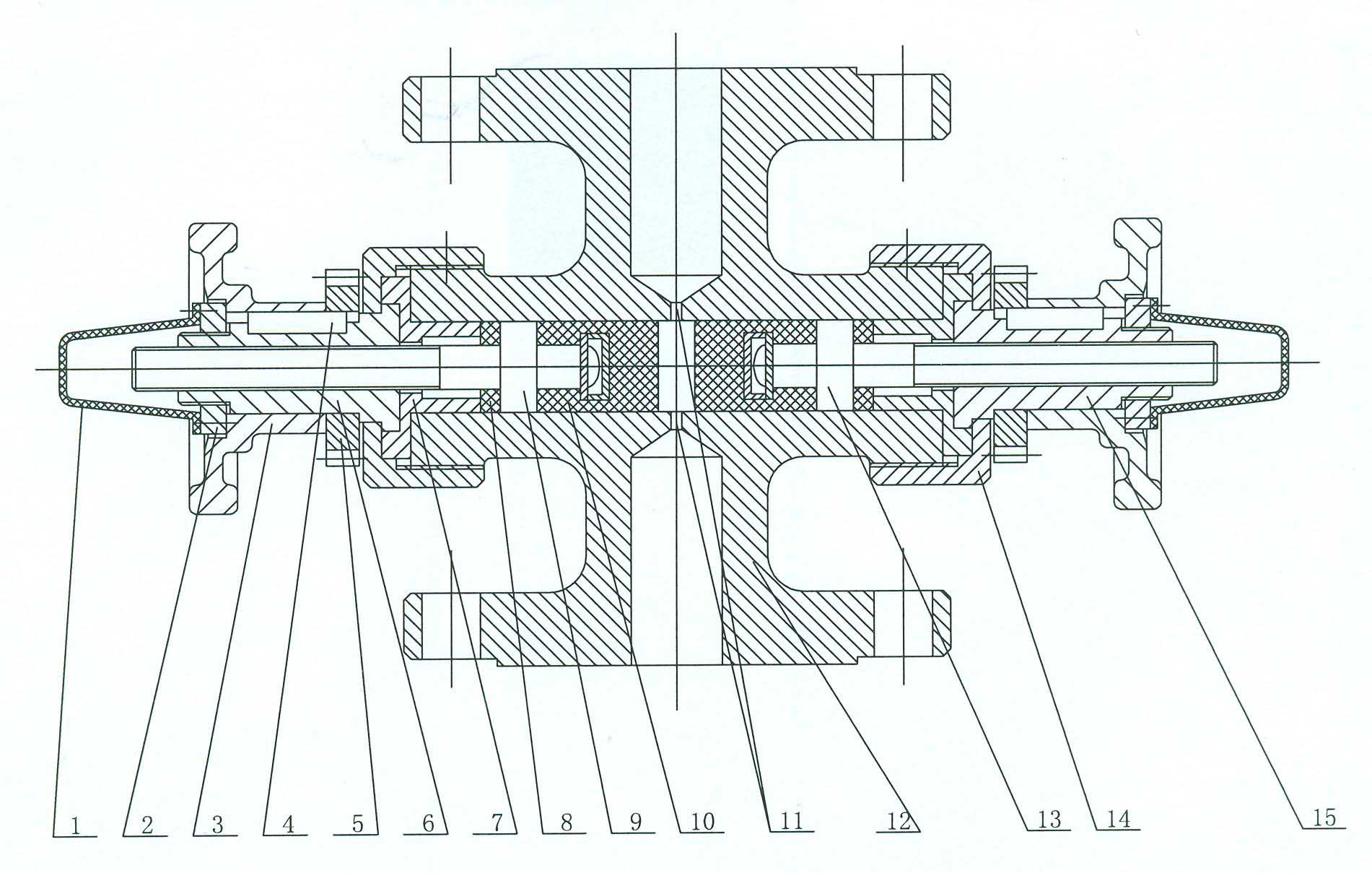

[0015] Such as Figure 1~2 As shown, the main structure of the present invention includes a valve body 12 with a connecting flange 21, an orifice 11 and a spool hole and a spool with external threads, and the orifice 11 is arranged on the longitudinal centerline of the valve body 12 The upper and lower spool holes are arranged on the transverse center line of the valve body 12, and the left spool 9 and the right spool 13 are arranged symmetrically in the spool holes on both sides of the orifice, and in the spool hole at the front end of the spool sealing plug. A front sealing assembly 10 is provided, and the front sealing assembly includes an elastic element I1001, an elastic element, a pressure pad 1002, a support member 1003 and an elastic element II1004. In order to ensure that the shut-off valve forms a secondary safety seal to the valve core when it is opened to the maximum position, a rear seal 8 is provided in the valve core hole at the rear end of the valve core sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com