Deburring device and deburring method for cast cylinder bodies

A cylinder block and deburring technology, which is applied to the deburring device and deburring processing field of the casting cylinder block, can solve the problems of stamping damage of the cooling fins of the cylinder block, and it is difficult to completely remove the flash and burr, so as to ensure that the damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

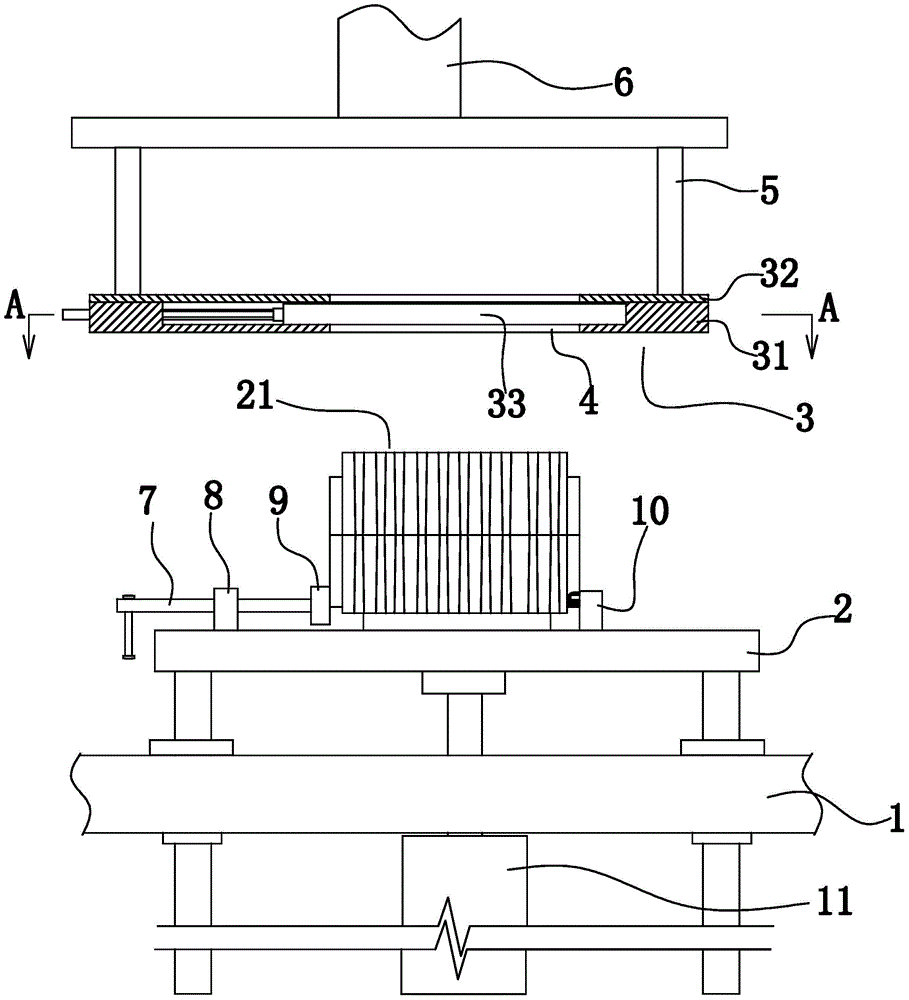

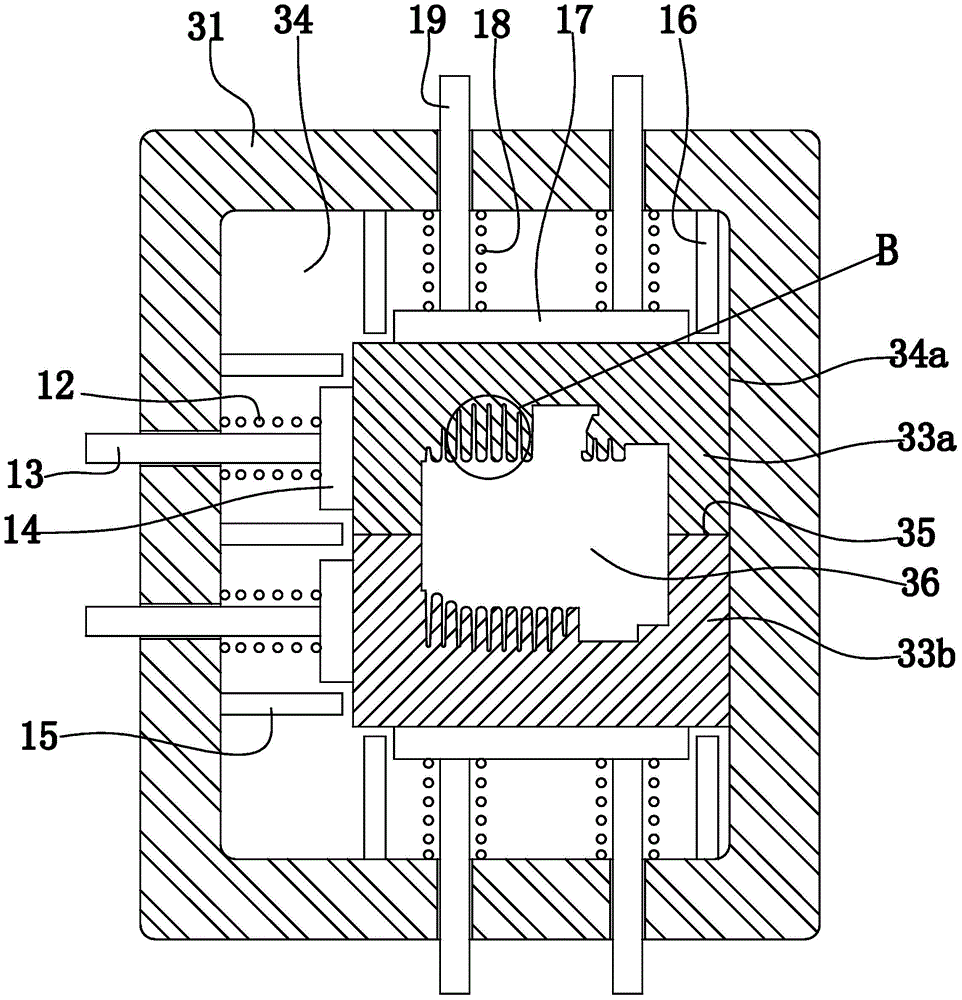

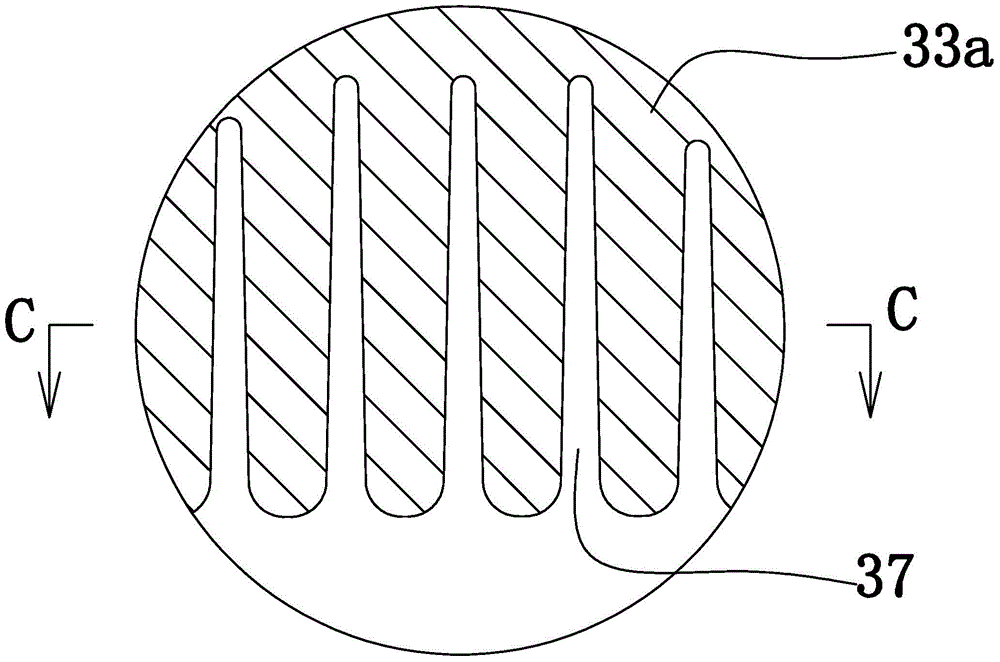

[0031] Embodiment 1: as figure 1 As shown, a deburring device for a cast cylinder block includes a frame 1, an installation platform 2, a floating pressing device 3 located above the installation platform, and a first lifting device arranged on the frame for lifting the installation platform 2 11 and the second lifting device 6 that is arranged on the frame and is used for lifting and lowering the floating pressing device 3. The top surface of the installation platform 2 is set horizontally. The bottom surface of the installation platform 2 is provided with a vertical guide rod. A vertical guide sleeve adapted to the vertical guide rod is arranged on the frame and below the installation platform. The first lifting device 11 is a lifting cylinder or a lifting oil cylinder. An installation frame 5 is arranged above the floating pressing device 3 . The second lifting device 6 is a lifting cylinder or a lifting oil cylinder arranged on the frame, and the piston rod of the lif...

Embodiment 2

[0043] Embodiment 2: A deburring processing method of a deburring device for a cast cylinder block, comprising the following steps in sequence:

[0044] a, Fix the cylinder block 21 on the installation platform 2 by clamping the tooling. After the cylinder block is fixed on the installation platform, the plane where the parting line 22 of the cylinder block is located is horizontally distributed, and the front and rear end surfaces of the cylinder block 21 are vertically distributed.

[0045] b, the first lifting device 11 drives the installation platform 2 and the cylinder block 21 to move upwards, and the upper part of the cylinder block is introduced into the press hole through the cylinder block inlet at the lower end of the press hole 36 until the mold parting line in the middle of the cylinder block 21 22. Pass through the upper port of the pressed hole gradually upwards from the inlet of the cylinder block, so that the parting line in the middle of the cylinder block is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com