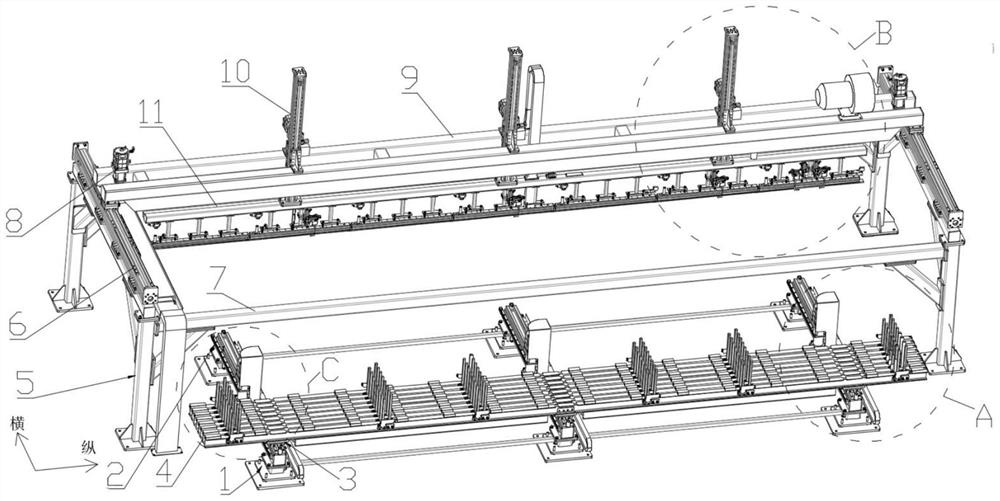

Feeding and discharging system and method for intelligent machining of copper bars

A technology of intelligent processing and copper bars, which is applied to the improvement of process efficiency, mechanical conveyors, conveyor objects, etc., can solve problems such as scratches on the surface of copper bars, misjudgment of copper bars, and failure of normal grasping of porous copper bars. To achieve the effect of ensuring the grasping effect and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

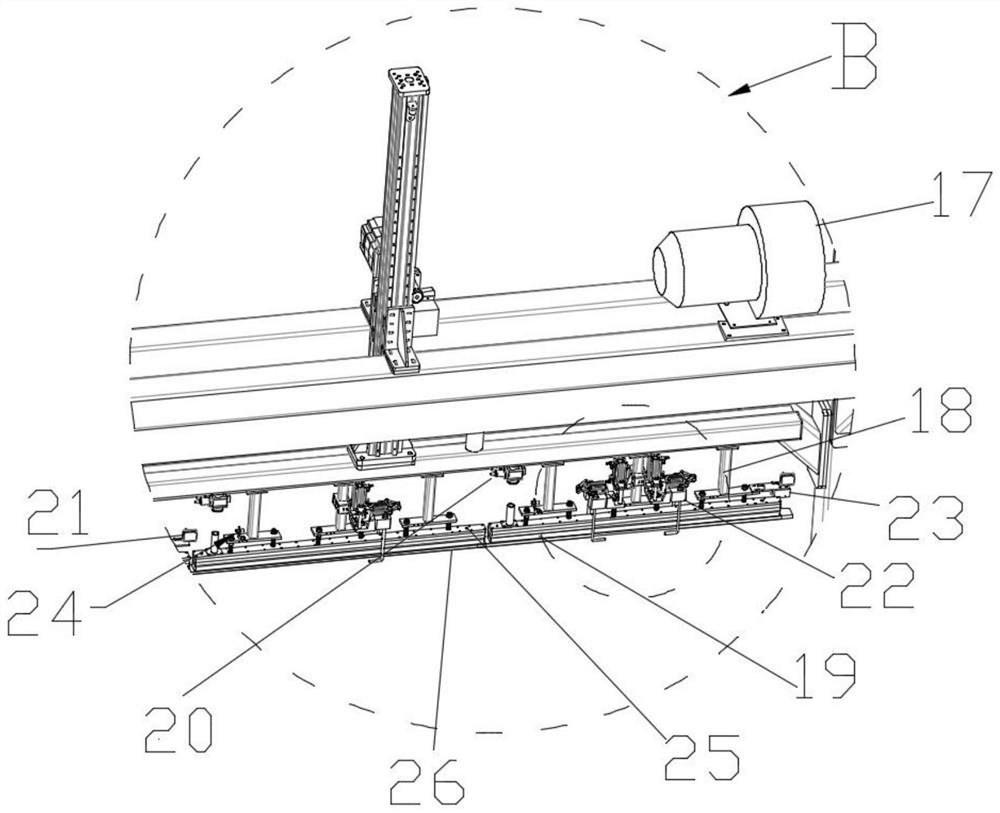

Embodiment 2

[0043] Different from Embodiment 1, an elastic buffer assembly 27 is also provided between the vertical connecting rod 18 and the suction cup 19, and the elastic buffer assembly 27 includes a buffer plate 271 and a connection buffer pad arranged at the lower end of the vertical connecting rod. The buffer spring 272 of the plate and the suction cup is used to slow down the impact force when the suction cup is in contact with the copper bar, so as to avoid damage to the copper medal.

Embodiment 3

[0045] The difference from Embodiment 1 is that a code scanning device 23 is provided at the outer end of the suction cup 19, and the scanning camera of the code scanning device is just aligned with the bar code on the copper plate, and the identity of the copper bar is identified by the bar code system to realize the traceability of the whole process.

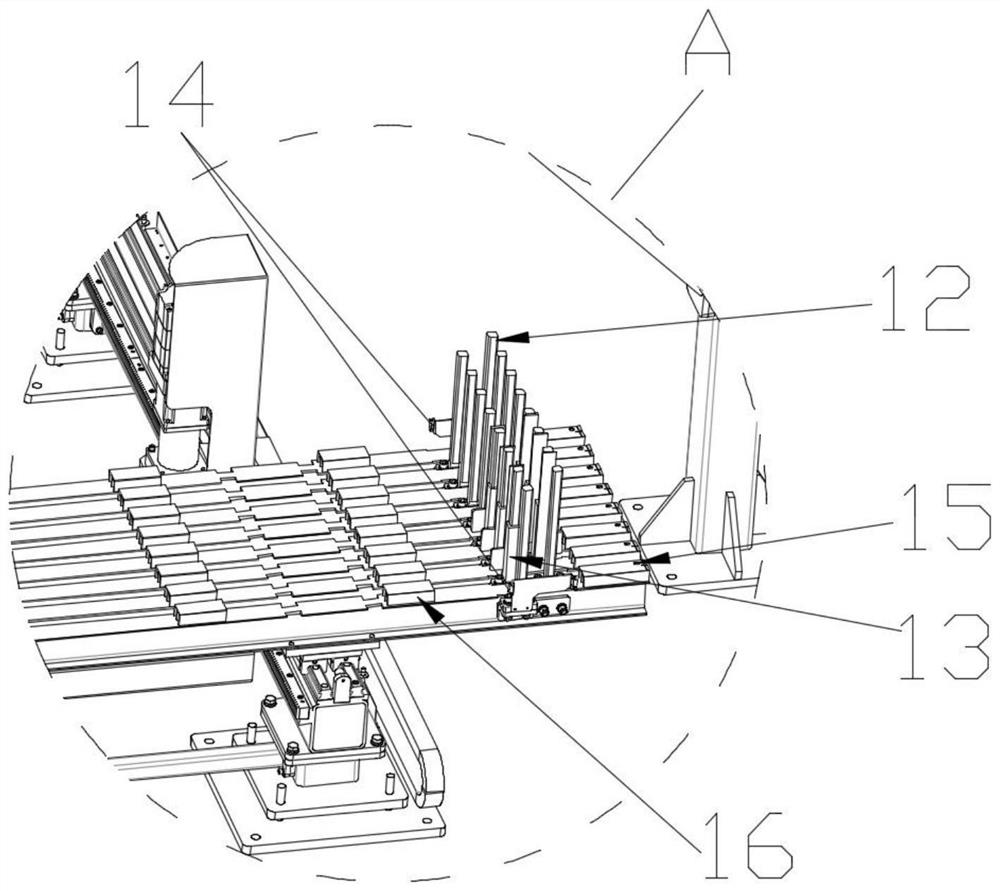

[0046] The beam silo 4 is also provided with a boss 16 made of channel steel. Because the manual feeding uses a sling to directly load the material, the copper bar will crush the sling and cannot be pulled out. A certain number of bosses are installed on the silo. 16 can provide the gap between the support boss and the boss for the copper bar to take out for the suspenders.

[0047] The above-mentioned loading and unloading method of the loading and unloading system for intelligent processing of copper bars includes the following steps:

[0048] Step 1. In the factory, when copper bars 26 (or other materials) need to be added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com