Equipment and method for protecting and cleaning surface of hollow titanium alloy wing rudder

A titanium alloy and wing rudder technology, applied in metal processing equipment, welding equipment, laser welding equipment, etc., can solve the problems of difficult to control coating quality, shorten the service life of titanium alloy, low efficiency, etc., and achieve accurate protection and cleaning process , Increase the working area, facilitate the installation and clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This example provides a hollow titanium alloy wing rudder superplastic diffusion surface protection and cleaning equipment, the material of the example parts is TA15 titanium alloy, the outer dimensions of the parts are 300mm×200mm, and the maximum thickness is 6mm, such as figure 2 shown.

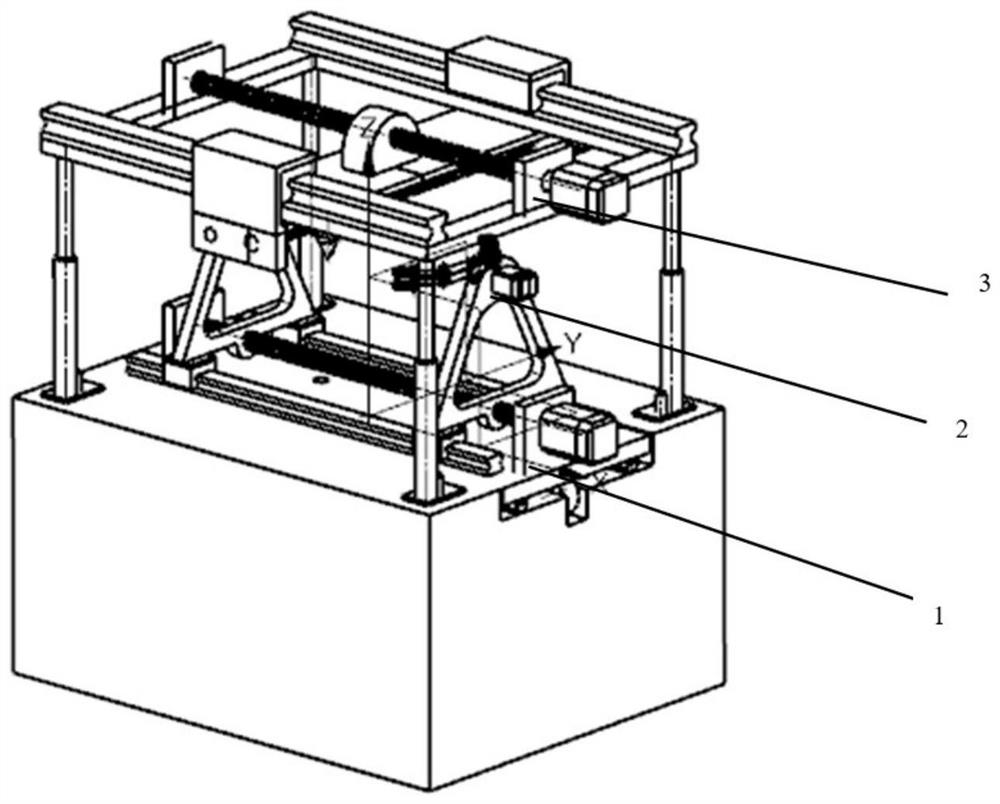

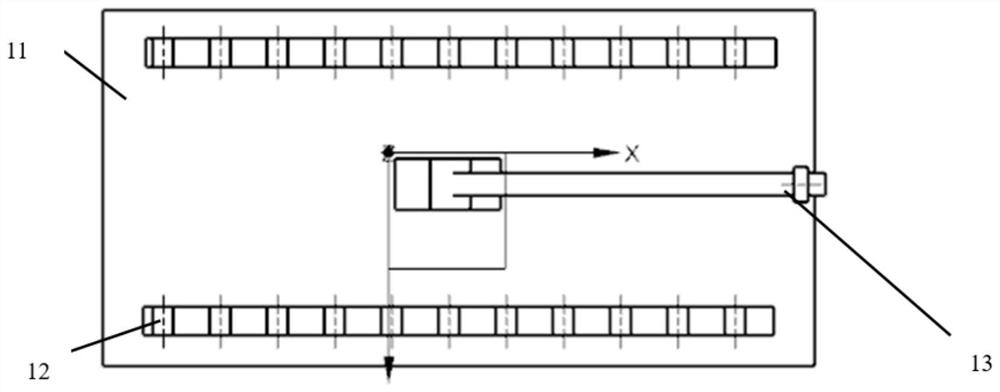

[0053] A hollow titanium alloy wing rudder superplastic diffusion surface protection and cleaning device according to the invention is designed and manufactured according to the three-dimensional model of the hollow titanium alloy wing rudder superplastic diffusion surface protection and cleaning equipment. The device structure is as figure 1 As shown, it consists of the following three parts: installation base 1, centering and clamping device 2, working head clamping device and mobile platform 3. The bottom view of the installation base 1 is as follows image 3 , mainly including a base plate 11, slide rails and guide wheels 12, a support rod 13, and the support rod 13 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com