Clamping part for novel optical fiber preforms

An optical fiber preform and clamping part technology, which is applied in the field of clamping parts for new optical fiber preforms, can solve problems such as jumping out, swaying, and processing difficulty of optical fiber preforms, and achieves the effect of satisfying positioning and clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

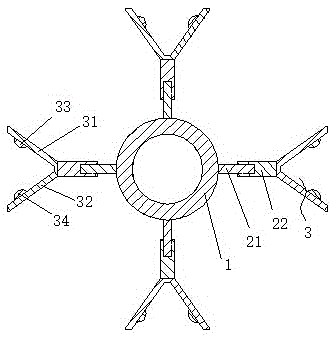

[0013] A new type of clamping part for optical fiber preform of the present invention, the clamping part is arranged on the vertical rod installed vertically in the suspension device, including the installation ring 1 fixedly arranged on the vertical rod, connected with the installation ring 1 and installed along the A number of ribs distributed in the radial direction of the ring 1, a positioning ring 3 arranged at the end of the ribs away from the installation ring 1, the side part of the optical fiber preform is placed in the positioning ring 3, and the ribs are formed by the first rib 21 connected to the installation ring 1 It is composed of the second rib 22 connected with the positioning ring 3 , and the second rib 22 is screwed on the first rib 21 . By adopting the above-mentioned structure, the rib adopts the method of screwing the first rib and the second rib, and the distance between the positioning ring 3 and the center of the mounting ring 1 is changed by changing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com