Automatic device for degreasing of air conditioner heat exchanger core body and application method thereof

A technology of automatic devices and heat exchangers, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve problems such as difficulty in ensuring product quality, high labor intensity, and low production efficiency, so as to reduce labor intensity and production efficiency. cost, increase productivity, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific implementation conditions.

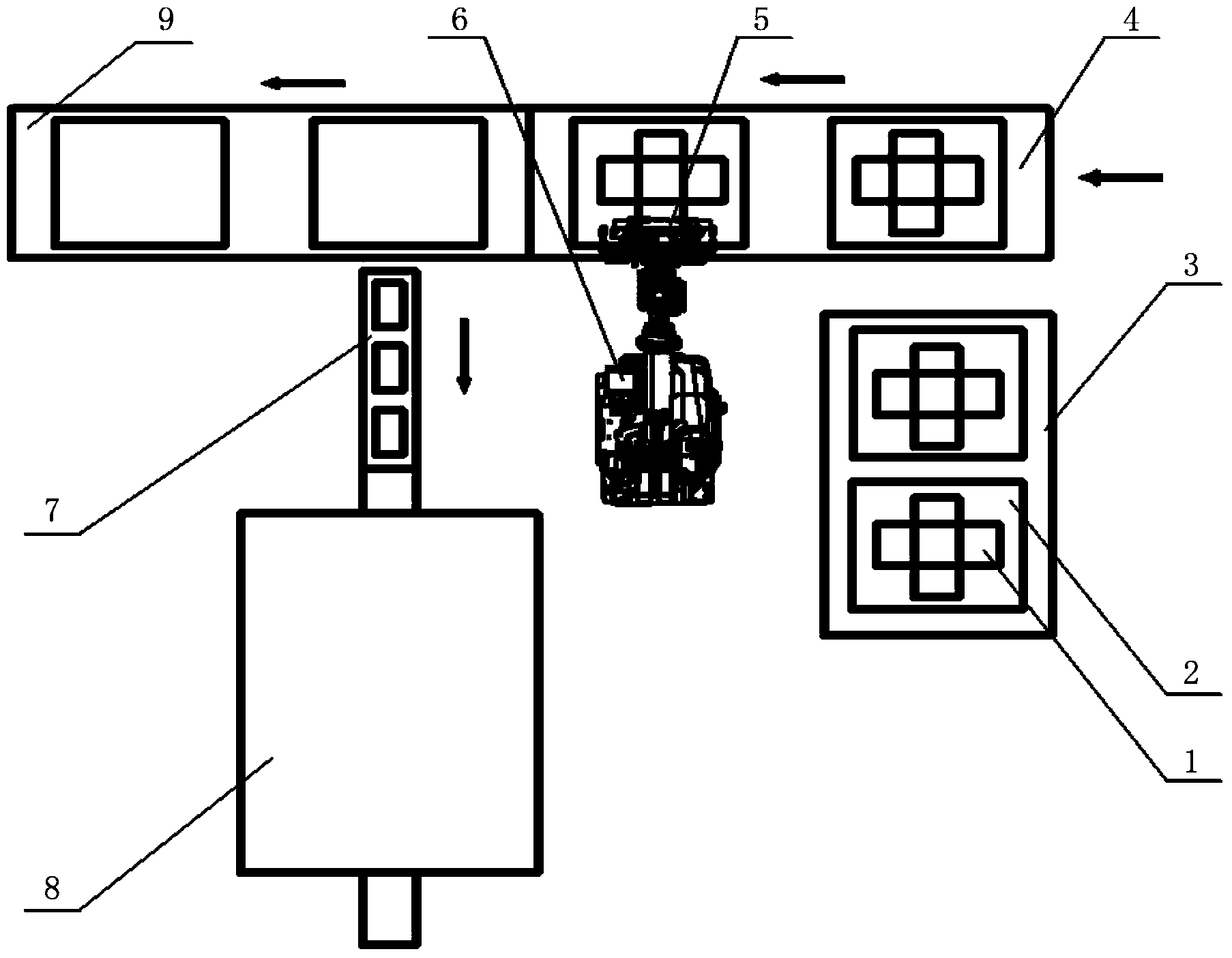

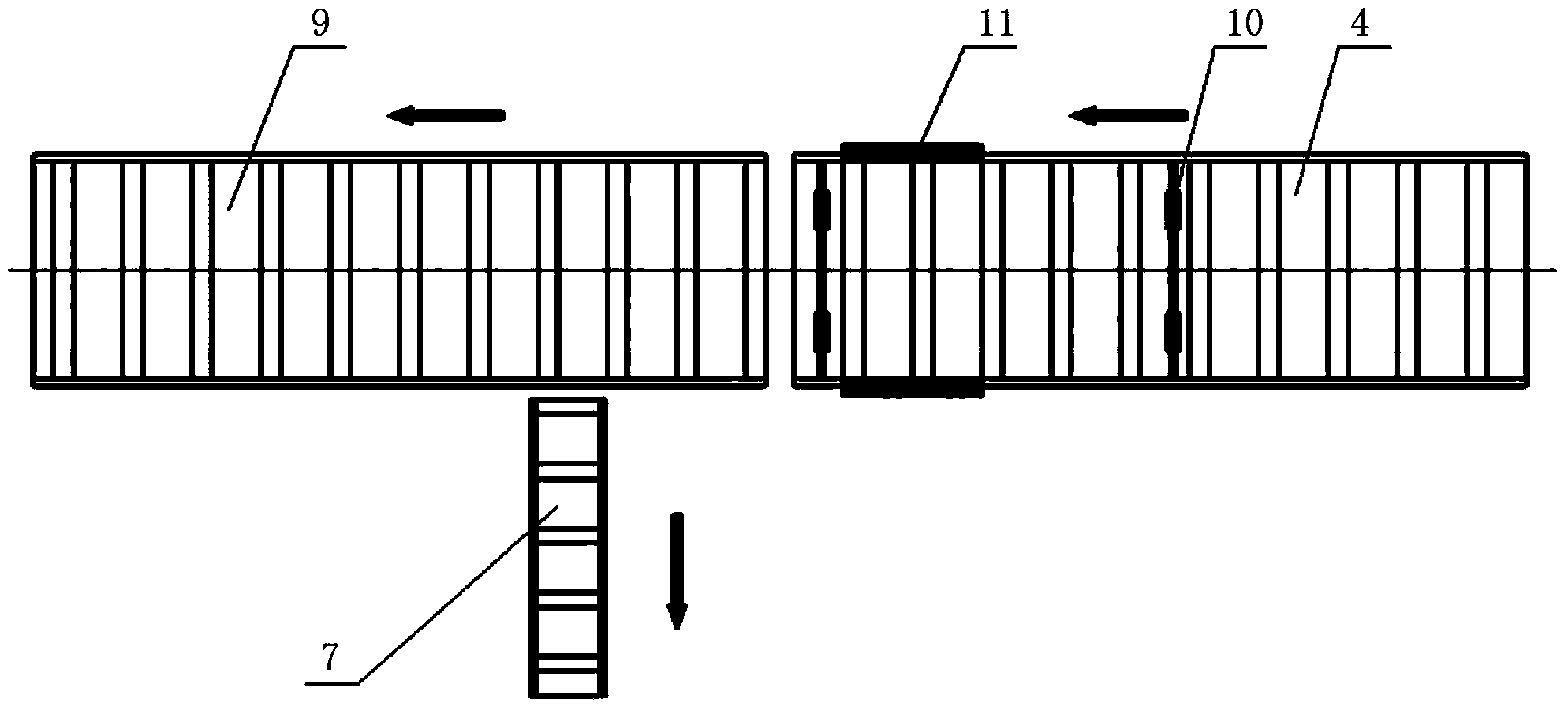

[0026] Such as figure 1 , figure 2 As shown, the automatic device for degreasing the core body of the air conditioner heat exchanger according to the embodiment of the present invention can be provided with a centralized tray 2 to be degreased, a storage line 3, a destacking chain accumulation line 4, a visual imaging device 5, a robot and a gripper 6, Furnace front conveying line 7, degreasing furnace 8, and empty tray return transfer line 9; wherein: the robot and the gripper 6 are at the approximate center position of the automatic device, and the visual imaging device 5 is placed above the front end of the robot and the gripper 6 The reserve line 3 is arranged on the right side of the robot and the gripper 6, and a plurality of concentrated trays 2 to be degreased are placed on the reserve line 3, and the heat exchanger core 1 is housed in the concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com