Vehicle with a leaf spring element for the spring suspension of the vehicle

A technology of leaf springs and car frames, applied in the direction of vehicle springs, vehicle components, elastic suspensions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The accompanying drawings should provide a further understanding of the embodiments of the invention. These drawings illustrate embodiments in a pictorial manner and serve to explain the principles and concepts of the invention in connection with the description. Further embodiments and many of the described advantages emerge from the drawings. Elements in the figures are not necessarily shown to scale.

[0036] In the figures, identical, functionally identical and identically acting elements, features and components are provided with the same reference symbols unless otherwise specified.

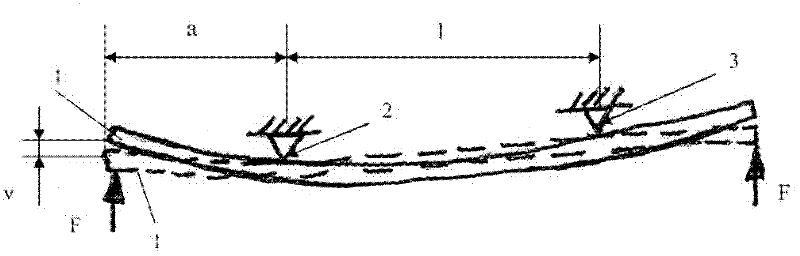

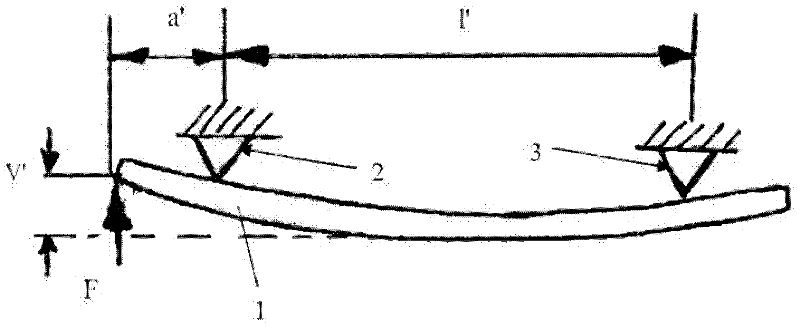

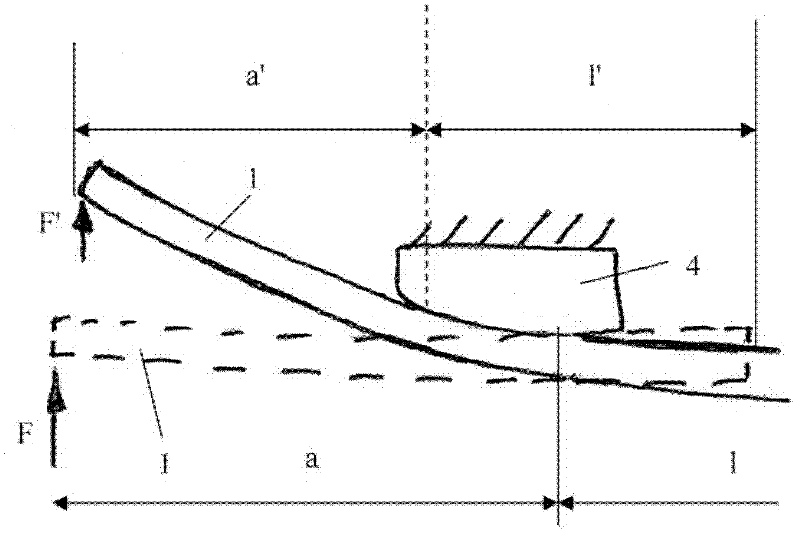

[0037] figure 1 A schematic diagram is shown of a single-layer leaf spring element 1 with a constant spring stiffness or spring stiffness c. In this case, the spring element 1 has two bearing points 2 , 3 which are spaced at a distance l from one another. The free end of the leaf spring element 1 forms here with the associated bearing point 2 a lever arm a, wherein when a force F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com