Tensioning means

A tensioning device and pre-tensioning technology, applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of large structural space, increased size of tensioning devices, etc., and achieve the effect of weight saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

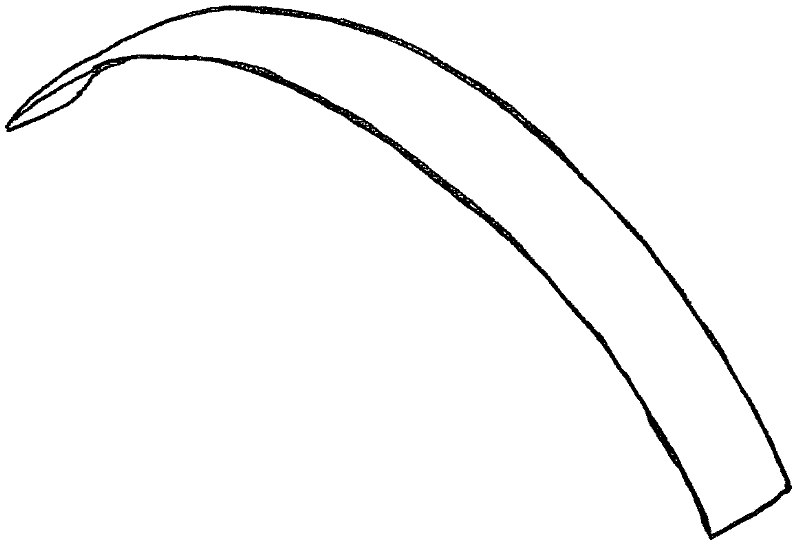

[0015] FIG. 1 shows a leaf spring known, for example, from laid-open publication DE 11 2006 001 473 T5. The leaf spring is rectangular and prebent in the shape of a bow. In the installed state, the leaf spring is deformed in an opposite bow-shape and thus exerts a pretensioning force on the tensioning rail.

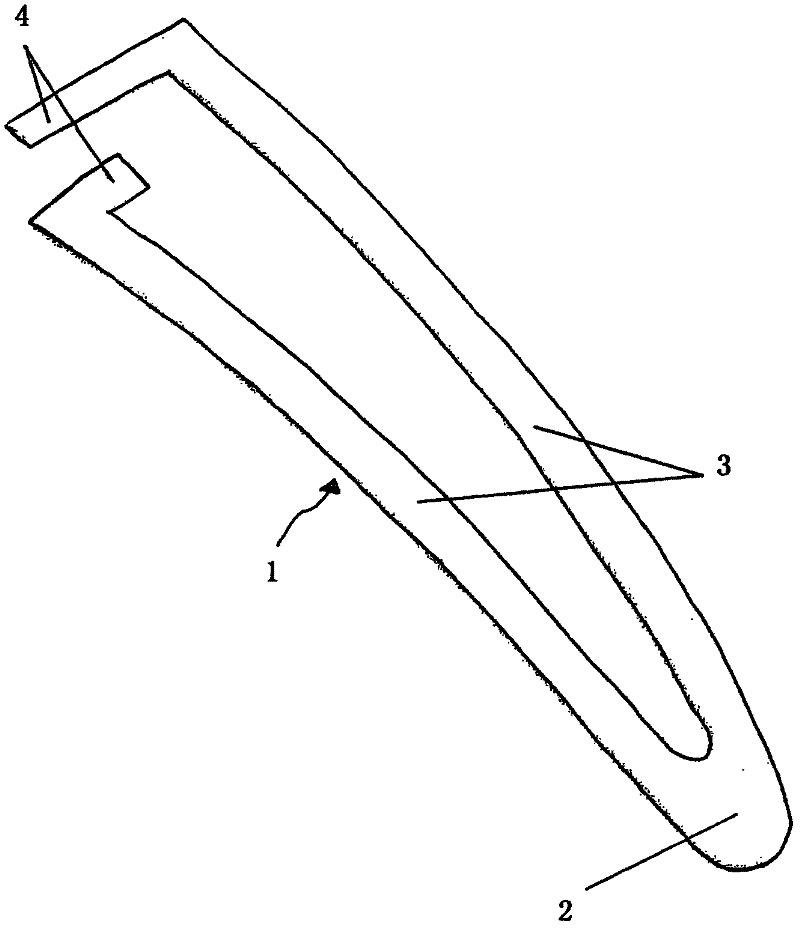

[0016] exist figure 2 A double-armed leaf spring 1 according to the invention is shown in . The two arms 3 of the leaf spring 1 each have a suspension point 4 . The suspension points 4 form end sections of the arms 3 and are substantially at right angles to the arms 3 , wherein the suspension points are each oriented in the direction of the other arm 3 . The suspension points 4 are arranged offset from one another and thus have different distances from the base section 2 of the connecting arm 3 .

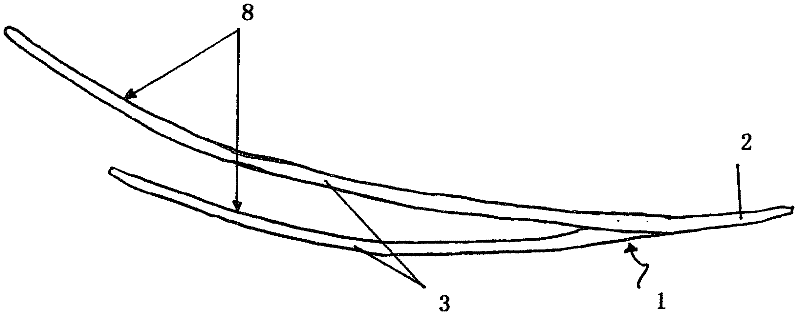

[0017] exist image 3 can be seen in side view from figure 2 It can be seen in this view of the leaf spring 1 that the arms 3 have different radii of curvature 8 and diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com