Vacuum absorbing device used for chip testing device

A technology of vacuum adsorption and chip testing, applied in measuring devices, electronic circuit testing, measuring electricity, etc., can solve the problems of increased maintenance man-hours and reduced work efficiency, and achieve the effect of avoiding station height changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

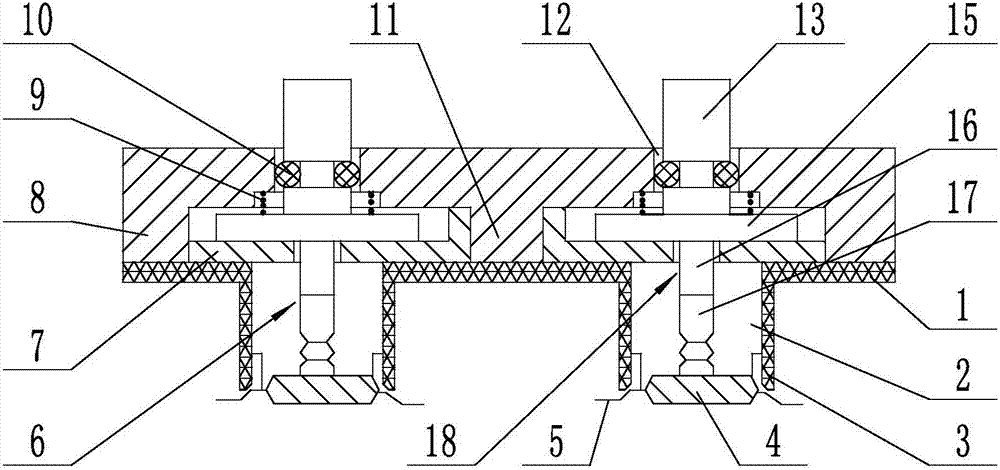

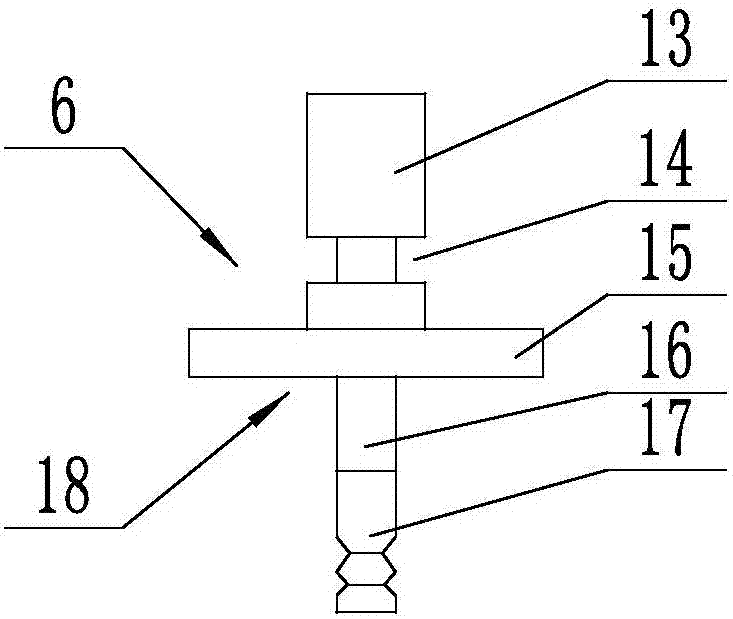

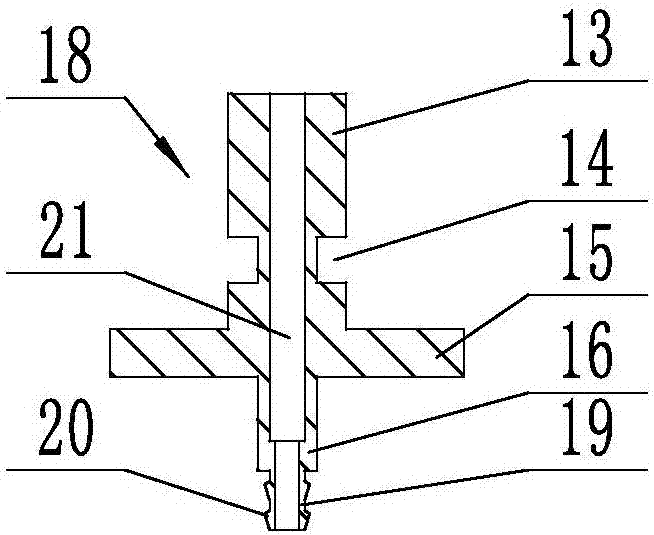

[0022] Such as figure 1 As shown, the present invention is a vacuum adsorption device, which is used to adsorb chips 4 in chip testing equipment, which includes a base body 8 and a cover plate 1 fixed together.

[0023] The outer surface of the cover plate 1 is provided with an outwardly protruding chip pin support wall 3 , and the chip pin support wall 3 is used to support the chip pins 5 of the chip 4 to be tested. Chip accommodating cavities 2 are formed between the chip lead support walls 3, and there may be one or more chip accommodating cavities, two in this embodiment.

[0024] The base body 8 is provided with through holes 12 corresponding to the positions of the chip receiving chambers 2; the number of the through holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com