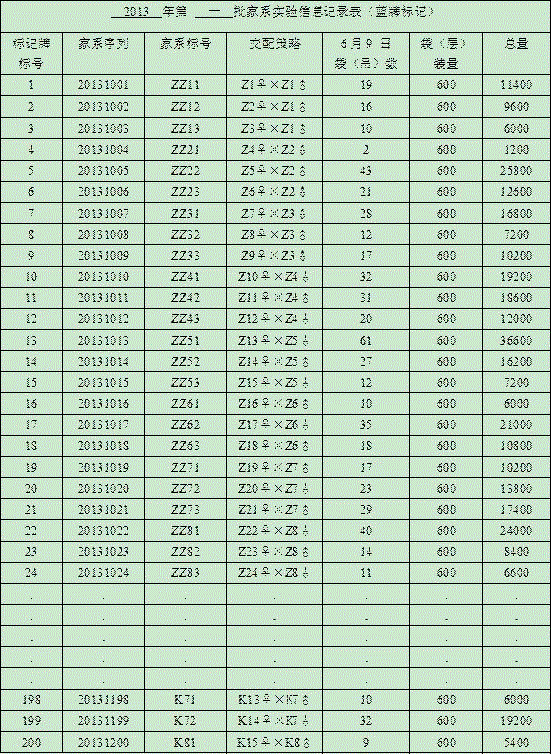

Patents

Literature

94results about How to "No physical damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

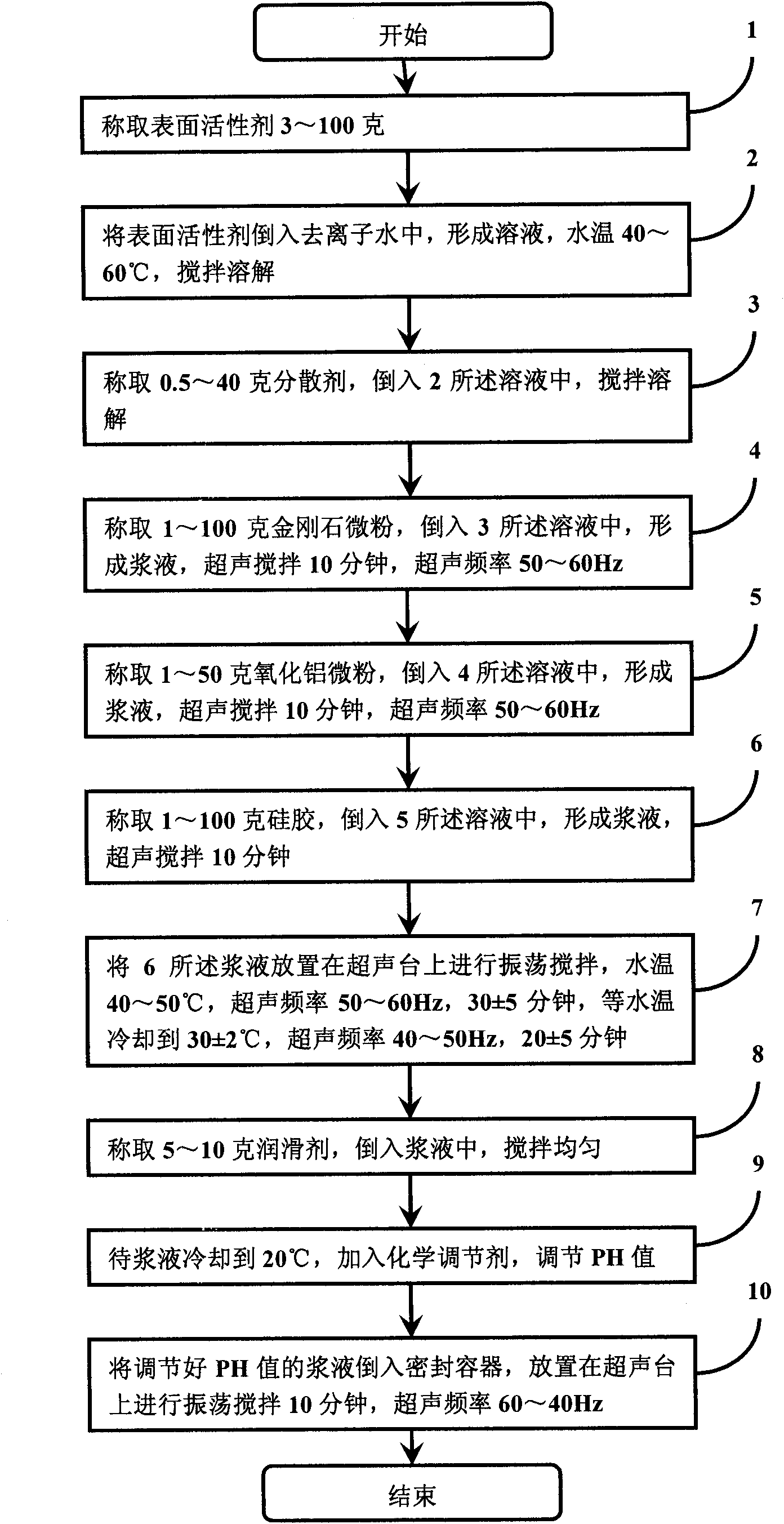

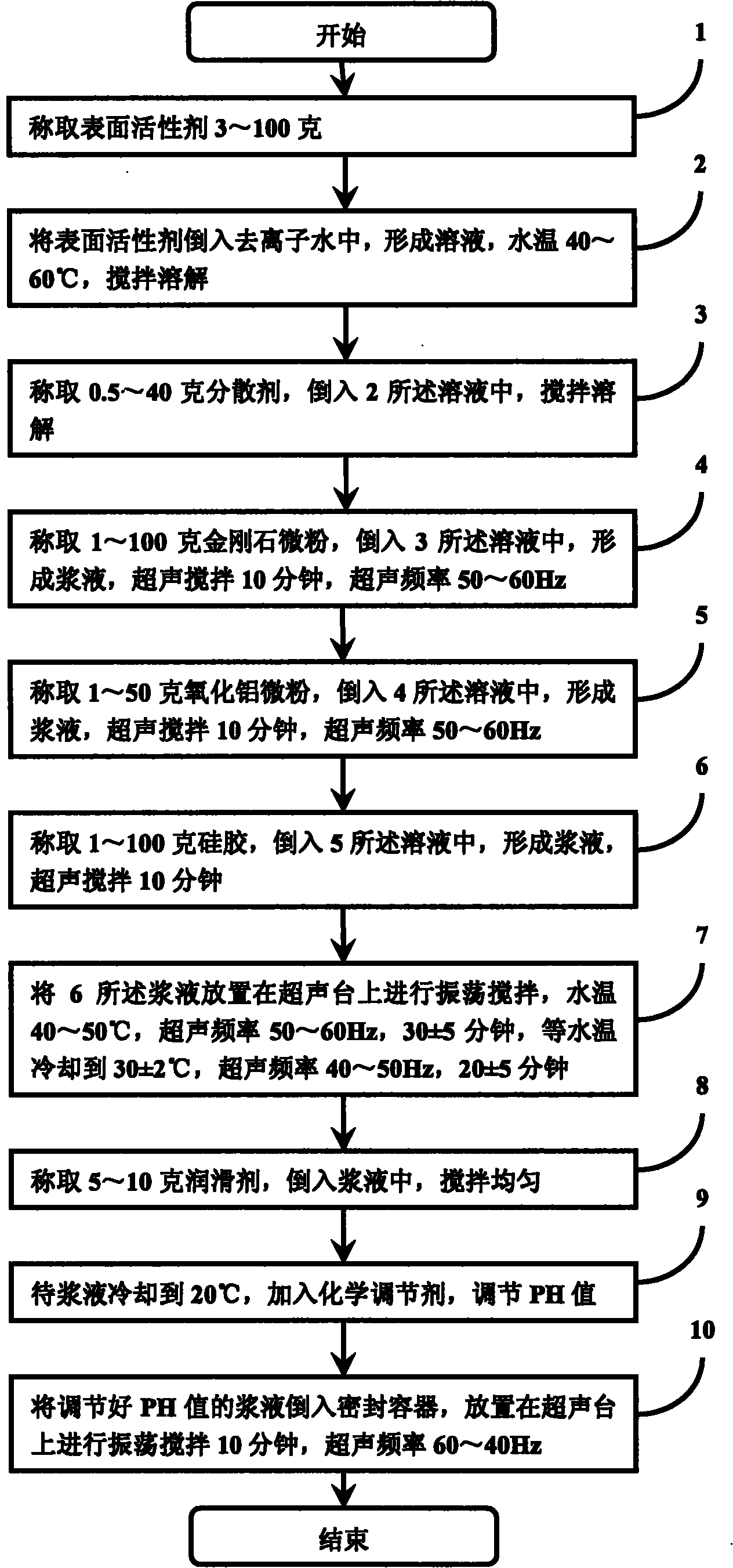

Nanometer level polishing solution and preparation method thereof

ActiveCN102311706AMeet the requirements of thinning grinding processEasy to polishPolishing compositions with abrasivesSilica gelSolvent

The invention discloses a nanometer level polishing solution and a preparation method thereof. The polishing solution is prepared from the following components in percentage by mass: 0.1 to 10 percent of monocrystal artificial diamond micro powder, 0.1 to 5 percent of aluminum oxide micro powder, 0.1 to 10 percent of silica gel, 0.3 to 10 percent of surfactant, 0.05 to 4 percent of dispersing agent, 0.5 to 1 percent of lubricant, 0.01 to 1 percent of chemical PH value regulator and 60 to 98.2 percent of solvent. The invention also discloses the preparation method for the nanometer level polishing solution. By the method, mixed serous fluid is prepared from the nanometer level diamond, the aluminum oxide and the silica gel, so an ideal polishing effect is achieved, the requirement of a process for thinning and grinding substrates (silicon carbide and sapphire) for GaN extension is met, and a technical means is provided for a polishing process for semiconductors.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

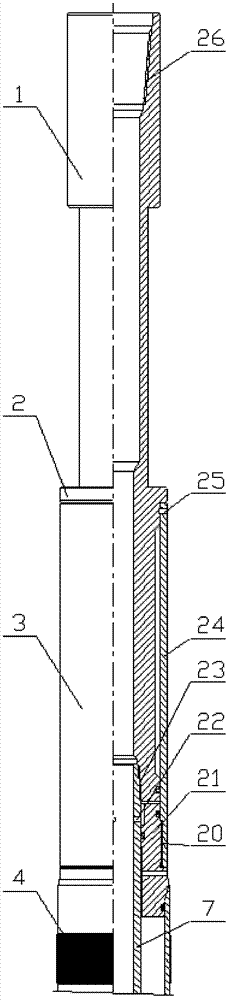

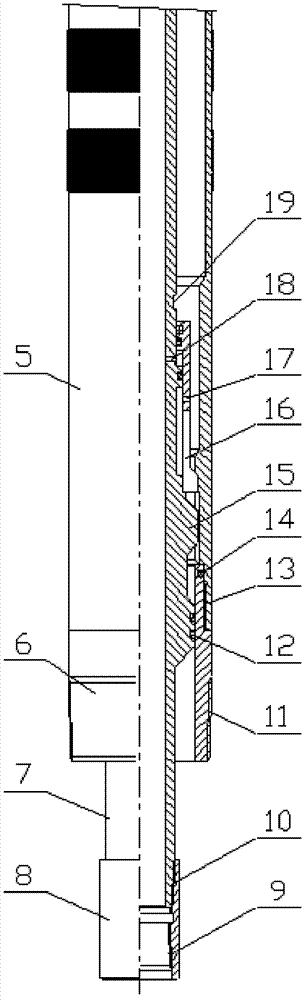

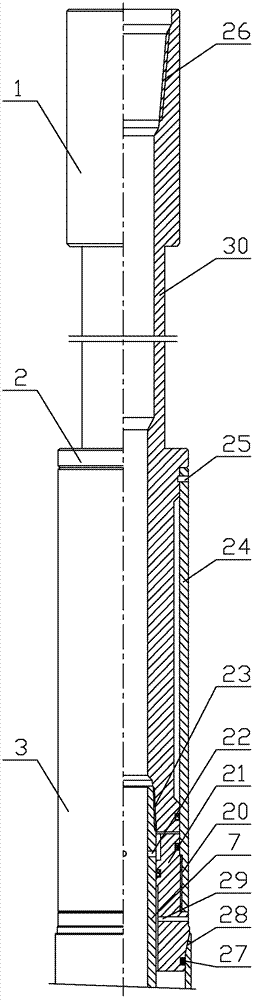

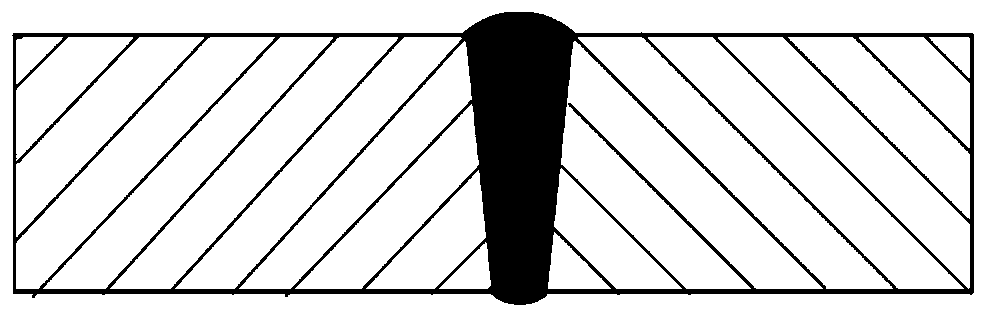

Expansion-type rotatable tail pipe hanger

The invention provides an expansion-type rotatable tail pipe hanger and belongs to the field of oil gas well fixation. The expansion-type rotatable tail pipe hanger comprises a hanger body and a feeding tool system, wherein the hanger body is an expandable metal tubing, a group of triangle-shaped annular protrusions are formed on the outer surface of an expansion section of the hanger body, annular rubber sections are vulcanized between every two adjacent triangle-shaped annular protrusions, and the diameter of each annular rubber section is larger than the outer diameter of top portion of each triangle-shaped annular protrusion. Rotation of a tail pipe can be realized, tripping-in capability and cement slurry displacement efficiency of the tail pipe are improved, sit-hanging and seal-separating functions of the hanger are realized via a hydraulic expansion hanger body. By the aid of the expansion-type rotatable tail pipe hanger, construction requirements on tail pipe cementation of an oil gas well can be met, and the technical difficulties like complex structure, many potential construction safety hazards and hardness in guaranteeing well cementation quality of a slip-type hanger are overcome. Operation process is simplified, tail pipe cementation quality is improved, risk is reduced, and cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

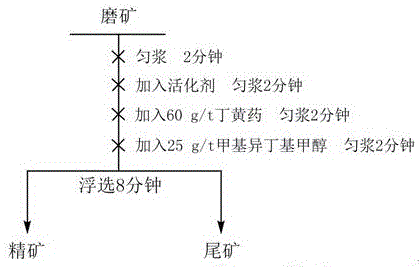

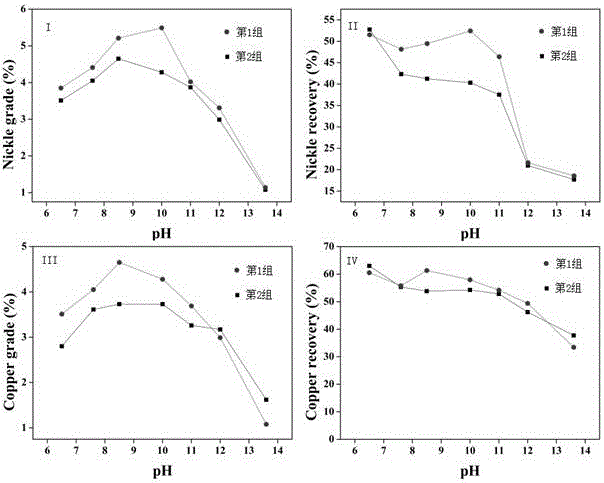

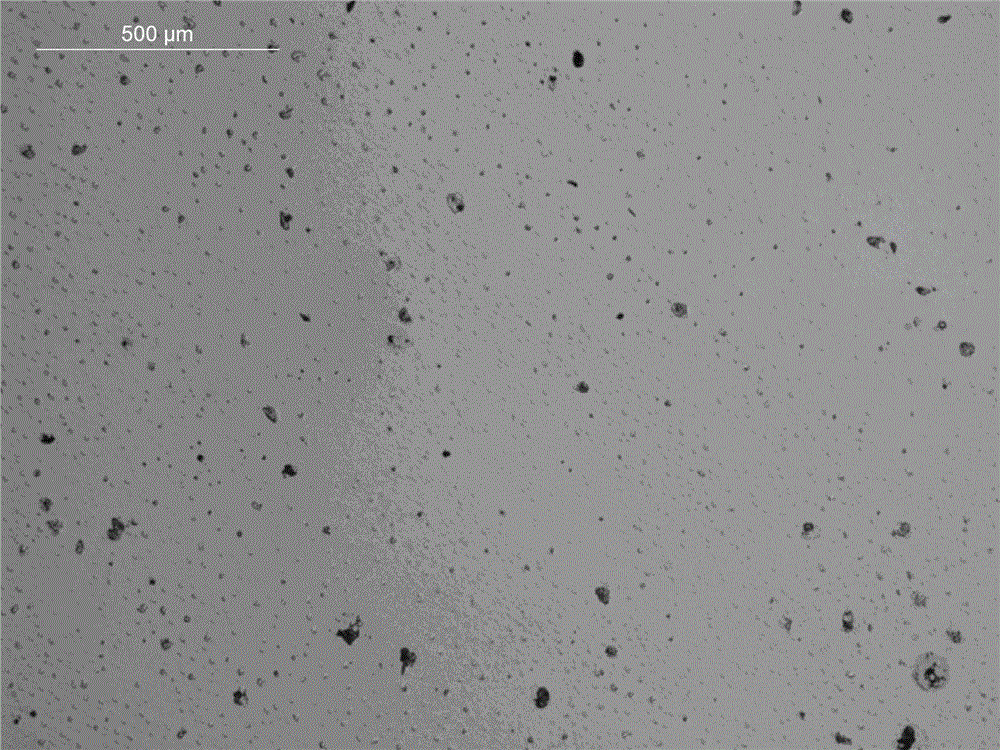

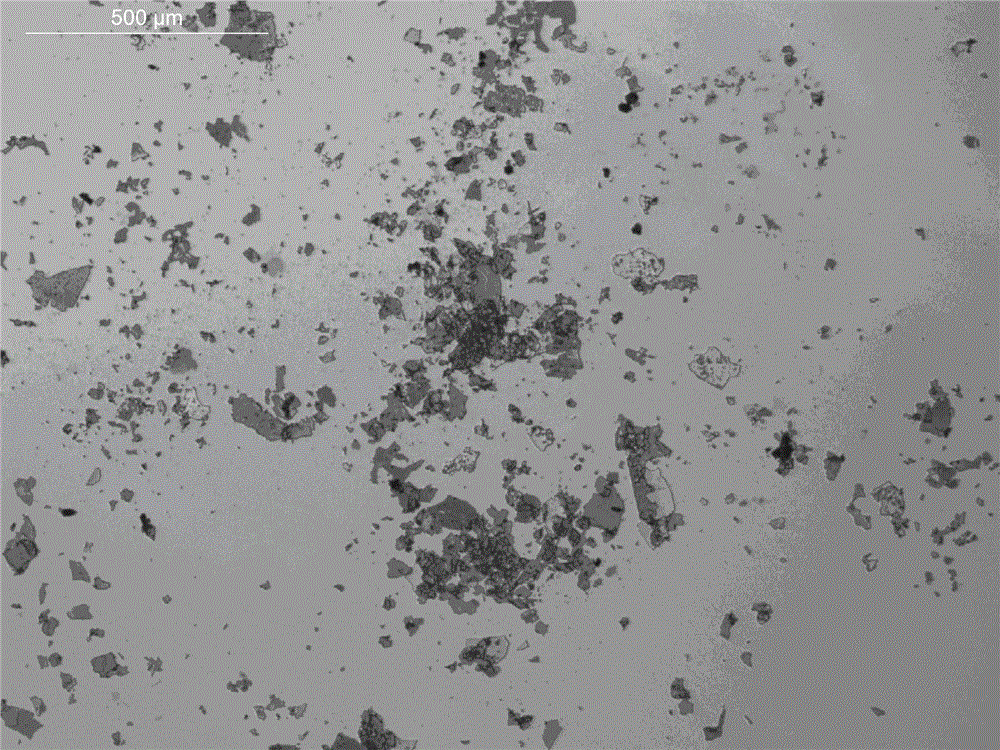

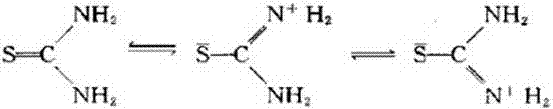

Activating agent for flotation of copper-nickel sulfide ores

InactiveCN105665152ARaw materials are cheap and easy to getApplicable industryFlotationNickel saltPhysical chemistry

The invention discloses an activating agent for flotation of copper-nickel sulfide ores.The activating agent is prepared from a component A and a component B, wherein the component A is copper salt or nickel salt, and the component B is amine, ammonia or ammonium salt.Compared with an existing activating agent for flotation of copper-nickel sulfide ores, the activating agent for flotation of the copper-nickel sulfide ores can remarkably improve the flotation and recovery rate and grade of the nickel-copper the copper-nickel sulfide ores, a good flotation effect can be obtained within the ore pulp pH value range of 7-11, the activating agent adapts to the complicated and volatile ore pulp conditions of industrial flotation, raw materials are cheap and easy to obtain, no harmful gas nor volatile substance is discharged after the activating agent is added into a flotation system, and the activating agent is green, is environmentally friendly, is harmless to the body of an operator and does not corrode flotation equipment.

Owner:LANZHOU UNIVERSITY

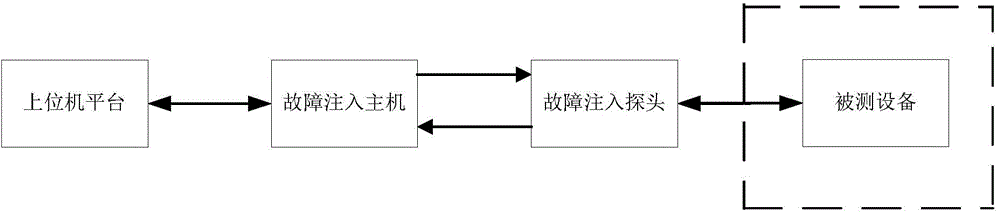

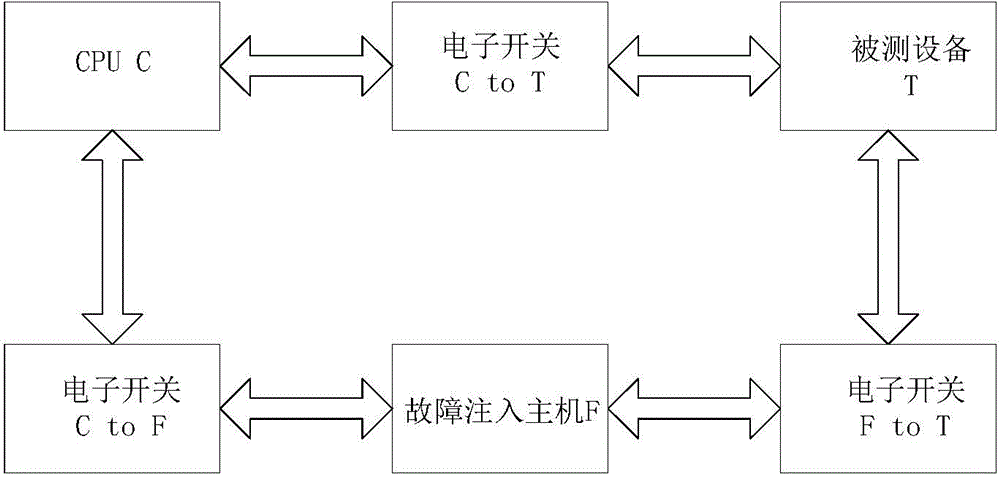

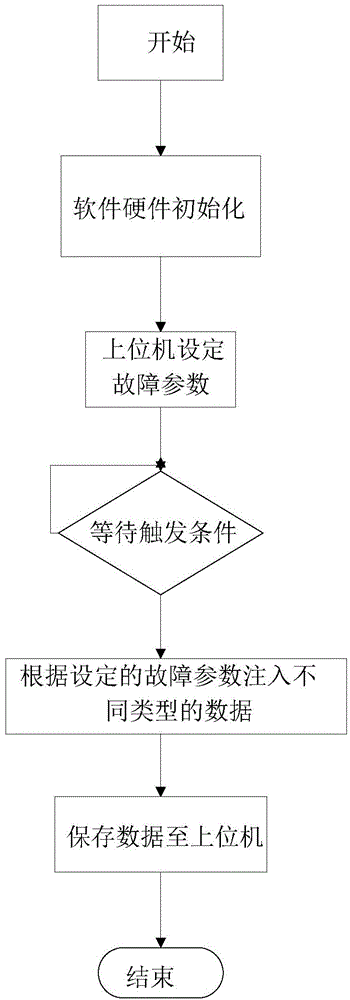

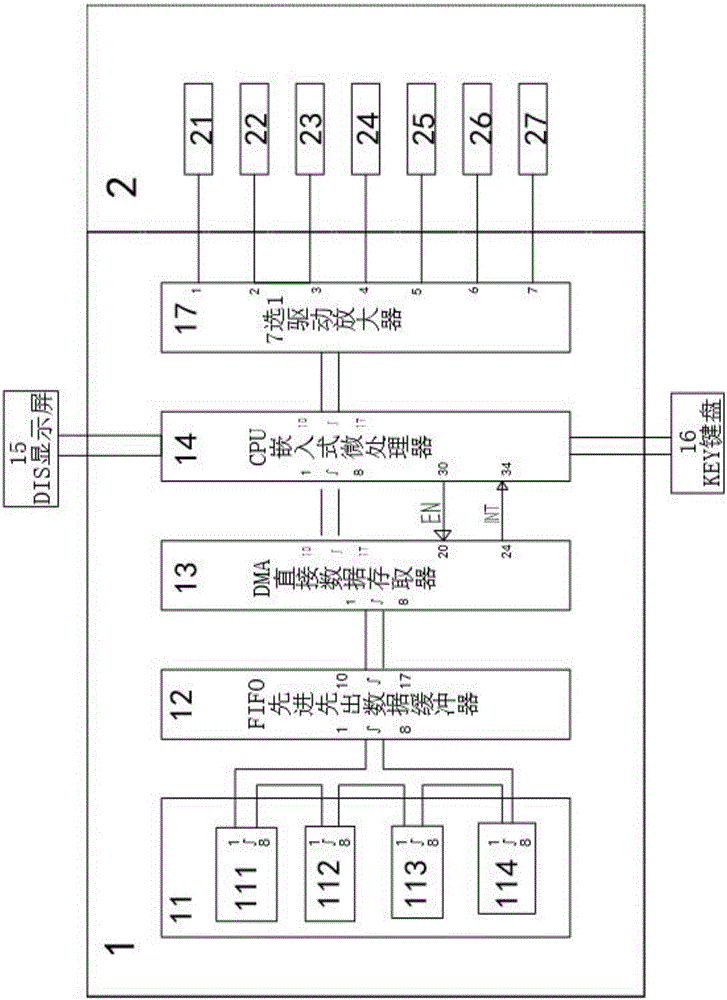

Embedded device CPU (Central Processing Unit) bus fault injection test system and test method

InactiveCN104657244AMeet comprehensive fault injection type requirementsNo physical damageDetecting faulty computer hardwareEthernetEmbedded system

The invention provides an embedded device CPU (Central Processing Unit) bus fault injection test system and a test method. The system comprises an upper computer platform, a fault injection host computer, a fault injection probe and a tested device, wherein the upper computer platform mainly operates fault injection software and the like; the fault injection host computer has the parameter functions of uploading data and issuing commands between an Ethernet network and the upper computer platform; the fault injection probe provides different CPU interface functions, and different probes are replaced for different CPUs; tested software is mainly operated in the tested device, and all signals of the tested device are connected with the fault injection probe through interfaces. According to the embedded device CPU bus fault injection test system and the test method, through the upper computer platform, fault setting parameters are set and fault injection commands are issued, a plenty of fault injection types can be carried out through parameter combination, the comprehensive fault injection type requirement of an embedded system is met, and the use is flexible and convenient.

Owner:VISION MICROSYST SHANGHAI

Method for preparing infrared cut-off filter

ActiveCN104977638ANot suitable for chippingIncrease productivityOptical filtersRejection rateInfrared cut-off filter

The invention relates to a method for preparing an infrared cut-off filter, specifically comprising the steps of cutting, shaping, slicing, chamfering, grinding, double-sided chemical polishing, coating, and the like. An infrared cut-off filter prepared by the method has high quality. The rejection rate is low. The production efficiency is high.

Owner:中山市飞科光学科技有限公司

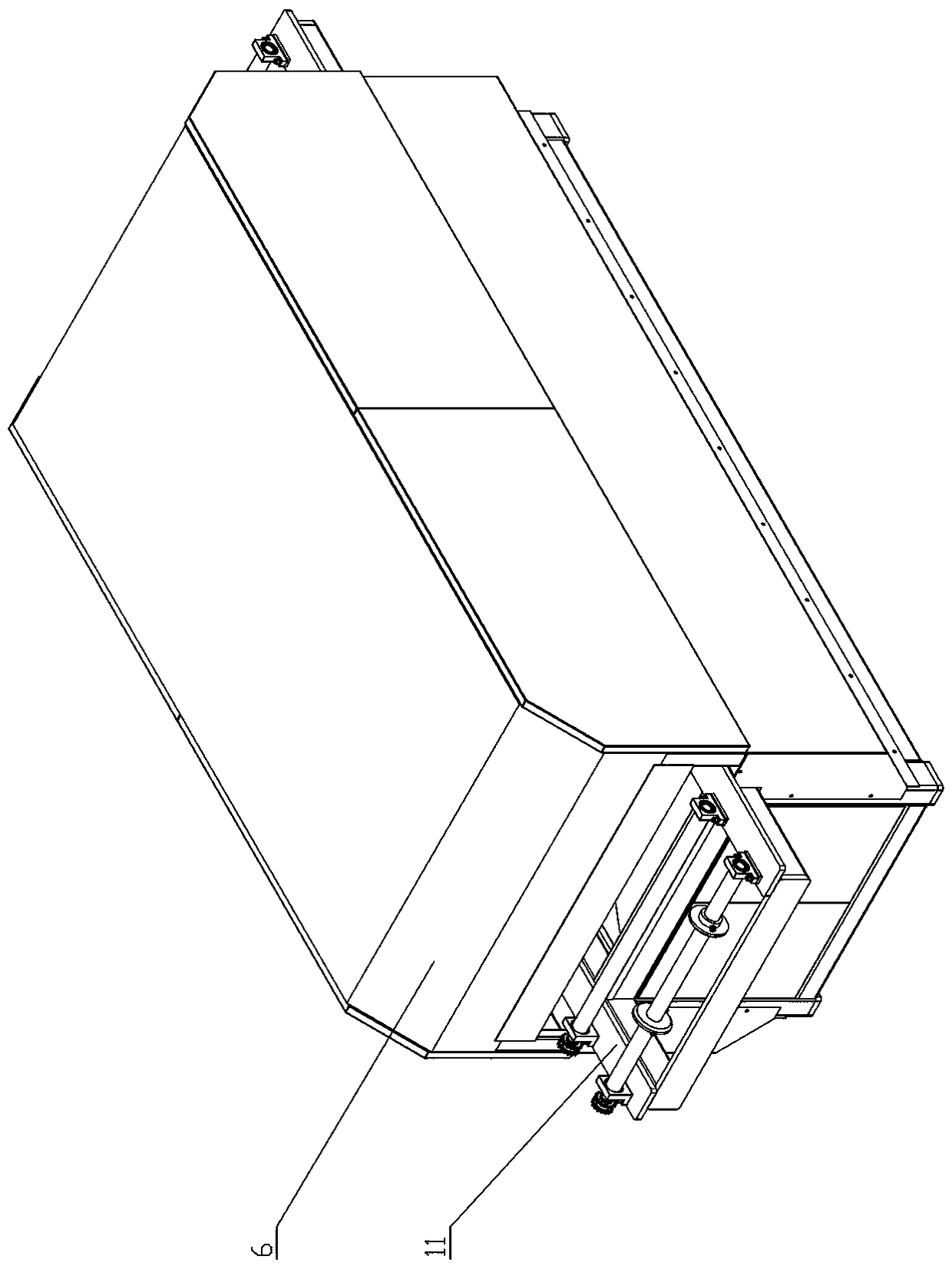

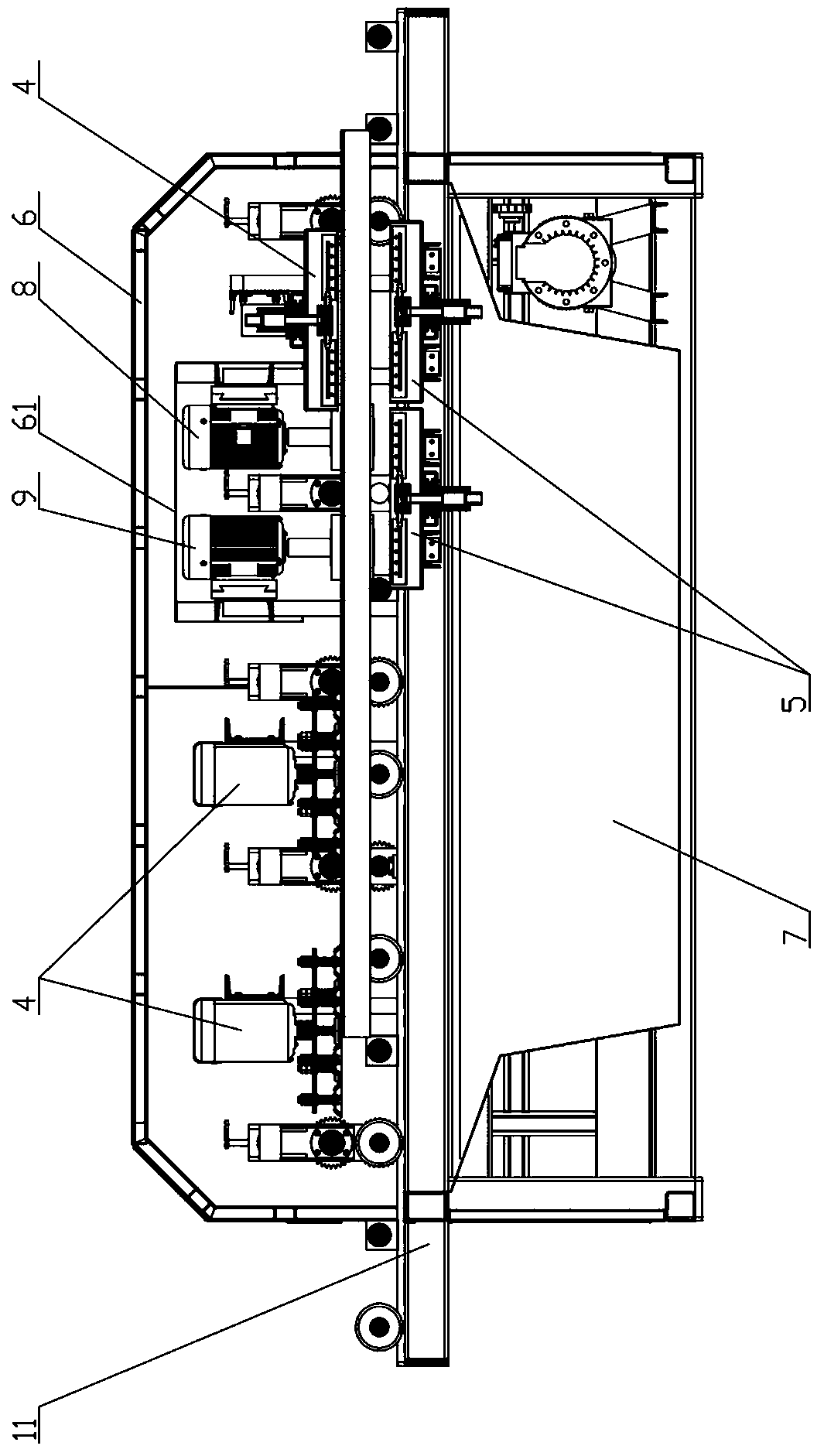

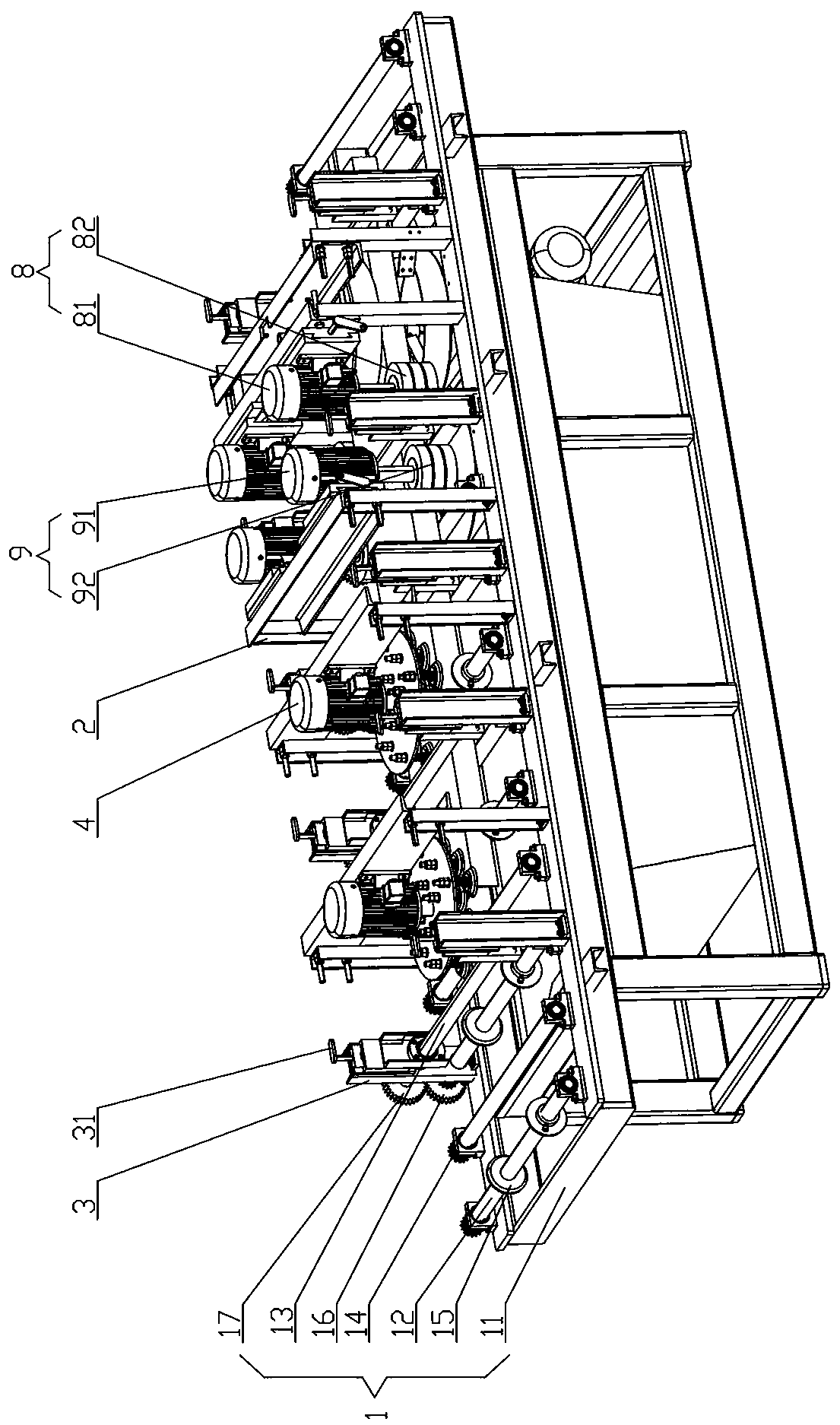

Novel building material template cleaning device

PendingCN109047130APrevent left and right shiftAvoid moving up and downPolishing machinesDirt cleaningEngineeringMechanical engineering

The invention relates to the technical field of construction machinery, in particular to a novel building material template cleaning device, which comprises a conveying table, a forward rotation cleaning mechanism, a reverse rotation cleaning mechanism, an upper surface flushing mechanism and a lower surface flushing mechanism, wherein the forward rotation cleaning mechanism and the reverse rotation cleaning mechanism are arranged on the conveying table; a building material template is conveyed through the conveying table; the upper surface flushing mechanism is arranged above the building material template; the lower surface flushing mechanism is arranged below the building material template; a sticky matter on the building material template can be effectively cleaned, and a physical means is used for cleaning, so that the chemical pollution is avoided, the cleaning efficiency is improved, and the production cost is reduced.

Owner:GUANGZHOU KINGHING CONSTR TECH

Chrysanthemum bud tea and preparation method thereof

The invention relates to chrysanthemum bud tea which is characterized by being prepared from the following raw materials in parts by weight: fresh and tender tea raw materials including 30-32 parts of chrysanthemum buds, 24-26 parts of semen cassiae and 28-32 parts of honeysuckle and other materials including 6-7 parts of purslane, 4-6 parts of poria cocos, 8-9 parts of colla corii asini, 7-9 parts of American ginseng, 14-16 parts of olive oil, 20-22 parts of fresh cucumber juice, 6-7 parts of lotus seeds, 14-17 parts of rock candy, 3-4 parts of fresh ginger, 2-3 parts of pepper, 7-9 parts of fructus amomi, 12-15 parts of groundnut kernels, 4-5 parts of an assistant and a proper amount of water. According to the chrysanthemum bud tea disclosed by the invention, Hangzhou white chrysanthemum flowers are picked as chrysanthemum buds when incompletely flowering, and other tea raw materials comprise honeysuckle and semen cassiae; in a process of preparing health tea, twisting can enable tea juice to overflow, the tea juice can relatively easily enter tea water when being soaked, but for the honeysuckle and the fresh and tender chrysanthemum buds in the chrysanthemum bud tea, twisting easily damages the completeness of petals, damaged parts of the petals are easily oxidized; according to the chrysanthemum bud, by using a smoking method, by virtue of high-temperature steam, fixation can be performed on the one hand, on the other hand, cells in the fresh and tender tea raw materials can be damaged by mechanical force of the steam, the twisting effect is achieved, no large physical damage is caused, the finished product tea is relatively complete, and nutrients in the finished product tea are well preserved.

Owner:安徽新泰药业有限公司

Method for preparing infrared cut-off filter

InactiveCN104977639ANot suitable for chippingIncrease productivityOptical filtersInfrared cut-off filterRejection rate

The invention relates to a method for preparing an infrared cut-off filter, specifically comprising the steps of cutting, shaping, slicing, chamfering, grinding, double-sided chemical polishing, coating, and the like. An infrared cut-off filter prepared by the method has high quality. The rejection rate is low. The production efficiency is high.

Owner:江苏苏创光学器材有限公司

Method for cleaning laser film

InactiveCN102873048AImprove cleaning efficiencyPrevent ablative damageCleaning using liquidsIonPhysics

The invention relates to a method for cleaning a laser film. The method specifically comprises the steps that a cotton swab dipped with acetone is used for slightly wiping the surface of the laser film, the wiped laser film is put in a first cleaning tank, alkaline solution is filled into the first cleaning tank to clean a sample, and the solution temperature is the room temperature; the volume ratio of the alkaline solution is that NH4OH: H2O2: H2O equals to 1: 10: 50; the obtained solution is respectively subjected to ultrasound for 2-4 minutes at the frequencies of 120 kilohertz-180 kilohertz and 200 kilohertz-300 kilohertz; the obtained sample is put in a second cleaning tank and is rinsed through deionized water, and the temperature of the deionized water is the room temperature; the sample is put in a third cleaning tank 3, the deionized water is added into the third cleaning tank, and the sample is respectively subjected to ultrasound for 3-6 minutes at the frequencies of 120 kilohertz-180 kilohertz and 200 kilohertz-300 kilohertz; and the sample is taken out, repeatedly cleaned and dried to obtains the required product. The method has the advantages that the high cleaning efficiency is realized, organic pollutants and contamination particles on the surface are effectively removed, meanwhile, the laser film cannot be physically damaged, the film is prevented from being eroded and damaged due to the particles which are absorbed to the surface of the film when the film is used in a high-power laser system, and the laser film is enabled to have high damage threshold when being used in the high-power laser system.

Owner:TONGJI UNIV

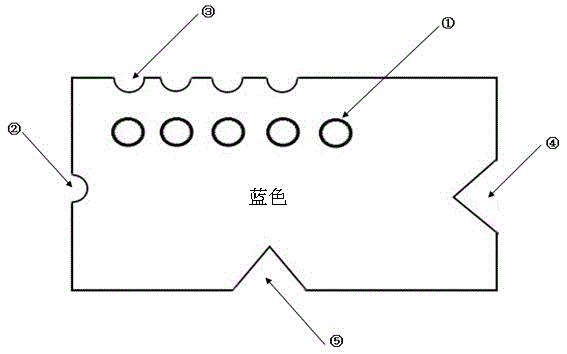

Shellfish pedigree breeding marking contrast method

ActiveCN105532529AReadableNo effect on growthClimate change adaptationPisciculture and aquariaZoologyPhases of clinical research

The invention relates to the technical field of aquatic organism selective breeding marking, and relates to a marking contrast method of an offshore intermediate breeding and development stage during a shellfish pedigree breeding process. The invention specifically relates to a shellfish pedigree breeding marking contrast method. According to the method, an environment-friendly plastic pad is adopted as a material for a geometric-shaped marker; different geometric holes are formed in the marker by cutting; and marking can be realized with the holes and the color of the marker. According to the method, the cost is low, and the marking is simple and clear. The marker can be accurately identified under a situation of foreign body adhesion. The recognition degree is high, and the marker meets production needs. The marker is convenient to manufacture, and is easy to carry. The marker can be widely and repeatedly applied. The marker has long preservation time and high preservation rate. Marking is carried out by tying the marker on a cultivation cage with a plastic tie, such that physiological damage to the shellfish is prevented, and the marker is stable and is prevented from falling and loss. Therefore, the stability of the marker is high. A marking rate and readable rate of the marker are both 100%, such that shellfish pedigree breeding large-scale industrialization development requirements are met. The method has an important significance in shellfish industry breeding.

Owner:孙欣

Manufacturing method for sapphire fingerprint recognition panel

ActiveCN105128157ANot suitable for chippingIncrease productivityPolycrystalline material growthAfter-treatment detailsAgricultural engineeringRejection rate

The invention relates to a manufacturing method for a sapphire fingerprint recognition panel. The manufacturing method comprises the specific steps of crystal growth, crystal bar drawing, crystal cutting, laser wafer taking, grinding, chamfering, annealing, double-face polishing, film plating, ink smearing, hot drying and the like. According to the manufacturing method for the sapphire fingerprint recognition panel, the quality of finished wafers is high, the rejection rate is low, and the production efficiency is high.

Owner:清远惠晶科技有限公司

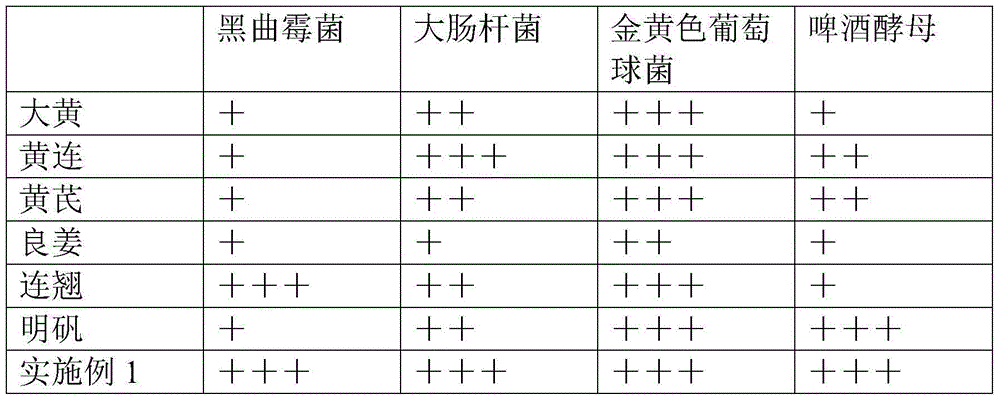

Traditional Chinese medicine preservative for fish stripping specimen and preparation method of traditional Chinese medicine preservative

InactiveCN104585159AGuaranteed anti-corrosion performanceGood broad-spectrum bactericidal effectDead animal preservationMedicinal herbsWater baths

The invention relates to a preservative, in particular to a traditional Chinese medicine preservative for a fish stripping specimen and a preparation method of the traditional Chinese medicine preservative. The method comprises the following steps: cleaning five traditional Chinese medicinal materials, namely rhubarb, coptis chinensis, astragalus membranaceus, falangal and fructus forsythiae; baking at 55-65 DEG C for 45-50 hours, and crushing until the granularity is below 40mesh; weighing all traditional Chinese medicines, putting the weighed traditional Chinese medicines into water, heating in a water bath at 55-65 DEG C for 10-14 hours, and then adding alums; or weighing all traditional Chinese medicines, putting the weighed traditional Chinese medicines into water, decocting into a paste with a slow fire, and then adding the alums; and adding p-nitrophenol to 95wt% ethyl alcohol, pouring the mixture into the medicinal materials in the step (2), stirring into a paste and sealing. The traditional Chinese medicine preservative for the fish stripping specimen has a good broad-spectrum bactericidal effect, is slow to release, nontoxic, healthy, and free of harm to bodies of preparation staff and users, and is capable of ensuring the preservative effect of the specimen for a long period of time; and the preparation method is simple and convenient, low in cost, relatively few in required equipment, and easy to popularize.

Owner:SHANGHAI OCEAN UNIV

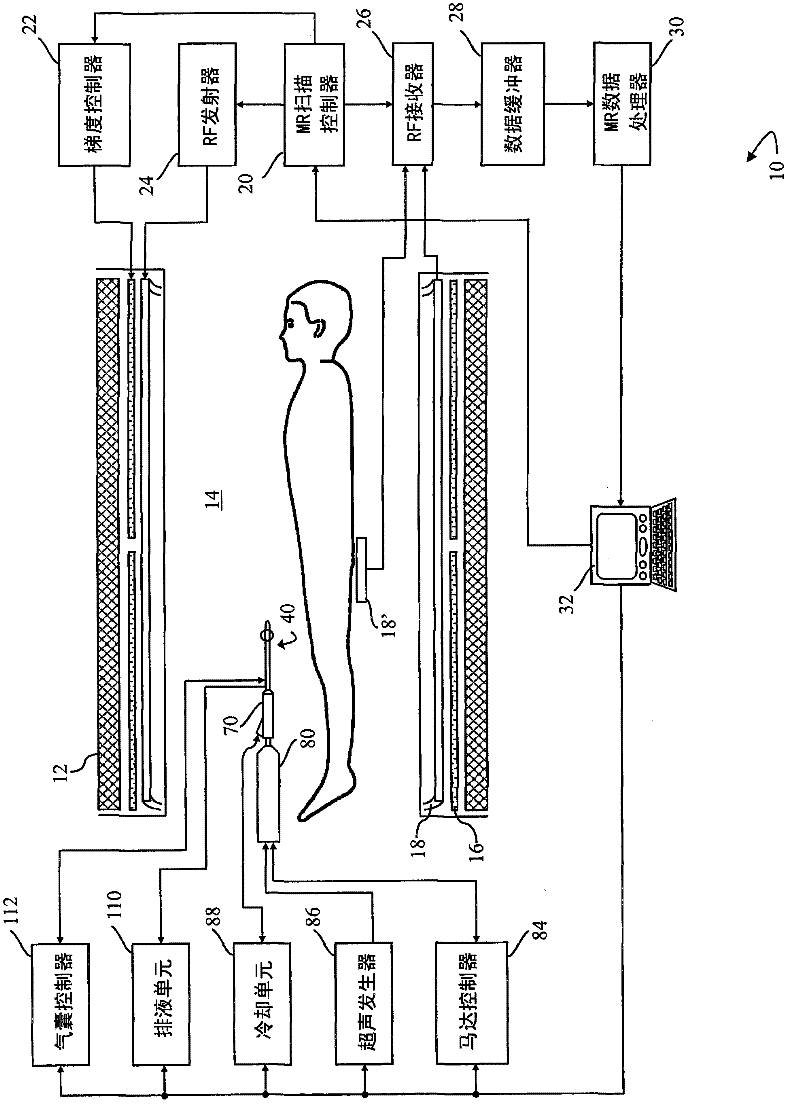

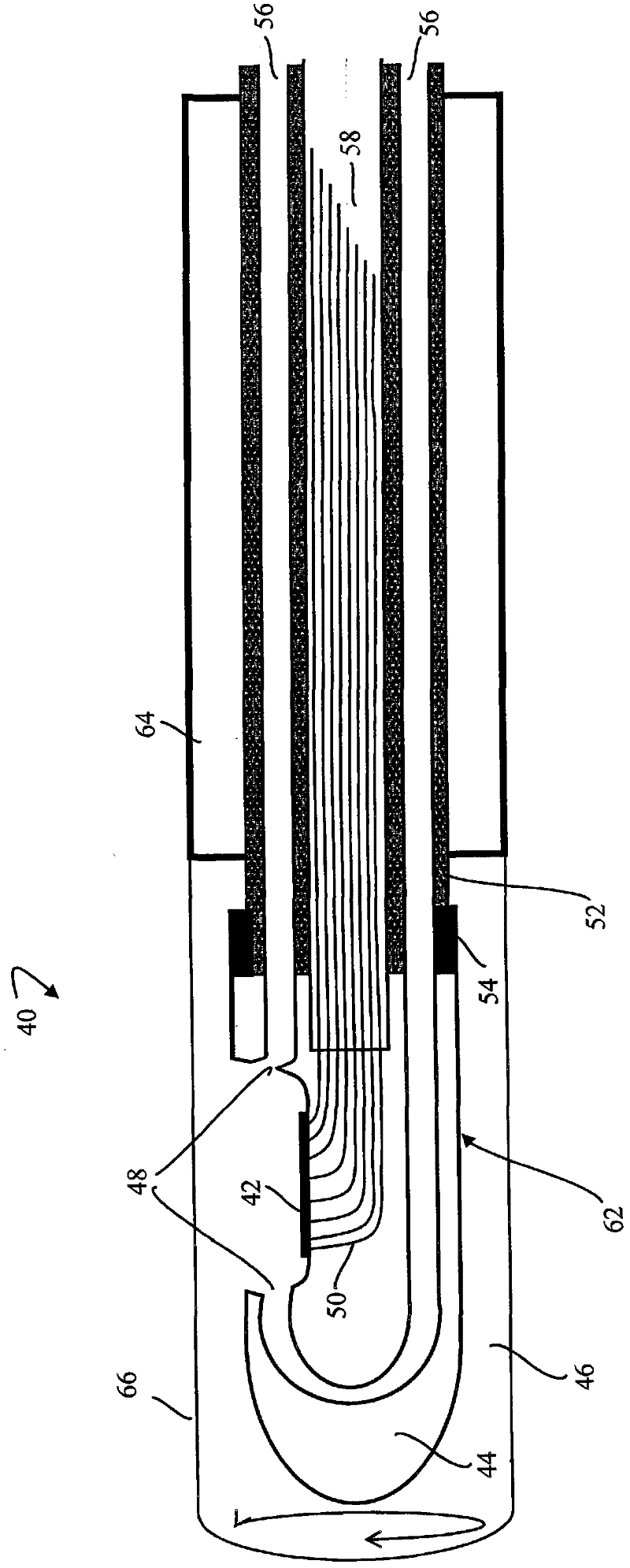

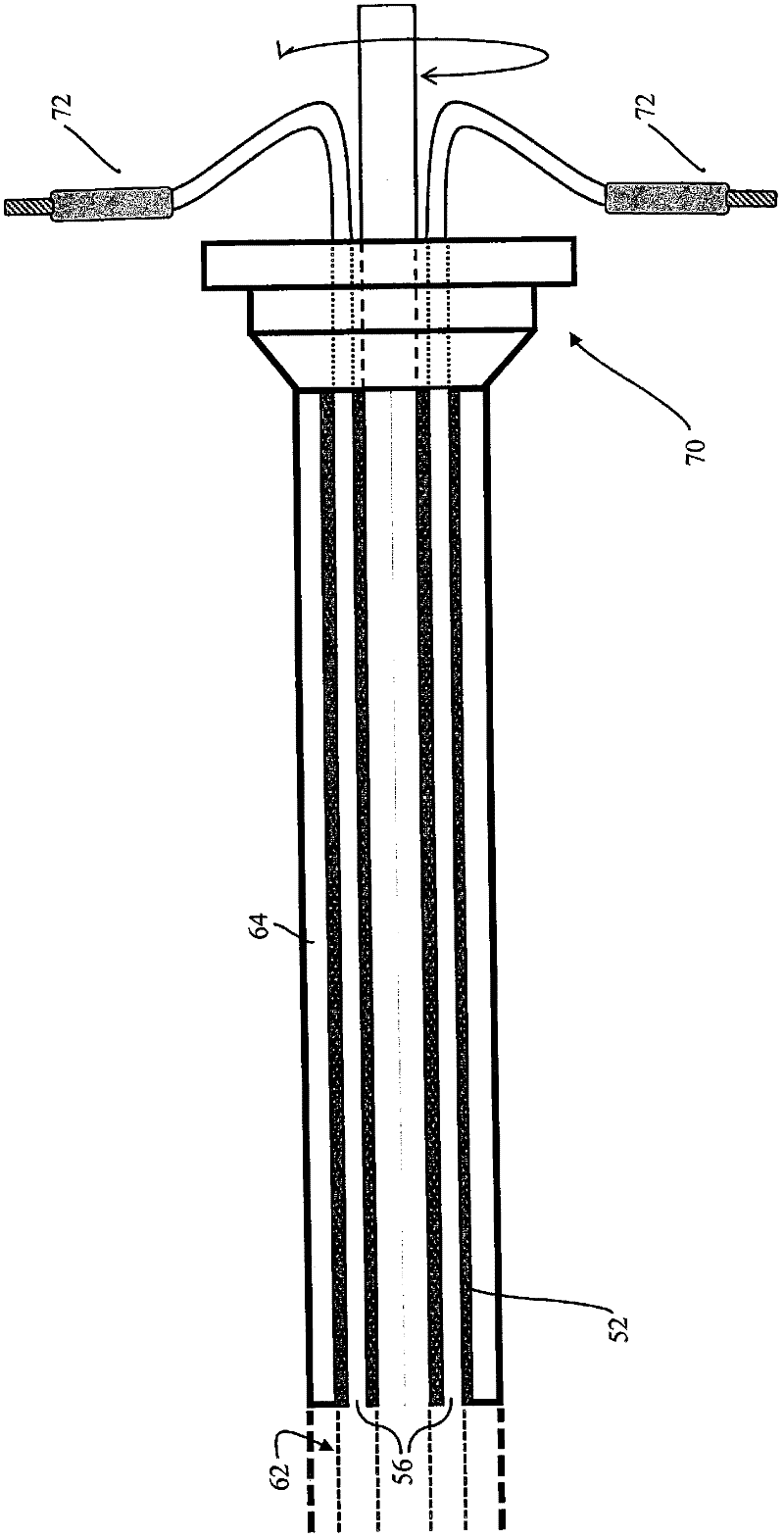

Transurethral ultrasound probe for treatment of prostate

InactiveCN102348480AReduce side effectsNo physical damageUltrasound therapyDiagnosticsAcoustic Coupling FluidUrethra

A probe (40) includes a shaft (52) on which an ultrasound element (42) is mounted. An outer sheath (64) and an acoustic membrane (66) surround the shaft and the ultrasound element such that the shaft and ultrasound element are rotatable therein. Passages (56) supply a cooling and acoustic coupling fluid to an inlet and outlet (48) adjacent the acoustic element to cool the acoustic element and fill a volume between the acoustic element and the acoustic sheath with the fluid. A balloon (90) mounted on the probe is selectively inflated in order to fix a position of the probe. A drain (94, 98) drains urine and other bodily fluids through the probe.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method for removing red spots on surface of pure gold product

The invention provides a method for removing red spots on the surface of a pure gold product. The method especially aims at recovery of the color changing part of the surface of the pure gold craft, mainly removal of red spots. The method comprises the steps that firstly, a washing solution is prepared, then the pure gold product with the color changed is put into the washing solution till the red spots disappear, and then the pure gold product is taken out, washed with deionized water and dried. The method has the advantages that the process is simple, the time for removing the red spots on the surface is short, and the surface of the pure gold product has no physical damage; and medium acid is nitric acid, the pure gold is not damaged, and the washing solution is recyclable and easy to wash away after the red spots are removed.

Owner:江苏盐城环保科技城重金属防治研究中心

Aluminium alloy electron beam welding method based on laser cleaning treatment

InactiveCN110385516ANot physically damagedNo physical damageElectron beam welding apparatusCleaning processes and apparatusMechanical propertyElectron

The invention belongs to the technical field of welding, and particularly relates to an aluminium alloy electron beam welding method based on laser cleaning treatment. A machining method is adopted, the to-be-welded face of an aluminum alloy to-be-welded test piece is machined, and the surface quality of the to-be-welded face is improved; a laser cleaning device is adopted for carrying out laser cleaning treatment on the to-be-welded face of the to-be-welded test piece, and oil contamination and non-metallic impurities of the surface of the test piece are removed; a welding clamp and a tool are used for assembling the to-be-welded test piece, and it is ensured that the welding face of the to-be-welded test piece is aligned, clamped and fixed; and an electron beam welding machine is used for welding the to-be-welded test piece. Laser cleaning is used for carrying out before-welding treatment on the material, a workpiece cannot be physically damaged, physical contact is not needed, operation is easy and convenient, and production efficiency is high. After welding, the welding line is good in forming, the welding line surface is free of defects of cracks, air holes, sinking, undercut,weld beading and the like, and welding inner quality and the normal-temperature mechanical property can meet the standard need.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

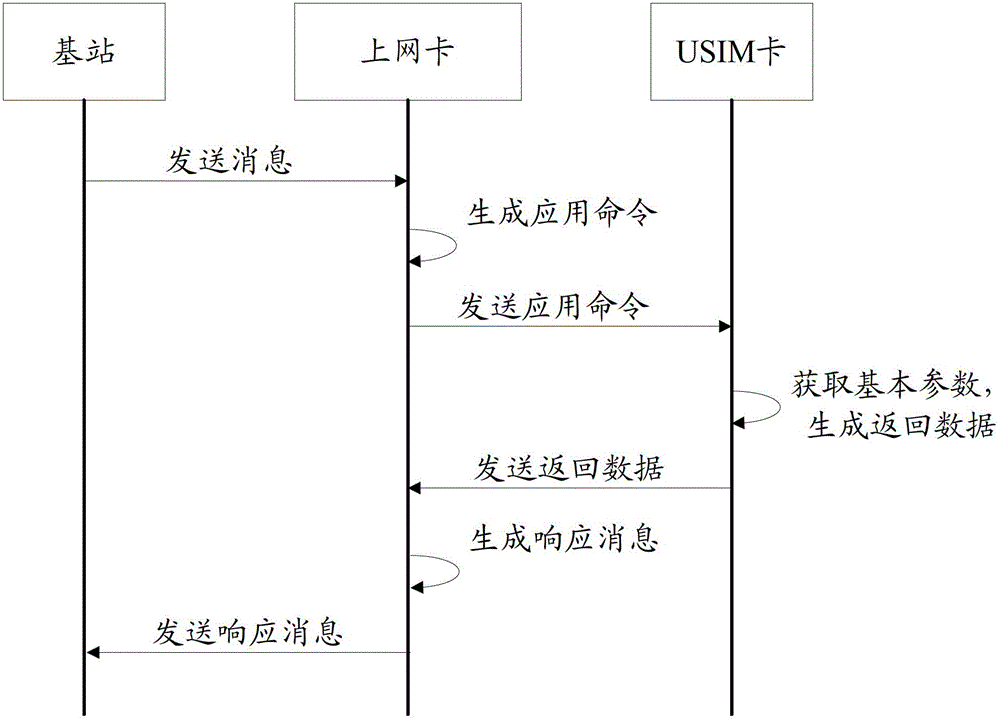

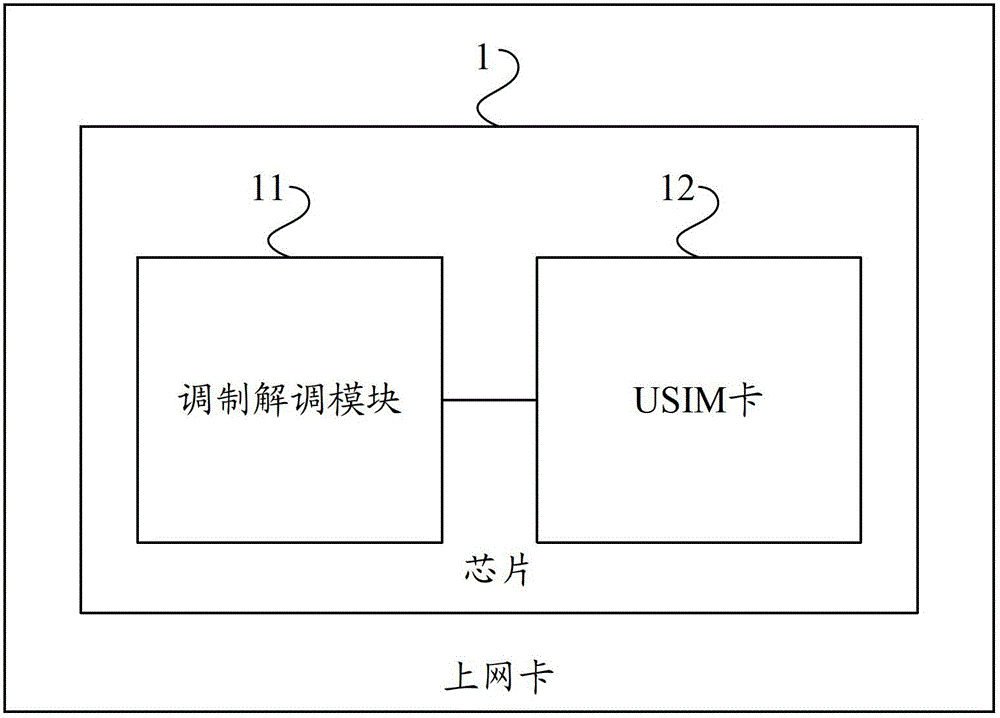

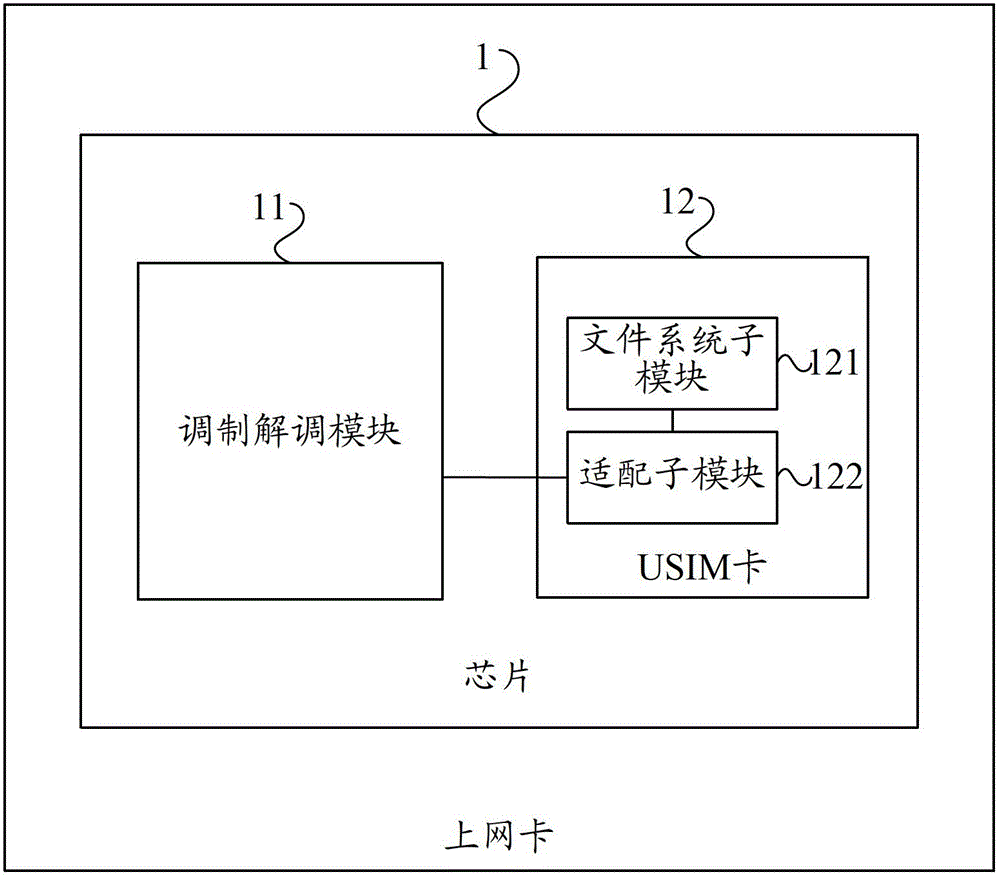

Wireless wide area network card and network accessing method of same

The invention provides a wireless wide area network card and a network accessing method of the same. The wireless wide area network card comprises a chip; a modem module and a USIM (universal subscriber identity module) card are arranged in the chip; the modem module is communicated with the USIM card mutually; and the USIM card is arranged in the chip in a software way. According to the wireless wide area network card and the network accessing method provided by the invention, no entity USIM card exists in the wireless wide area network card, thus, no physical damage of the USIM card exists in the process of adopting the wireless wide area network card to perform network accessing test, and the cost for test can be effectively reduced. Moreover, no additional processes such as packaging, and replacing USIM card exist in the network accessing test process of the wireless wide area network card, thus, the test efficiency can be effectively improved.

Owner:이노피데이인코포레이티드 +1

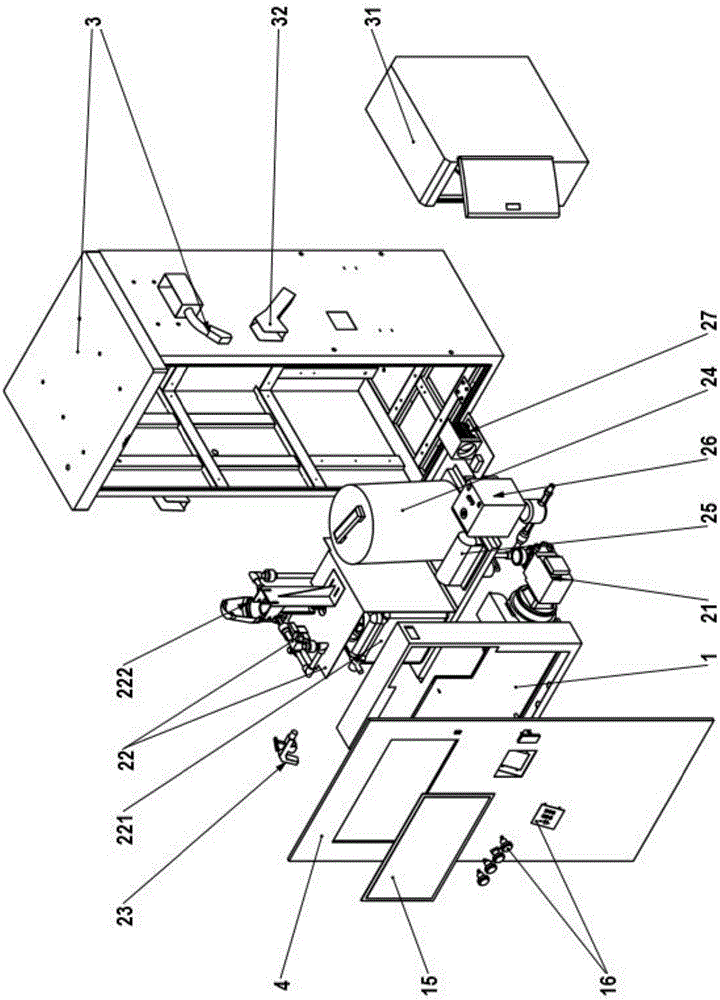

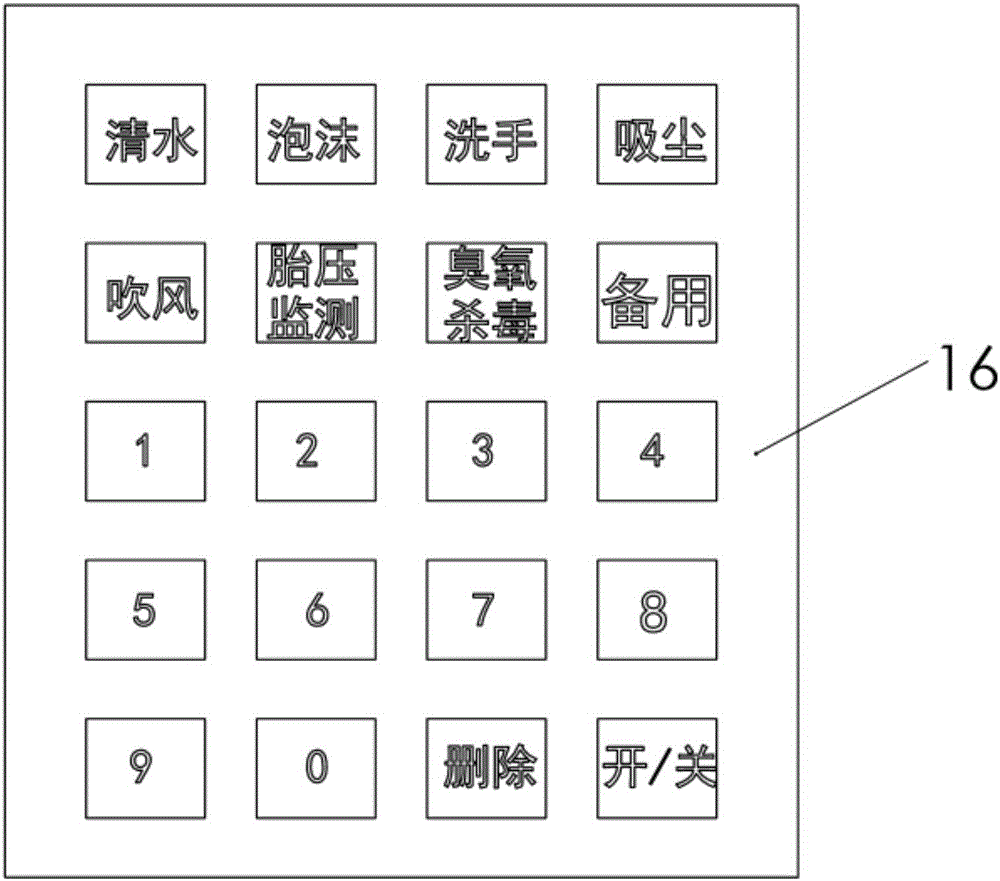

Intelligent control vehicle cleaning system based on internet communication

ActiveCN106274834AAdvanced technologyHigh degree of automationCleaning apparatus for vehicle exteriorsApparatus for meter-controlled dispensingInternet communicationWork task

The invention discloses an intelligent control vehicle cleaning system based on internet communication. The intelligent control vehicle cleaning system comprises an integrated service processing center controller (1), terminal equipment (2), a vertical cabinet frame (3) and an operation panel (4), wherein the integrated service processing center controller (1) is mounted above the back of the operation panel (4), and the terminal equipment (2) is arranged on a base in the vertical cabinet frame (3) and is combined with the operation panel (4) to constitute a whole. With the adoption of the internet communication technology, the system admits member login and registration under the control of a main program, completes various work tasks of vehicle cleaning by the aid of a keyboard, and completes statistics of member accounts, names, cleaning time and cost by the aid of a display screen. The intelligent control vehicle cleaning system based on the internet communication has the characteristics of being wide in coverage and application range, good in safety, high in reliability, green, environment-friendly and the like.

Owner:武汉一洗来环保科技有限公司

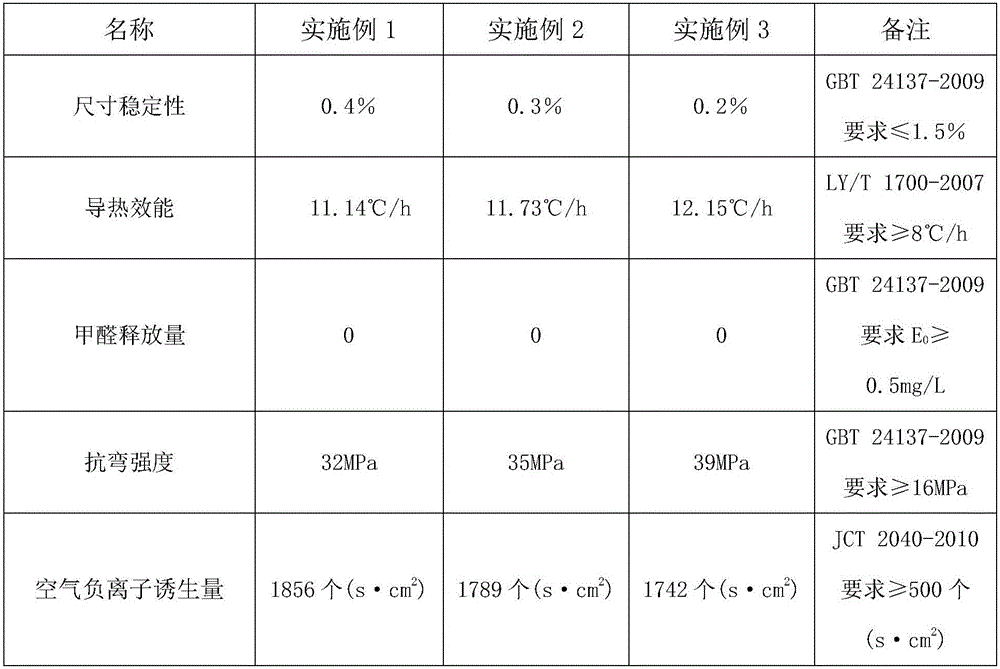

Facing bamboo plastic heat conduction wallboard with negative ions and processing method thereof

ActiveCN105754361AImprove thermal efficiencyHigh heat resistance and dimensional stabilityThermoplasticGlass fiber

The invention discloses a facing bamboo plastic heat conduction wallboard with negative ions and a processing method thereof. The facing bamboo plastic heat conduction wallboard is characterized by comprising a bamboo plastic wallboard substrate layer, a glass fiber cloth layer, and a reconsolidated bamboo veneer layer. The bamboo plastic wallboard substrate layer comprises the following components by mass: 20-25% of bamboo powder, 30-35% of a PVC and polyether block amide blend, 8-10% of nanoscale bamboo charcoal powder, 2-4% of a lubricant, 1-3% of a foaming agent, 2-3% of a coupling agent, and the balance germanite powder. The wallboard provided by the invention adopts bamboo processing waste, germanite powder, thermoplastic plastics (PVC and polyether block amide blend) as the main raw materials, and the facing bamboo plastic heat conduction wallboard with negative ions is manufactured by crushing, pretreatment, high-speed mixing, extrusion, curing, gluing, assembling compounding, cold pressing, sanding, painting, slotting and other processes. The wallboard has natural texture, high negative ions and heat conduction efficiency, and low thermal expansion coefficient, is not easy to warp, can be widely used in the field of functional wallboards, and has good market prospects.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Titanium alloy electron beam welding method based on laser cleaning treatment

InactiveCN110385517AGuaranteed to clamp and secureImprove surface qualityElectron beam welding apparatusCleaning processes and apparatusTitanium alloyMechanical property

The invention belongs to the technical field of welding, and particularly relates to a titanium alloy electron beam welding method based on laser cleaning treatment. The titanium alloy electron beam welding method based on laser cleaning treatment comprises the steps that a machining method is adopted, the faces, to be welded, of titanium alloy test parts to be welded are processed, and the surface quality of the faces to be welded is improved; a laser cleaning facility is adopted to conduct laser cleaning treatment on the faces, to be welded, of the test parts to be welded, and oil stains andnon-metallic impurities on the surfaces of the test parts are removed; welding clamps and tools are utilized to assemble the test parts to be welded, and the situation that the welded faces of the test parts to be welded align and are clamped and fixed is guaranteed; and an electron beam welding machine is utilized to weld the test parts to be welded. According to the titanium alloy electron beamwelding method based on laser cleaning treatment, the laser cleaning is utilized to conduct pre-welding treatment on materials, no physical damage to workpieces can be caused, the physical contact isnot required, the operation is easy and convenient, and the production efficiency is high. A weld joint is well formed after welding is accomplished, the surface of the weld joint is free of the defects such as cracks, pores, pits, undercutting and overlap, and the welding interior quality and the normal temperature mechanical properties can meet the standard requirements.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

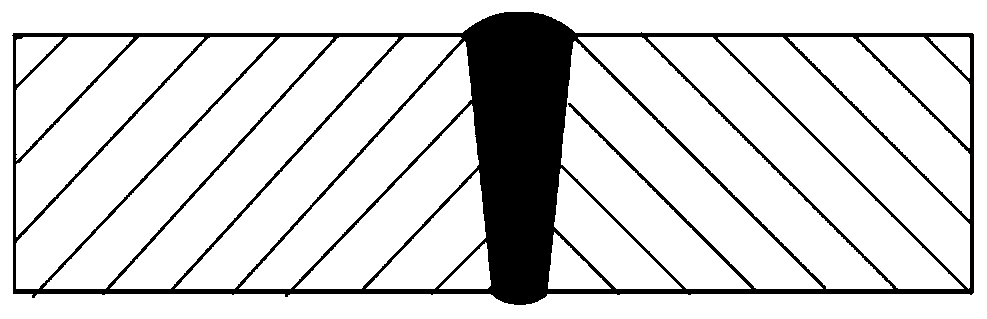

Dip-coating technology for transverse stabilizer rod

InactiveCN102989643ANo pollution in the processNo physical damagePretreated surfacesCoatingsWater basedEpoxy

The invention provides a dip-coating technology for a transverse stabilizer rod, and aims at solving the problem of environment pollution caused by the prior art. A first technical scheme is as follows: the dip-coating technology for the transverse stabilizer rod is characterized in that a treatment method of the transverse stabilizer rod sequentially comprises the following steps of: carrying out shot blasting, cleaning, carrying out epoxy water based paint dip-coating, leveling and carrying out surface drying, baking, and cooling into be up to room temperature. The epoxy water property has the advantages of being environment-friendly, free from environment pollution, non-toxic, and free from burning, and has an integrated bottom surface; and paint is high in use ratio, and simple and feasible to construct. The dip-coating technology is free from injury to human bodies of constructors, and convenient to construct, the yield can be easily improved, the time spent on a salt fog test of the dip-coating technology is longer than that spent on the existing coating level, the hardness of the paint is higher than that of the existing paint by two stages, and the impact resistance can be enhanced.

Owner:CHONGQING HONGYAN FANGDA AUTOMOBILE SUSPENSION

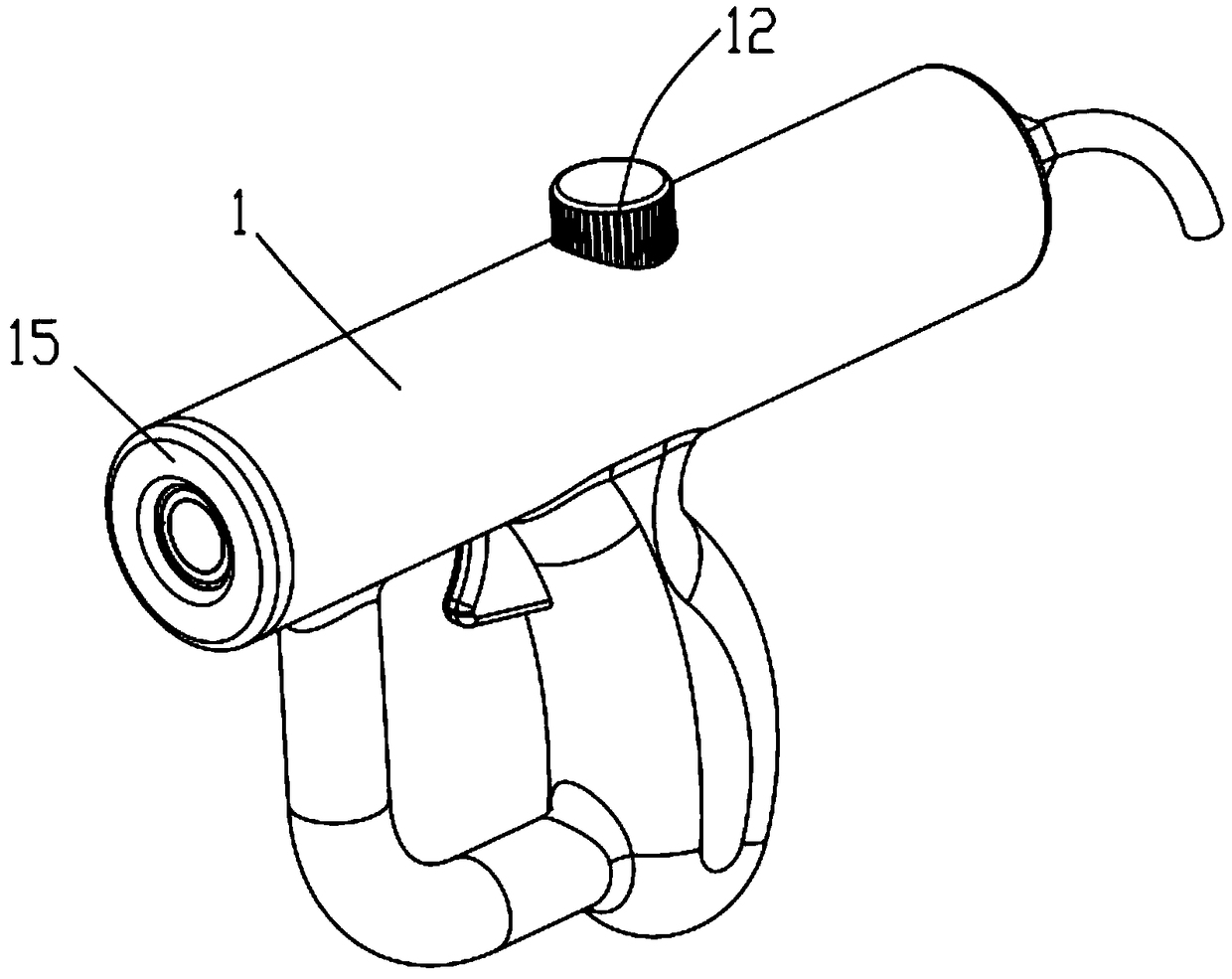

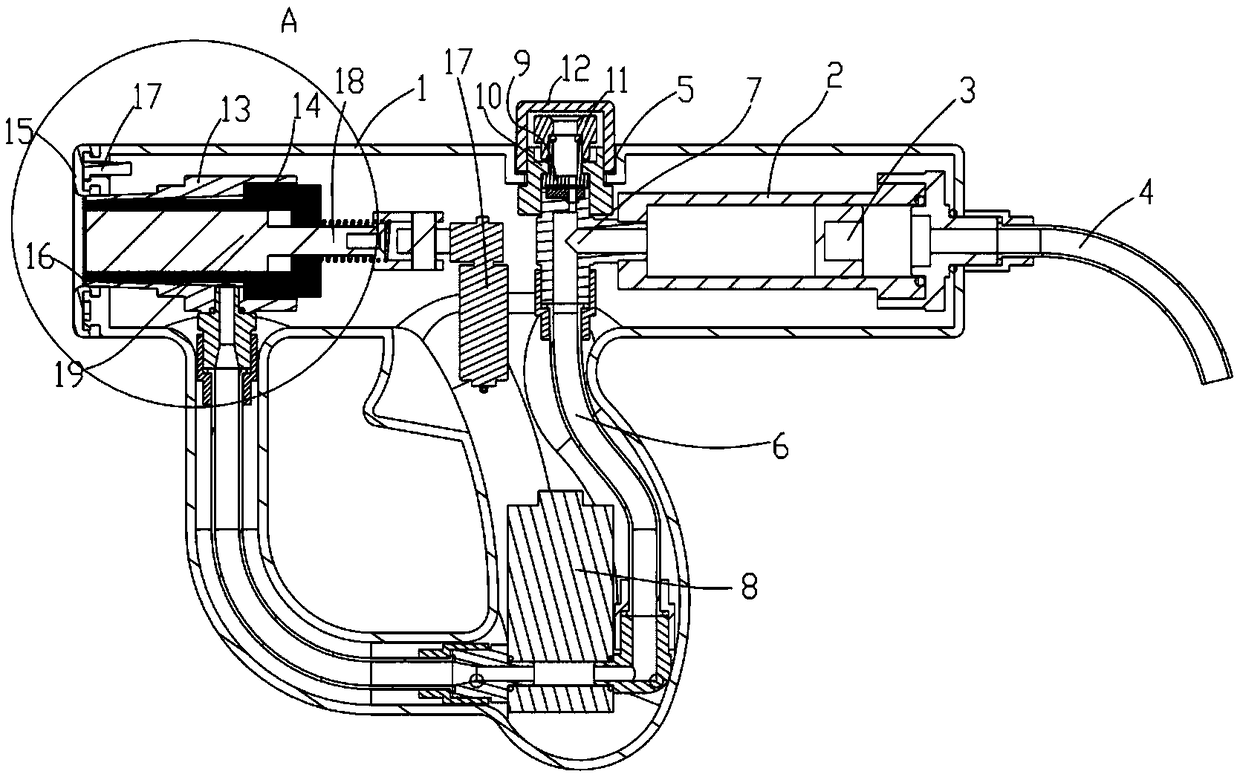

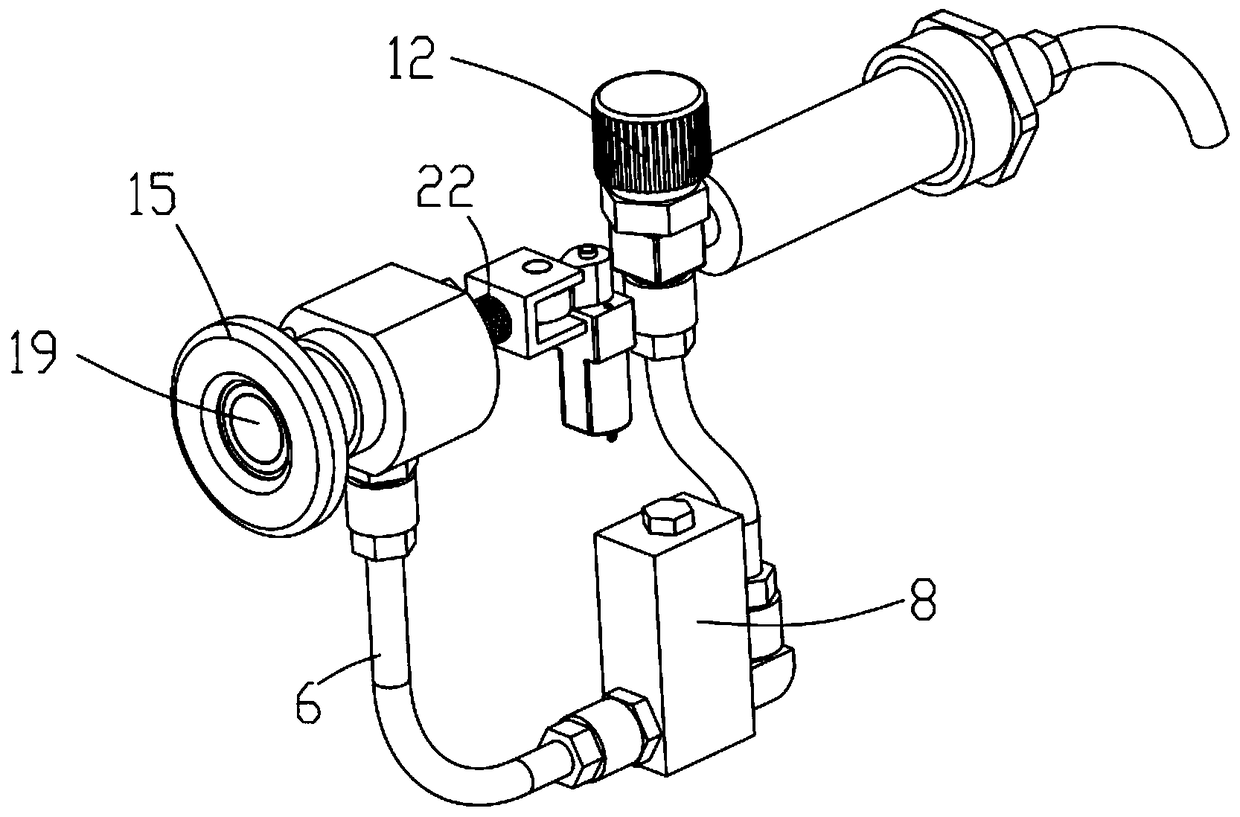

Spray gun of intensive spraying massager and intensive spraying massager

PendingCN108686300APromote absorptionImproves absorbency and comfortMedical devicesVibration massageAbsorption rateEngineering

The invention provides a spray gun of an intensive spraying massager and the intensive spraying massager. The spray gun includes a housing, and a pressurizing mechanism, a liquid inlet mechanism, a liquid outlet mechanism and a flapping mechanism are arranged in the housing; the liquid inlet mechanism is positioned in the middle of the housing and communicated with the liquid outlet mechanism; thepressurizing mechanism is positioned at the end of the housing and communicated with the liquid outlet mechanism; the flapping mechanism is positioned at the other end of the housing and used for flapping the face and stretches back and forth outside the housing. According to the spray gun, through pressurization of a high-pressure air pump, a cosmetic solution and the like are sprayed out through intensive spraying holes and directly sprayed into pores of the skin, the absorption rate of skin care products is ensured, and physical damage of the surface of the skin cannot be caused; through arrangement of flapping silica gel, flapping is conducted on the skin when the skin care products permeate into the skin, and adsorption of the skin care products is facilitated; through arrangement ofa heating sheet, the pores of the skin can be opened under moderate temperature. The intensive spraying massager is provided with a control panel, and adjustment of the temperature, the flapping frequency and the strength of intensive spraying is achieved; the intensive spraying massager is small in size and applicable to families.

Owner:瑾颜丽莎(苏州)美容科技有限公司

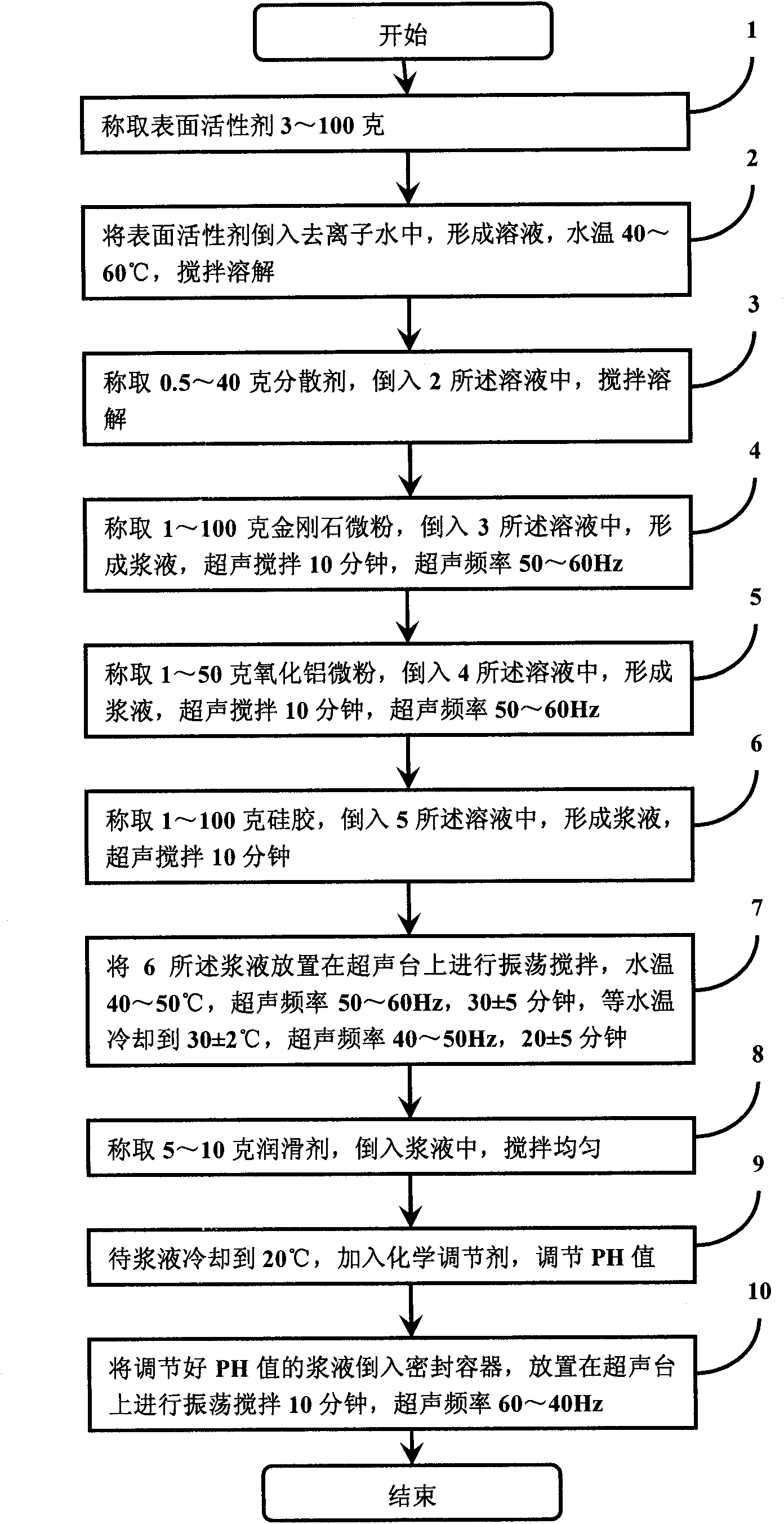

Nanometer level polishing solution and preparation method thereof

ActiveCN102311706BMeet the requirements of thinning grinding processEasy to polishPolishing compositions with abrasivesSilica gelSolvent

The invention discloses a nanometer level polishing solution and a preparation method thereof. The polishing solution is prepared from the following components in percentage by mass: 0.1 to 10 percent of monocrystal artificial diamond micro powder, 0.1 to 5 percent of aluminum oxide micro powder, 0.1 to 10 percent of silica gel, 0.3 to 10 percent of surfactant, 0.05 to 4 percent of dispersing agent, 0.5 to 1 percent of lubricant, 0.01 to 1 percent of chemical PH value regulator and 60 to 98.2 percent of solvent. The invention also discloses the preparation method for the nanometer level polishing solution. By the method, mixed serous fluid is prepared from the nanometer level diamond, the aluminum oxide and the silica gel, so an ideal polishing effect is achieved, the requirement of a process for thinning and grinding substrates (silicon carbide and sapphire) for GaN extension is met, and a technical means is provided for a polishing process for semiconductors.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

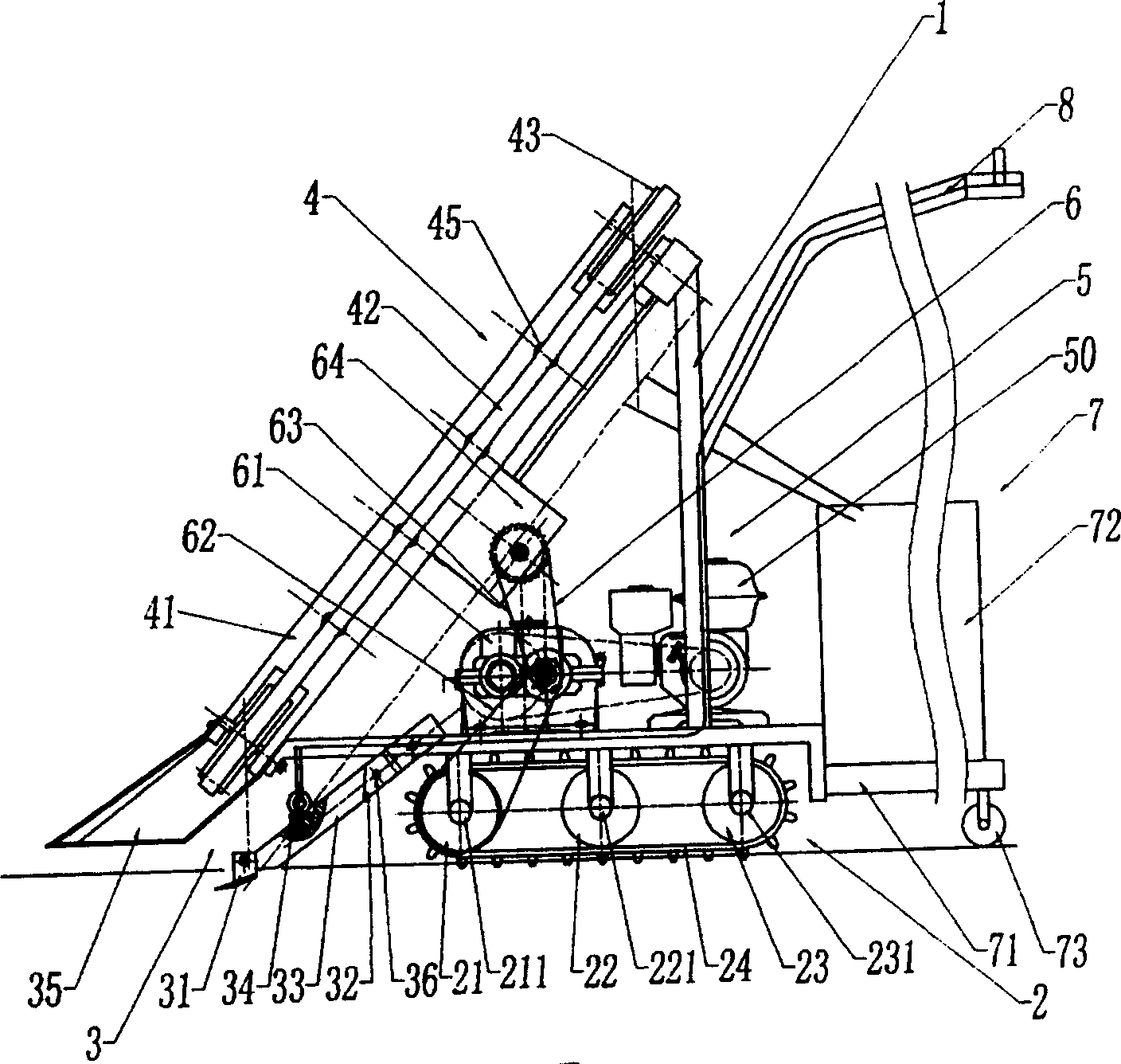

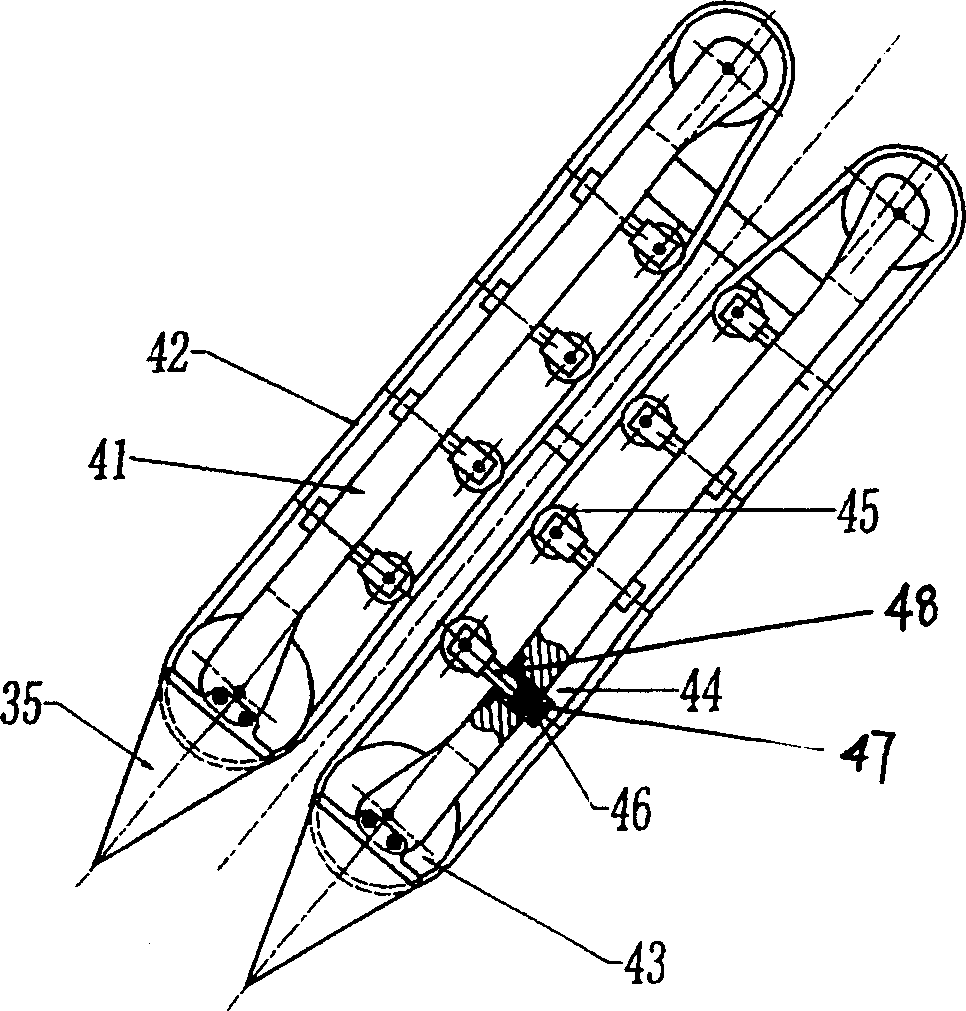

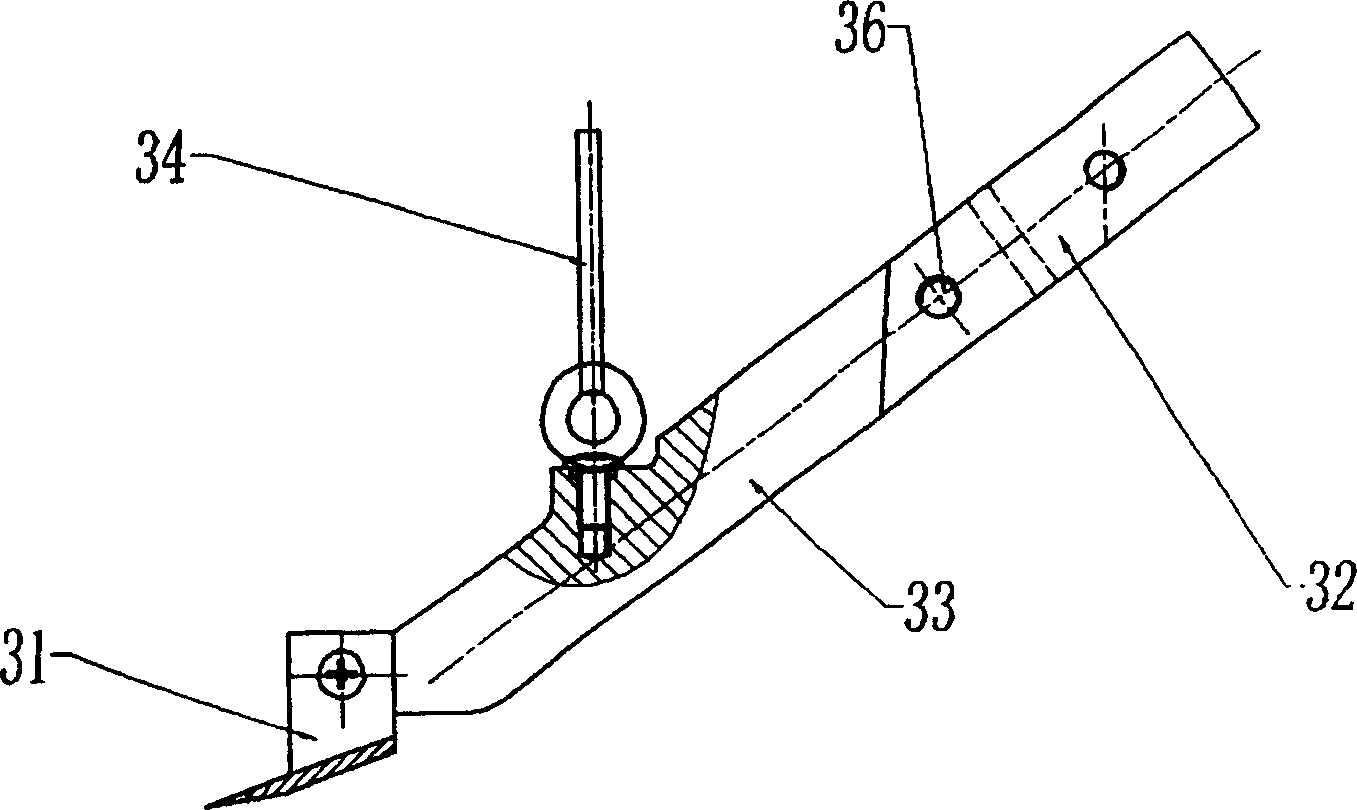

Celery harvester

The celery harvester includes frame, driving source, walking unit, cutting unit, holding and conveying unit and handle. The driving unit and the driving source are connected together and fixed successively on the bottom of the frame in the moving direction of the harvester, the walking unit is fixed below the frame, the holding and conveying unit is fixed in the front of the frame, the driving source provides the walking unit and the holding and conveying unit with driving force, the cutting unit is fixed on the frame, and the handle is connected to the cutting unit to control the height of the cutting unit. The present invention is simple, and high in work efficiency in harvesting celery.

Owner:CHINA AGRI UNIV

Traditional Chinese medicine for treating children exogenous cough and preparation method thereof

InactiveCN106309781AEasy to acceptAvoid reactionPharmaceutical delivery mechanismRespiratory disorderWestern medicineCurative effect

The invention discloses a traditional Chinese medicine for treating children exogenous cough and a preparation method thereof. The traditional Chinese medicine comprises 10-15 weight parts of fried semen brassicae, 10-12 weight parts of blackberry lily, 8-10 weight parts of corydalis tuber, 6-8 weight parts of asarum and 6-8 weight parts of liquorice. The holism of the traditional Chinese medicine is adopted by the invention for regulating body immunity function; the medicine is pasted on the specific acupoint for cough so as to treat; the children are easy to accept; the operation is convenient; the curative effect is excellent; the diseases are treated while the body is not damaged; various untoward effects and anaphylactic reactions caused by long-term use of vast antibiotics can be avoided; defects and deficiencies of the western medicine can be overcome.

Owner:刘盈盈

Vibration-proof hard disk

InactiveCN1949390ANo physical damageUndesired vibrations/sounds insulation/absorptionRecord information storageAluminiumComputer engineering

Owner:YITUO SCI & TECH CO LTD SHENZHEN

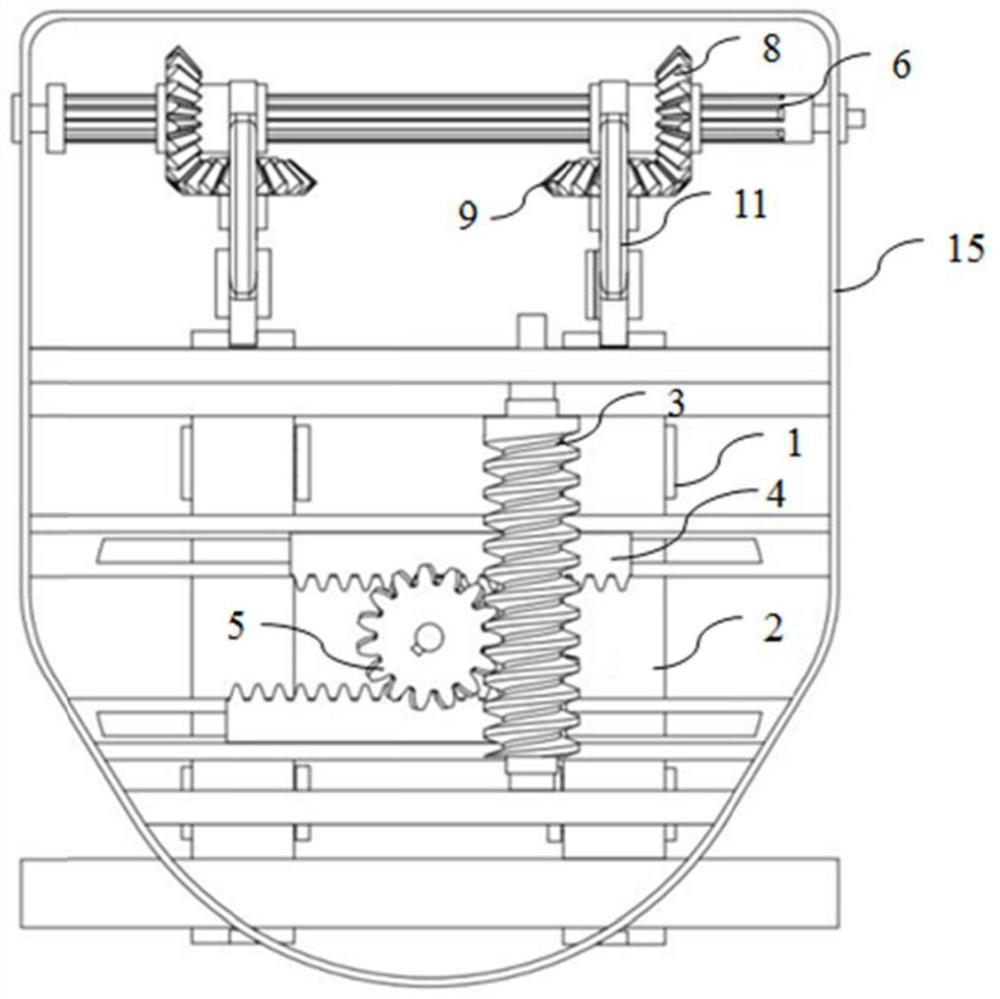

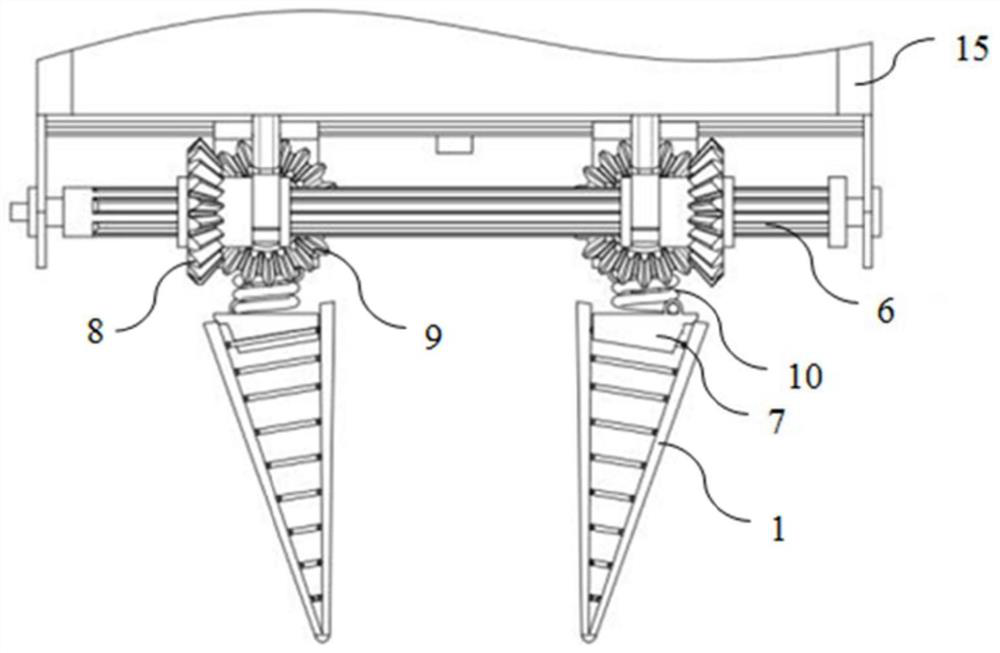

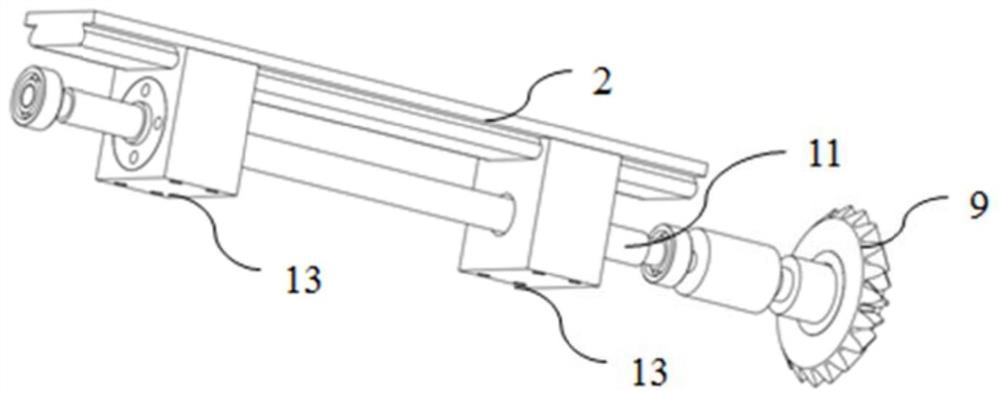

Flexible mechanical claw for teaching mechanical arm

PendingCN113635287ANo physical damageGood grabbing effectProgramme-controlled manipulatorGripping headsGear wheelElectric machinery

The invention discloses a flexible mechanical claw for a teaching mechanical arm, and belongs to the field of mechanical claws. A main body part comprises a fin-shaped flexible claw head, a claw head mounting base, a transverse moving module, a longitudinal moving module and a synchronous driving module. The fin-shaped flexible claw head is of a fin-shaped flexible structure, the whole mechanical claw can be driven by a motor to move in the transverse direction and the longitudinal direction, the functions of tightening and loosening of the mechanical claws in each group at the same time are achieved through a sliding gear, passive adaptive rotation is conducted through a torsion spring, and therefore self-adaptive grabbing of various types of objects can be achieved. According to the whole structure, the structural characteristics of the fin-shaped effect are fully exerted, and the flexible mechanical claw has the advantages of being high in adaptability, good in object enveloping effect, free of damage to grabbed objects and the like, and high in practicability.

Owner:ZHEJIANG UNIV

Preparing method for sapphire touch screen panel

InactiveCN105171583ANot suitable for chippingIncrease productivityPolishing machinesLapping machinesPrinting inkIngot

The invention relates to a preparing method for a sapphire touch screen panel. The preparing method comprises the specific steps of crystal growing, crystal ingot drawing, crystal cutting, laser sheet taking, grinding, chamfering, annealing, double-sided polishing, printing ink coating, heat baking and other procedures. According to the preparing method for the sapphire touch screen panel, the sheet forming quality is high, the rejection rate is low, and the production efficiency is high.

Owner:江苏苏创光学器材有限公司

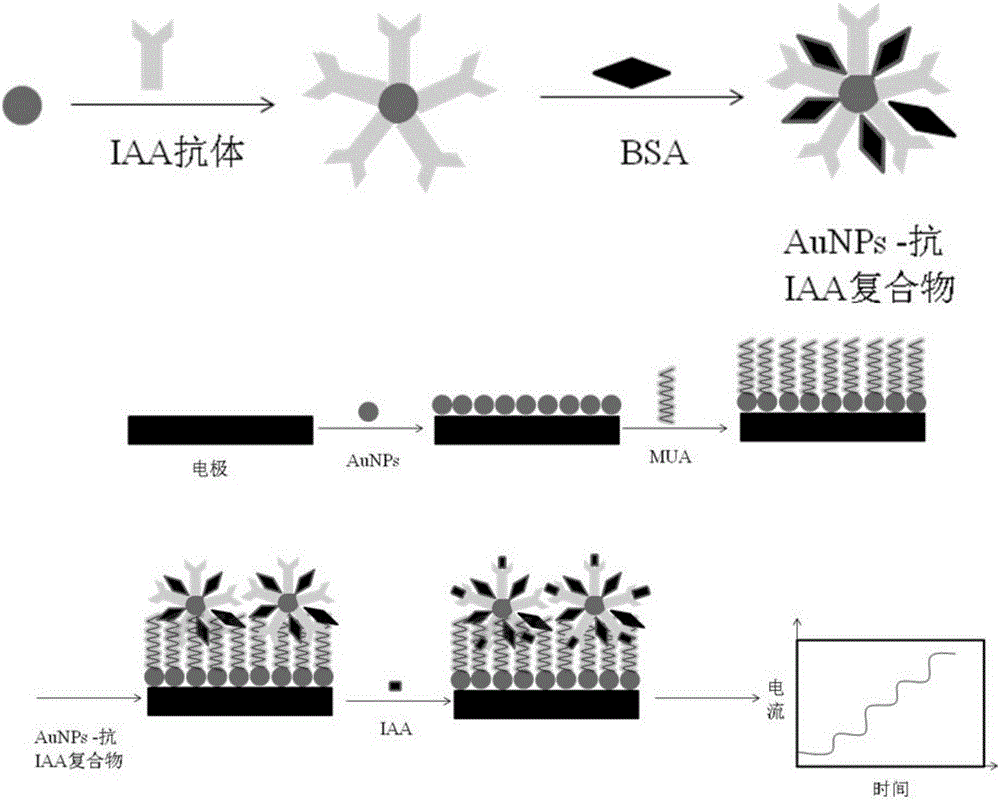

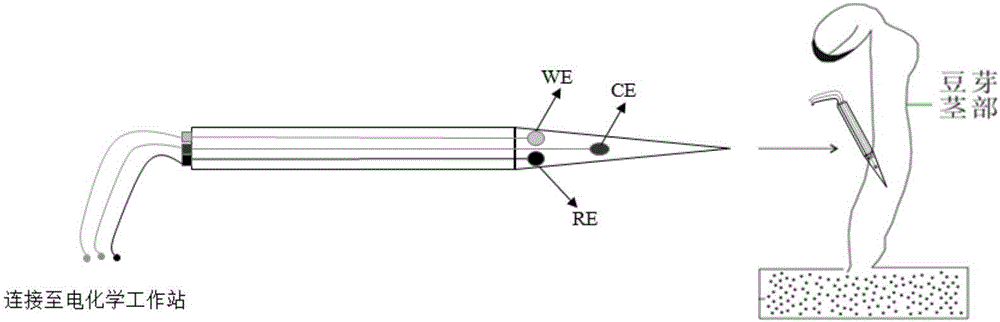

Microelectrode biosensor for online detection of IAA (auxin) in living plant and application of microelectrode biosensor

InactiveCN106404865ARealize highly sensitive detectionNo physical damageMaterial electrochemical variablesLiving systemsPlatinum

The invention relates to a microelectrode biosensing technology, and particularly discloses a microelectrode biosensor for online detection of IAA (auxin) in a living plant. The microelectrode biosensor is characterized in that the specific recognition on the IAA is performed through an IAA-modified antibody on a gold (or platinum) working electrode, and the highly sensitive detection of the IAA is performed through AuNPs (gold nanoparticles) and modified IAA-AuNPs compounds deposited on the electrode. The microelectrode biosensor disclosed by the invention has the advantages that dynamic change information of the IAA in a plant body is mastered in situ and in real time by means of continuously monitoring the IAA in the living plant online, the metabolic process of the IAA is understood, and a theoretical basis is provided for understanding the participation of the IAA in the regulation mechanism of a plant living system; the IAA in the living plant can be continuously monitored online by utilization of the microelectrode biosensor disclosed by the invention, and a to-be-detected specimen is prevented from being essentially damaged; an obtained data result can dynamically reflect the IAA content change in the plant body in real time, and the actual application operation is simple and convenient and is easy to master.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

Preparation method of sapphire fingerprint identification panel

InactiveCN105160286ANot suitable for chippingIncrease productivityPrint image acquisitionRejection rateCrystal growth

The invention relates to a preparation method of a sapphire fingerprint identification panel, which specifically comprises the working procedures of crystal growth, crystal extracting, crystal cutting, laser slice taking, grinding, chamfering, annealing, double-sided polishing, film coating, ink printing, baking and the like. The preparation method of the sapphire fingerprint identification panel is high in slice forming quality, low in rejection rate and high in production efficiency.

Owner:江苏苏创光学器材有限公司

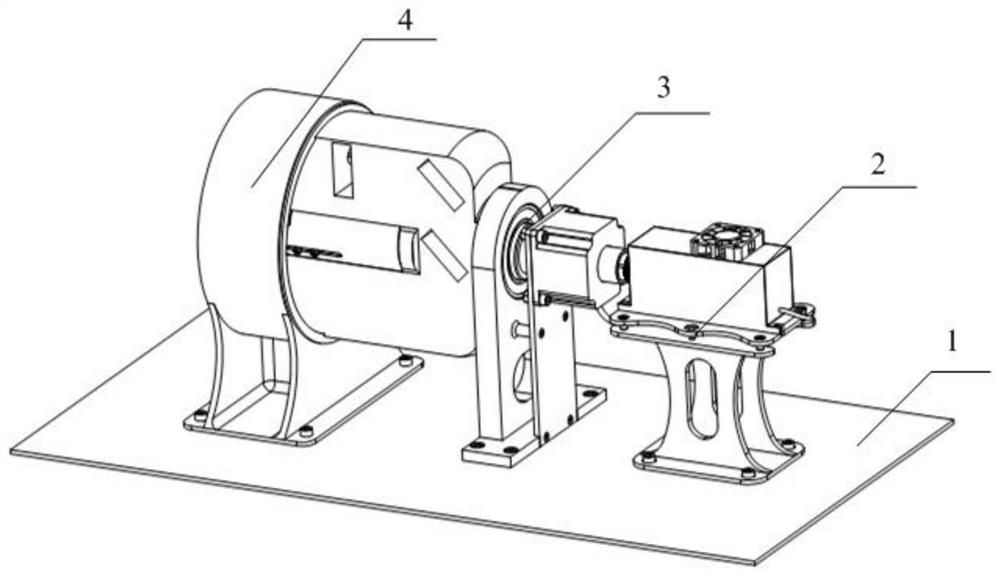

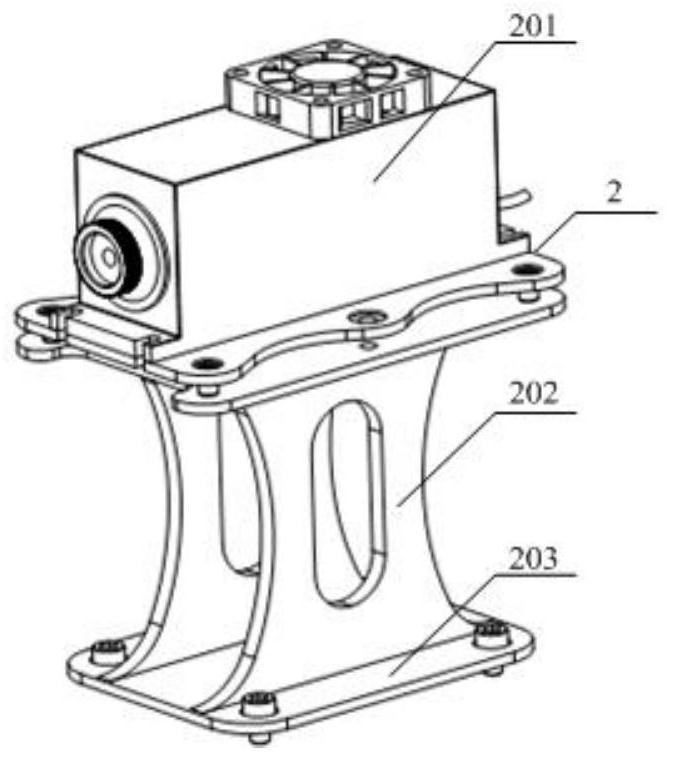

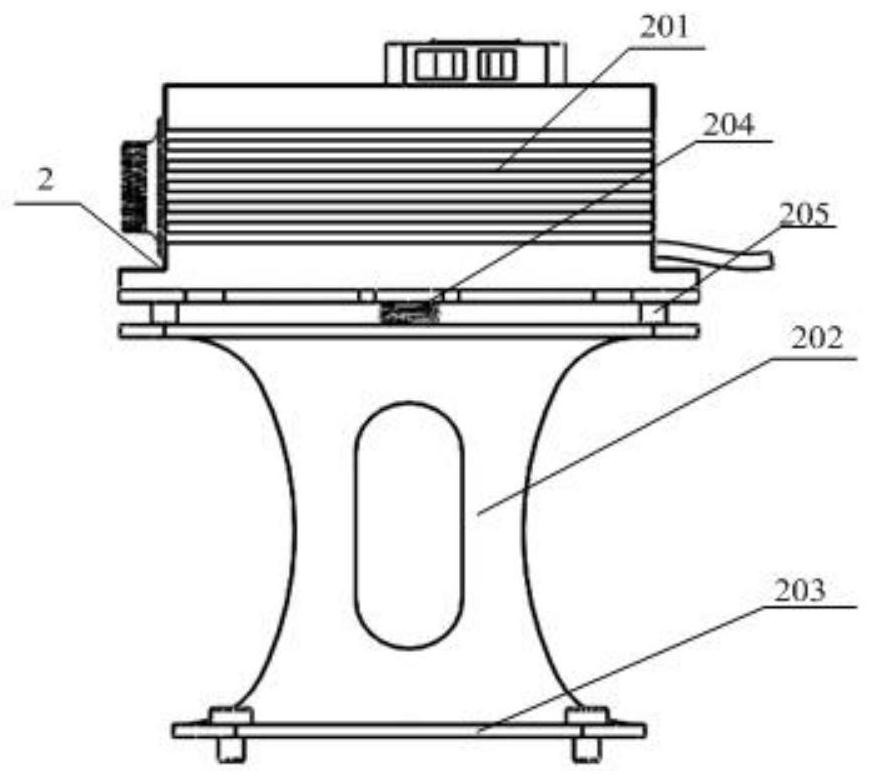

Aviation wire harness end laser processing equipment

ActiveCN112164961AEfficient processingRealize processingLine/current collector detailsApparatus for removing/armouring cablesAviationLaser processing

The invention provides an aviation wire harness end laser processing equipment, and relates to the field of aviation wire harness processing. The equipment comprises a bottom plate, a wire clamping mechanism, a rotating mechanism, a laser mechanism and an optical system arranged in the rotating mechanism, wherein the wire clamping mechanism, the rotating mechanism, and the laser mechanism are arranged on the bottom plate in sequence. Laser is adopted for machining the aviation wire harness end, an optical system is driven by a rotating mechanism to surround a machined aviation wire harness byone circle mainly based on a nanosecond short-pulse laser with the wavelength of 405 nm, and high-precision and high-efficiency aviation wire harness end machining serves as the target. And the processing of wire stripping, windowing, longitudinal cutting, regional evaporation ablation and the like of the aviation wire harness end is realized. According to the invention, the wire taking PTFE and PVC as insulating materials is taken as a processed material, the processing time is less than 5s, the fixed-length precision is not more than 0.2 mm, the processing length is 3-30mm, and the wire coreV is physically damaged, so that the equipment is compact in structure, reliable in processing quality, high in processing efficiency, high in processing precision, small in occupied space and convenient to move.

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com