Nanometer level polishing solution and preparation method thereof

A polishing liquid and nano-level technology, applied in polishing compositions containing abrasives, etc., can solve the problems of difficult dispersion performance processing, insufficient performance, loss of nano-diamonds, etc., and achieve small overall size deformation and complete wafer structure. , easy to store effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

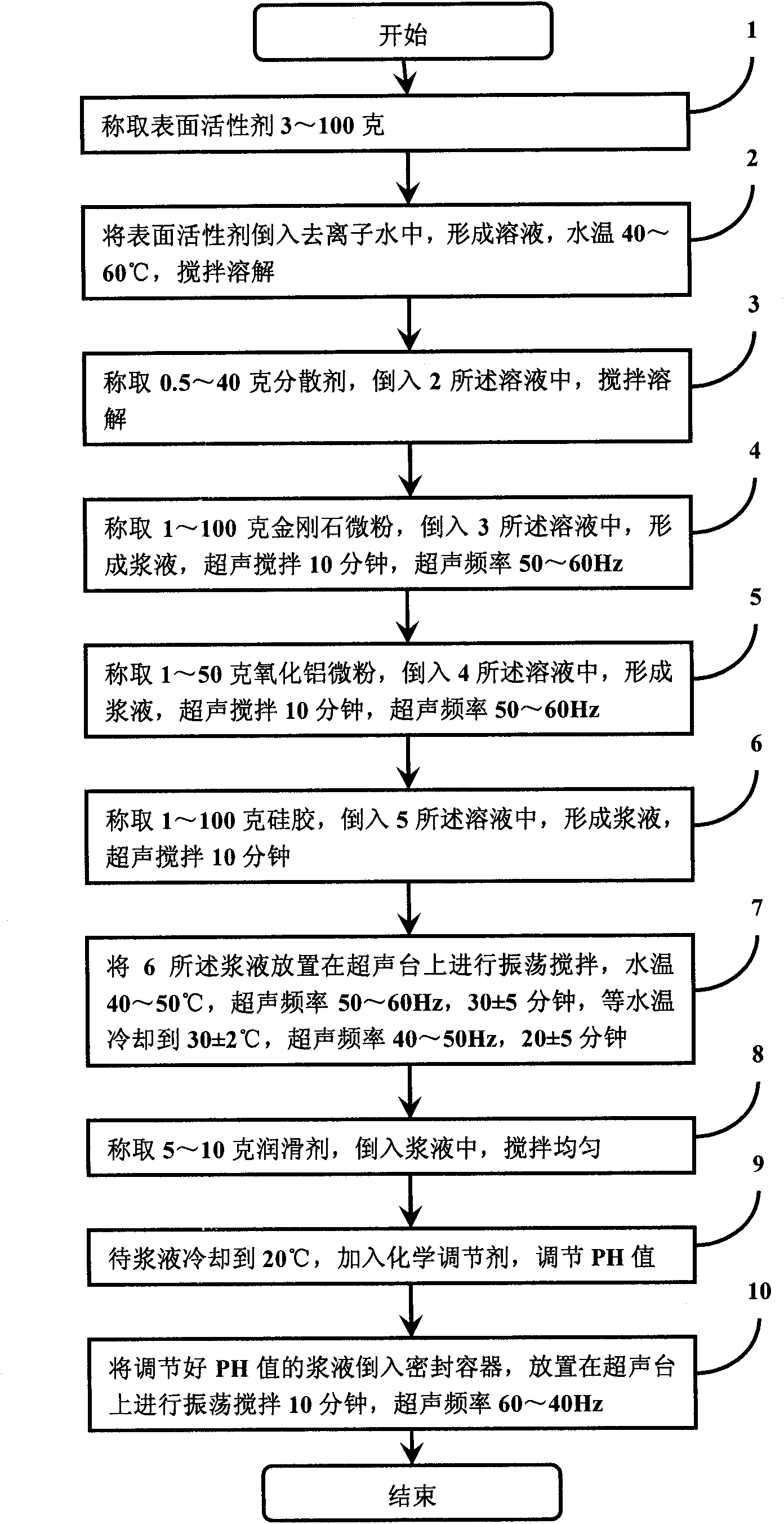

Image

Examples

Embodiment Construction

[0038] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

[0039] When the thinning process enters the polishing stage, a synthetic disk with a soft texture and good elasticity coefficient should be used, such as a tin disk, an antimony disk, a resin disk, etc., and a polishing liquid that matches with it should be used.

[0040] The nano-grade polishing liquid provided by the present invention adopts the following components: (1) Diamond powder: particle size of 30nm~500nm; (2) Alumina powder: particle size of 30nm~1μm; (3) Silica gel (silica hydrate) : Particle size 30nm~1μm; (4) Surfactant: sodium dodecylbenzene sulfonate / sodium lauryl sulfate / maleic anhydride mixture; (5) Dispersant: sodium silicate / sodium hypochlorite / Sodium pyrophosphate mixture; (6) Lubricant: polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com