Dip-coating technology for transverse stabilizer rod

A technology of horizontal stabilizer bar and process, which is applied in the direction of coating, liquid coating device on the surface, pretreatment surface, etc., which can solve environmental pollution and other problems, and achieve the effects of convenient construction, enhanced anti-collision ability, and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The dip coating process of the stabilizer bar in this implementation is as follows

[0012] 1. Process flow:

[0013] Shot blasting → cleaning and dust removal (mainly to remove dust generated during shot blasting) → dip coating (2 minutes) → leveling surface dry (≥ 40 minutes) → baking (50 minutes) → cooling to room temperature → touch-up paint (use Self-drying paint) → inspection → packaging and storage

[0014] 2. Process requirements:

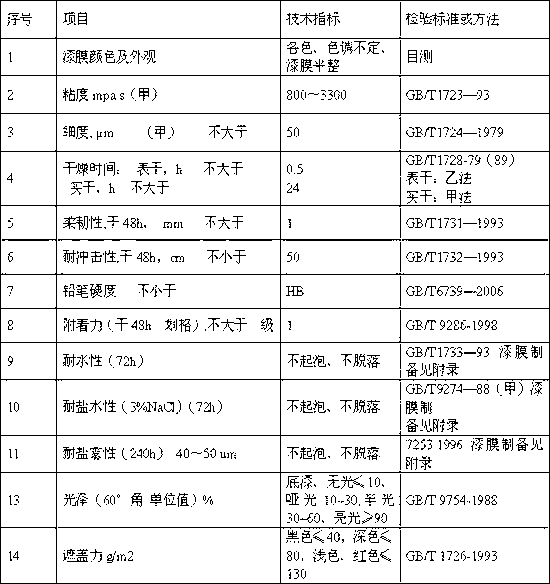

[0015] 1. Paint film thickness: ≥30μm; impact strength: ≥50cm; hardness: ≥2H; salt spray resistance ≥168;

[0016] 2. Coating Appearance: The coating color conforms to the standard template. The appearance of the paint film should be uniform, and slight flow marks are allowed;

[0017] 3. The product is required to be free from the following defects: lack of paint, exposed bottom, poor coverage, blistering, peeling, rust, cracks, pinholes, obvious flow marks, obvious orange peel; before dipping, the product surface is not allowed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com