Aluminium alloy electron beam welding method based on laser cleaning treatment

A technology of electron beam welding and laser cleaning, which is applied to electron beam welding equipment, cleaning methods and utensils, welding equipment, etc., to achieve the effects of simple operation, good welding seam formation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

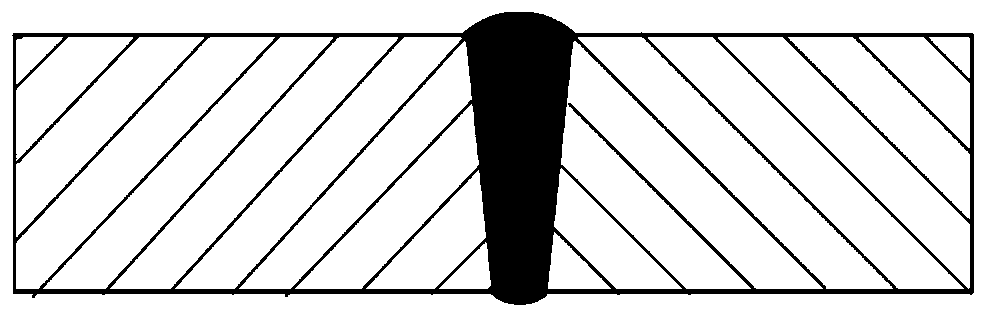

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] This embodiment proposes a 5A06 aluminum alloy electron beam welding method based on laser cleaning treatment. The specification of the 5A06 aluminum alloy electron beam welding test piece is 300mm×100mm×1.5mm. The electron beam welding method includes the following steps:

[0032] S1. Welding surface treatment: use mechanical processing methods to process the surface to be welded of the test piece to be welded to ensure that the maximum allowable value of the surface roughness Ra is 3.2 μm, and the butt joint surface is smooth, clean, burr-free, and maintain edges and corners;

[0033] S2. Pre-welding preparation: Laser cleaning the surface to be welded and the surrounding 20mm area of the test piece to remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com