Device for cleaning contact lenses

A technology for contact lenses and placement parts, which is applied in the directions of glasses/protective glasses, glasses/goggles, optics, etc., can solve problems such as eye and body injury, affecting health, etc., and achieves low cost, simplified components, and good waterproof effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

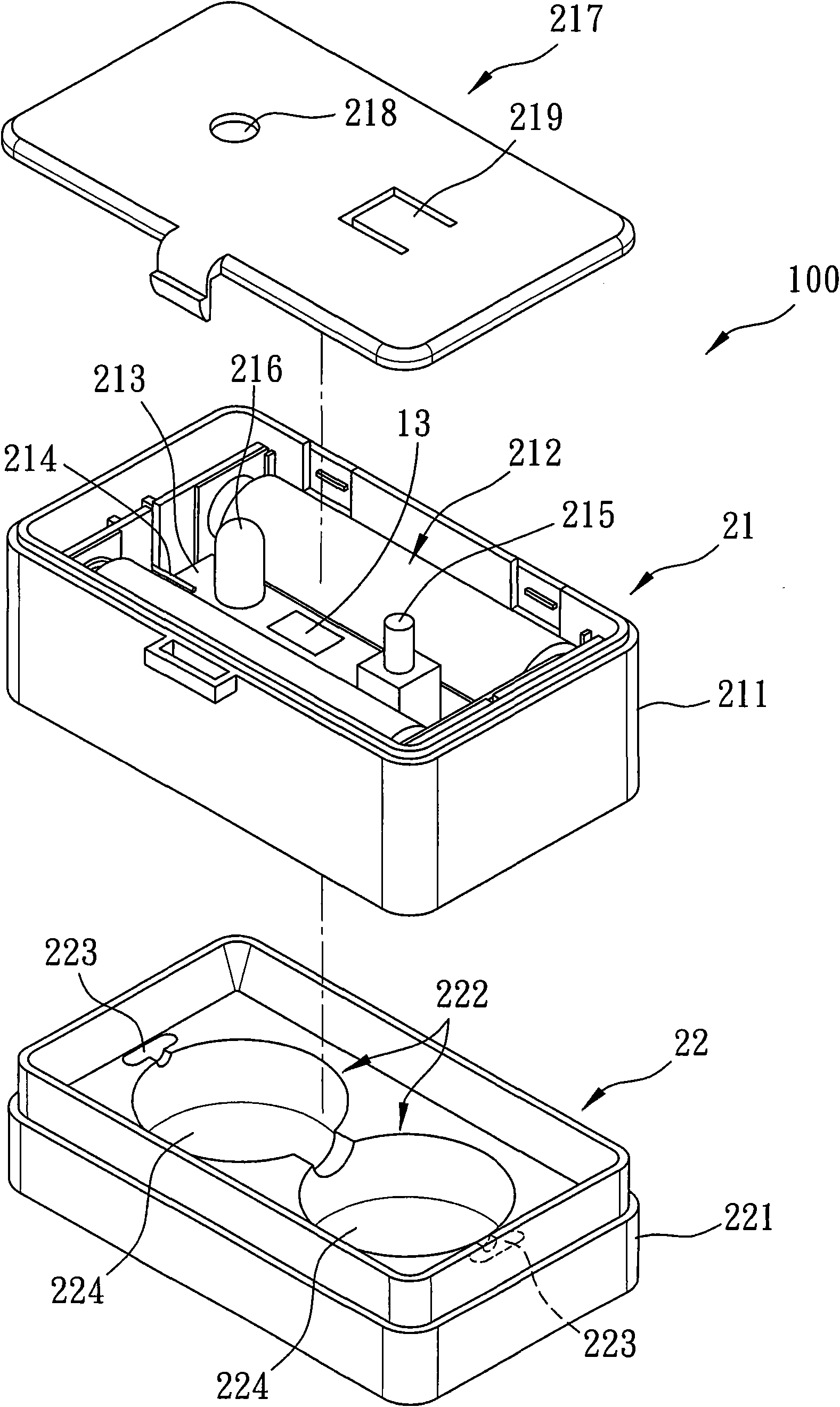

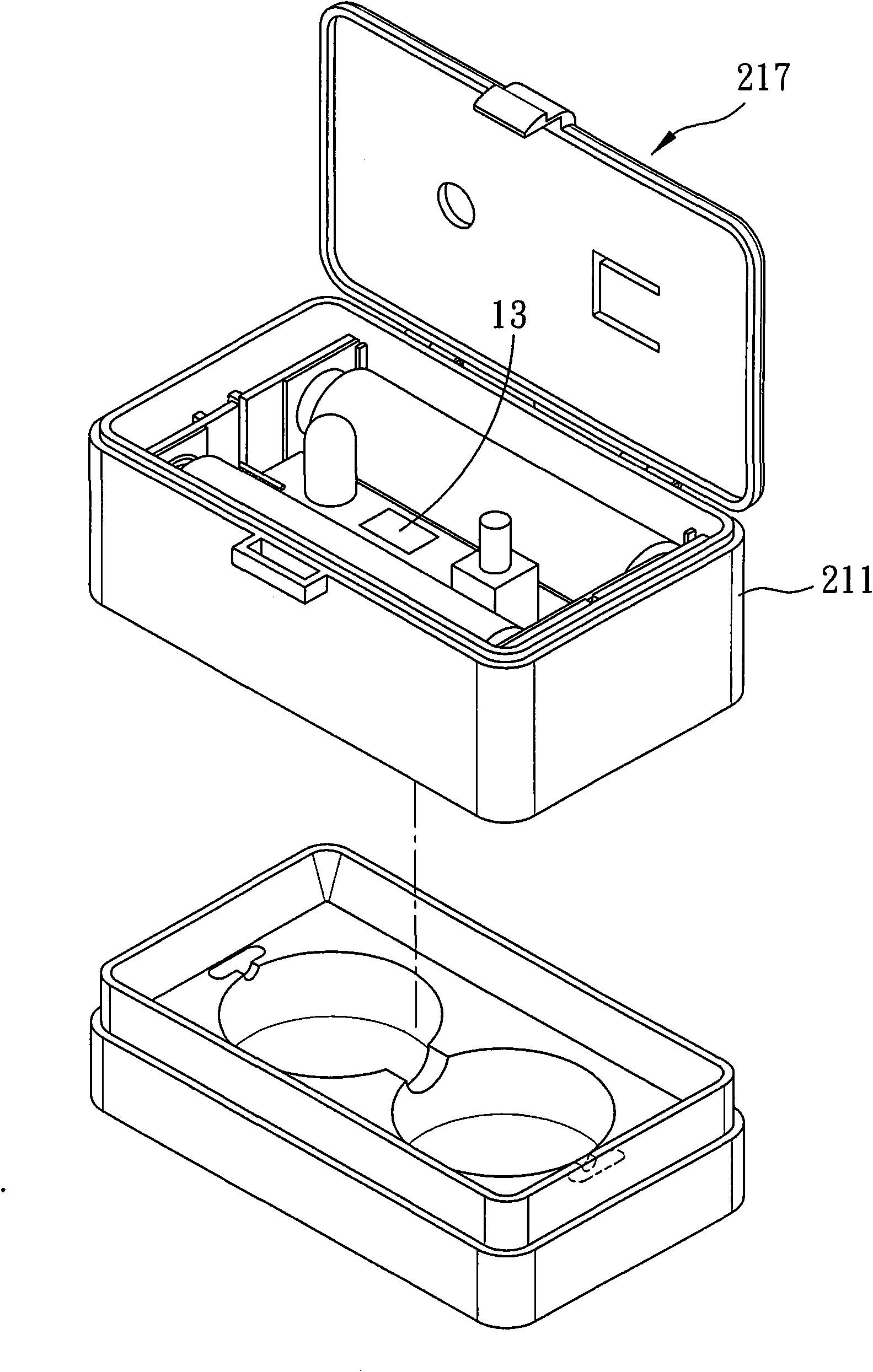

[0044] refer to figure 1 , is the first preferred embodiment of the contact lens cleaning device of the present invention, used for pouring a cleaning agent to clean the contact lens, the contact lens cleaning device 100 includes a cleaning unit 22 and a cleaning unit 22 above The control unit 21. In this example, a detergent containing protease was used.

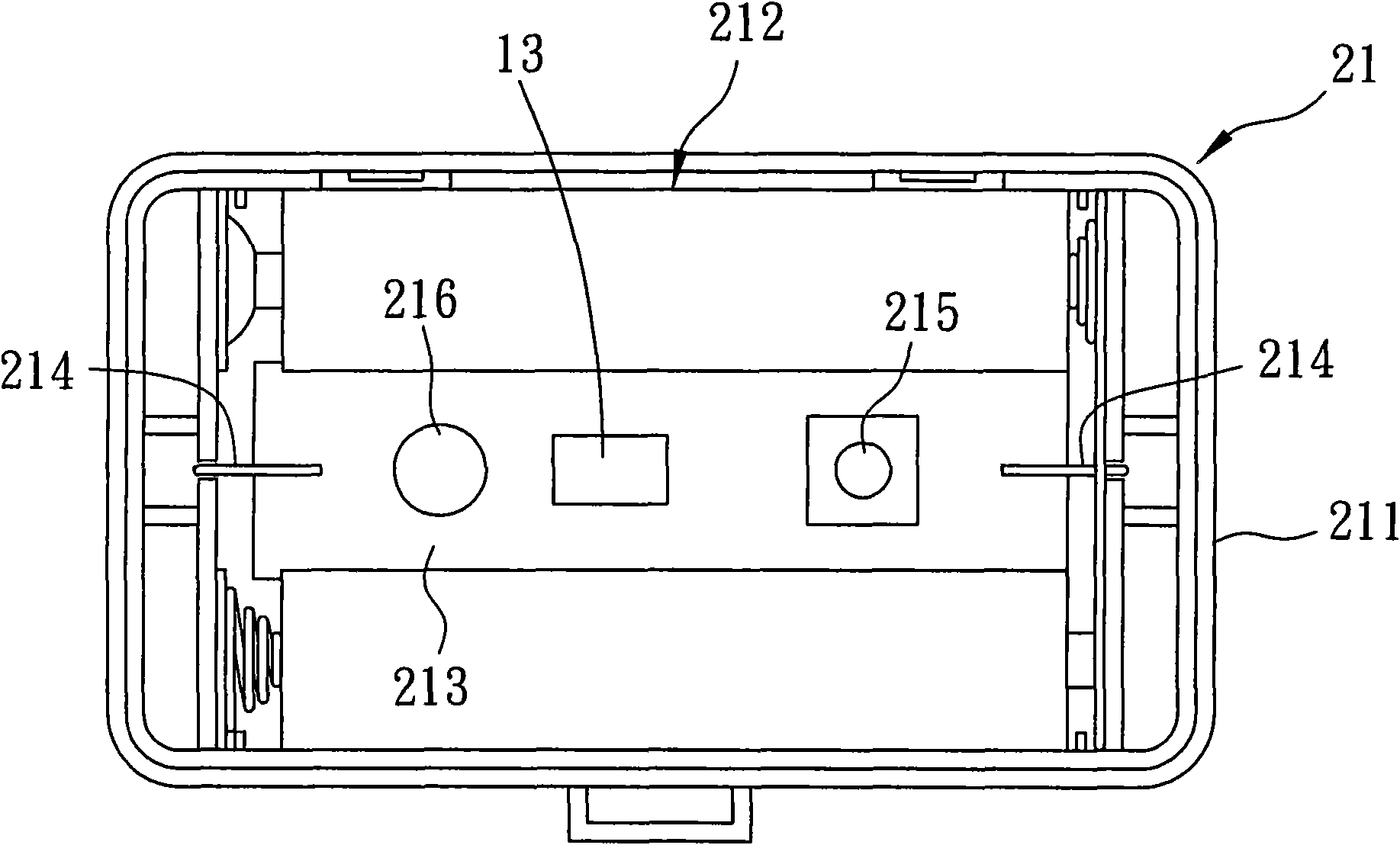

[0045] refer to figure 1 and figure 2 The control unit 21 includes a housing 211, a power supply 212 disposed in the housing 211, a circuit board 213 disposed in the housing 211 and electrically connected to the power supply 212, two electrically connected to the The conductive member 214 of the circuit board 213 (in figure 1 Only one is shown in the figure), an electric starter 215 electrically connected to the circuit board 213 and used to activate the conductive member 214, an operation in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com