Activating agent for flotation of copper-nickel sulfide ores

A copper-nickel sulfide ore and activator technology, applied in flotation, solid separation, etc., can solve the problems of lower concentrate grade and lower sorting effect, achieve environmental protection, improve flotation recovery rate, grade, and raw materials Inexpensive and easy to get effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

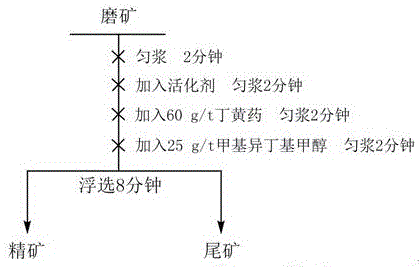

[0028] The experiment adopts open circuit flotation, and the flotation process is as follows: figure 1 shown. The ore used in the experiment is Jinchuan copper-nickel sulfide rich ore; the equipment used is XFD with a volume of 3L Ⅱ Single tank flotation machine.

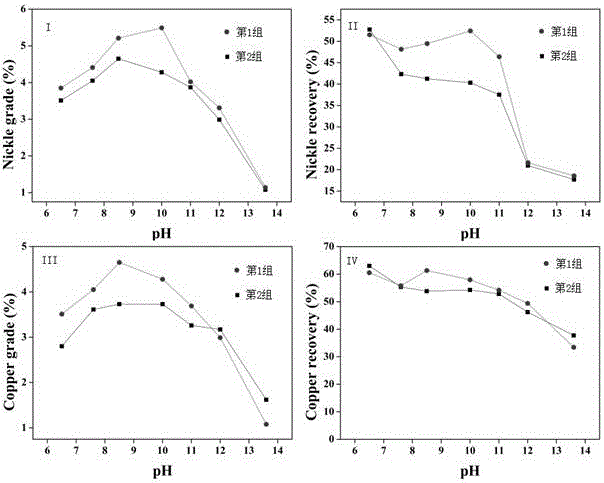

[0029] After grinding 800 grams of ore to 80% -74μm, according to figure 1 The flow shown is dosing and operation, and 90mL of tap water is added per minute during the flotation process to keep the liquid level balanced. The experiment was divided into two groups. The first group used the mixture of copper sulfate and ammonium sulfate (mass ratio: 1:1) as the activator, and the dosage was 60g / t; the second group used copper sulfate as the activator, and the dosage was 30g / t. Flotation effects of two activators at different pH values. Collect concentrates and tailings obtained from flotation, prepare samples and analyze them. For flotation results, see figure 2 , figure 2 (1) is the relationship curve of ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com