Novel building material template cleaning device

A technology of cleaning device and new building materials, applied in the field of construction machinery, can solve the problems of high cost of chemical cleaning, low efficiency, difficult to pass environmental protection standards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

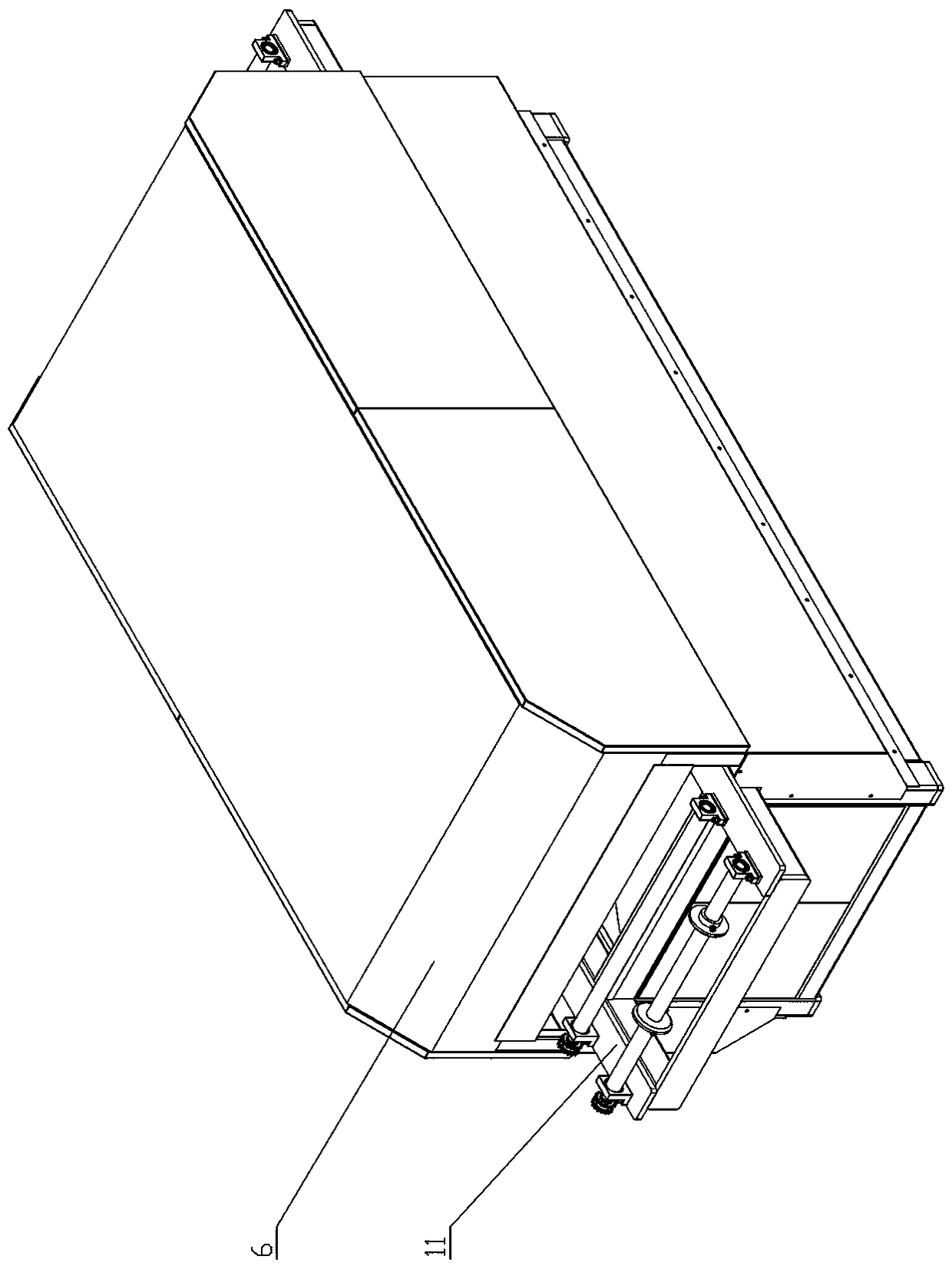

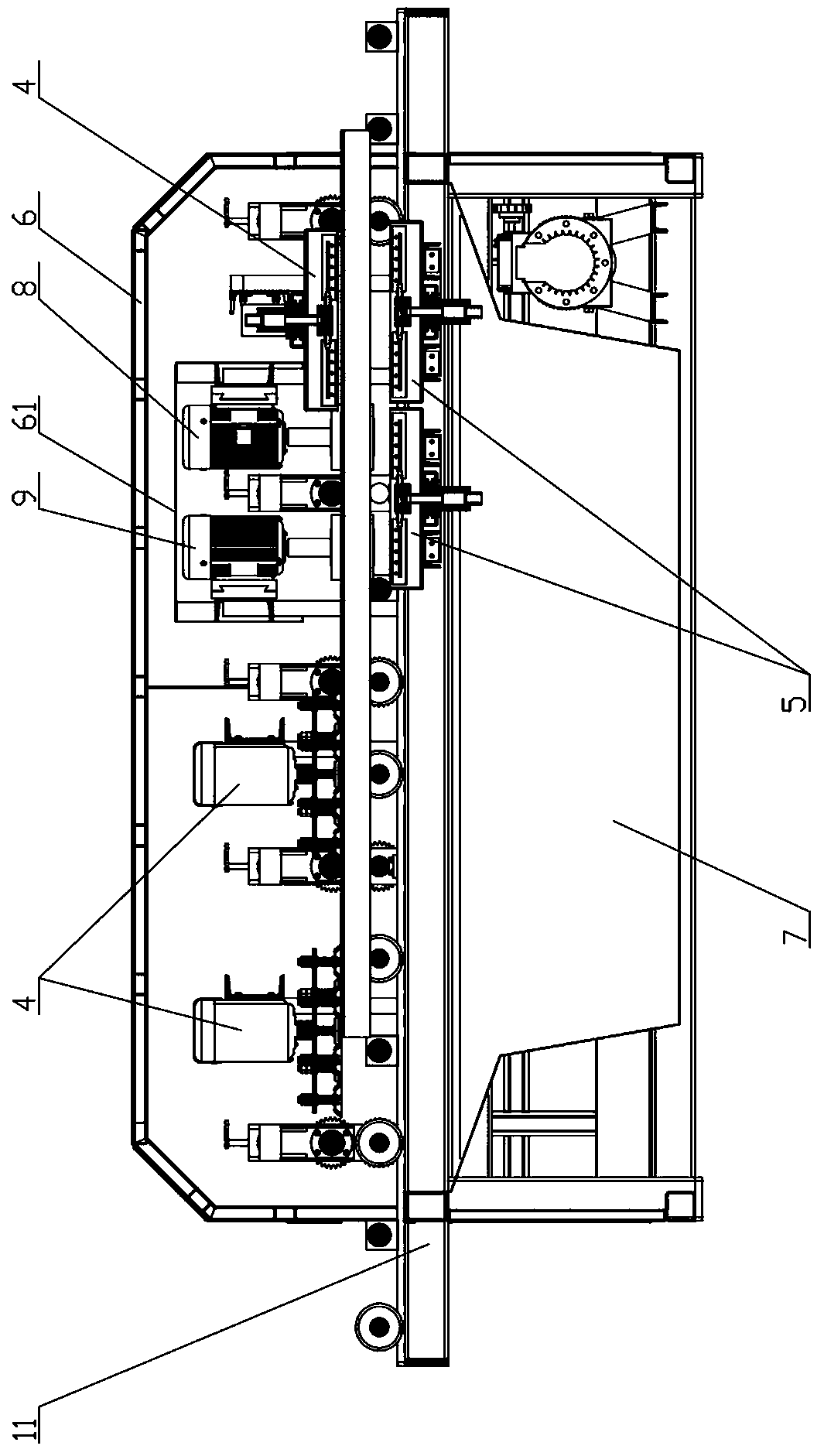

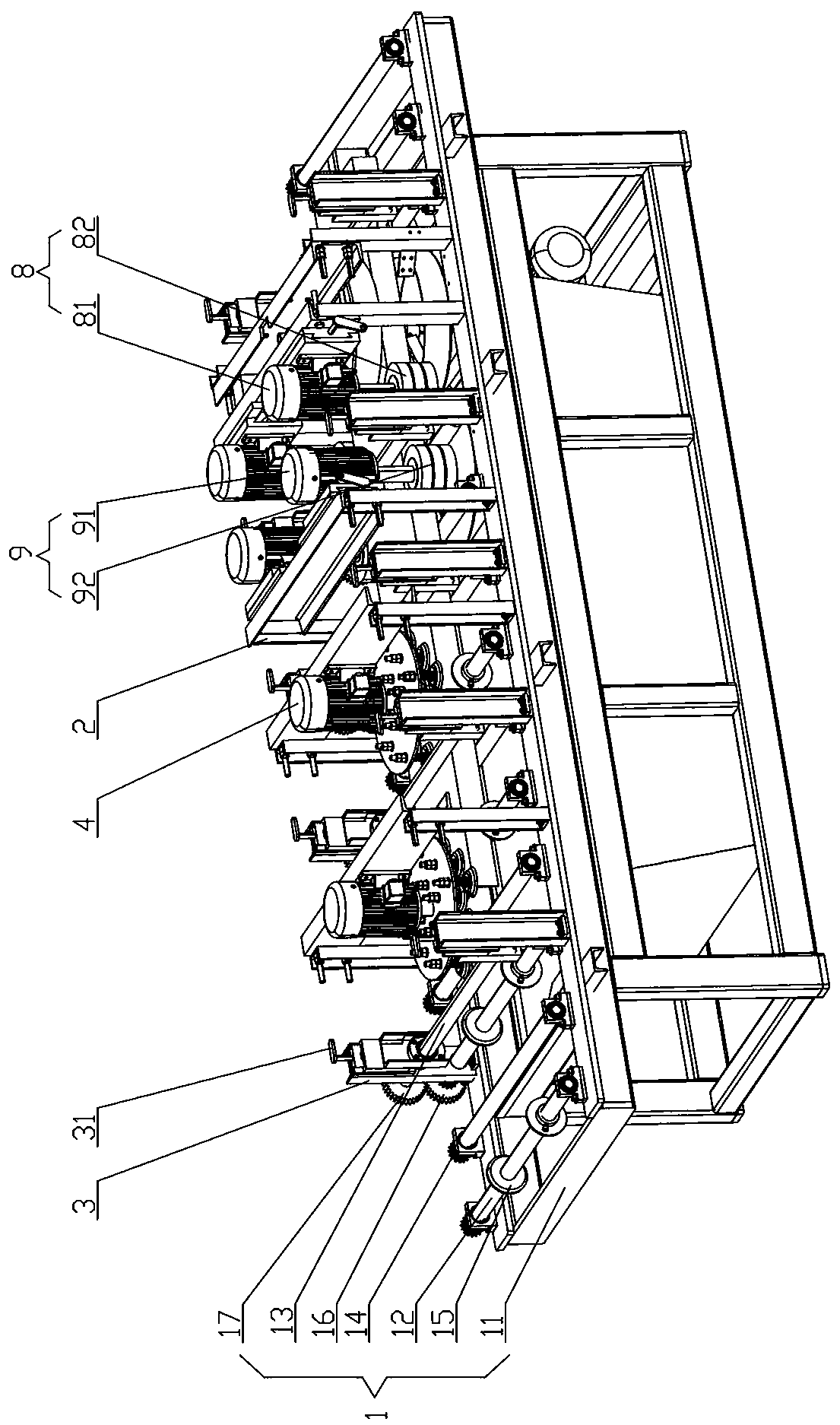

[0065] Such as Figure 1-3 As shown, a new type of building material formwork cleaning device includes a transport table 1, a forward cleaning mechanism 8, a reverse cleaning mechanism 9, an upper surface washing mechanism 4 and a lower surface washing mechanism 5, a forward cleaning mechanism 8 and a reverse cleaning mechanism 9 is set on the transport platform 1, the building material template is transported through the transport platform 1, the upper surface washing mechanism 4 is arranged above the building material template, and the lower surface washing mechanism 5 is arranged below the building material template.

[0066] Wherein, the delivery platform 1 of the device includes a frame 11, a driving shaft 12 and a driven shaft 13, several driving shafts 12 are installed on the frame 11 through bearing blocks 539, and the driven shaft 13 is arranged on the top of the driving shaft 12, The driven shaft 13 is installed on the dovetail slide table 3, the driven shaft 13 and ...

Embodiment 2

[0084] This embodiment is similar to Embodiment 1, the difference is that in this embodiment, as Figure 12 As shown, the lower surface flushing mechanism 5 adopts a swing nozzle 53, which includes a mounting seat 533, a nozzle 532, a driving device 540 and a reciprocating swing mechanism. Several nozzles 532 are arranged on the mounting seat 533, and the driving device 540 is connected with the reciprocating swing mechanism. The reciprocating swing mechanism is connected with the mounting base 533 to drive the mounting base 533 to swing back and forth, wherein the drive device 540 is a servo motor 409, and the reciprocating swing mechanism includes a second driving gear 534, a second driven gear 535, a push rod 536 and a transmission plate 537, Mounting base 533 both sides are provided with second rotating shaft 531, and driving device 540 is connected with second driving gear 534 and drives second driving gear 534 to rotate, and second driving gear 534 and second driven gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com