Differential spiral height adjustment LED lamp holder and T-shaped calibration template using the differential spiral lamp holder structure

A technology of LED lamp holder and differential screw, applied in the field of visual measurement, can solve the problems of influence and increase the complexity of calibration, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

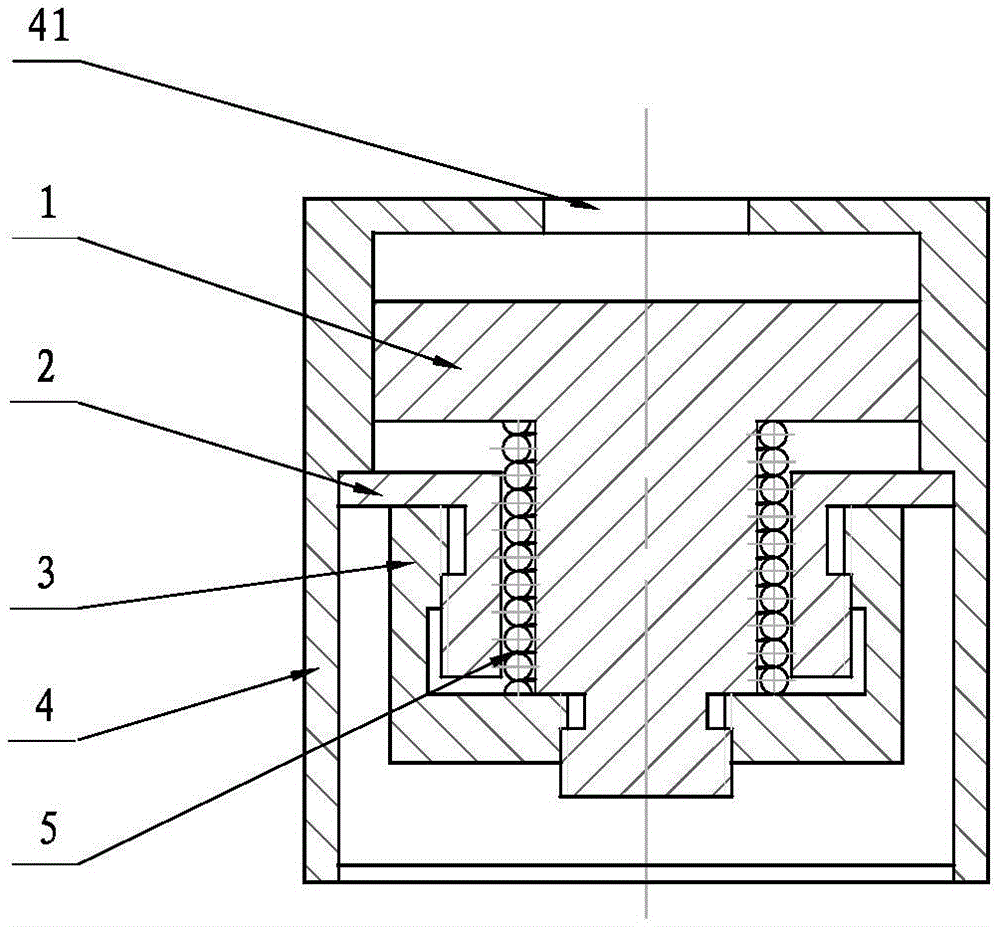

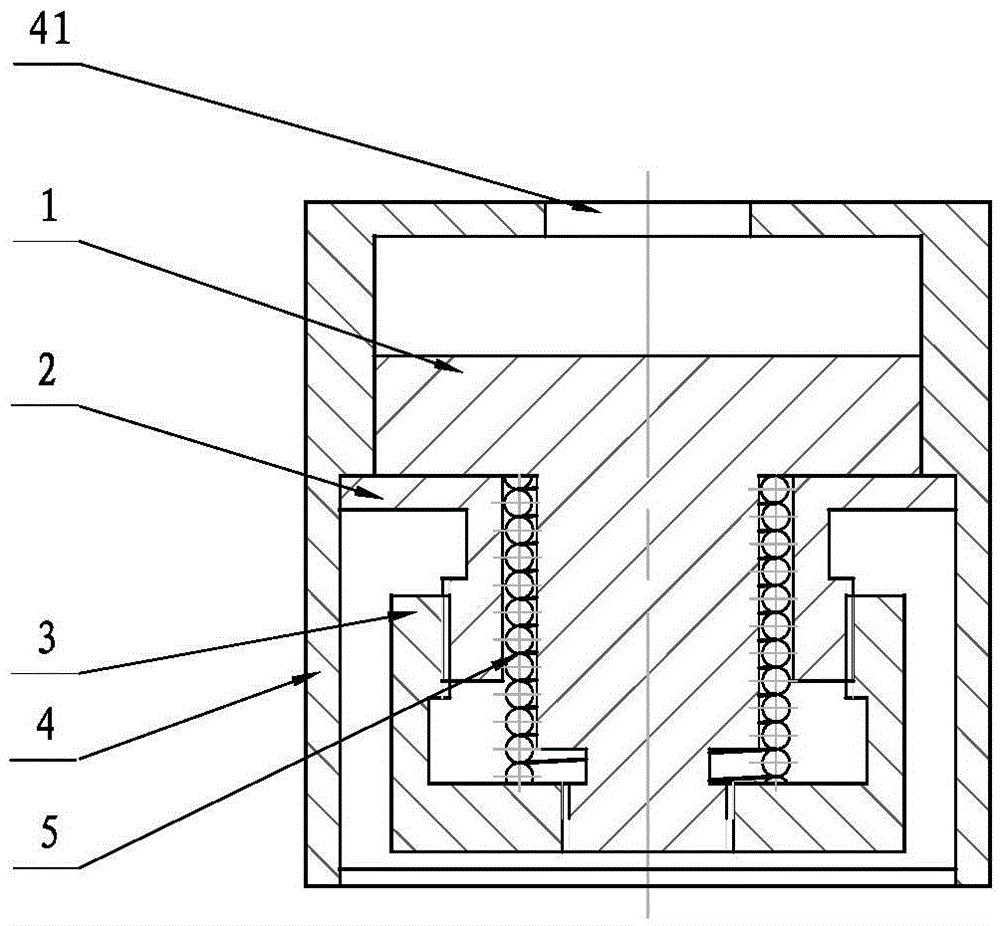

[0009] Specific implementation mode one, see Figure 1-9 This embodiment will be described. This embodiment describes a differential screw height adjustment LED lamp holder, which includes a height adjustment lamp holder 1, a fixing seat 2, an adjustment sleeve 3, a housing 4 and a compression spring 5,

[0010] The housing 4 is a regular hexahedron housing made up of a top surface and four sides. A light-transmitting hole 41 is arranged in the middle of the top surface of the housing 4, and one or more anti-corrosion holes in the vertical direction are provided on the inner wall of the housing 4. transfer chute;

[0011] The height-adjusting lamp holder 1, the fixing seat 2, the adjustment sleeve 3 and the compression spring 5 are all located inside the housing 4, wherein:

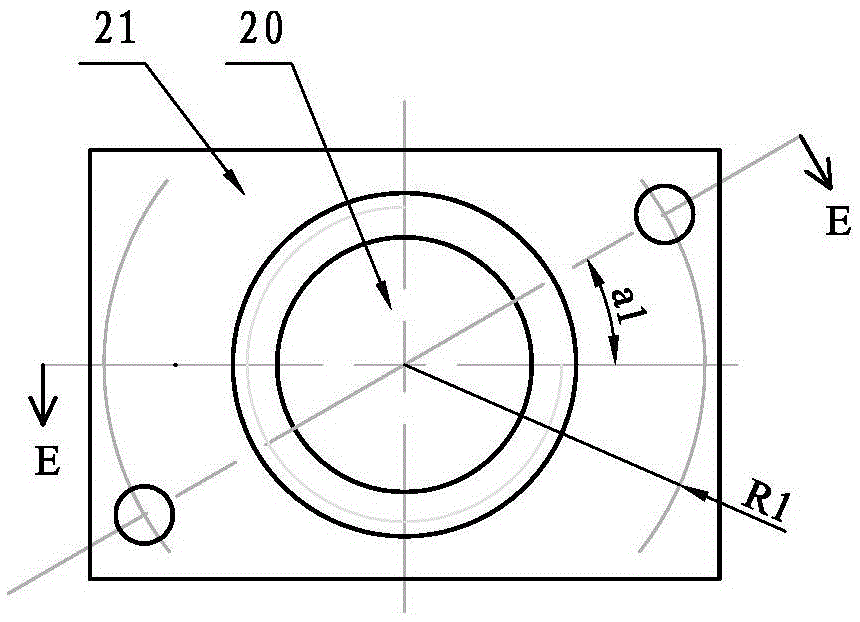

[0012] For the structure of the fixed seat 2, see image 3 and 4 Shown: there is a circular through hole in the middle of the fixed seat 2, the axis of the circular through hole 20 passes through the c...

specific Embodiment approach 2

[0021] Specific Embodiment 2. This embodiment is a further limitation of the differential spiral height-adjusting LED lamp holder described in Embodiment 1. In this embodiment, the outer diameter of the lower part of the height-adjusting lamp holder 1 is outside the d cylinder 12 The external thread of the fixed base 2 is N circles, and the external thread of the base column 22 at the bottom of the fixed seat 2 is also N circles, and the N bit is greater than or equal to an integer of 3.

[0022] In this embodiment, it is defined that the outer diameter of the lower part of the height-adjusting lamp holder 1 is d. The number of turns of the external thread on the outside of the cylinder 12 is equal to the number of turns of the external thread on the base column 22 at the bottom of the fixing seat 2 . The choice of the specific value can be selected according to the height that needs to be adjusted actually, for example: when the height to be adjusted is 3mm, N can be 6.

specific Embodiment approach 3

[0023] Specific Embodiment 3. This embodiment is a further limitation of the differential spiral height adjustment LED lamp holder described in specific embodiment 1. In this embodiment, the inner wall of the housing 4 is provided with a shoulder, and the shoulder is used for It is fixedly connected with the rectangular plate-shaped fixed platform 21 on the top of the fixed base 2 .

[0024] The connection method can be realized by bonding, clamping or screw fixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com