Reading microscope calibrating device

A technology for reading microscopes and verification devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., and can solve problems such as difficult operation of initial alignment, undetected reading microscopes, inaccurate reading microscopes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

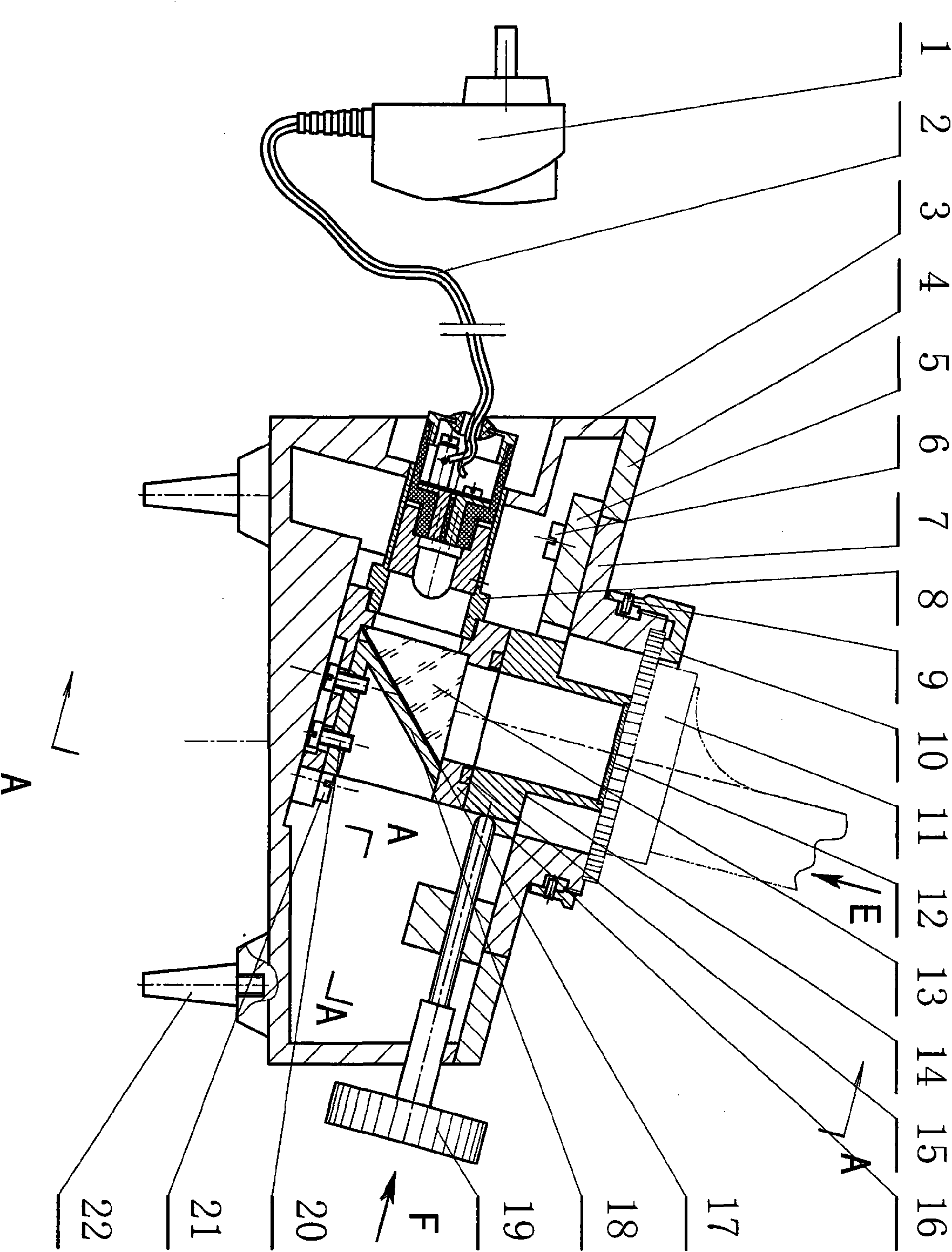

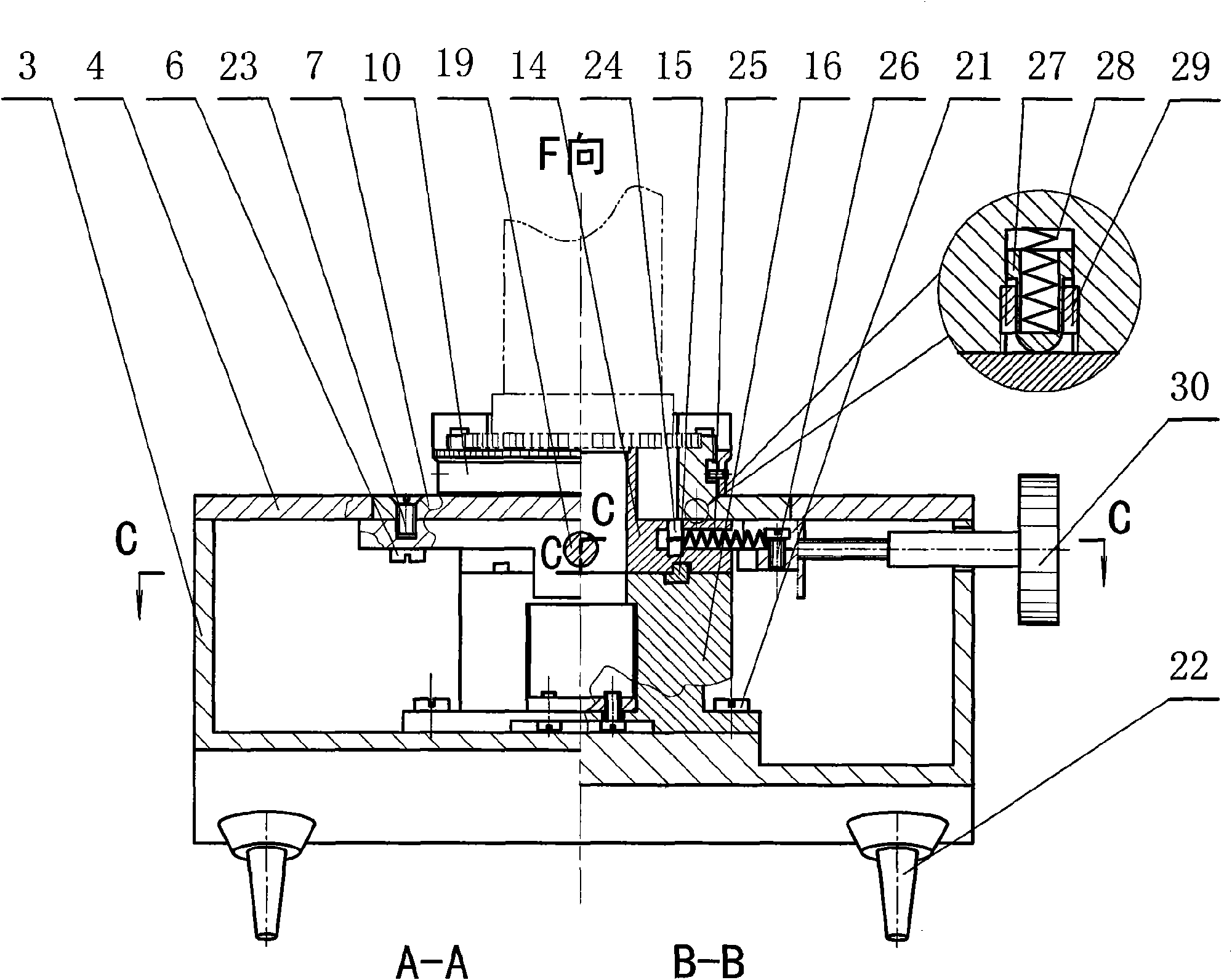

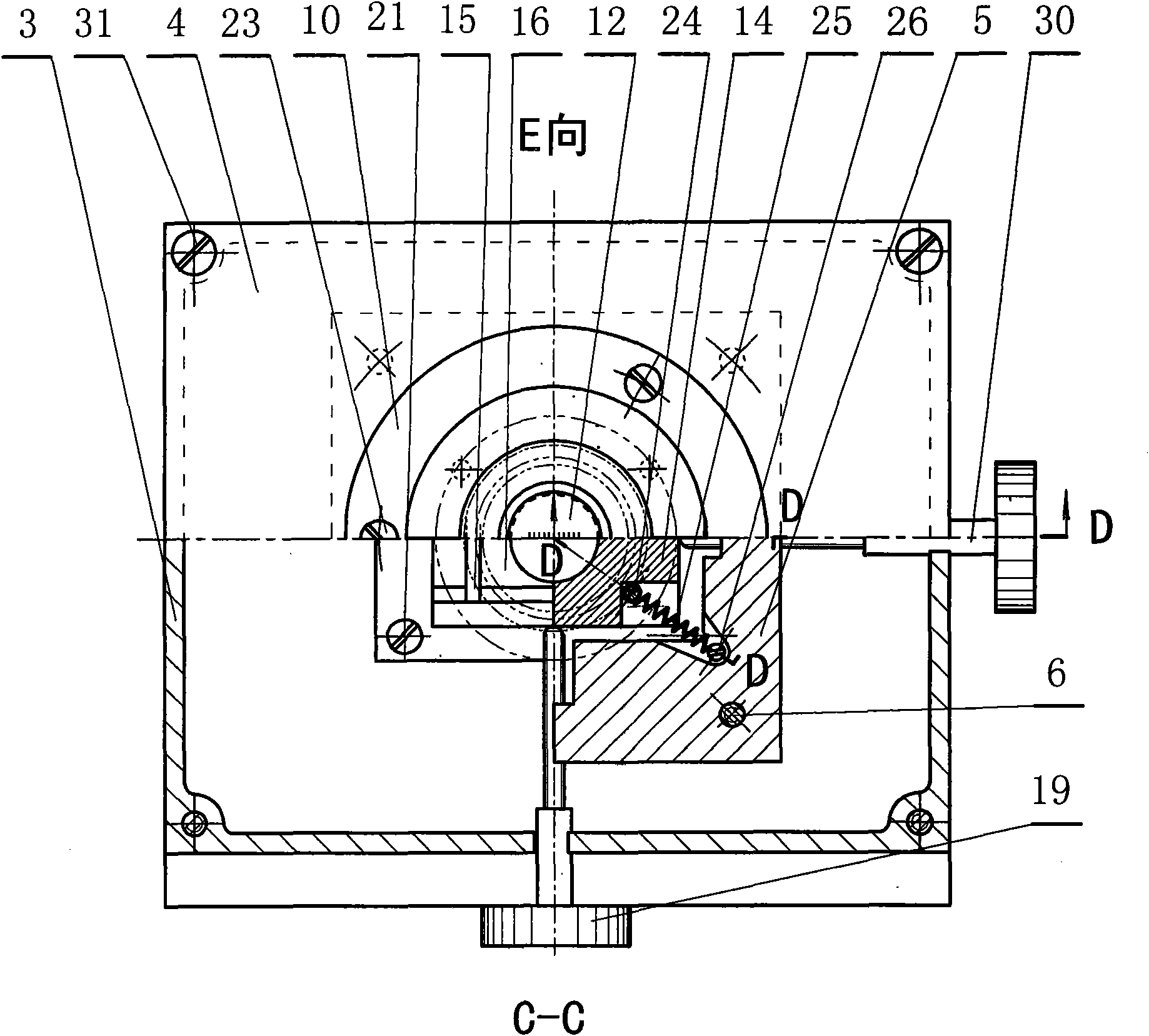

[0010] Casing (3) is the main body of fuselage part, and its rear wall is high and front wall is low and forms the installation facet of 15 ° of included angles with horizontal plane. Fix the table top (4) at the 4 corners by 4 screws (48). And the lower surface of table top (4) is connected and installed backing plate (5) by 4 screws (6) before this. 4 threaded feet (22) at the upper end are fixed on the flanges at the 4 corners of the bottom of the casing (3).

[0011] The positioning seat (7) is the main body of the clamping mechanism and is in the shape of a flange. The lower disk is embedded in the table top (4) and fixed on the backing plate (5) by 3 screws (23); the upper circle is connected with the half-circle gland (10) with threads, and the half-circle gland (10) When 3 to 4 limit screws (9) at the waist limit the non-working state, the half-turn gland (10) is rotated away from the positioning seat (7). The half-circle gland (10) is a top at the diameter and cuts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com