Patents

Literature

149results about How to "Optimization principle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Path planning method for mobile robot in dynamic environment

ActiveCN103823466AOptimization principleRealize path planningPosition/course control in two dimensionsSimulationPath plan

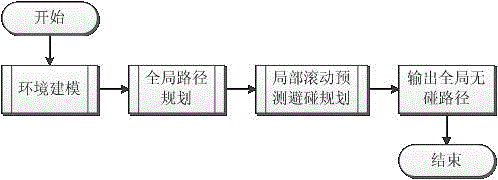

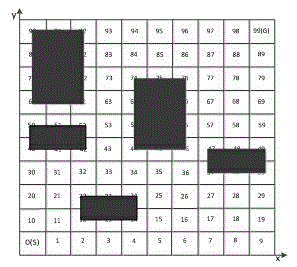

The invention discloses a double-layer planning method based on the combination of global path planning and local rolling prediction collision avoidance planning, so as to solve the problem of path planning for a mobile robot in a dynamic environment. The method mainly comprises two parts: the global path planning and the local rolling prediction collision avoidance planning. The path planning method can better realize robot navigation, and improve intelligence of the robot. The double planning method can be utilized to prevent the blindness of planning in the beginning, and searching space of the problem is reduced; based on the uncertainty of the moving direction of a dynamic barrier and by utilizing the two collision prediction strategies and two corresponding collision avoidance strategies, the dynamic barrier can be avoided well; and particularly, in order to adapt to the change of environment better, in the second layer of planning, a Follow_wall behavior based on behavior method is added, so that when the environment changes, the mobile robot can still arrive at the target without touching the barriers safely.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

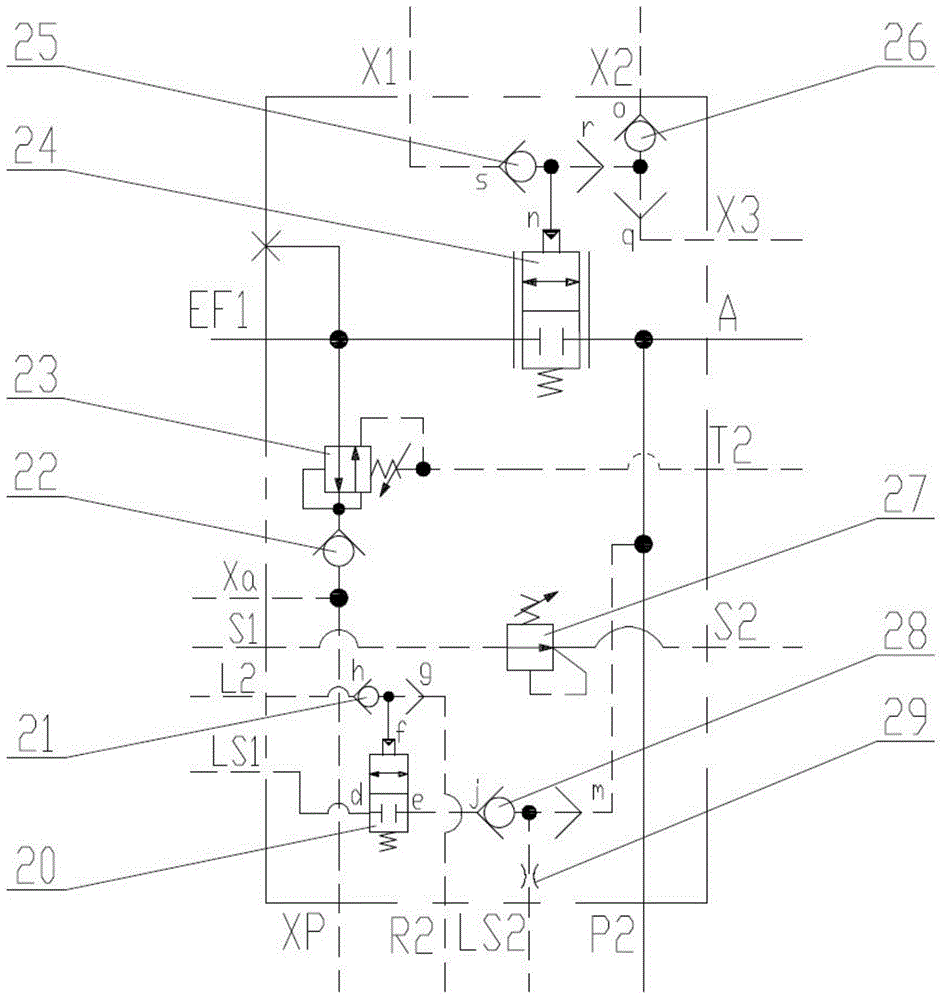

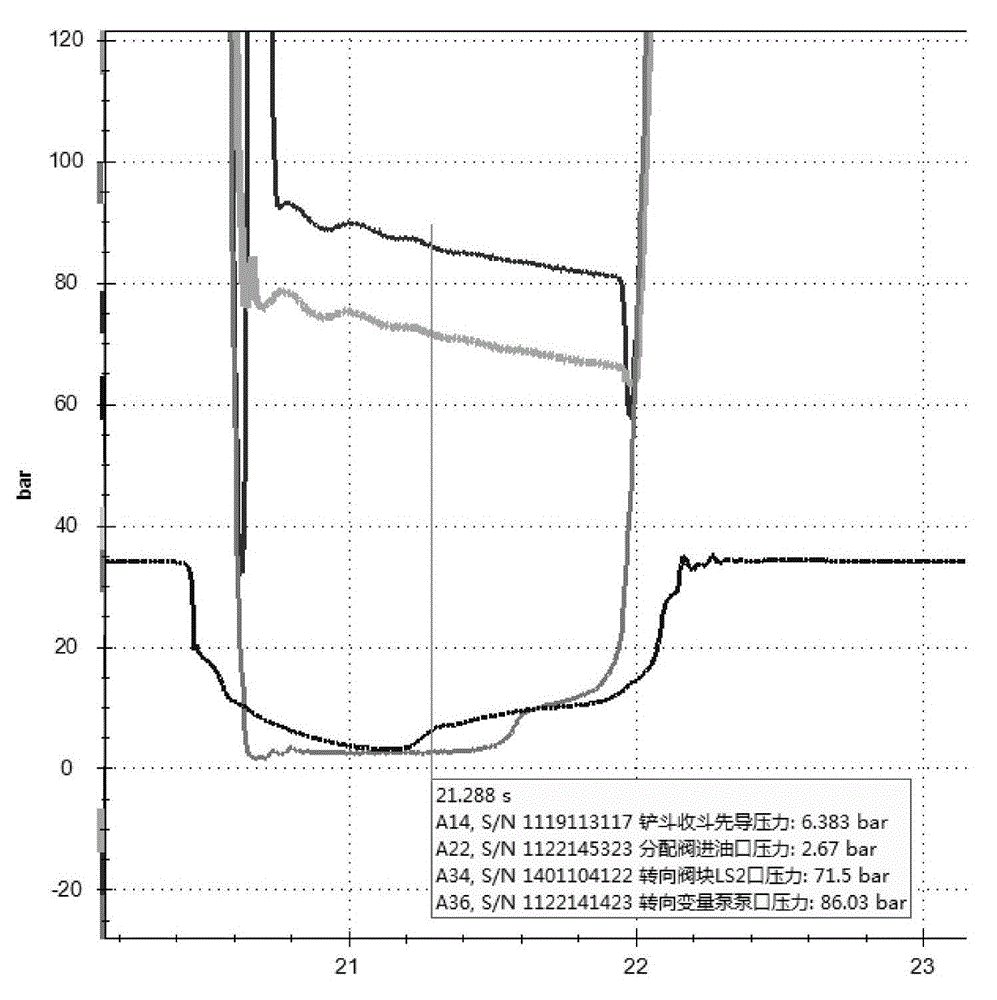

Loader constant and variable hydraulic system based on flow amplifying steering

ActiveCN104929183ALow powerProtect against high pressure shocksSoil-shifting machines/dredgersSolenoid valveEngineering

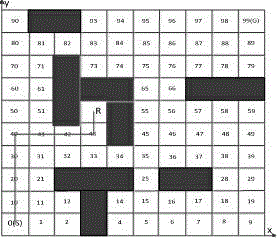

The invention discloses a loader constant and variable hydraulic system based on flow amplifying steering. The loader constant and variable hydraulic system comprises a hydraulic oil tank, a variable pump, a steering gear, a right limiting valve, a left limiting valve, a flow amplifying valve, a left steering cylinder, a right steering cylinder, a flow control valve block, an energy accumulator, a distribution valve, a tipping bucket cylinder, a movable arm cylinder, a pilot valve, an unloading valve block, a constant flow pump, a working mode switching electromagnetic valve and a working mode selector switch. The small-displacement steering gear is adopted to serve as a hydraulic pilot stage of the flow amplifying valve, throttling losses inside a coaxial flow amplifying steering gear in the rapid steering process can be removed, and fuel consumption is reduced; a low-cost home-made element is adopted to replace an inlet element, and steering stability of a variable system is achieved; a feedback signal of the flow amplifying valve is controlled in a time-shared manner, stability of a steering system is improved, and energy consumption is reduced; and meanwhile, the energy-saving effect and good control characteristics of the variable pump can be played out well, and the energy-saving effect and the control precision of a working system are improved.

Owner:XCMG CONSTR MACHINERY

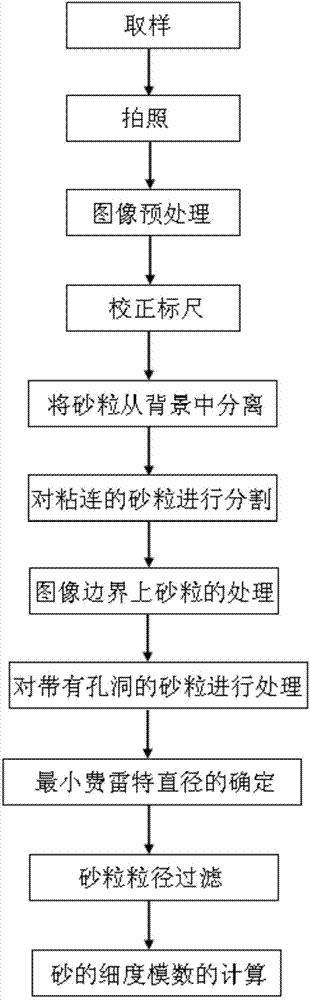

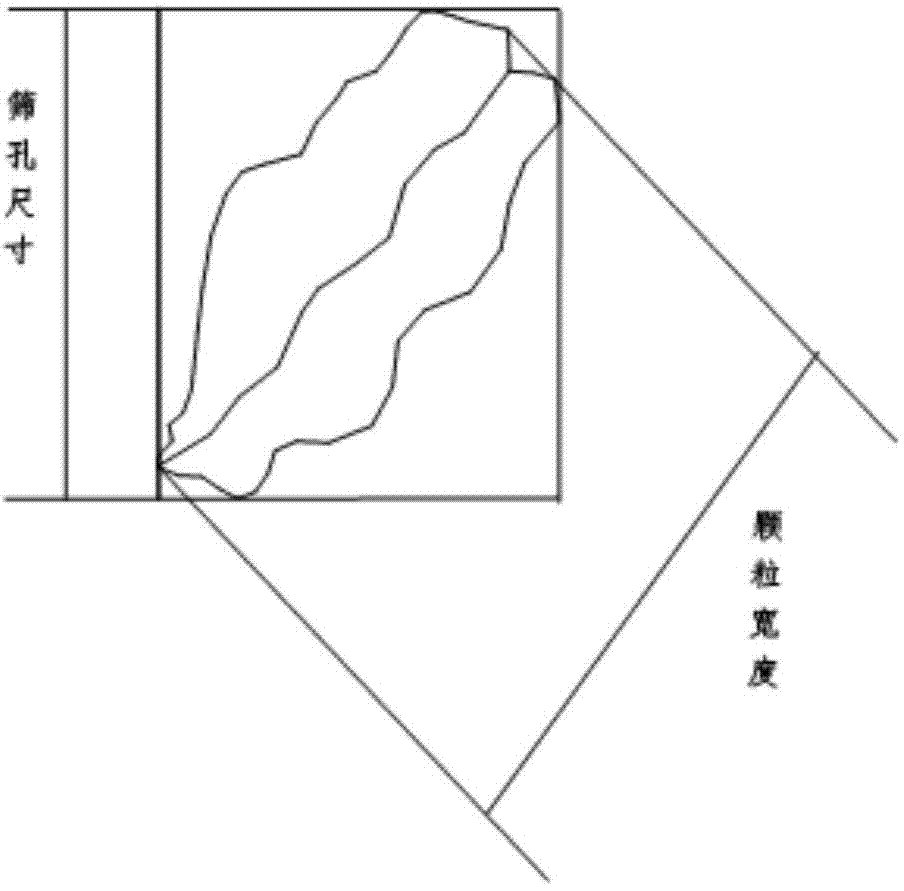

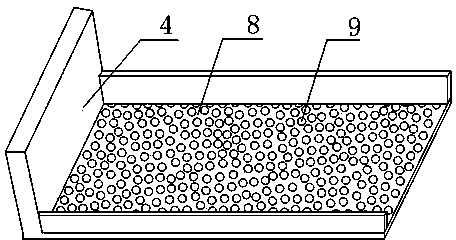

Method for determining fineness modulus of sand by utilizing image analysis technology

InactiveCN104502245AAvoid weighingGuaranteed accuracyImage analysisParticle size analysisImaging analysisFineness modulus

The invention belongs to the technical field of research and application of civil engineering materials and relates to a method for determining the fineness modulus of sand by utilizing an image analysis technology. The method comprises the eleven specific steps: sampling, photographing, preprocessing images, calibrating a scale, separating sand grains from the background, dividing the adhered sand grains, treating the sand grains on the image boundary, treating the sand grains with holes, determining the minimum Ferrette diameter, carrying out grain-diameter filtering on the sand grains and calculating the fineness modulus of the sand. The method has the advantages that the image analysis method is adopted for calculating the fineness modulus of the sand for the first time, and the criterion that the volume ratio and the weight ratio is equal is applied, so that the weighing process of the sand is avoided; the minimum Ferrette diameter is adopted as the equivalent grain diameter of the sand which can be sieved, so that the accuracy of determined data is better guaranteed; and the method is novel in design, reliable in principle, simple in operation, scientific in calculation, accurate in data, low in cost and high in automation degree.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

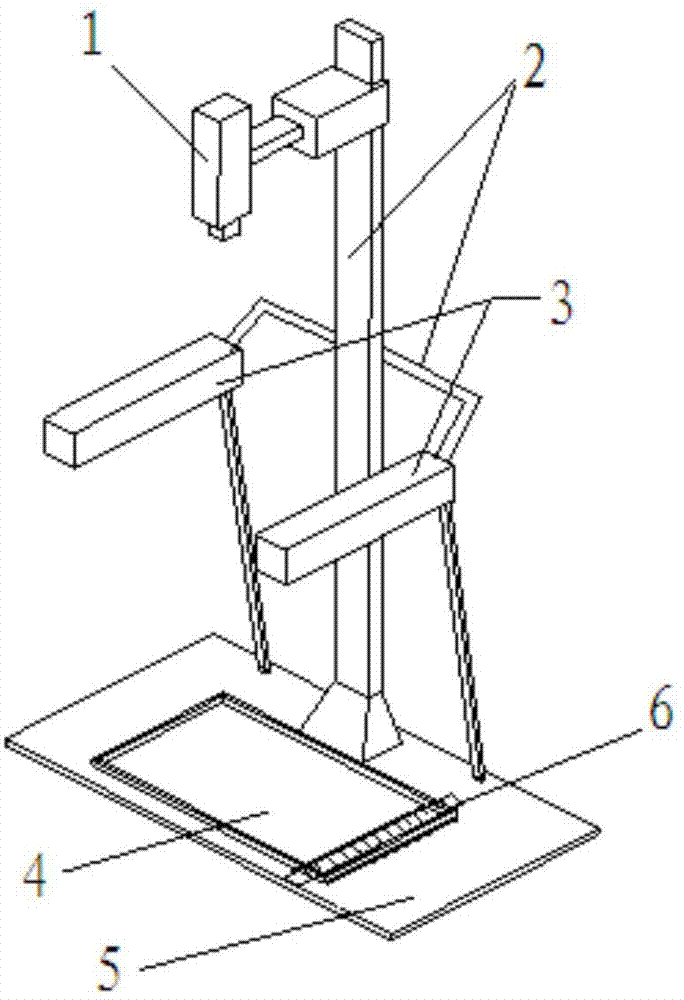

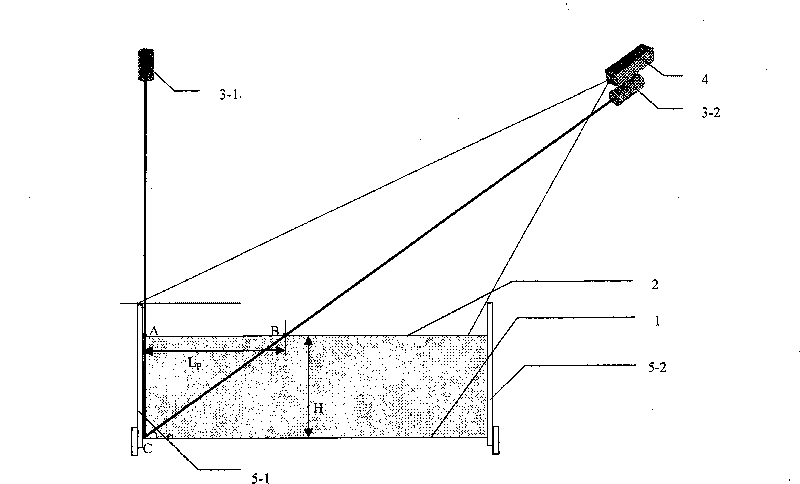

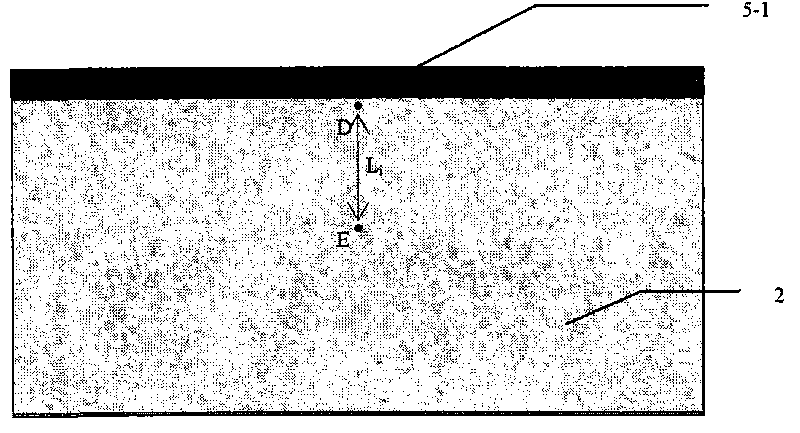

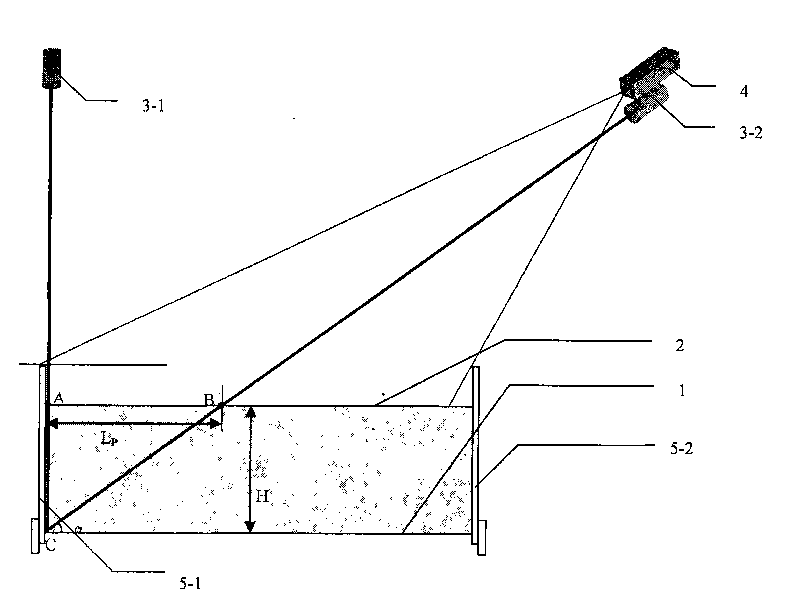

Sintering layer thickness on-line detecting method

ActiveCN101750022AAvoid wear and tearNo mechanical componentsUsing optical meansPoint lightVertical plane

The present invention discloses a sintering layer thickness on-line detecting method. Two point light sources are arranged at the upper side of a trolley of a sintering machine to enable a flat surface formed by the light rays of the two point light sources vertical to the wall and the bottom of the trolley. In the vertical flat surface, two light rays are gathered on one point of the bottom of the trolley; one of the two light rays is vertical to the bottom of the trolley, and the other one forms an acute angle a wit the bottom of the trolley. Image collecting equipment is arranged above thetrolley to enable an image collecting range bigger than the lighting range of the two point light source on a charge level. Light point distance Lp of the two point light sources projected on the charge level by the image collecting equipment is collected in a computer, images are processed, and the material layer thickness is calculated by a formula H = tga*Li*g. The present invention solves theproblems of equipment loss, large maintaining volume and the like caused by touching measurement, can be suitable to the bed environment of sintering production, and has the advantages of low equipment cost, small volume, easy arrangement, reliable work, convenient use and the like.

Owner:ANGANG STEEL CO LTD

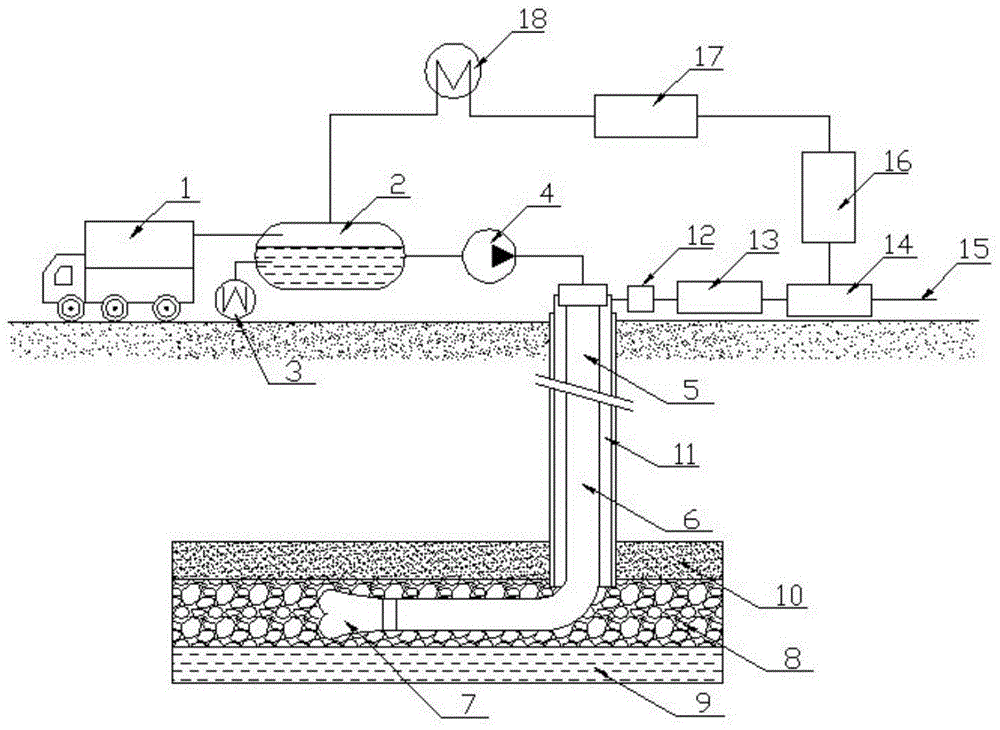

Supercritical carbon dioxide jet injection drilling exploitation hydrate device and method

InactiveCN104563974AEmission reductionMaintain integrityConstructionsLiquid/gas jet drillingJet injectionHigh pressure

The invention belongs to the technical field of hydrate drilling exploitation equipment and processes and relates to a supercritical carbon dioxide jet injection drilling exploitation hydrate device and method. The supercritical carbon dioxide jet injection drilling exploitation hydrate device is adopted to realize exploitation of hydrate, a carbon dioxide storage device is filled with carbon dioxide firstly, then the carbon dioxide is continuously cooled to the liquid state via a storage tank cooling device, the liquid carbon dioxide is pressurized by a high pressure pump prior to be pumped into a drilling tool for jet drilling by the aid of the prior art, after the drilling tool drills into a hydrate reservoir, the jet temperature of the high-pressure supercritical carbon dioxide injected by a drill bit is lowered, the hydrate brought out of a wellbore and a near wellbore formation moves upwards along an annular space; after reaching a wellhead throttling device, the hydrate sequentially passes through a three-phase separator and a gas separator to spate natural gas and carbon dioxide so as to complete exploitation of the hydrate. The used device is simple in structure, convenient to operate, low in maintenance cost, simple in exploitation method, scientific in principle and safe in exploitation process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

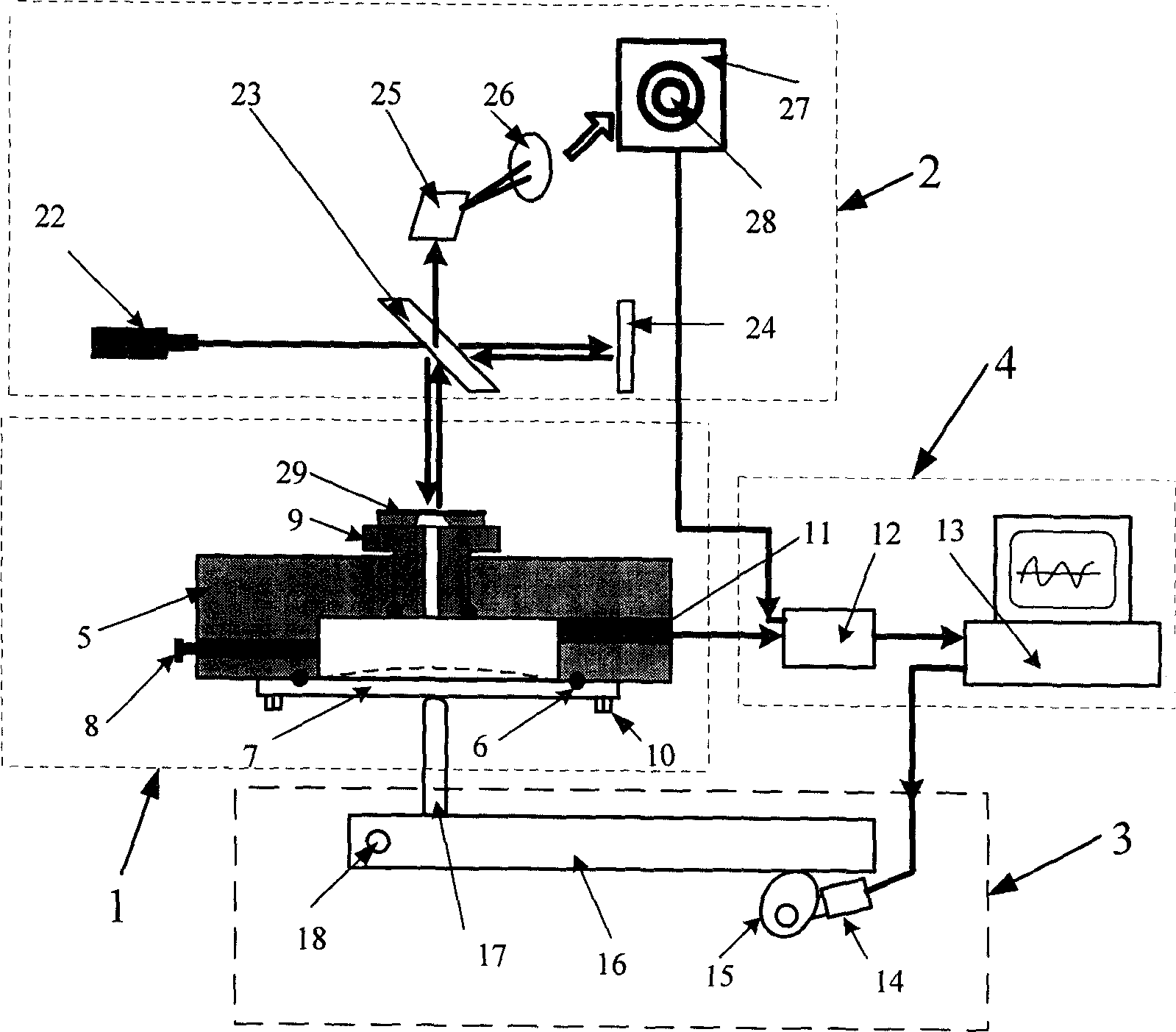

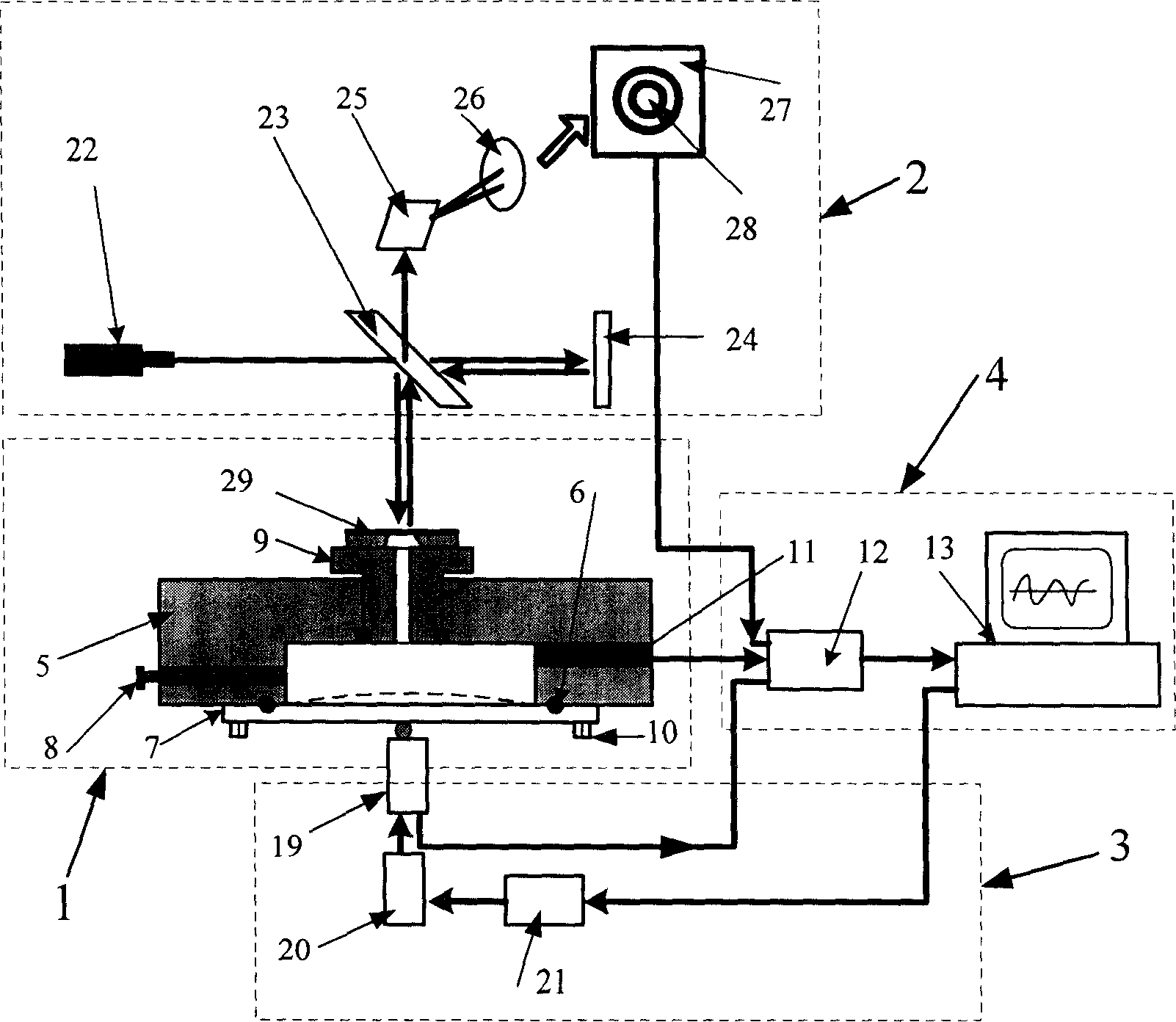

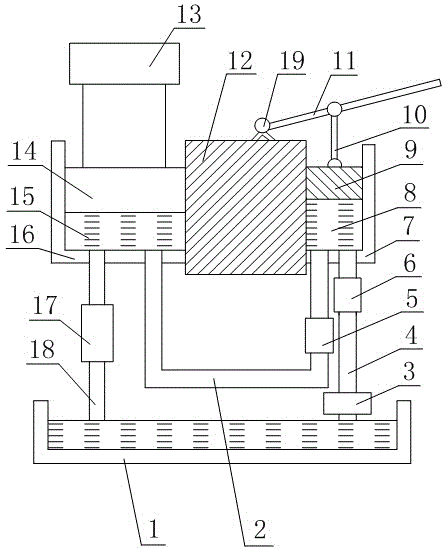

Measuring installation for testing adhesion strength and operating life of diamond coated cutter

InactiveCN1727874APrecise quantification of dynamic adhesion strengthSimple methodUsing mechanical meansUsing optical meansMeasurement deviceData acquisition

An unit for measuring adhesive intensity of diamond coating layer on tool and its service lifetime is prepared as connecting load system of dynamic charge with base , exerting dynamic pressure on liquid in base cavity and transmitting pressure onto sample film to be measured in sound speed , using He ¿C Ne laser interference measurement system above base to detect height variation of film , connecting said system to data collection device and computer as well as base for obtaining variation value of liquid pressure and film height then obtaining dynamic film adhesive intensity through computer analysis .

Owner:SHANGHAI JIAO TONG UNIV

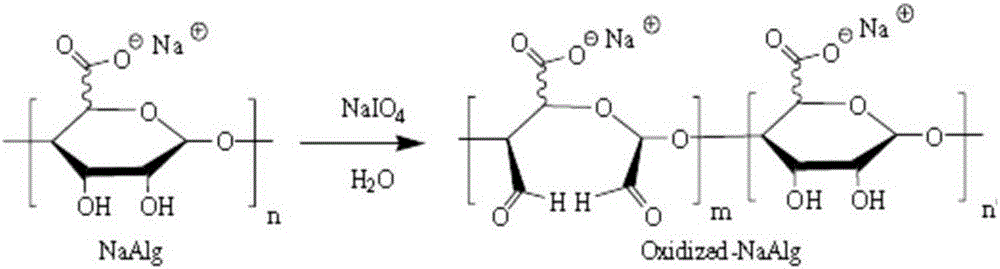

Preparation method for hydroxyethyl chitosan in-situ hydrogel

The invention belongs to the technical field of biomedicines and particularly relates to a preparation method for hydroxyethyl chitosan in-situ hydrogel. The preparation method comprises the following steps of firstly, dissolving sodium periodate powder into deionized water to obtain an aqueous solution of the sodium periodate; secondly, stirring an aqueous solution of sodium alginate and the aqueous solution of the sodium periodate to form a mixed solution; after the mixed solution is enabled to perform an oxidizing reaction, adding ethylene glycol to end the reaction; carrying out suction filtration on the mixed solution, carrying out dehydration precipitation on the mixed solution with absolute ethyl alcohol, and then carrying out low-temperature vacuum drying to obtain an oxidized sodium alginate crude product; dissolving the oxidized sodium alginate crude product into an aqueous solution of oxidized sodium alginate crude product with distilled water; carrying out complete dialysis on the aqueous solution of oxidized sodium alginate crude product, centrifuging, taking supernate for freeze drying to obtain oxidized sodium alginate; finally, mixing hydroxyethyl chitosan with the oxidized sodium alginate, carrying out cross-linking reaction on the mixed solution by a double-linkage syringe, and then pushing the reacted product into a test tube to obtain the hydroxyethyl chitosan in-situ hydrogel. The hydroxyethyl chitosan in-situ hydrogel is used for quickly coating and transplanting. The preparation method is simple in preparation process, safe and reliable in principle and low in preparation cost; the hydroxyethyl chitosan in-situ hydrogel has the advantages of good quality, safety and sanitation in use, and environment friendliness in a treatment environment.

Owner:QINGDAO UNIV

Energy-saving temperature-regulating humidity-regulating air processing method

ActiveCN102809198AAchieve recyclingImprove recycling effectEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsEconomic benefitsProcess engineering

The invention belongs to the technical field of air conditioners, and relates to an efficient and energy-saving temperature-regulating and humidity-regulating air processing method. According to the method, each cycle of four subsystems is filled with cycle medium after pumped out, and the four subsystems include an inside-outside combined-type gas-liquid two-phase flow heat pipe cold quantity recovery subsystem, a multi-stage shunt-wound refrigeration cycle subsystem, an inside-outside combined-type heat-extraction heat pump cycle subsystem and an inside-outside combined-type heat-extraction-free heat pump cycle subsystem; both air-out temperature and dew-point temperature of a central control subsystem are set according to a temperature-regulating and humidity-regulating air processing technology; and all compressors of the multi-stage shunt-wound refrigeration cycle subsystem are started after an induced-draft fan in an air post-processing section is started, and the inside-outside combined-type gas-liquid two-phase flow heat pipe cold quantity recovery subsystem is started, as a result, the air-out temperature and the dew-point temperature of the system reaches the set value, and the stable operation of the system is realized; and accordingly, in such a way, the air meeting the requirement of the air-out temperature and the dew-point temperature can be continuously provided. The system device has the advantages of simple structure, reliable principle, low running cost, good energy saving effect, friendly production environment, and remarkable economic benefit.

Owner:QINGDAO UNIV

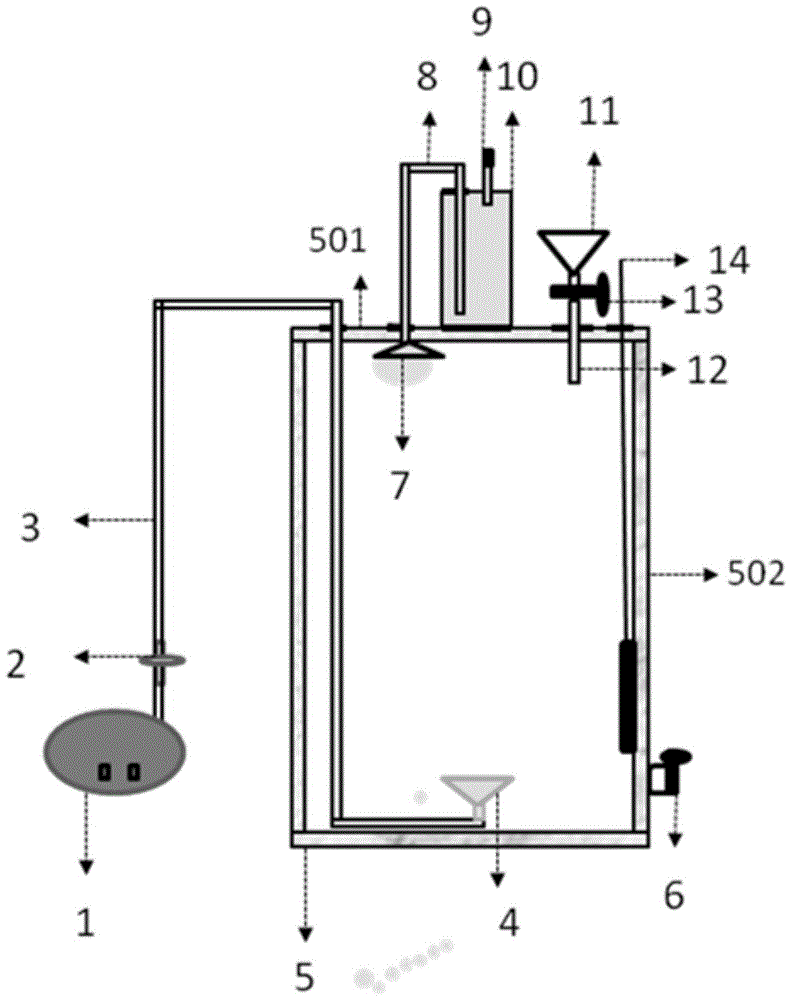

Culturing device for formaldehyde degradation bacteria

InactiveCN104946527AControl internal temperatureAvoid secondary pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringBiological filter

The invention belongs to the technical field of air purification equipment and particularly relates to a culturing device for formaldehyde degradation bacteria. A reaction tank which is of a box-type structure consists of a tank cover and a tank body; an air inlet pipeline reaches the bottom of the reaction tank through the tank cover; an aeration pump is arranged at the outer end of the air inlet pipeline; a swirl-mixing aerator is arranged at the inner end of the air inlet pipeline; a micro-porous biological filtering membrane is arranged at the end, close to the aeration pump, inside the air inlet pipeline; a temperature controller is arranged at the lower right part inside the tank body; a sampling hole is formed at the lower right part outside the tank body; a tail gas absorbing bottle is arranged in a central line at the top outside the tank cover; a tail gas pipeline is led out from the tail gas absorbing bottle, penetrates through the tank cover and then is provided with a tail gas collecting opening; a supplementing pipeline penetrates through the tank cover and then is provided with a valve and a supplementing opening in sequence. The culturing device is simple in structure, safe to use, convenient in preparation method, reliable in principle and low in cost, is capable of reducing the risk of exposure to surrounding people, and is applicable to screening, acclimatization and batch culture of formaldehyde degradation bacteria.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

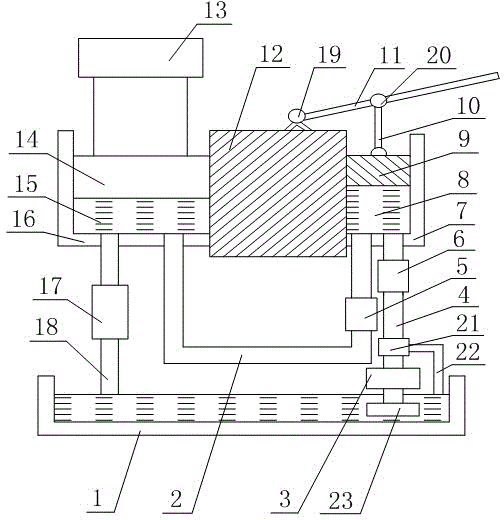

Fuel rod contact type measuring anti-collision structure and anti-collision method thereof

ActiveCN106448763AExpand the scope of activitiesNot brokenNuclear energy generationNuclear monitoringContact pressureContact type

The invention discloses a fuel rod contact type measuring anti-collision structure and an anti-collision method thereof. The fuel rod contact type measuring anti-collision structure comprises a base capable of sliding; a mounting block is arranged on the base and is connected with the base, a supporting slide block is arranged on the mounting block and can slide along the upper surface of the mounting block on the mounting block, and the sliding direction of the supporting slide block is the same as that of the base; a buffer mechanism is arranged on the supporting slide block and is connected with a measuring probe, the measuring probe can slide along with the buffer mechanism, and the sliding direction is the same as that of the supporting slide block. The fuel rod contact type measuring anti-collision structure and the anti-collision method thereof disclosed by the invention have the benefits that the anti-collision can be automatically realized; the pressure design increases step by step; the contact pressure can be limited within a safety range in the fuel rod contact type measuring process, so that not only is the larger moving range in the fuel rod contact type measuring process ensured, but also the contact pressure can be enabled not to damage the probe or a fuel rod.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

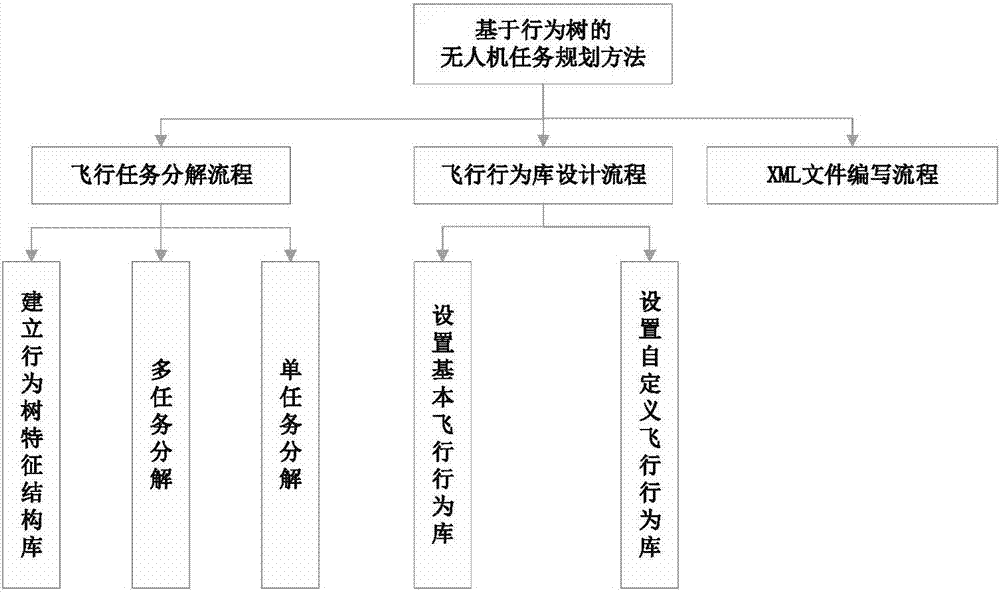

Multi-unmanned aerial vehicle complex task planning method

InactiveCN106933246ASolve practical problemsOptimization principlePosition/course control in three dimensionsDecompositionTheoretical computer science

The invention relates to a multi-unmanned aerial vehicle complex task planning method and belongs to the unmanned aerial vehicle field. The method includes a flight task decomposition flow, a flight behavior library design flow and an XML file editing flow; according to the task decomposition flow, behavior tree decomposition is performed on a multiple-task under execution, and behavior tree decomposition is performed on obtained single tasks; according to the flight behavior library design flow, basic behavior library and customized behavior library design is performed according to flight behaviors required in the single tasks; and according to the XML file editing flow, a customized XML format language is adopted to edit behavior tree knots obtained through decomposition. With the multi-unmanned aerial vehicle complex task planning method adopted, a user can be facilitated to plan a whole task process; task decomposition is performed according to task levels; task execution is performed according to actual conditions; and the practical problem of multi-unmanned aerial vehicle complex tasks can be solved. The method has the advantages of simple principles, flexible planning, high practicability, excellent implementation effects and the like.

Owner:XIAMEN UNIV

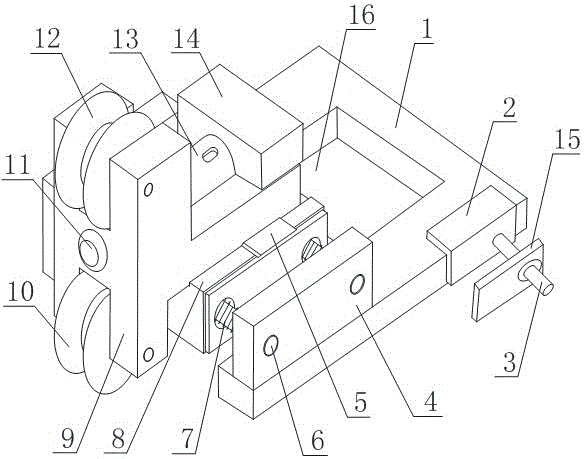

Pressing plate structure fixed on clamping groove and use method thereof

InactiveCN104227453ASimple structureThe principle is simplePositioning apparatusMetal-working holdersEngineeringScrew thread

The invention discloses a pressing plate structure fixed on a clamping groove and a use method thereof. The pressing plate structure fixed on the clamping groove comprises a fixed block, wherein a screw thread through hole is formed in the fixed block; a screw rod is screwed in the screw thread through hole; a nut sleeves the outer wall of the screw rod; a positioning device is arranged between the nut and the fixed block; the positioning device is provided with a through hole, and the screw rod penetrates the inner part of the through hole. The fixed block is fixed in the clamping groove; the top end face of the fixed block is arranged below the top end face of the clamping groove; a work-piece is placed between the clamping groove and a positioning bar; the positioning bar moves vertically on the screw rod; after the positioning bar reaches to the height of the work-piece, the positioning bar is tightly pressed on the top face of the work-piece; the nut rotates along the screw rod and is tightly pressed to realize tight pressing of the pressing plate structure for the work-piece. The pressing structure is simple in structure, convenient and simple in principle, and convenient and simple in use method, can fix the work-piece efficiently, increases a clamping force for the product as a special structure and the clamping groove are used cooperatively, achieves more accurate positioning, and avoids movement while a product is produced.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

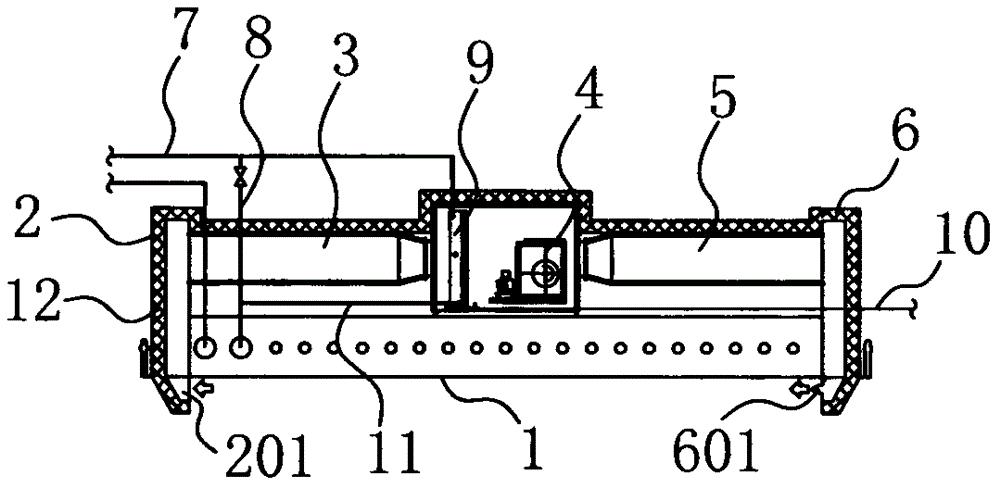

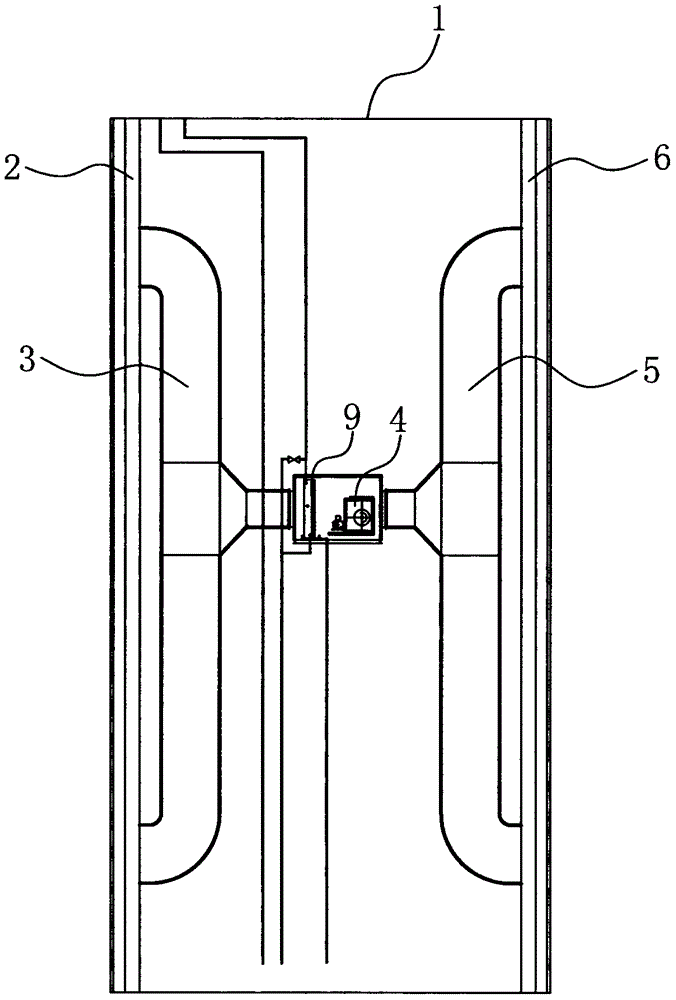

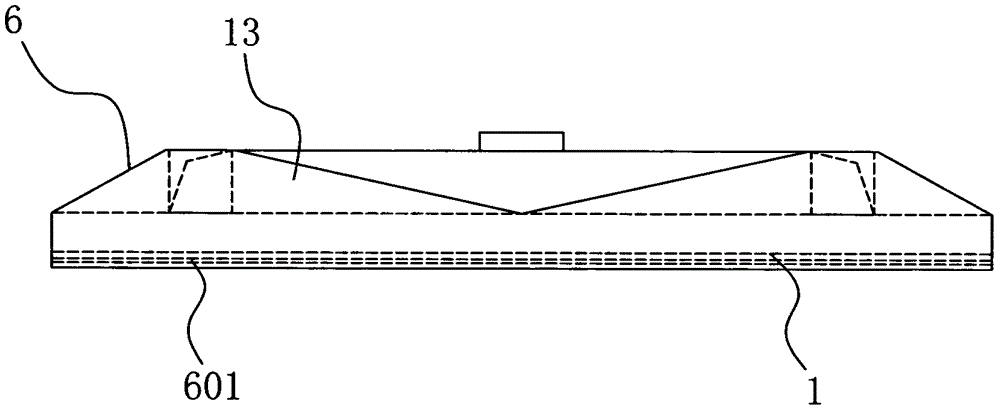

Anti-condensation air conditioning radiant panel and work method thereof

ActiveCN105757858AAvoid condensationGuaranteed uptimeCondensate preventionLighting and heating apparatusEngineeringAir blower

The invention relates to an anti-condensation air conditioning radiant panel in a radiation air-conditioning system and a work method of the anti-condensation air conditioning radiant panel.The anti-condensation air conditioning radiant panel comprises an air supply device and an air conditioning radiant panel body, the air supply device comprises an air blower, an air supply plenum chamber and an air return plenum chamber, the air inlet end of the air blower is connected with the air return plenum chamber through an air return pipe, an air outlet end of the air blower is connected with the air supply plenum chamber through an air supply pipe, the air supply plenum chamber and the air return plenum chamber are fixed to the two edges of the air conditioning radiant panel body respectively, the air supply plenum chamber is provided with an air outlet, the air return plenum chamber is provided with an air return opening, and air flow blown out of the air outlet is closely attached to the radiant surface of the air conditioning radiant panel body and jetted to the air return opening along the radiant surface; the air inlet end of the air blower is internally provided with a condensing coil for conducting temperature and humidity adjustment on inlet air of the air blower.The work method includes the steps that the air blower is started, a jet air membrane is formed on the surface of the air conditioning radiant panel body through the air outlet and the air return opening, the temperature and humidity of the jet air membrane is adjusted through the condensing coil, and condensation of the air conditioning radiant panel is effectively prevented.

Owner:余志锋

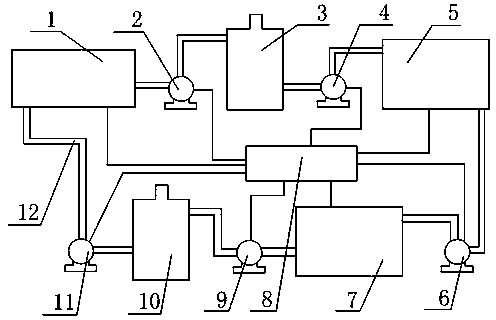

Microetching waste liquor regeneration and recovery system

InactiveCN103628068AOptimization principleImprove recycling efficiencyProduction lineProgrammable logic controller

The invention discloses a microetching waste liquor regeneration and recovery system. The system comprises an etching tank and a waste liquor storage tank communicated with the etching tank, the waste liquor storage tank is connected with a central two-stage system which is communicated with a regeneration liquor adjusting tank, the regeneration liquor adjusting tank is connected with a regeneration liquor storage tank which is communicated with the etching tank, water pumps are arranged between the etching tank and the waste liquor storage tank, between the waste liquor storage tank and the central two-stage system, between the central two-stage system and the regeneration liquor adjusting tank, between the regeneration liquor adjusting tank and the waste liquor storage tank as well as between the waste liquor storage tank and the etching tank and are simultaneously connected with a PLC (programmable logic controller) control system, and the etching tank, the central two-stage system and the regeneration liquor adjusting tank are simultaneously connected with the PLC control system. The recovery system is simple in principle, brings direct economic benefit and is high in copper recovery efficiency, reutilization of microetching liquor is achieved, cost is saved, cylinder changing time of a production line is shortened, production efficiency is improved, environmental protection pressure of factories is relieved, and social image of enterprises is improved.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

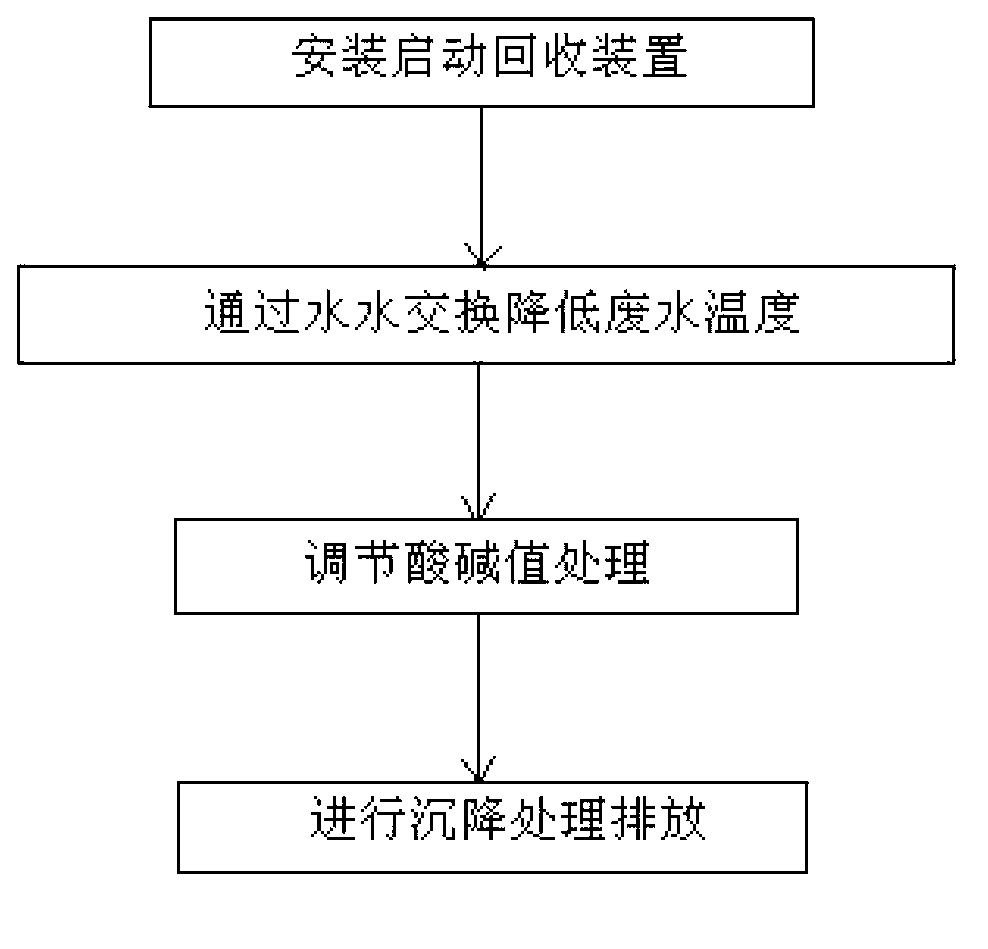

Printing and dyeing wastewater heat energy recovery and anti-dirty treatment method

InactiveCN103304071ASave steam and circulation pump powerReduce manufacturing costMultistage water/sewage treatmentCentrifugal pumpControl switch

The invention belongs to the technical field of wastewater heat energy recovery, and relates to a printing and dyeing wastewater heat energy recovery and anti-dirty treatment method. The method comprises the steps of starting a control switch in a switch box so that a recovery device begins to run and work; starting a control system, at which time high-temperature wastewater from a printing and dyeing production workshop is introduced to the recovery device through a centrifugal pump, open a faucet so that running water enters into the recovery device through a clean water inlet, implementing water-water exchange between cold clean water and heat wastewater through a heat exchange host machine, transmitting the heat wastewater to a regulating tank through a sewage outlet after reducing temperature and implementing acid-base equilibrium regulation until the sewage is neutral, and settling; discharging the sewage to a next wastewater treatment project through a discharge port after being settled for three times. The method is simple in process, simple and convenient to operate, rational in device structure, reliable in principle, low in manufacturing cost, good in recovery effect, high in recovery efficiency, and environmentally-friendly.

Owner:青岛德泰线业有限公司

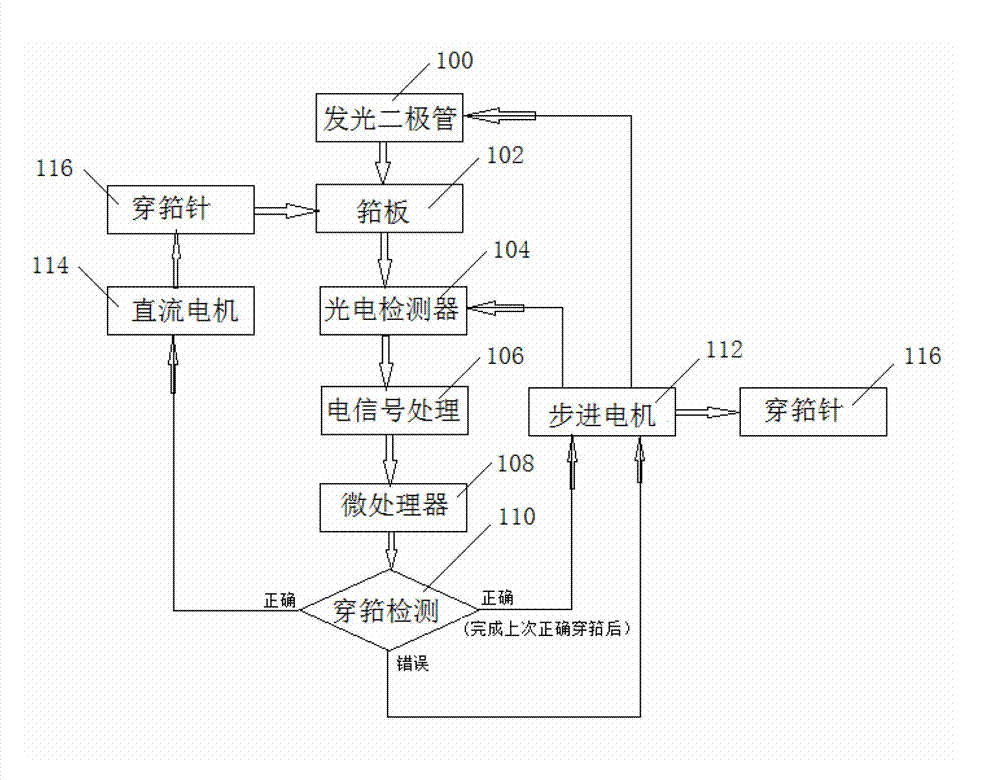

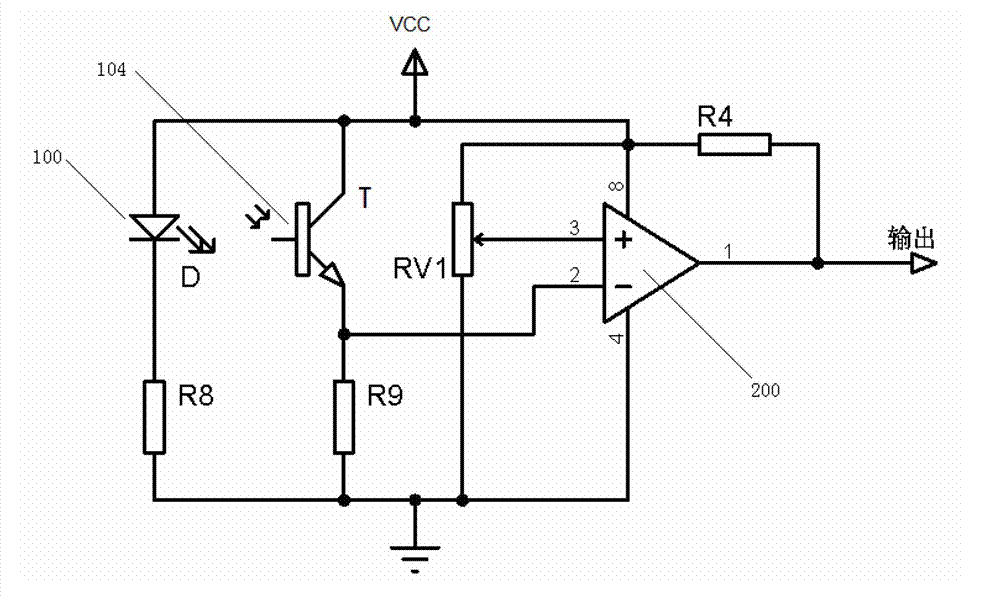

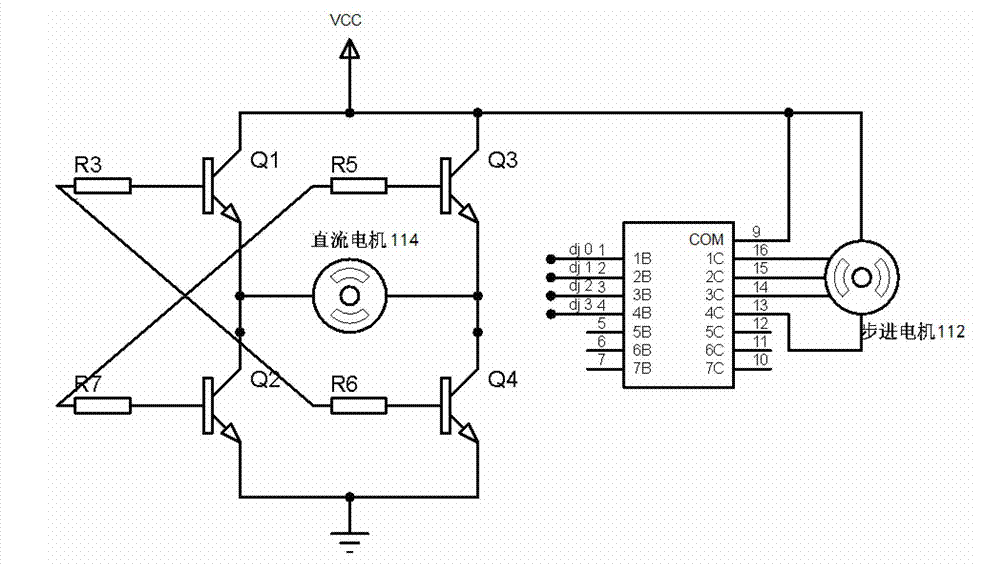

Photoelectric positioning system reeded by reeding machine

InactiveCN102733054AMeet various requirements for fast reedingSimple structureAuxillary apparatusOpto electronicElectric signal

The invention discloses a photoelectric positioning system reeded by a reeding machine. The system comprises a light emitting diode, a photoelectric detection device and a micro processing unit, wherein the light emitted by the light emitting diode is incident on a reeding plate so as to obtain an optical signal relevant with physical distribution of a dent reeding gap; the photoelectric detection device is used for performing photoelectric detection on the optical signal and outputting a corresponding electrical signal; the micro processing unit is used for detecting the physical distribution of the dent reeding gap according to the electrical signal and sending an adapted operation instruction to a stepper motor and a reeding device; and the reeding device finishes reeding operation or continuously moves according to the operation instruction of the micro processing unit. The photoelectric positioning system is simple in structure and principle, low in cost, convenient to use and widely applied to various automatic reeding machines.

Owner:FOSHAN UNIVERSITY

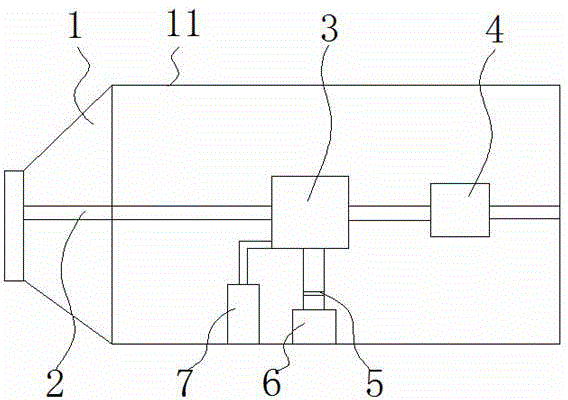

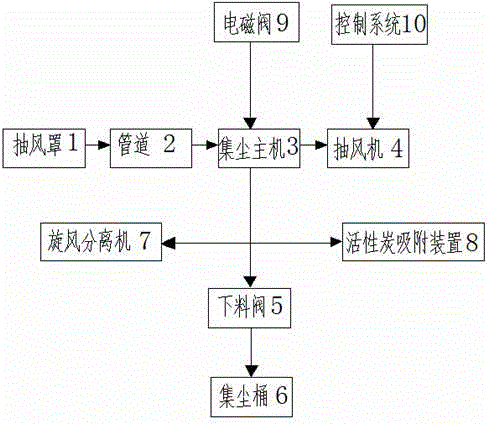

Efficient dust removal equipment

The invention discloses efficient dust removal equipment which comprises a dust removal equipment body, a main dust collecting unit and an exhaust fan, wherein the main dust collecting unit is arranged in the dust removal equipment body and connected with the exhaust fan, the exhaust fan discharges clean air through a pipeline, an exhaust hood is arranged at the front end of the dust removal equipment body, one end of the exhaust hood is connected with dust, the dust is sucked into the main dust collecting unit through a pipeline, a discharge valve is connected with the lower end of the main dust collecting unit and connected with a dust collecting bucket, and the main dust collecting unit is connected with a cyclone separator. According to the efficient dust removal equipment, the dust is sucked into the main dust collecting unit for treatment through the pipeline by the aid of the exhaust fan, a dust removal system can rapidly remove dust in air, air cleanness is guaranteed, and the dust removal equipment is good in dust removal effect, simple in principle and flexible to control, can rapidly remove the dust in the air to guarantee cleanness of the air and is particularly suitable for people working or living indoors.

Owner:黄浩

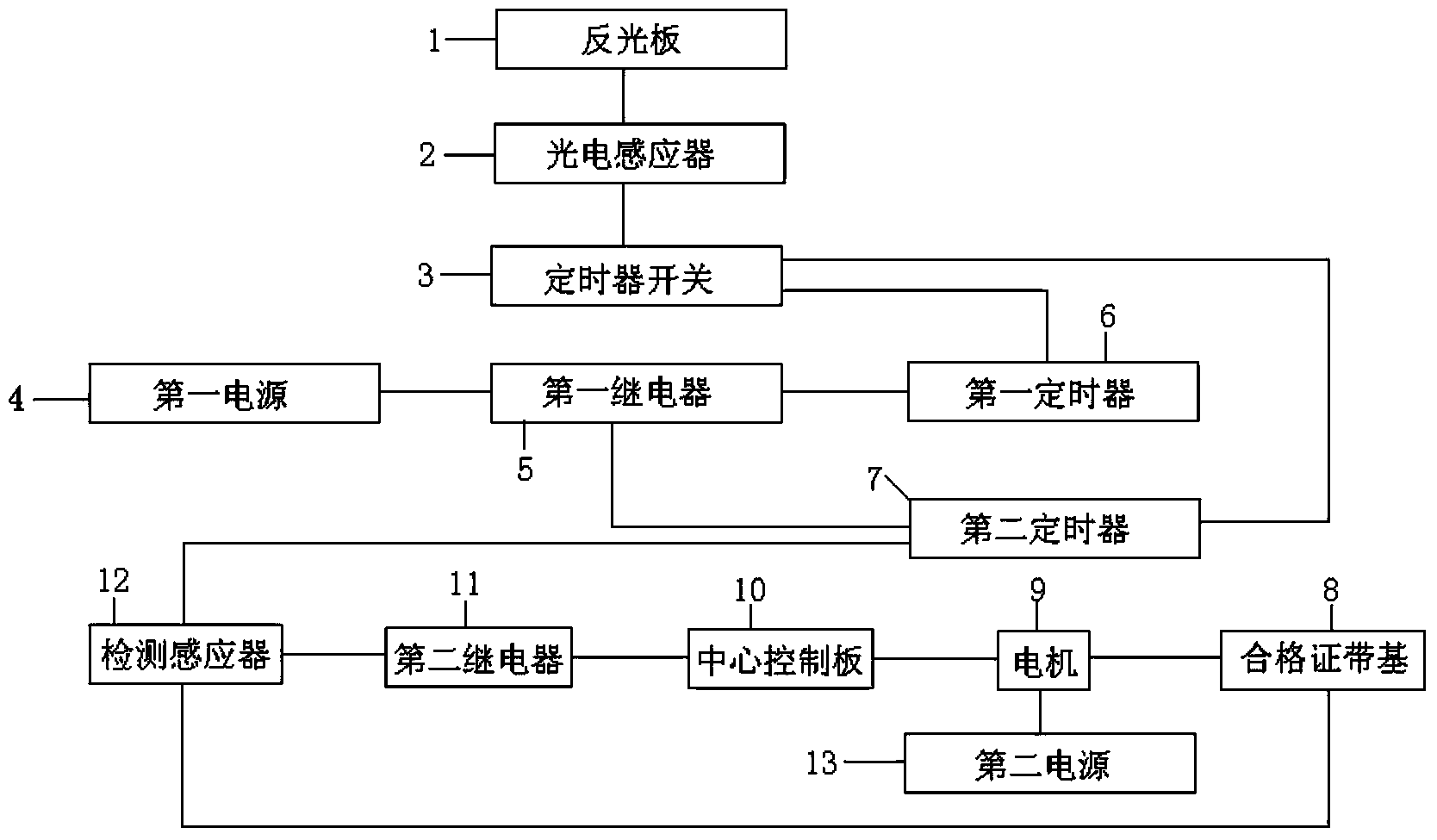

Automatic ammeter certificate pasting device

ActiveCN103587766AAvoid missed stickersSave human effortLabelling machinesElectricityManufacturing technology

The invention belongs to the technical field of electronic equipment manufacture, and relates to an automatic ammeter certificate pasting device. A reflector is arranged at the front end of the pasting device, a photoelectric sensor is mounted right in front of the reflector and is electrically connected with a timer switch, and the timer switch is electrically communicated with a first timer and a second timer; the left end of the first timer is electrically connected with a first relay, a first power supply supplies power to the first relay, and the right end of the first timer is electrically connected with the second timer; the second timer is electrically communicated with a second relay, the ports of the second relay are respectively and electrically communicated with the first power supply, a detection sensor and a central control panel, the central control panel is electrically connected with a motor, the take-up shaft of the motor is sleeved with a certificate backing tape, a certificate separation plate is formed above the certificate backing tape, and a second power supply supplies power to the central control panel. The device has the advantages of simple structure, reliable principles, high automation level, productivity, pasting accuracy and pasting speed, as well as environmental friendliness.

Owner:元启工业技术有限公司

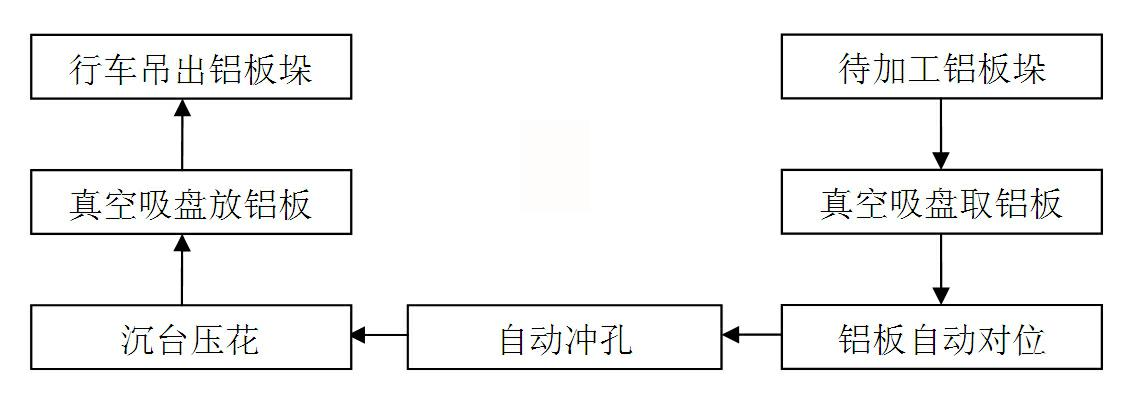

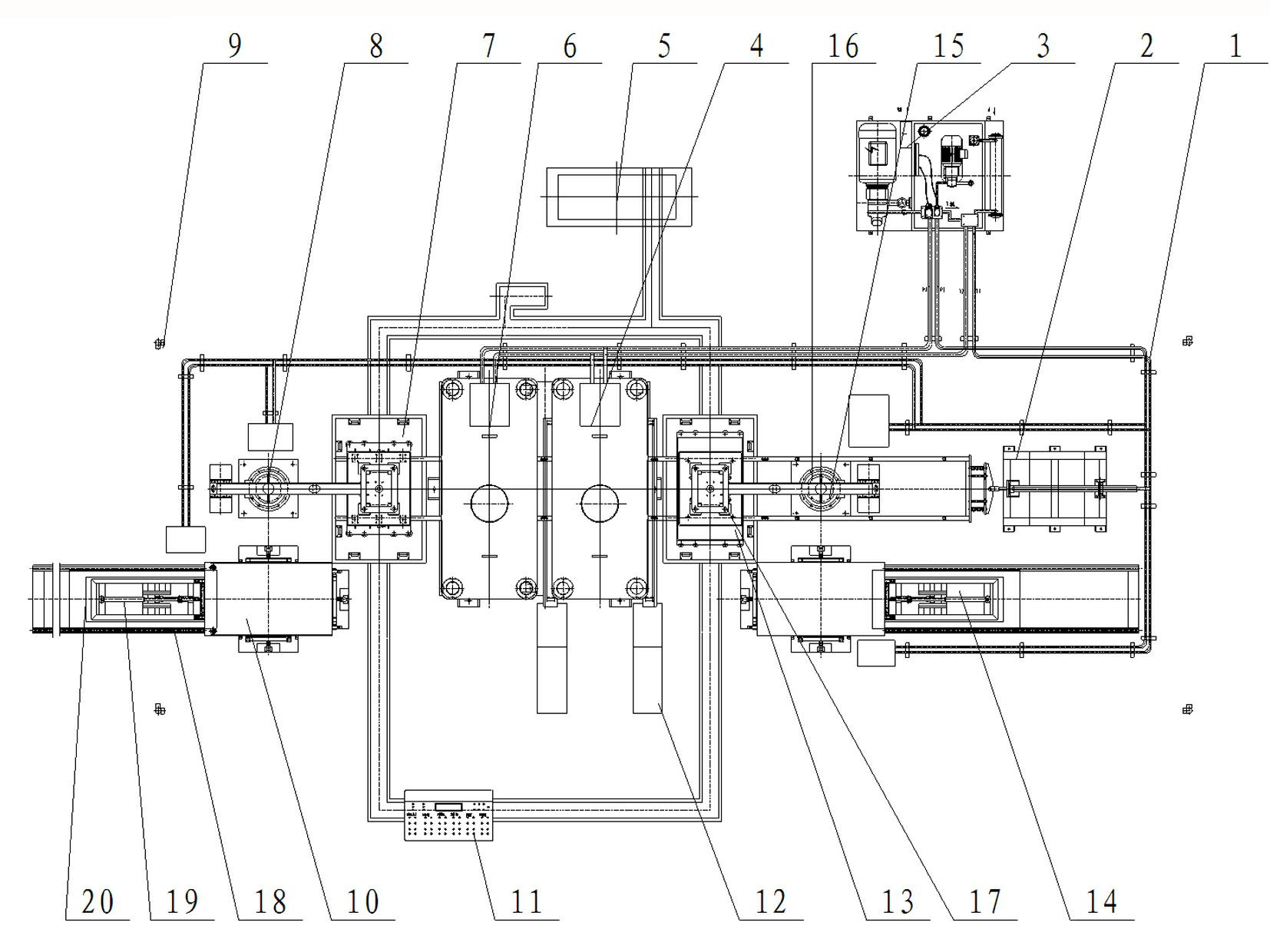

Automatic punching and discharging machine for large-area zinc electrolyzing cathode plate

ActiveCN102430643AChanging the problem of liftingNo damageMetal-working feeding devicesStripping-off devicesPunchingElectrolysis

The invention discloses an automatic punching and discharging machine for a large-area zinc electrolyzing cathode plate. The automatic punching and discharging machine for the large-area zinc electrolyzing cathode plate consists of a feeding mechanism (14), a feeding manipulator (13), a material pushing device (2), a punching machine (4), an excess material collecting box (12), a sunk table flattener (6), a material bearing platform (7), a discharging manipulator (8), a plate material discharging mechanism (10), an infrared safety protecting rail (9), a console (11), a GGD cabinet (5), a hydraulic pipeline (1) and a hydraulic station (3). A 3.2m<2> zinc electrolyzing cathode plate is pushed onto the punching machine and the sunk table flattener through the feeding manipulator and the material pushing device and automatically punched and discharged, a sunk table at a release opening is manufactured, and the side edge of an aluminum plate is knurled. The automatic punching and discharging machine for the large-area zinc electrolyzing cathode plate has the obvious advantages of compact structure, high punching efficiency, high automatic degree, easy operation, reliable performance and the like; and multiple workstations work at the same time, so that a continuous production is realized.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

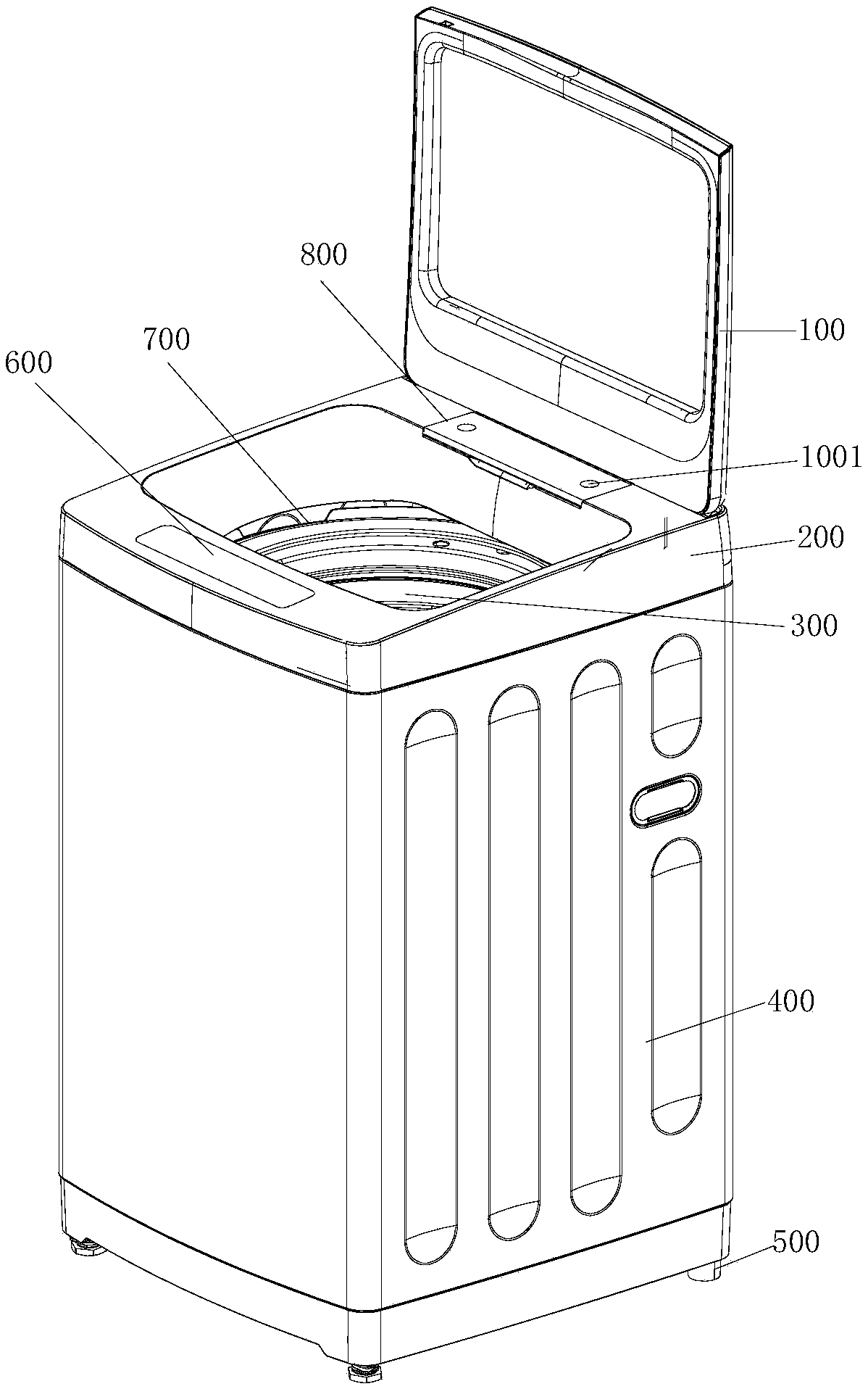

Clothing treating agent release device and washing machine

PendingCN110965276AOptimization principleEasy to operateOther washing machinesTextiles and paperLaundry washing machineReciprocating motion

The invention provides a clothing treating agent release device and a washing machine. The clothing treating agent release device comprises a pneumatic driving device, a pneumatic release device and astorage device; the pneumatic driving device comprises a pneumatic chamber and a pressing component; the pneumatic release device is provided with a release chamber, and a liquid inlet, a liquid outlet and a gas access are formed in the release chamber; a liquid inlet one-way conducting component is arranged on the liquid inlet; the storage device is internally provided with a storage chamber forstoring a clothing treating agent; and the gas access of the pneumatic release device communicates with the pneumatic chamber of the pneumatic driving device, and the liquid inlet communicates with the storage device. Exhaust pressure reduction / ventilation pressurization of the pneumatic driving device is achieved by pressing the pressing component to do reciprocating motion to change the volumeof the pneumatic chamber, and the liquid inlet one-way conducting component opens / closes the liquid inlet under the action of exhaust pressure reduction / ventilation pressurization, and the pneumatic release device is used for extracting the clothing treating agent from the storage device and discharging the clothing treating agent from the liquid outlet.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

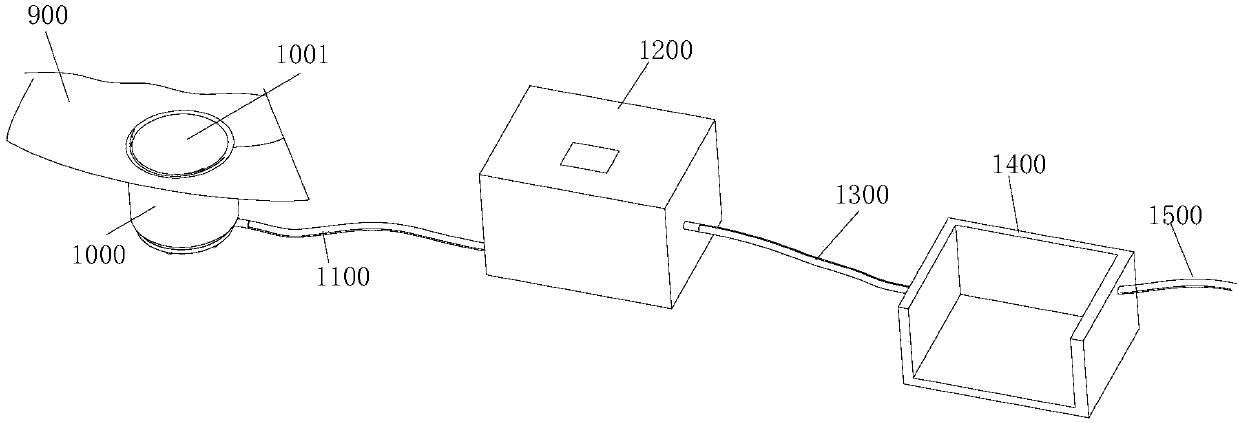

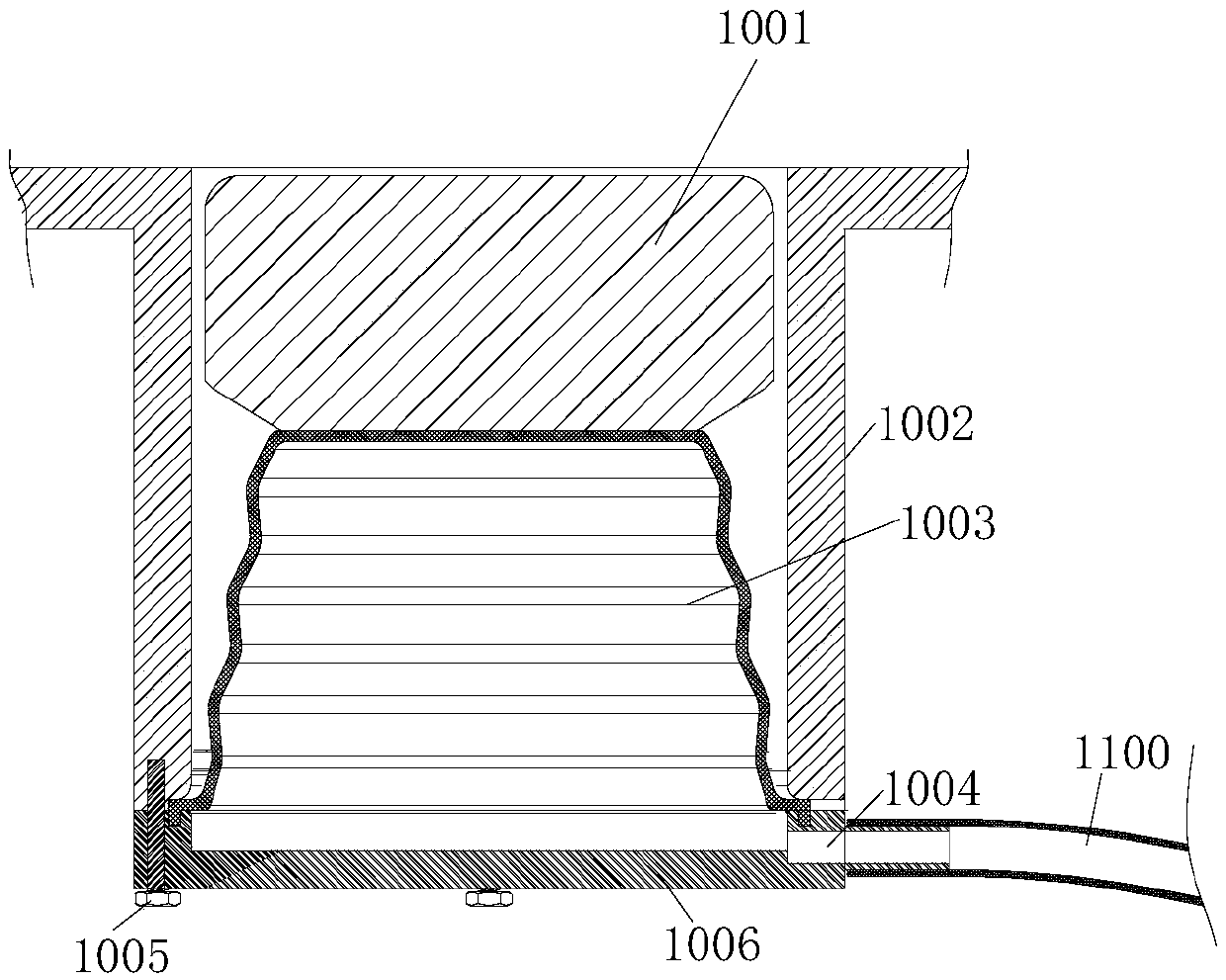

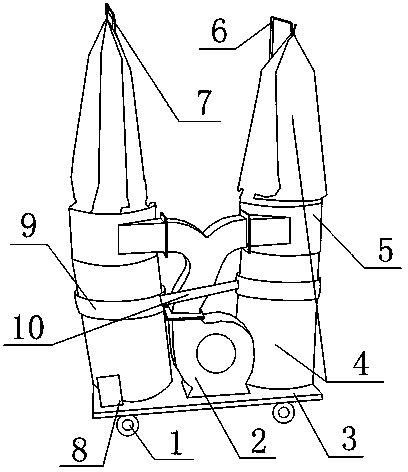

Movable twin-tub cloth bag dust-collection device

InactiveCN103659959ASimple structureOptimization principleBark-zones/chip/dust/waste removalPhysical healthEngineering

The invention discloses a movable twin-tub cloth bag dust-collection device which comprises a support plate. Two containers and a vacuum cleaner are arranged on the support plate, the container is connected with the vacuum cleaner, a plurality of rollers are arranged at a bottom end of the support plate, a support clamp is arranged between the rollers and the support plate, and the vacuum cleaner is arranged between the two containers and is simultaneously connected with the two containers. Hoops are sleeved on external walls of the containers, a connecting plate is arranged between the hoops, and two ends of the connecting plate are respectively connected with the hoops. The dust-collection device is simple in structure, simple and convenient in principles, and is capable of moving quickly so that timeliness of dust collection is guaranteed. And meanwhile, the dust-collection device is fine in dust-collection effect, dust content in the air of a production department is reduced, maintenance of production equipment is reduced, physical health of operators is protected, and collected dust can be used in other fields, and accordingly environmental protection and reusability of resources are achieved.

Owner:CHENGDU TIANPAN TECH

Petroleum component lifting equipment adopting hydraulic pressure as power

InactiveCN104828741AEasy to operateReasonable diversion treatmentLifting framesHydraulic cylinderFuel tank

The invention discloses petroleum component lifting equipment adopting hydraulic pressure as power. A filtering device is arranged in an oil tank; a hydraulic pump is arranged above the oil tank; a large hydraulic cylinder and a small hydraulic cylinder are arranged above the hydraulic pump; a positioning block is arranged between the large hydraulic cylinder and the small hydraulic cylinder; a large piston is arranged in the large hydraulic cylinder, and is fixed with a support table; a small piston is arranged in the small hydraulic cylinder; a press rod is arranged above the positioning block; the press rod is connected with a rotating head; a connecting rod is arranged under the press rod, and is connected with a lantern ring; the press rod passes through the lantern ring; an oil inlet pipe is arranged between the oil tank and the small hydraulic cylinder, and passes through the hydraulic pump; an oil inlet one-way valve is arranged on the oil inlet pipe; the oil inlet pipe is communicated with a flow rate control valve; an oil discharging pipe is arranged on the oil inlet pipe. The equipment has the advantages that the lever and hydraulic pressure principle is utilized for lifting metal components, the occupied area is small, the cost is low, the operation by operators is convenient, the carrying is convenient, in addition, the reasonable flow guide treatment can be realized on hydraulic oil, and the service life is prolonged.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

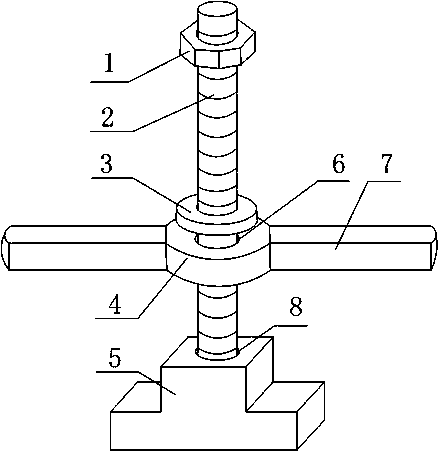

Manual hydraulic lifting device in machining

The invention discloses a manual hydraulic lifting device in machining. A hydraulic pump is arranged above an oil tank and is connected to the oil tank, wherein a large hydraulic cylinder and a small hydraulic cylinder are arranged above the hydraulic pump; the small hydraulic cylinder is connected to the hydraulic pump; an opening is formed in the top of each of the large hydraulic cylinder and the small hydraulic cylinder; a positioning block is arranged between the large hydraulic cylinder and the small hydraulic cylinder and is fixed to the large hydraulic cylinder and the small hydraulic cylinder; a large piston is arranged in the large hydraulic cylinder; a support table is fixed on the top of the large piston and is arranged above the large hydraulic cylinder; a small piston is arranged in the small hydraulic cylinder; a pressing rod is arranged above the positioning block; the pressing rod is connected to a connector; the connector is fixed to the positioning block; a connection rod is arranged under the pressing rod and is respectively connected to the pressing rod and the small piston. The manual hydraulic lifting device is simple in structure, simple in principle, small in occupied area, low in cost and convenient to carry; metal parts can be lifted by using the principles of levers and hydraulic pressure; the manual hydraulic lifting device can be conveniently operated by operators.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

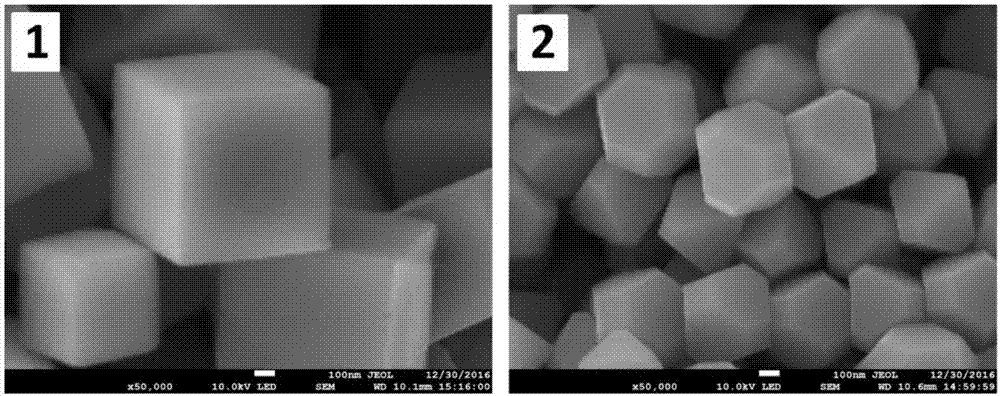

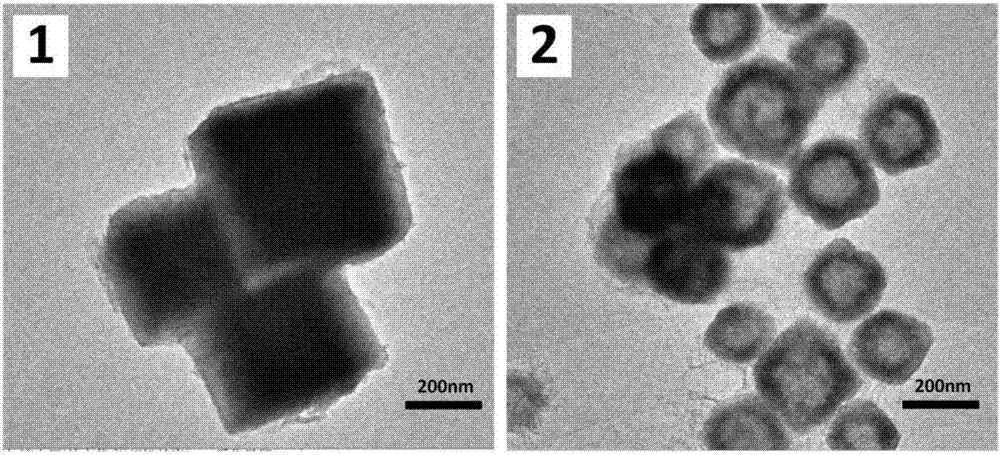

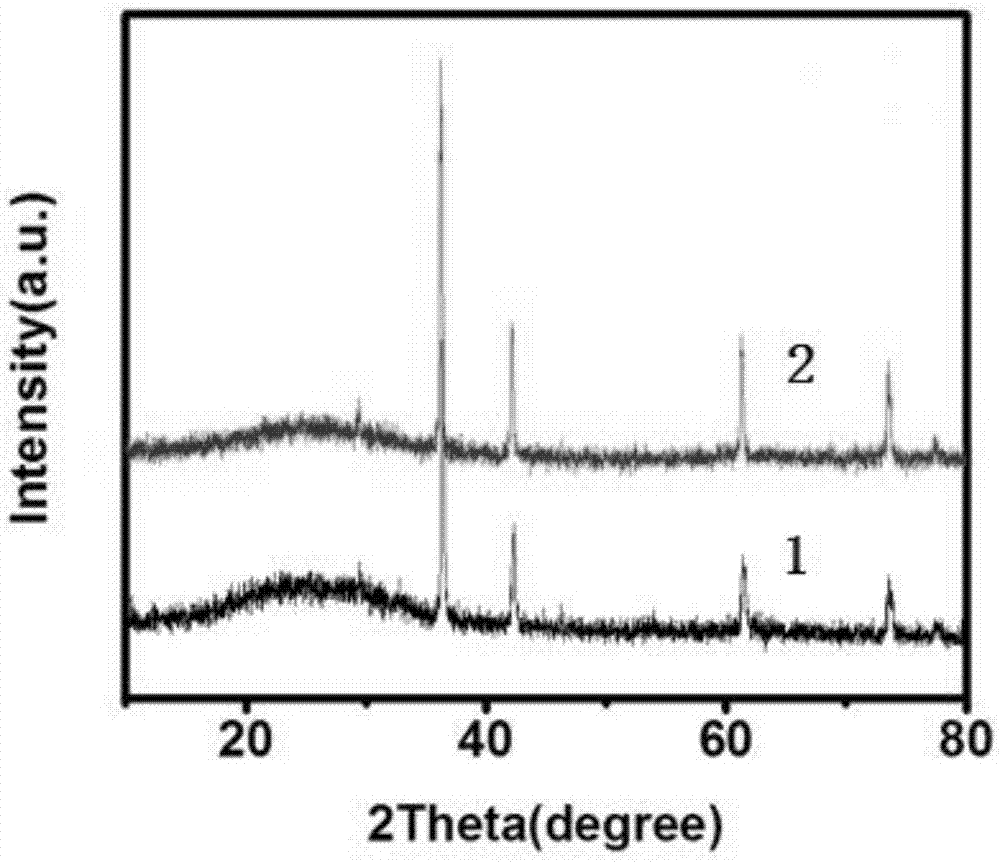

Preparation method of Cu2O nanocrystalline cubes and hollow polyhedrons

InactiveCN107954463AGood photodegradation effectEasy to detectCopper oxides/halidesMetal/metal-oxides/metal-hydroxide catalystsCopper platingNitrobenzene

The invention belongs to the technical field of preparation of transition metal oxides and relates to a preparation method of Cu2O nanocrystalline cubes and hollow polyhedrons to be applied to preparation occasions of catalytic materials, antifouling paint, insecticides as well as various copper salts, analytical reagents, red glass, copper plating and copper plating alloy solutions. The problem about industrial preparation of Cu2O nanocrystalline cubes and hollow polyhedrons is solved, and synthesized nanocrystals have good photocatalytic performance, can quickly adsorb azo dyes, are easy toseparate and have a good detection effect on nitrobenzene in a Na2SO4 solution. Firstly, copper acetate monohydrate and sodium hydroxide are subjected to a reaction, sodium dodecyl sulfate is used asa surfactant and a stabilizer, deionized water and a hydrazine hydrate aqueous solution in different volume ratios are added, and the Cu2O nanocrystalline cubes and hollow polyhedrons are prepared. The preparation technology is simple, the principle is reliable, the preparation cost is low, and products are high in purity, good in performance, wide in application range and environmentally friendlyin use.

Owner:QINGDAO UNIV

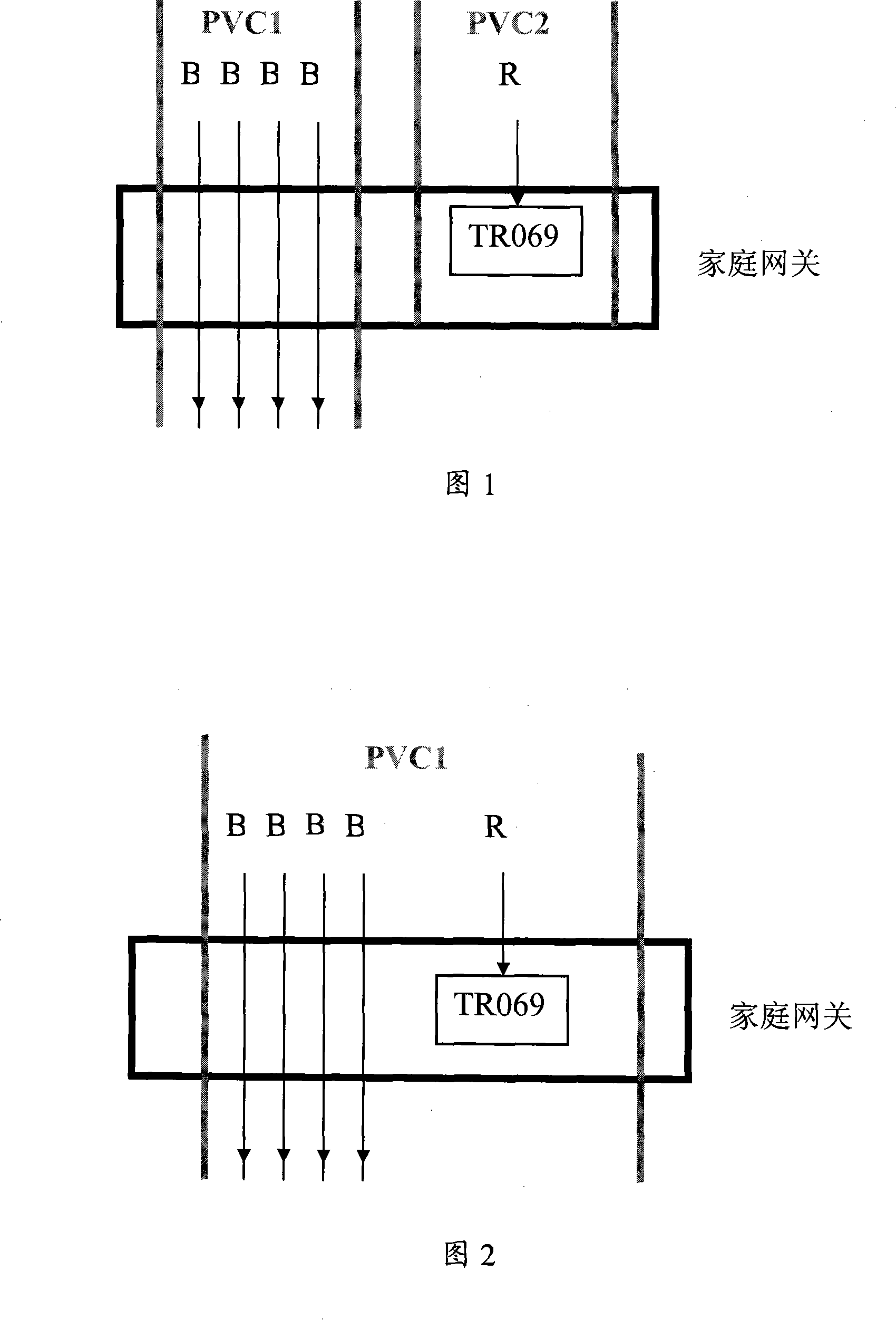

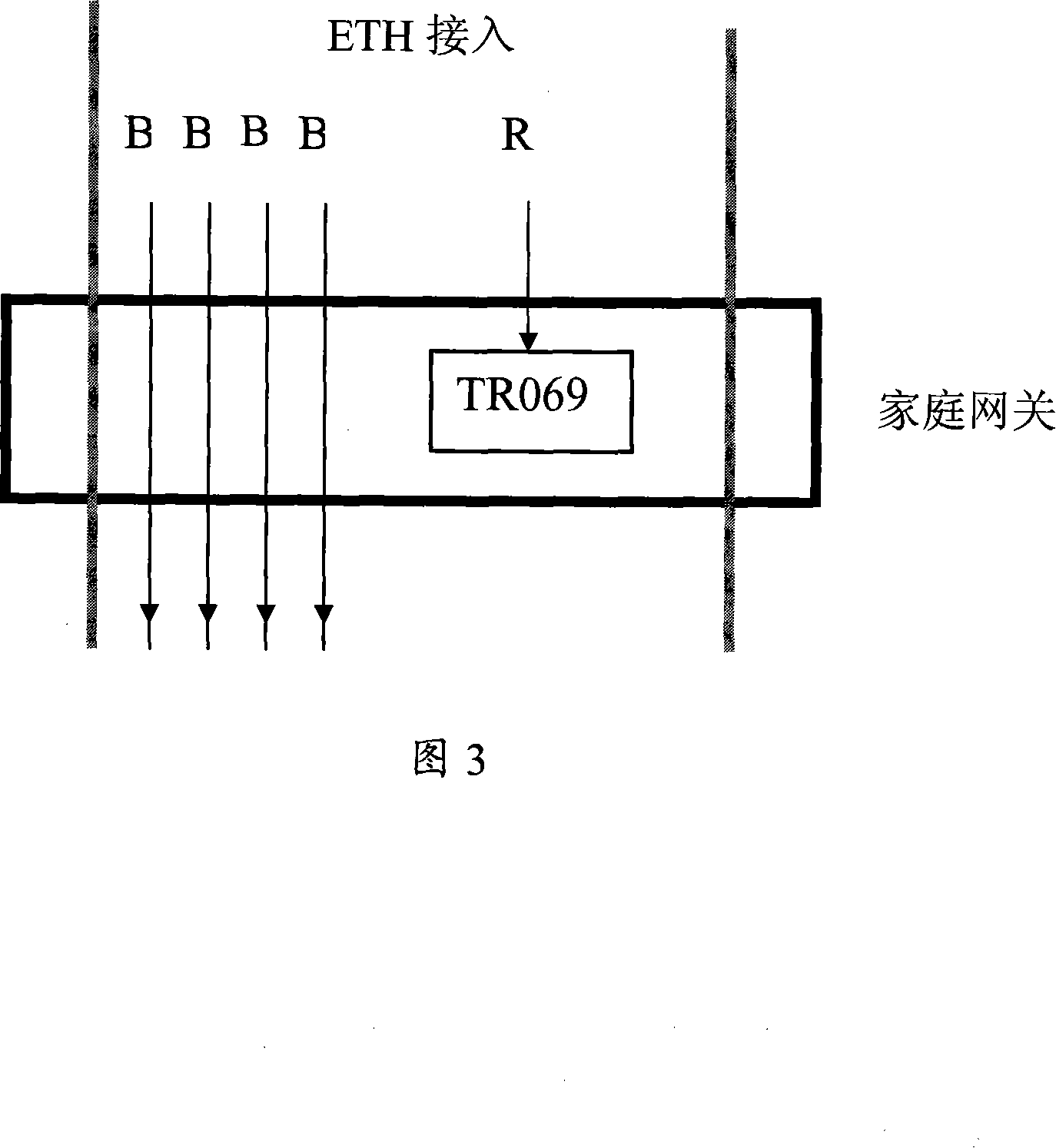

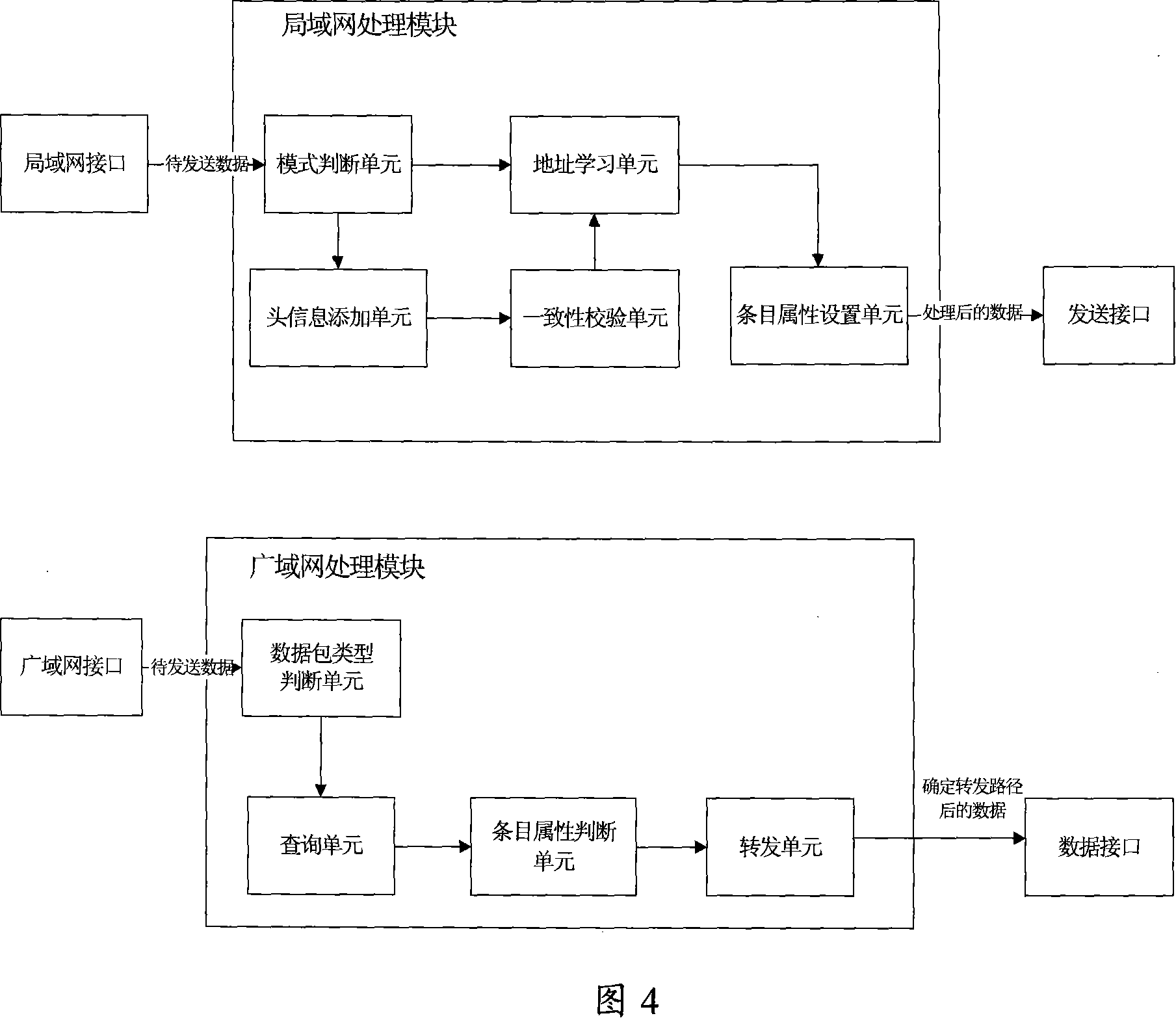

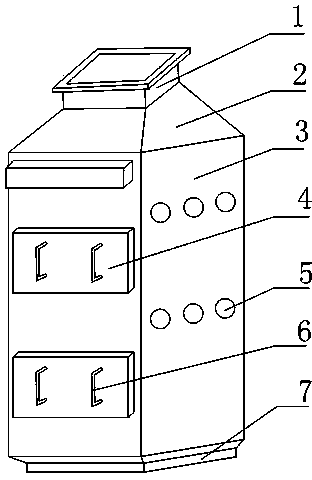

A method and device for improving data forwarding performance of WAN bridge

InactiveCN101150480AImprove performanceOptimization principleNetworks interconnectionNetwork packetComputer science

The invention discloses a method and a device for improving the performance of data forwarding of the WAN Bridge. The invention comprises the processes that the corresponding address learning items are set in a forwarding table after the WAN bridge receives the data packets; when the WAN bridge forwards the data packets, the WAN bridge first judges the type of the data packets; if the data packets are uni-packets, the WAN bridge determines the forwarding path of the data packets to be sent by querying the address learning items in the forwarding table so as to further forward the data packets according to the forwarding path. Compared with the prior art, the data forwarding mechanism of the invention effectively improves the performance of data forwarding of the WAN bridge with a simpler principle for operation and an easier method for implementation. With respect to the processing of the data packets, the invention realizes the transition from forwarding all data packets blindingly to all link accesses in the prior art to precise forwarding via the forwarding path of data packets determined by the invention, and particularly shows obvious improvement in data forwarding performance of the WAN bridge when a large number of the shared-links exist.

Owner:ZTE CORP

Organic waste gas treatment system for process of recycling etching liquid

InactiveCN103623695AEfficient decompositionSimple structureDispersed particle separationPhoto catalyticCarboxylic acid

The invention discloses an organic waste gas treatment system for a process of recycling etching liquid. The organic waste gas treatment system comprises a treatment tower with the hollow inside, a gas inlet and a gas outlet are respectively arranged at two ends of the treatment tower, the gas outlet is positioned above the gas inlet, a plurality of chemical agent boxes are arranged in the treatment tower, the chemical agent boxes can horizontally move in the treatment tower, and a plurality of lamp tubes are positioned above each chemical agent box. The system is simple in structure and simple and convenient in principle, organic waste gas in the air can be directly oxidized into non-toxic and harmless materials through photo-catalytic oxidation to avoid any secondary pollution, some organisms which are difficult to oxidize by ozone can be effectively resolved, the treatment system has effect on various organisms from hydrocarbon to carboxylic acid, service life of the treatment system is long, cost is saved, and replacement frequency is reduced.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

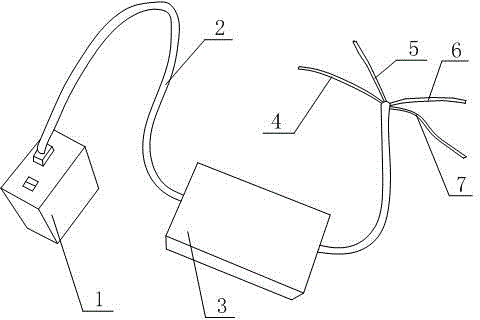

System capable of accurately detecting oil consumption

InactiveCN103335683ASimple structureOptimization principleRelative volume flow measurementsFuel tankFood consumption

The invention discloses a system capable of accurately detecting oil consumption. The system comprises an oil consumption detector, wherein the oil consumption detector is provided with a power supply cord; the power supply cord is connected with an oil consumption detection box; the oil consumption detector box is provided with a plurality of data lines; and the oil consumption detection box is provided with an LED (Light Emitting Diode) display. The oil consumption detection system is simple in structure, simple in principle, the condition of oil consumption can be digitally displayed through connection with an oil tank and an oil gauge and is convenient for a user and an owner to check, false reporting conditions such as oil theft are prevented, and the loss of the owner is reduced.

Owner:CHENGDU CONETON SCI & TECH

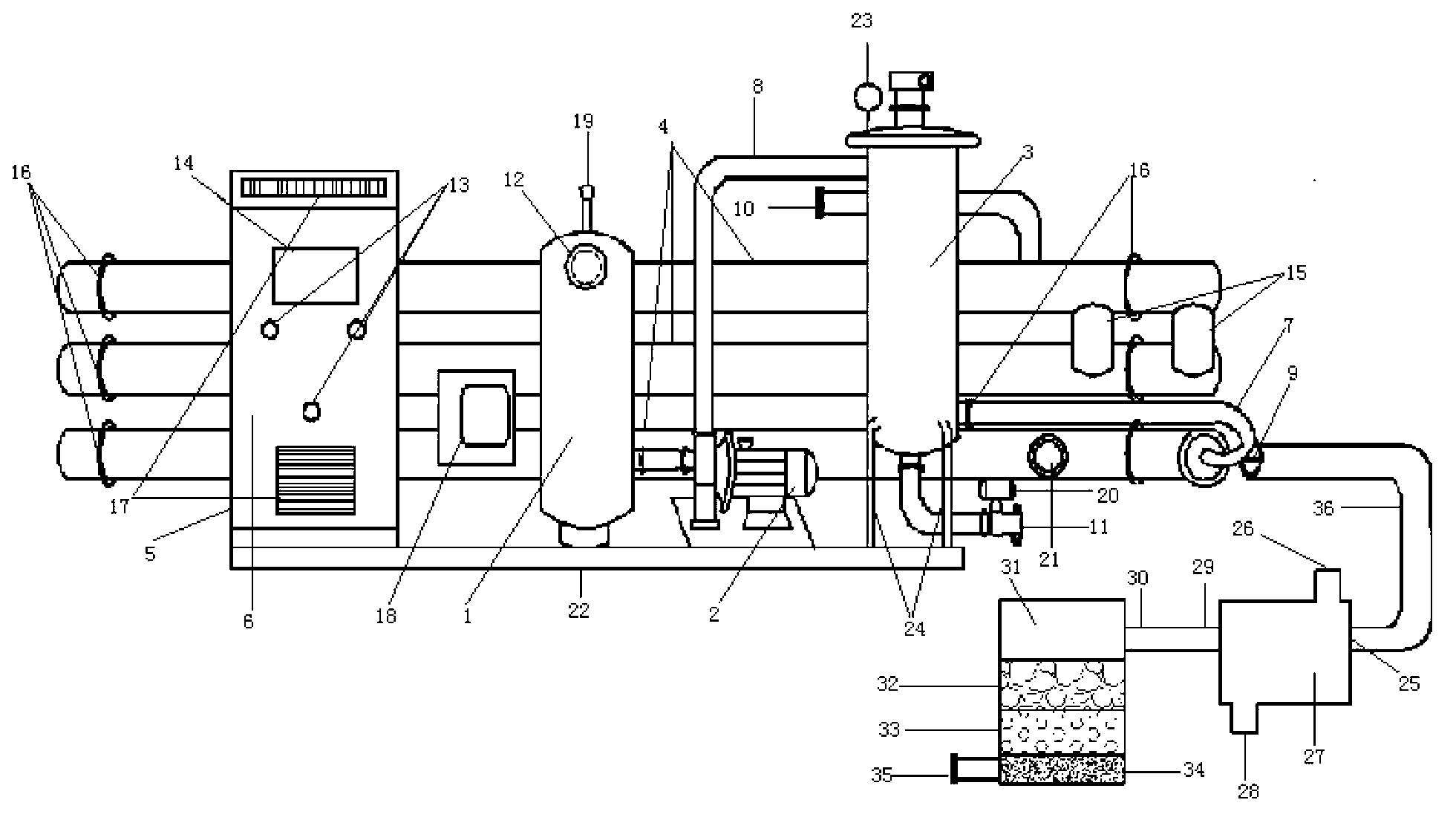

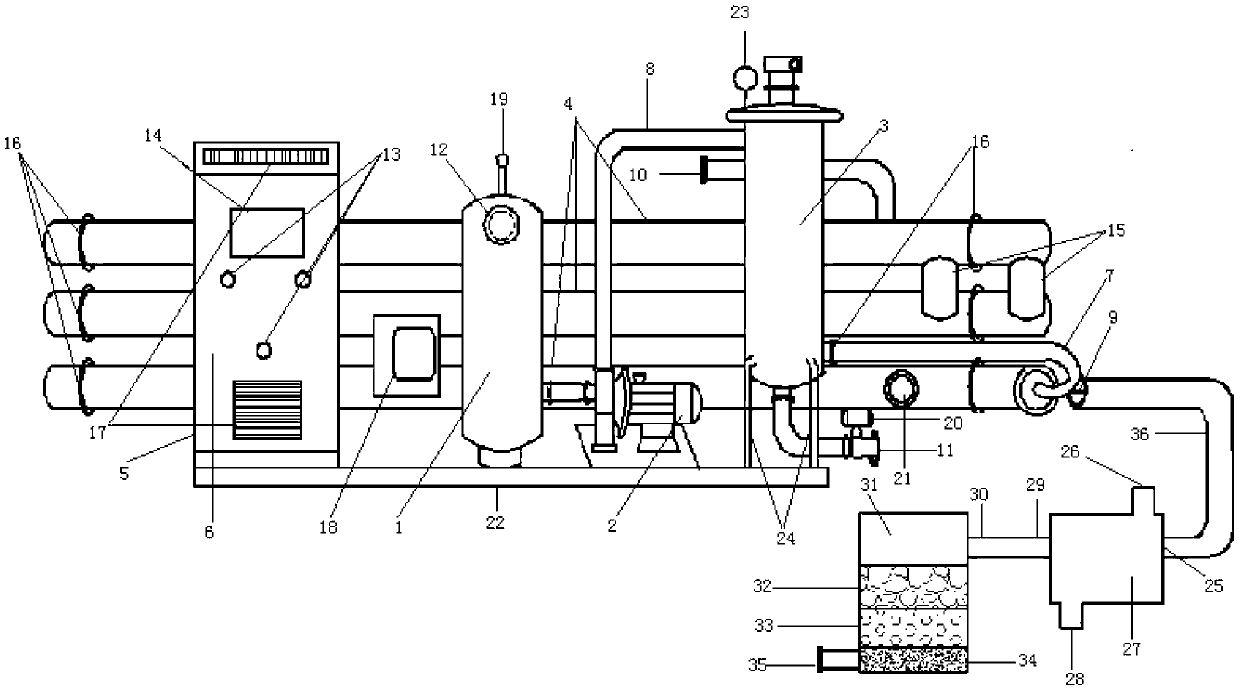

Dyeing wastewater heat recovery and antifouling treatment device

InactiveCN103342422AReduce manufacturing costReduce running timeMultistage water/sewage treatmentThermal energySwitch box

The invention belongs to the technical field of wastewater heat recovery, and relates to a dyeing wastewater heat recovery and antifouling treatment device. A centrifugal pump is fixedly communicated with a vacuum tank; the top of the vacuum tank is provided with an air valve; the surface of the upper end of the vacuum tank is provided with an instrument board; an automatic filter is fixed to the right end of a base; a water outlet valve is arranged above a clear water outlet; the top of the automatic filter is provided with a control valve; the abutting section of the bottommost end pipeline of the host heat exchanger and a sewage outlet is provided with a thermometer board; the upper surface of a control cabinet is provided with buttons and a display screen; a control system is installed in the control cabinet; a switch box is fixed between two pipelines on the lower part of the host heat exchanger; the right upper end and left lower end of a conditioning tank are respectively provided with a filler port and a discharge port; and a coarse grain layer, a medium grain layer and a fine sand layer are laid in a settling tank. The device has the advantages of reasonable structure, reliable principle, simple technical process, low manufacturing cost, favorable recovery effect and high recovery efficiency, and is simple to operate and environment-friendly.

Owner:青岛德泰线业有限公司

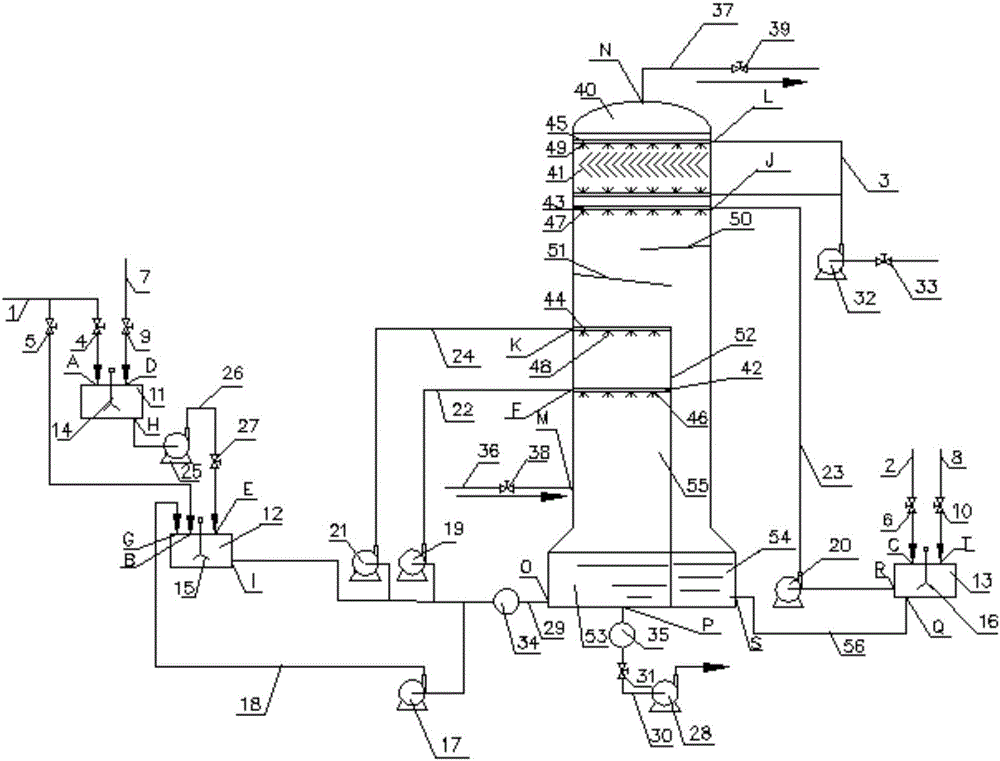

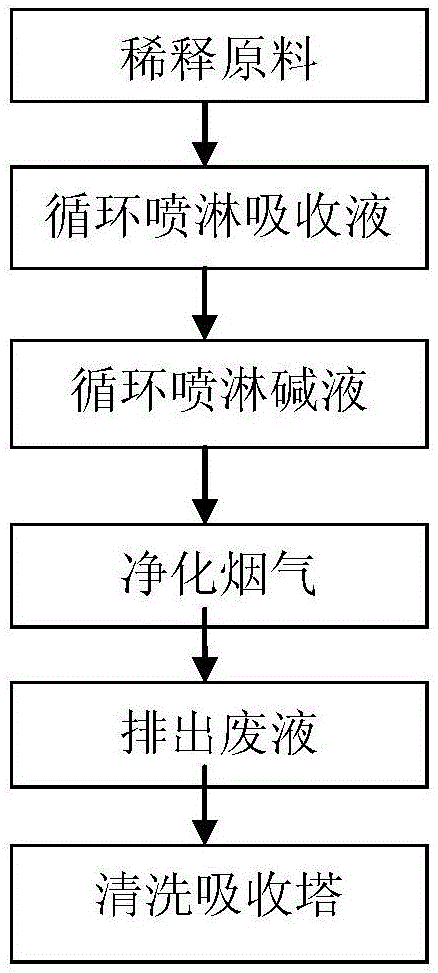

Solution-method fume desulfurization and denitrification integral device

InactiveCN106731601AReduce consumptionReduce supplementationGas treatmentDispersed particle separationPotassium hypochloriteNitric oxide

The invention belongs to the technical field of environment protection equipment, relates to a fume desulfurization and denitrification integral device, in particular relates to a solution-method fume desulfurization and denitrification integral device, and is applicable to industrial kiln gas fume desulfurization and denitrification situations. Sodium hypochlorite and sodium chlorite or potassium hypochlorite and potassium chlorite are adopted as a composite absorption solution for fume treatment, the composite absorption solution has a concerted reaction property for oxidizing nitric oxide and absorbing sulfur dioxide, a process method comprises a spraying process, a part of unoxidized acid gases can be reoxidized and absorbed, the fume desulfurization and denitrification efficiency can be improved, the device is simple and convenient in process, simple in structure, convenient to construct and use, low in maintenance cost and long in service life, reasonable utilization of wastes can be achieved, pollution discharge can be effectively reduced, and wide and great social benefits and industrial application values can be made.

Owner:QINGDAO UNIV

Method capable of accurately determining suspended solids in water quality

InactiveCN107764684AAccurate measurementProtect your healthParticle suspension analysisWeighing by absorbing componentFiltrationRoom temperature

The invention discloses a method capable of accurately measuring suspended matter in water quality. Use tweezers to pick up medium-speed quantitative filter paper, move it into an oven, dry it at 103-105°C for half an hour, take it out, put it in a desiccator and cool it to room temperature, and call it Weight, repeated drying, cooling, and weighing until the weight difference between the two weighings was ≤0.2mg, folded the medium-speed quantitative filter paper with constant weight into the funnel, put it into the Erlenmeyer flask, and measured the fully mixed and uniform sample Filter 50mL of the sample to make all the water pass through the filter paper. After stopping the filtration, move it into an oven for drying at 103-105°C for one hour, then move it in and out, let it cool to room temperature, weigh it, and repeat drying, cooling, and weighing until The weight difference between the two weighings is ≤0.4mg. The principle of the method is simple, and it can accurately measure the quantity and type of suspended matter in the water quality, determine whether the water quality meets the drinking standard for human body, and protect people's health.

Owner:张鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com