Fuel rod contact type measuring anti-collision structure and anti-collision method thereof

A contact measurement and anti-collision technology, which is used in nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve the problems that fuel rods cannot be returned to the reactor for reuse, unfavorable inspection work economy, fuel rod damage, etc. The principle is simple and avoids contact. Or the effect of grasping is not firm and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

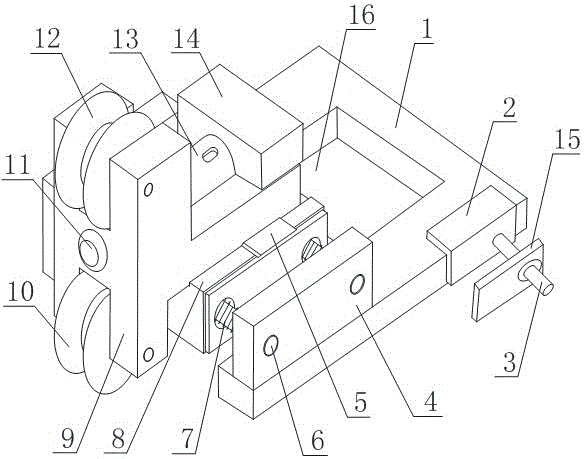

[0026] Such as figure 1 As shown, a fuel rod contact type measurement anti-collision structure, which is installed on the main working platform in the poolside inspection equipment, includes a base 1 that can slide, and the base 1 is provided with a mounting block 8, and the mounting block 8 Connected to the base 1, a support slider 9 is provided on the installation block 8, and the support slider 9 can slide on the installation block 8 along the upper surface of the installation block 8, and the sliding direction of the support slider 9 is consistent with the sliding direction of the base 1 In the same direction, a buffer mechanism 13 is provided on the support slider 9, and the buffer mechanism 13 is connected with a measuring probe 11, and the measuring probe 11 can slide along with the buffer mechanism 13, and the sliding direction is the same as that of the supporting slider 9, and the supporting slider The block 9 is provided with an upper guide pulley 12 and a lower gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com