Transfer robot

A technology of robots and servo motors, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as inability to distinguish the size and shape of objects, damage to grasped objects, wrongly grasping target objects, etc., to achieve high reliability, Reduces injuries and increases the range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

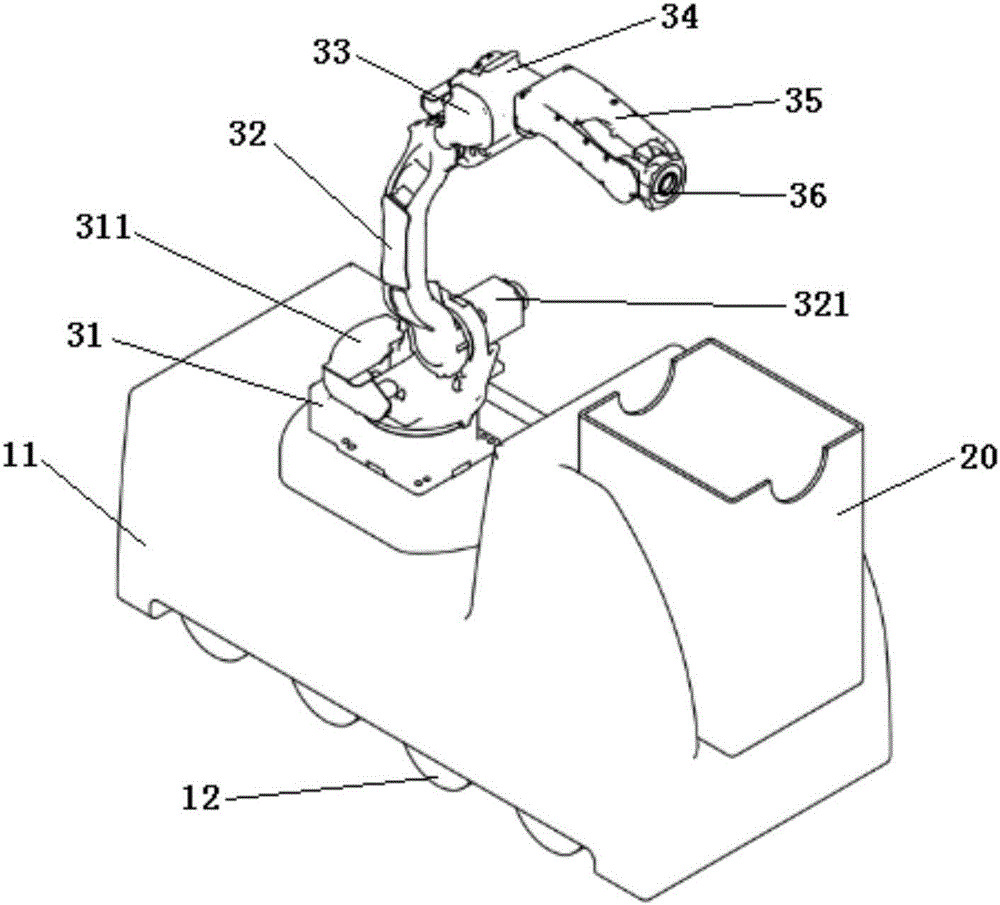

[0019] see figure 1 , a transfer robot described in the present invention includes an AGV trolley, a material grabbing arm that can freely grab objects, and a main controller. The AGV trolley includes a car body 11 and a transfer chassis 12 for driving the car body 11 to move. The car body 11 is an internal cavity structure, and the car body 11 is provided with a main controller, the main controller is located in the control box, and the control box is hidden in the car body 11. The car body 11 is also provided with a material storage box 20 and an automatic positioning mechanism. The grasping arm includes a base 31 , a first connecting arm 32 , a second connecting arm 33 , a third connecting arm 34 , a fourth connecting arm 35 and a fifth conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com