Dyeing wastewater heat recovery and antifouling treatment device

A technology of heat energy recovery and antifouling treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of high recycling efficiency, low manufacturing cost and reducing the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

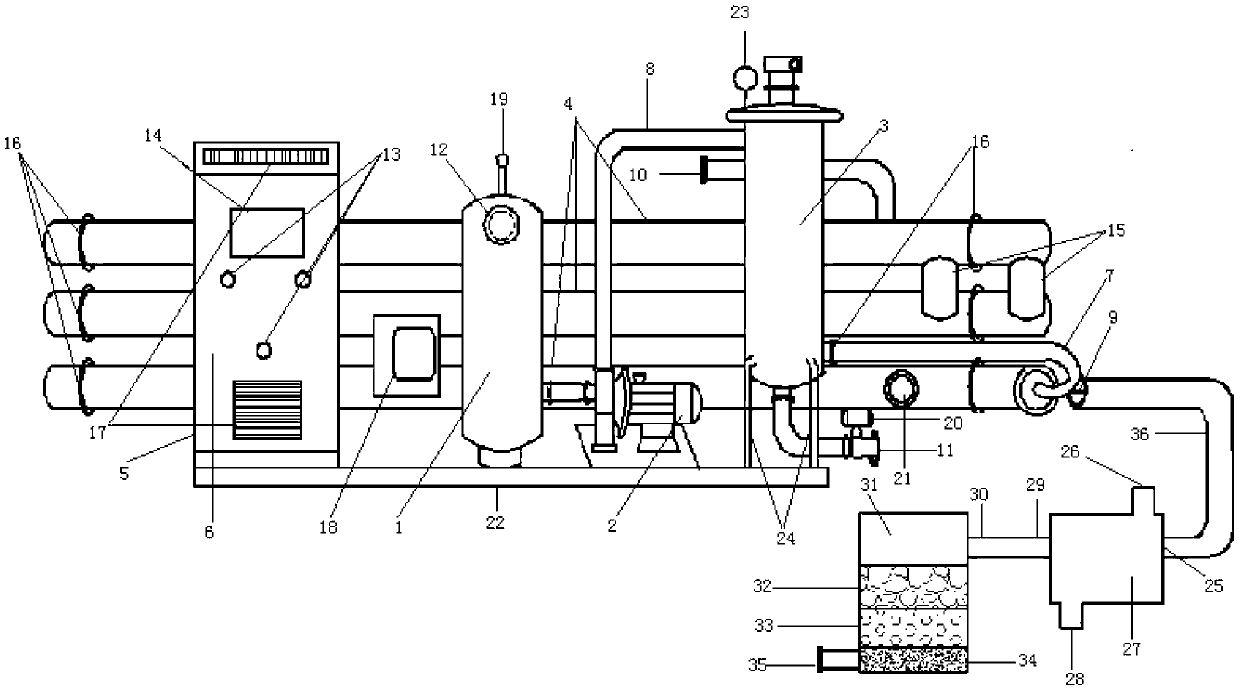

[0009] The main structure of this embodiment includes a vacuum tank 1, a centrifugal pump 2, an automatic filter 3, a heat exchange host 4, a control cabinet 5, a control system 6, a recoil cleaning pipe 7, a sewage inlet 8, a sewage outlet 9, and a clean water inlet. 10. Clean water outlet 11, instrument panel 12, button 13, display screen 14, connecting pipe 15, butt ring buckle 16, heat dissipation window 17, switch box 18, air valve 19, water outlet valve 20, temperature dial 21, base 22, control Valve 23, bracket 24, water inlet 25, filling port 26, regulating tank 27, discharge port 28, water outlet 29, discharge port 30, sedimentation tank 31, coarse-grained layer 32, medium-grained layer 33, fine sand layer 34, Outlet 35 and pipe 36; Control cabinet 5, vacuum tank 1, centrifugal pump 2 and automatic filter 3 are fixed on base 22 from left to right. Centrifugal pump 2 is connected to vacuum tank 1 and the top of vacuum tank 1 An air valve 19 is fixed to extract air from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com