Preparation method for hydroxyethyl chitosan in-situ hydrogel

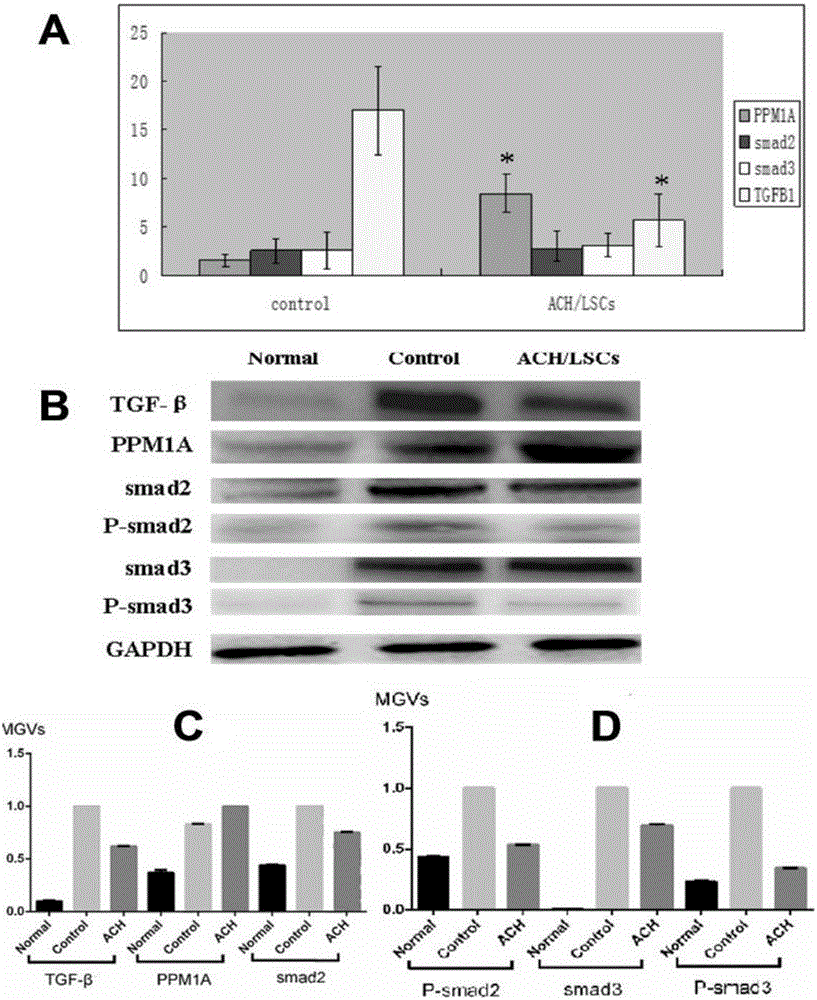

A hydroxyethyl chitosan and hydrogel technology, applied in the field of biomedicine, can solve the problems of reducing the expression level of transforming growth factor on the wound surface, uncontrollable gel degradation speed, and increased collagenase expression, and achieves a friendly treatment environment. , Safe to use, and the effect of promoting corneal epithelial reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

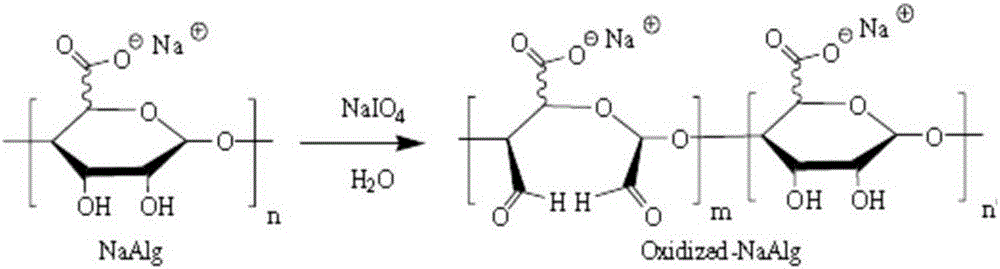

[0016] The preparation process of the hydroxyethyl chitosan in situ hydrogel involved in this example includes three steps of preparation of sodium periodate aqueous solution, preparation of oxidized sodium alginate and preparation of hydroxyethyl chitosan in situ hydrogel:

[0017] (1), preparation of sodium periodate aqueous solution: take by weighing sodium periodate (sigma, S1878) powder 1g under normal temperature and be dissolved in 50ml deionized water, the obtained mass percentage concentration is the sodium periodate aqueous solution of 2%;

[0018] (2), preparation of oxidized sodium alginate: in the sodium alginate aqueous solution that the mass percent concentration is 2%, the molar ratio of sodium alginate and sodium periodate reaction is 10:1 and adds the periodic acid prepared in step (1) Sodium aqueous solution, stir the mixed solution formed by mixing sodium alginate aqueous solution and sodium periodate aqueous solution at room temperature to make oxidation re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com