Process and system for purifying titanium tetrachloride by removing vanadium

A technology of titanium tetrachloride and crude titanium tetrachloride, which is applied in the fields of titanium halide, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of harsh working environment, low flow rate, low heat exchange efficiency, etc., and improve labor efficiency. conditions, prolong service life, and improve heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

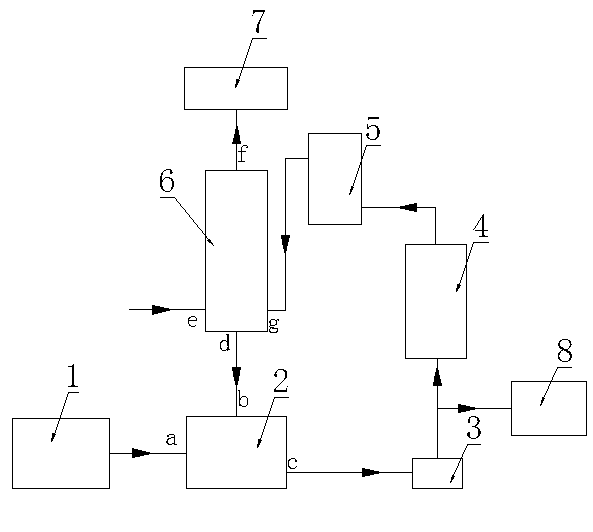

[0016] Such as figure 1 As shown, the titanium tetrachloride purification vanadium removal system includes a crude titanium tetrachloride storage tank 1, a circulation tank 2 and a vanadium removal reaction tower 6, and the vanadium removal reaction tower 6 has a feed port g, a feed port e , discharge port d and discharge port f, the discharge port of described thick titanium tetrachloride storage tank 1 links to each other with circulation tank 2 feed ports a, and the discharge port f of described vanadium removal reaction tower 6 is connected with cooling Kettle 7, the discharge port d of the vanadium removal reaction tower 6 is connected with the feed port b of the circulation tank 2, and the discharge port c of the circulation tank 2 is connected with a heat exchanger 4 through a feed pump 3, and the A flash tank 5 is connected between the discharge port of the heat exchanger 4 and the feed port g of the vanadium removal reaction tower 6 , and a chlorination dust collectio...

Embodiment 2

[0021] The titanium tetrachloride purification and vanadium removal system is the same as in Example 1.

[0022] During production, the crude titanium tetrachloride is sent into the circulation tank 2 by the crude titanium tetrachloride storage tank 1, and the crude titanium tetrachloride is sent to the tube side of the heat exchanger 4 by the feed pump 3, and the liquid crude tetrachloride The flow velocity of titanium dioxide in the heat exchanger 4 tube side is controlled at 6m / s, and steam is passed into the shell side of the heat exchanger 4 to heat the crude titanium tetrachloride material to 180°C, and the crude tetrachloride of the heat exchanger 4 The titanium outlet pressure is 0.1MPa, and the thick titanium tetrachloride after heating enters the flash tank 5 by the heat exchanger 4 outlet, and after being vaporized in the flash tank 5, it enters the removal tank at a speed of 15 tons / hour by the feed port g. At the bottom of the vanadium reaction tower 6, the minera...

Embodiment 3

[0026] The titanium tetrachloride purification and vanadium removal system is the same as in Example 1.

[0027] During production, the crude titanium tetrachloride is sent into the circulation tank 2 by the crude titanium tetrachloride storage tank 1, and the crude titanium tetrachloride is sent to the tube side of the heat exchanger 4 by the feed pump 3, and the liquid crude tetrachloride The flow rate of titanium dioxide in the tube side of heat exchanger 4 is controlled at 3m / s, and steam is introduced into the shell side of heat exchanger 4 to heat the crude titanium tetrachloride material to 150°C, and the crude tetrachloride of heat exchanger 4 The titanium outlet pressure is 0.5MPa, and the thick titanium tetrachloride after heating enters the flash tank 5 by the outlet of the heat exchanger 4, and after being vaporized in the flash tank 5, it enters the removal tank at a speed of 10 tons / hour by the feed port g. At the bottom of the vanadium reaction tower 6, the mine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com