Sintering layer thickness on-line detecting method

A detection method and light technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of not being able to adapt to the harsh environment of the sintering site, the impact of measurement results, and easy damage to equipment, so as to achieve low equipment cost and avoid The effect of equipment wear and tear and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

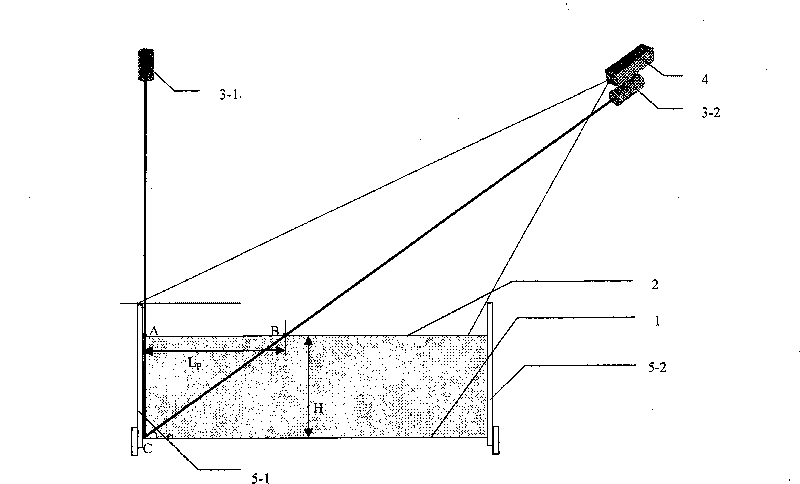

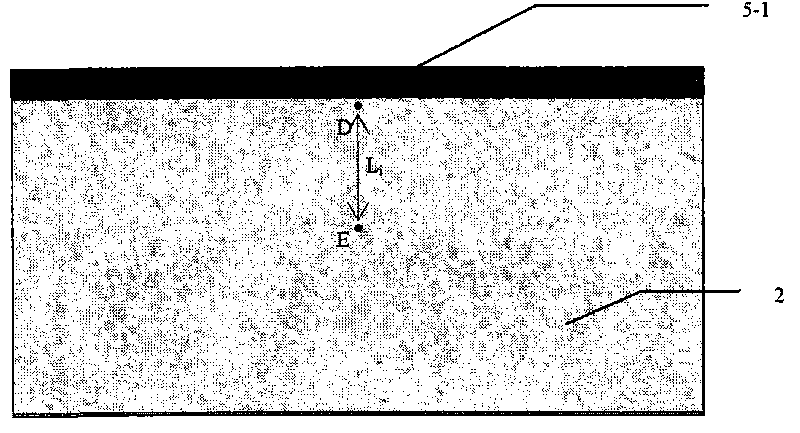

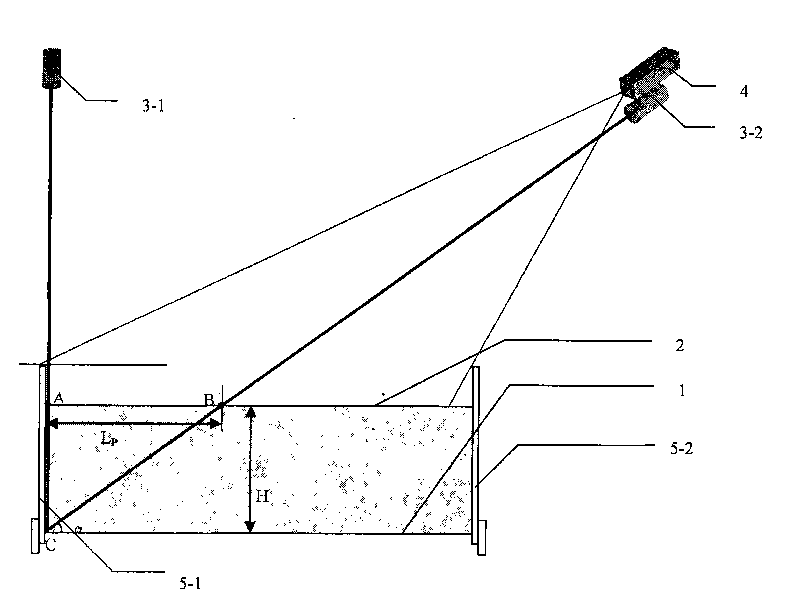

[0018] like figure 1 , 2 As shown, in the online detection method for the thickness of a sintered pavement of the present invention, two point light sources 3-1 and 3-2 are arranged above the sintering machine trolley, so that the plane formed by the light rays of the two point light sources is perpendicular to the platform at the same time. The car walls 5-1, 5-2 and the bottom 1 of the car, in this vertical plane, two light rays converge at a point on the bottom of the trolley, one of which is perpendicular to the bottom of the trolley, and the other light forms an acute angle with the bottom of the trolley α; set an image acquisition device 4 above the trolley, so that the range of image acquisition is greater than the irradiation range of the two point light sources on the material surface, and the distance between the two point light sources projected on the material surface 2 by the image acquisition device L p Collect it into the computer, and process the image, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com