Energy-saving temperature-regulating humidity-regulating air processing method

A technology of temperature and humidity regulation and air treatment, applied in the direction of using air flow as shielding, heating method, air conditioning system, etc., can solve the problems of high energy consumption of low-humidity air, and achieve good effect and high-efficiency cooling capacity recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

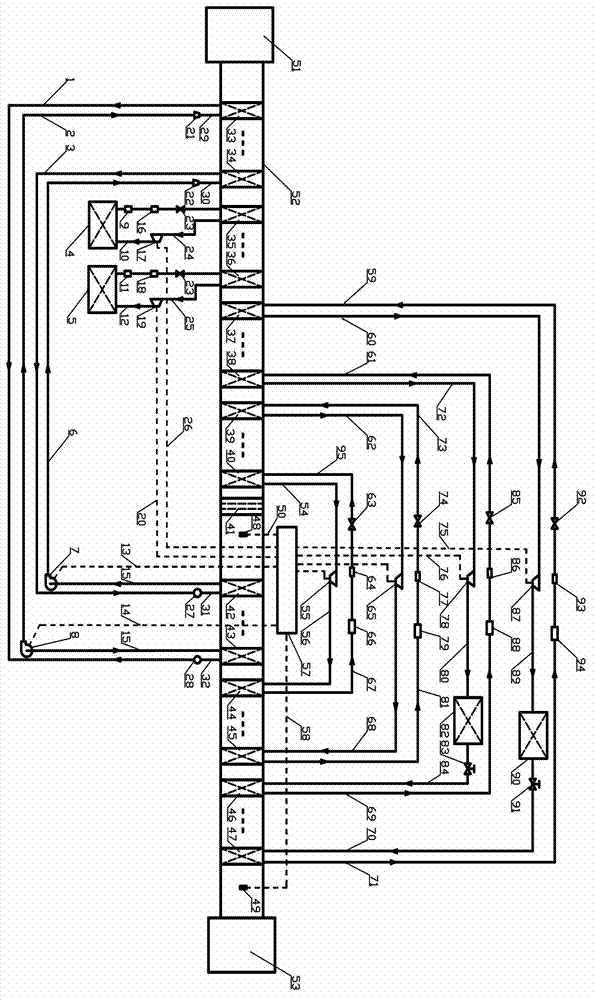

[0023] A schematic diagram of the work flow structure principle of the system device of an energy-saving temperature-adjusting and humidity-adjusting air treatment method specifically involved in this embodiment is as follows figure 1 As shown; by the internal circulation heat pipe evaporator 34, the internal circulation heat pipe gas-liquid two-phase flow pipe 3, the internal circulation heat pipe gas-liquid two-phase flow distribution main pipe 27, the internal circulation heat pipe two-phase flow equalizing pipe 31, the internal circulation heat pipe condenser 42. Heat pipe condenser liquid return pipe 15, internal circulation heat pipe solution pump 7, internal circulation heat pipe liquid supply pipe 6, internal circulation heat pipe liquid separator 22, internal circulation heat pipe equalizing pipe 30, external circulation heat pipe evaporator 33, external circulation Heat pipe gas-liquid two-phase flow pipe 1, outer circulation heat pipe gas-liquid two-phase flow distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com