Photoelectric positioning system reeded by reeding machine

A positioning system and reed reed technology, applied in the field of textiles, can solve the problems of unfavorable intelligent control, insufficient positioning accuracy and density, and large damage to the reed plate. The effect of simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further explained below in conjunction with the drawings.

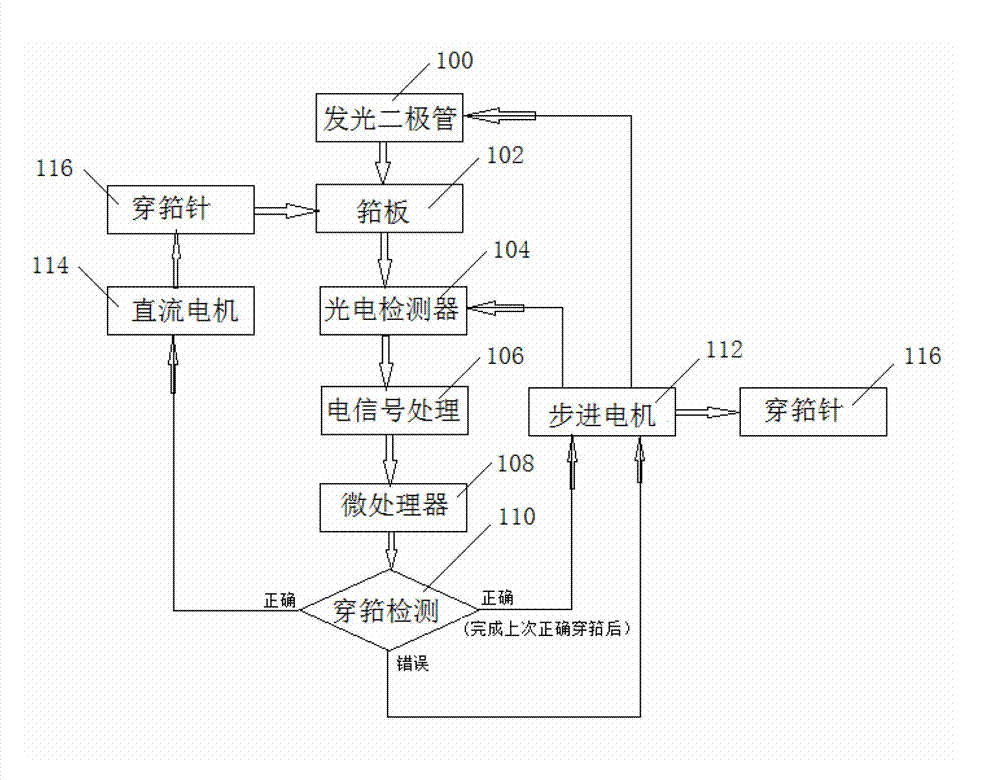

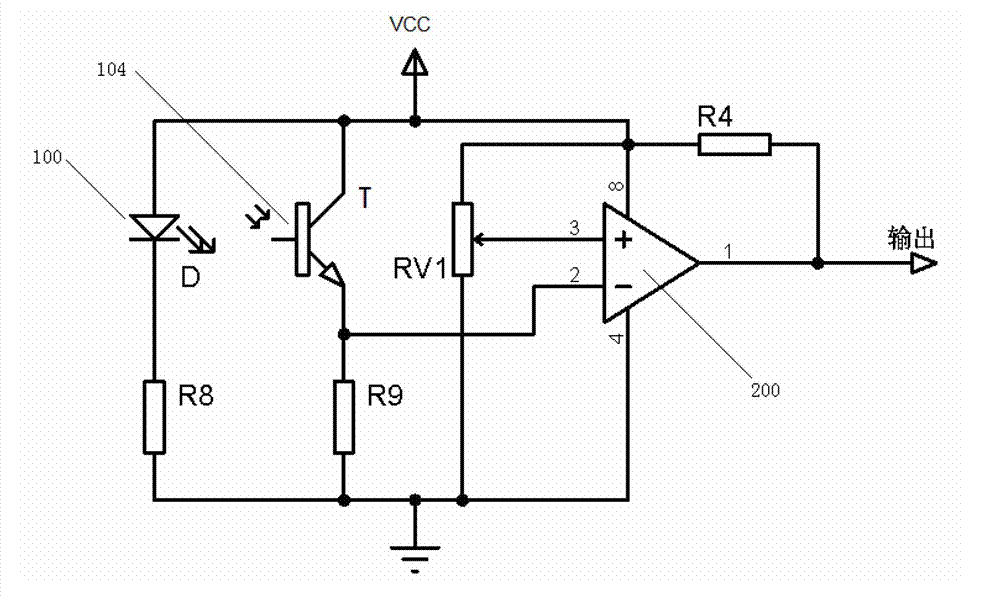

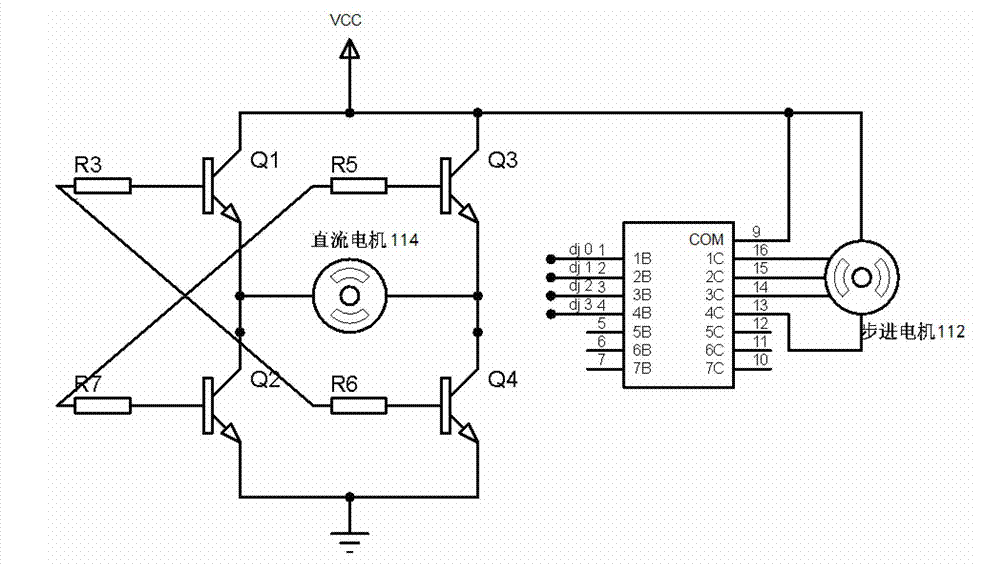

[0016] Such as figure 1 What is shown is a schematic diagram of the working principle of the embodiment of the present invention. The specific implementation is as follows: the light emitted by the light-emitting diode 100 can be approximately regarded as parallel light. Generally, from the perspective of simplicity, reliability and availability, the light-emitting diode can be an infrared light-emitting diode. Infrared light is irradiated on the reed board 102, which includes the reed teeth and the reed gap. A phototransistor with a detection surface smaller than the width of the reed tooth is placed directly opposite the light emitting diode 100 (to avoid detection confusion), that is, the photodetector 104. When the light passes through the reed, because it is not transparent, the infrared light cannot hit the phototransistor detection surface, the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com