Anti-condensation air conditioning radiant panel and work method thereof

A radiant panel, anti-condensation technology, applied in air-conditioning systems, heating methods, prevention of condensation, etc., can solve problems affecting the normal operation of air-conditioning systems, condensation on air-conditioning radiant panels, etc., to achieve a simple overall structure and principle, and prevent condensation. , the effect of improving the air environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

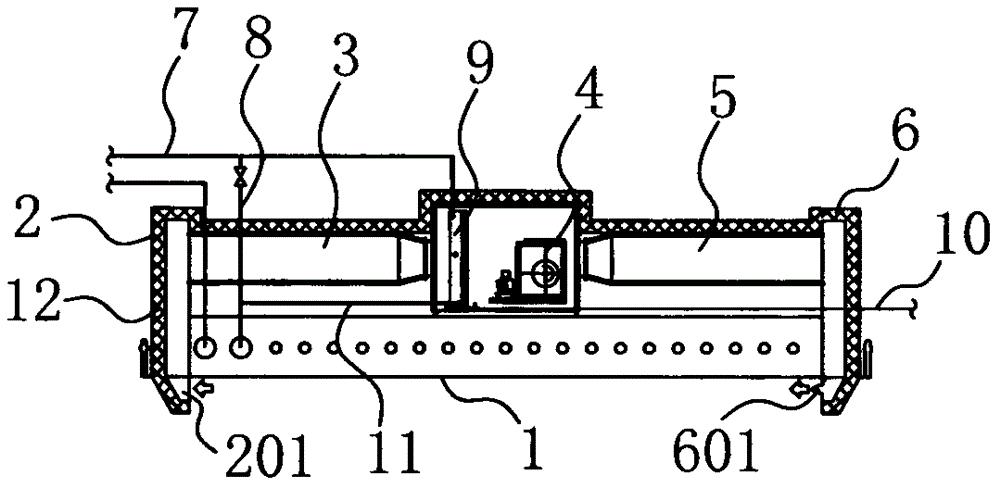

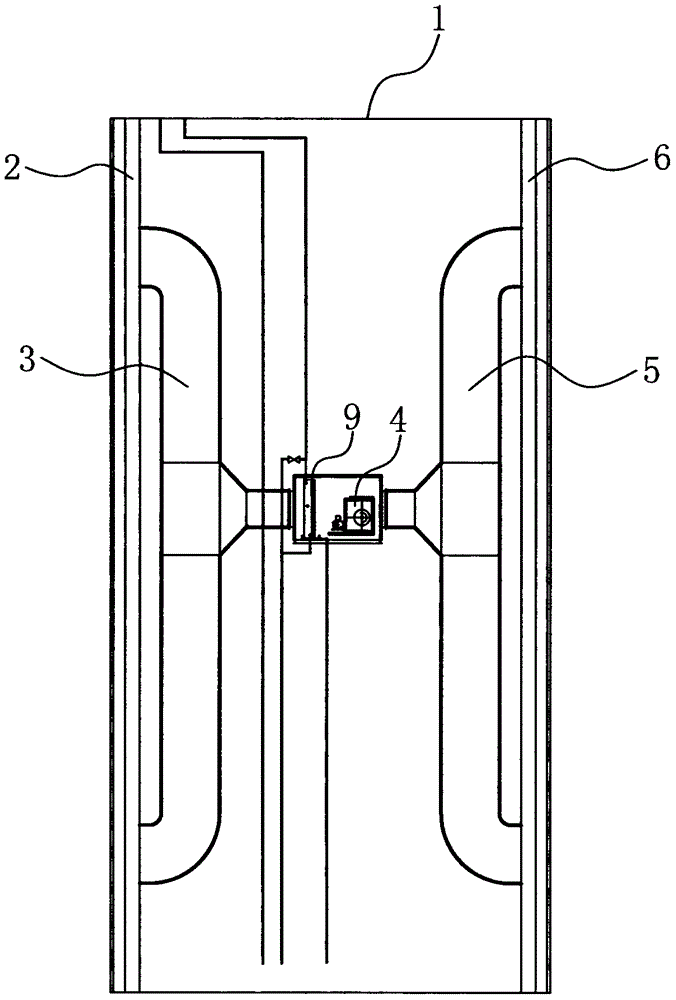

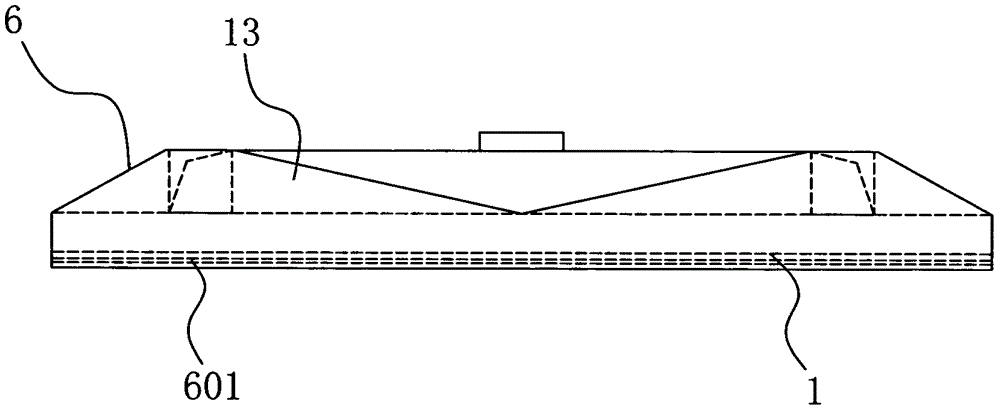

[0019] Now in conjunction with accompanying drawing, this is further described.

[0020] like Figure 1-3 As shown, the anti-condensation air-conditioning radiant panel includes an air supply device and an air-conditioning radiant panel 1, and the air supply device includes a blower 4, a supply air plenum 6, a return air plenum 2, an air supply pipe 5, and a return air pipe 3. The air inlet end of the blower is connected to the return air plenum box through the air return pipe, and the air outlet end of the blower is connected to the air supply plenum box through the air supply pipe. On both sides of the board, the air supply plenum is provided with an air outlet 601, and the air outlet is a slit-shaped opening, and the return air plenum is provided with a return air outlet 201, and the return air opening is a rectangular opening. The airflow blown out of the tuyere is close to the radiation surface of the air conditioning radiant panel, and jets along the radiation surface t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com