Organic waste gas treatment system for process of recycling etching liquid

A technology of organic waste gas and treatment system, applied in the field of treatment system, can solve the problems of operators and hidden dangers in the atmosphere, and achieve the effects of long service life, cost saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

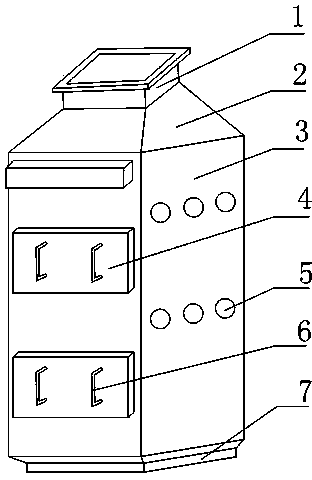

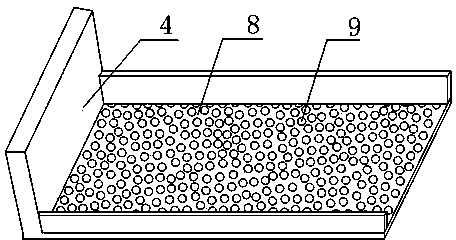

[0017] like figure 1 , figure 2 As shown, the organic waste gas treatment system applied to the etching liquid recovery process includes a hollow processing tower 3, and the two ends of the processing tower 3 are respectively provided with an air inlet 7 and an air outlet 1, and the air outlet 1 is arranged at the inlet The top of the air port 7; the inside of the processing tower 3 is provided with several chemical boxes, and the chemical boxes can move laterally in the processing tower 3, and several lamp tubes 5 are arranged above each chemical box. The gas is introduced from the air inlet 7, and the vacuum wave ultraviolet light generated by the lamp tube 5 is used as an energy source to activate the photocatalyst, drive the "oxidation-reduction" reaction, use the oxygen in the air as the oxidant, and effectively degrade the toxic organic waste gas. The non-toxic gas is exhausted to the atmosphere through the gas outlet 1.

[0018] Both the end face size of the air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com