Culturing device for formaldehyde degradation bacteria

A formaldehyde-degrading bacteria and culture device technology, which is applied in the field of formaldehyde-degrading bacteria culture devices, can solve problems such as increasing the health risks of operators, increasing the volatilization speed of formaldehyde, and disrupting human cell metabolism, so as to reduce exposure risks and reduce the total amount of formaldehyde volatilization. Quantity, the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

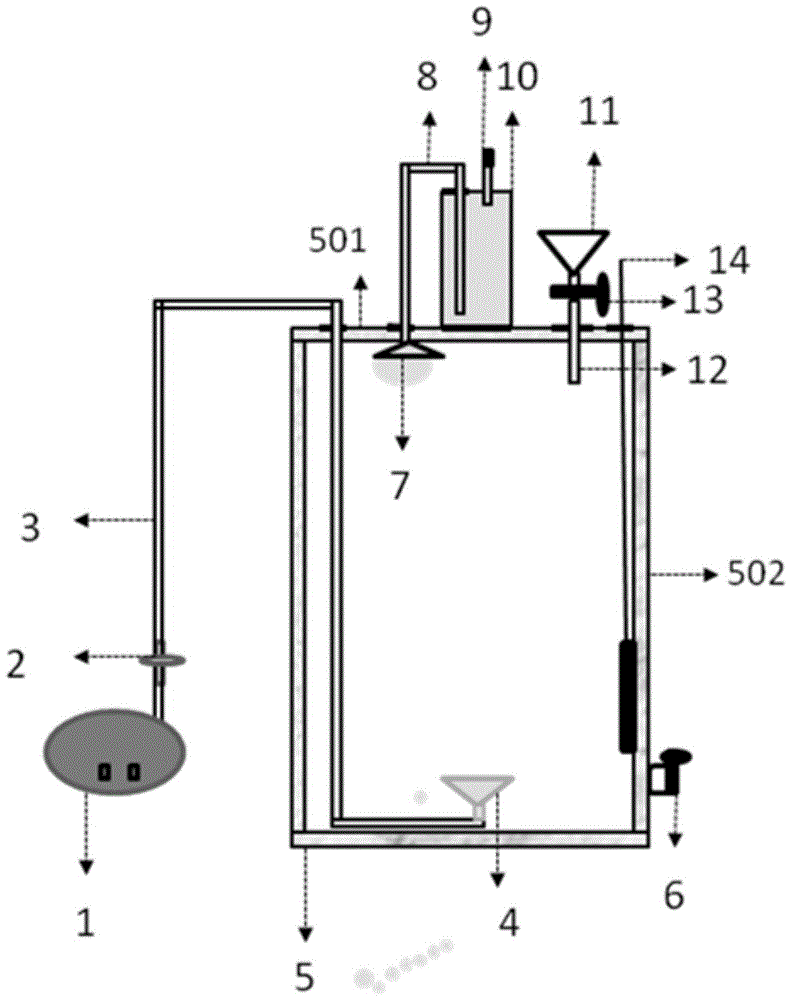

[0012] The main structure of the formaldehyde-degrading bacteria culture device involved in this embodiment includes an aeration pump 1, a microporous biological filter membrane 2, an air inlet pipe 3, a cyclone aerator 4, a reaction tank 5, a tank cover 501, a tank body 502, Sampling hole 6, exhaust gas collection port 7, exhaust gas pipeline 8, clean gas pipeline 9, exhaust gas absorption bottle 10, feeding port 11, feeding pipeline 12, valve 13 and temperature controller 14; The cover 501 and the tank body 502 are combined. The air intake pipe 3 passes through the pool cover 501 and enters the bottom of the reaction tank 5. The outer end of the air intake pipe 3 is provided with an aeration pump 1, and the inner end of the air intake pipe 3 is provided with a rotary mixer. The aerator 4 is provided with a microporous biological filter membrane 2 at the end close to the aeration pump 1 inside the air intake pipe 3 , a temperature controller 14 is provided at the lower right i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com