Patents

Literature

202 results about "Formaldehyde degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of environment-friendly floor cushion coat

The invention provides a method for preparing an environment-friendly floor board underlayer. The underlayer is prepared by firmly covering a composite catalyst material on a flaky adsorbing filter material. Only by evenly paving the environment-friendly floor board underlayer under a floor board so that the back side of the floor board is contacted with the environment-friendly floor board underlayer closely, the environment-friendly floor board underlayer can clear off harmful gases such as formaldehyde, benzene and the like and off flavor generated and released by the floor board and auxiliary materials, prevent damp and humidify, reject milden and rot, kill and inhibit bacteria, expel insects and prevent moths, increase vitamin-anions and far infrared rays in the air, and reduce the harm of dust mites and respirable particles. The environment-friendly floor board underlayer is advantageous to keep body healthy, prevent floor board form polluting, and prolong the service life of the floor board. The use is simple and convenient without professional constructions, the purification lasts without rebound, and the effect is fast and thorough; and experimental detections show that the degradation rate of the formaldehyde within 24 hours reaches 99 percent, the degradation rate of the benzene within 24 hours reaches 92 percent, the antibacterial rate is 99 percent, the mold prevention is at a zero level, the insect expelling rate is 92.8 percent, and the acute property is is actually at a nontoxic level by oral toxicity test.

Owner:HENAN MUBO INDAL

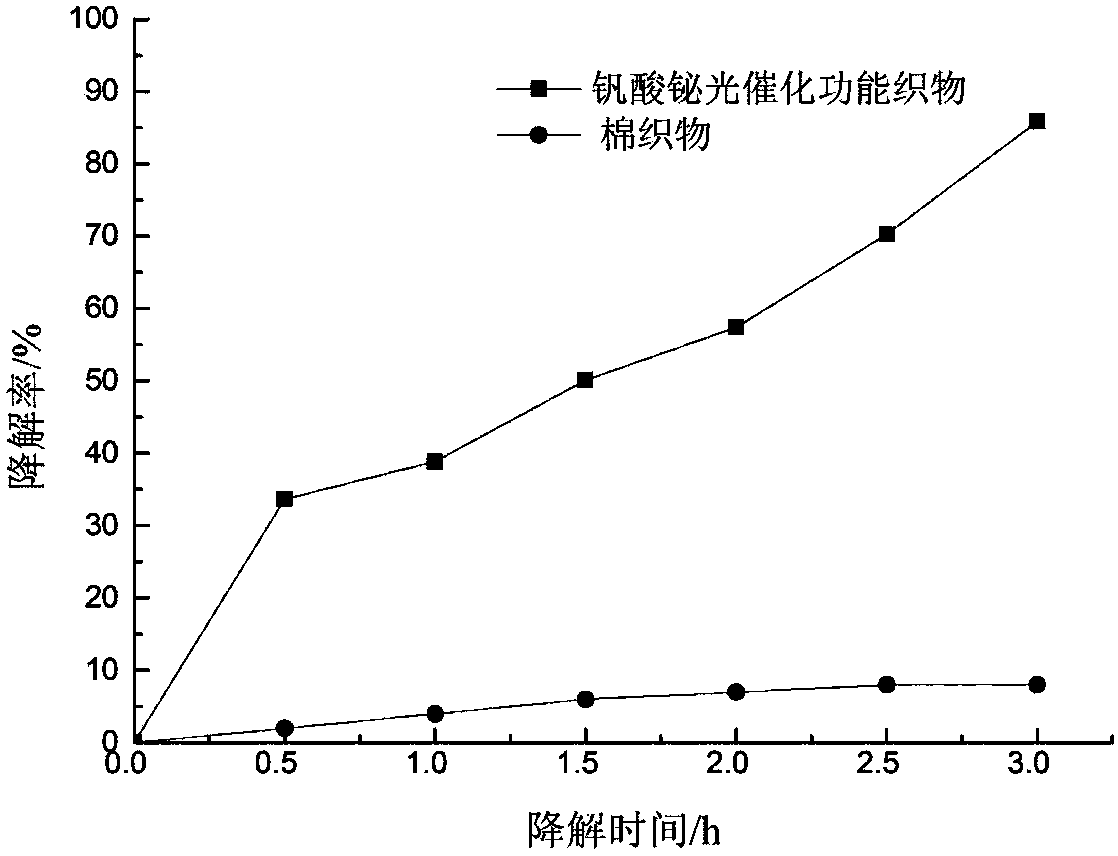

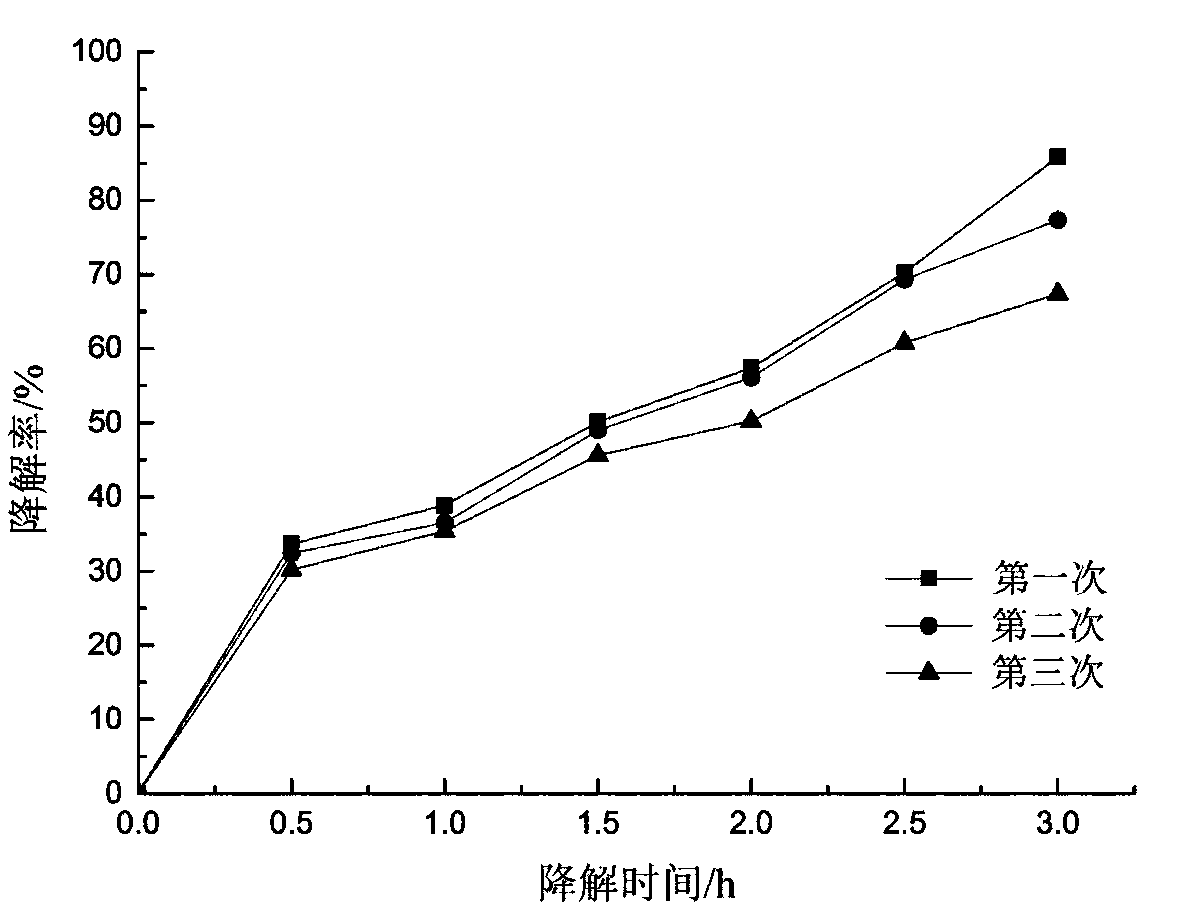

Preparation method and application of photocatalytic functional fabric

ActiveCN108532290AGood economic benefitsImprove photocatalytic activityGas treatmentWater/sewage treatment by irradiationPhotocatalytic degradationCatalytic efficiency

The invention provides a photocatalytic functional fabric and a preparation method thereof. The preparation method comprises the following steps: firstly treating zeolite imidazole skeleton material (ZIF-8) onto a fabric, then loading bismuth vanadate (BiVO4) onto the fabric treated by the ZIF-8 by adopting an in-situ growth method, and preparing the photocatalytic functional fabric. The functional fabric can efficiently and catalytically degrade organic pollutants under the radiation of visible light and can be used for treating the printing and dyeing waste water and purifying the air. The preparation method is simple in preparation process. The prepared photocatalytic functional fabric has the advantages of good adsorption performance, high catalytic efficiency, good stability, reusability and the like. The photocatalytic degradation rate for active black KN-B can reach 85 percent or above, and the photocatalytic degradation rate for the active black KN-B after being reused for three times can be still kept at 65 percent or higher. The degradation rate for formaldehyde in the air can reach 87 percent or above.

Owner:JIANGSU TANGWEAR IND

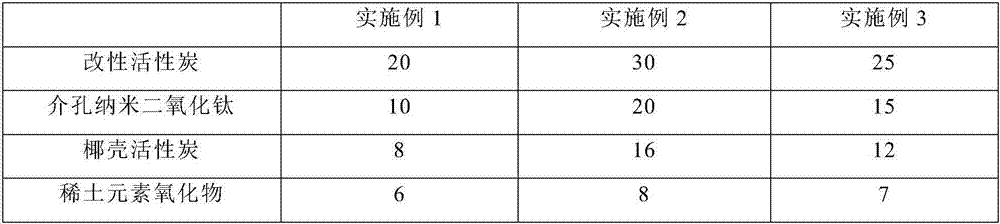

Environmental filter element material for air purifier

InactiveCN107376641AIncreased UV responsivenessImprove photocatalytic reactivityGas treatmentDispersed particle separationRare-earth elementEnvironmental resistance

The invention relates to an environmental filter element material for an air purifier. Modified active carbon, mesoporous nanoscale titanium dioxide and coconut shell activated carbon are added. The modified active carbon has strong adsorption capacity; mesoporous nanoscale titanium dioxide greatly enhances UV response capability of the filter element material and improves photo-catalytic reaction activity of the filter element material and formaldehyde degradation adsorption removal efficiency; with addition of rare earth oxide, catalytic activity can be enhanced, and formaldehyde removal efficiency is further improved; as modified attapulgite, bentonite, diatomite and natural Chinese medical stone have micropore structures as carriers, catalytic activity, adsorption capacity and microbicidal efficacy are greatly raised; with addition of negative ion powder, negative ions which are beneficial to human health also can be released; and a Chinese herbal extracting solution and fig peel hydrolysate are both plant extracts, the filter element material is safe and environmentally friendly, contains no toxic chemical substances and effectively raises air quality. Sources of the raw materials are wide; cost is low; the preparation method is simple and scientific; and energy consumption is low.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

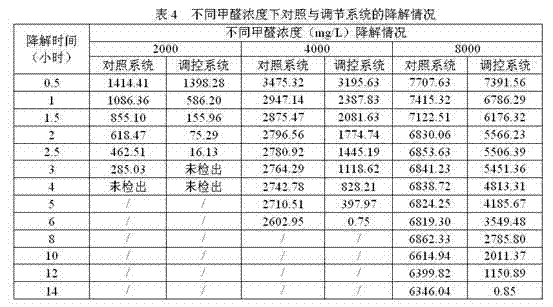

Method for cooperatively treating formaldehyde by microorganism and enzyme

The invention relates to the technical field of environmental friendless and particularly discloses a method for cooperatively treating formaldehyde by a microorganism and an enzyme. The method comprises the following steps: S1, preparing a liquid culture medium; S2, inoculating a formaldehyde degrading microorganism: carrying out inclined plane culture on the formaldehyde degrading microorganism to prepare a spore suspended solution, wherein the concentration of spores is 0.1*10<9> / ml-10*10<9> / ml; then inoculating the spore suspended solution into the liquid culture medium containing the formaldehyde, and adding catalase; and S3, degrading the formaldehyde: under the conditions of 25-35 DEG C, carrying out vibration culture for 18-36 hours. According to the method provided by the invention, the cooperative effect is generated by the catalase and the formaldehyde degrading microorganism, so that the degradation rate of the formaldehyde is improved and the method has a very good industrial application value.

Owner:广州荣天环保科技有限公司

Preparation method of adsorption-photocatalysis compound type formaldehyde removing coating

InactiveCN103980759AWith adsorption-photocatalytic composite abilitySolve the problem of saturation and regenerationCoatingsFiberSorbent

The invention relates to a preparation method of an adsorption-photocatalysis compound type formaldehyde removing coating, relating to a preparation method of a coating and aiming at solving the problems of low formaldehyde degradation efficiency and incapability of enriching formaldehyde in an existing photocatalysis coating. The preparation method disclosed by the invention comprises the following steps: (1), preparing ACF (Active Carbon Fiber) modified by concentrated nitric acid; (2), mixing butyl titanate, ethanol and acetic acid; (3), mixing ethanol, acetic acid and water, adding urea and iron nitrate nonahydrate crystals, and adjusting pH; (4), preparing TiO2 sol containing iron and nitrogen; (5), preparing ACF loaded with TiO2; (6), preparing TiO2 / ACF compound powder; and (7), mixing the TiO2 / ACF compound powder with the coating. By means of the enrichment action of ACF, the problem of low TiO2 efficiency is solved to a great extent; by means of the catalytic action of TiO2, the saturated regeneration problem of an adsorbent is effectively solved; the characteristics of the ACF and the TiO2 are complementary; the formaldehyde degradation efficiency is greatly improved. The preparation method disclosed by the invention can be used for preparing the adsorption-photocatalysis compound type formaldehyde removing coating.

Owner:HARBIN INST OF TECH

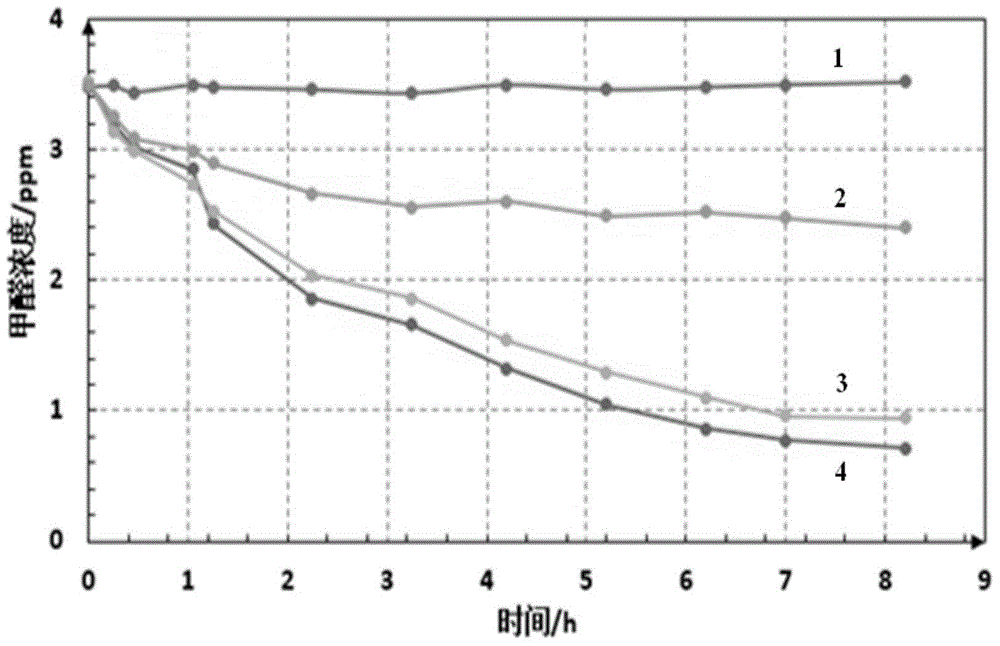

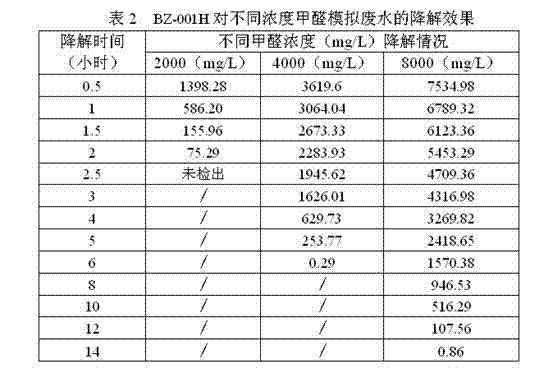

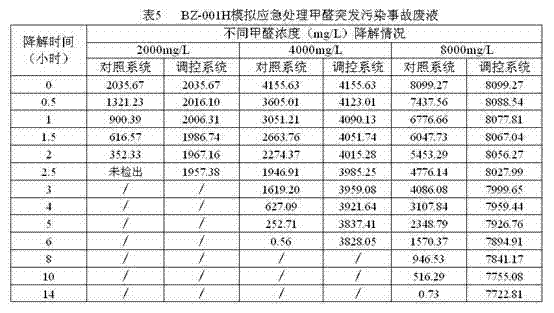

A high-efficiency formaldehyde-degrading bacterium and its application and application method

ActiveCN102260634AStrong toleranceFast degradationBacteriaWater contaminantsMicroorganismSewage treatment

The invention belongs to the technical field of environment protection and particularly relates to high-efficiency formaldehyde degrading bacteria and use and using method thereof. The number of the high-efficiency formaldehyde degrading bacteria is BZ-001H. The bacteria were approved as Bacilluscereus and were collected in China General Microbiological Culture Collection Center on March 22th, 2010, and the collection number of the bacteria is CGMCCNo.3685. The strain can be used for treating high-concentration formaldehyde waste water and handling emergent formaldehyde sudden pollution accidents. The high-efficiency formaldehyde degrading bacteria have the advantages of quick high-concentration formaldehyde degradation, high tolerance, no secondary pollution, safety for use, no adverse influence on microorganisms in an original sewage treatment system.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

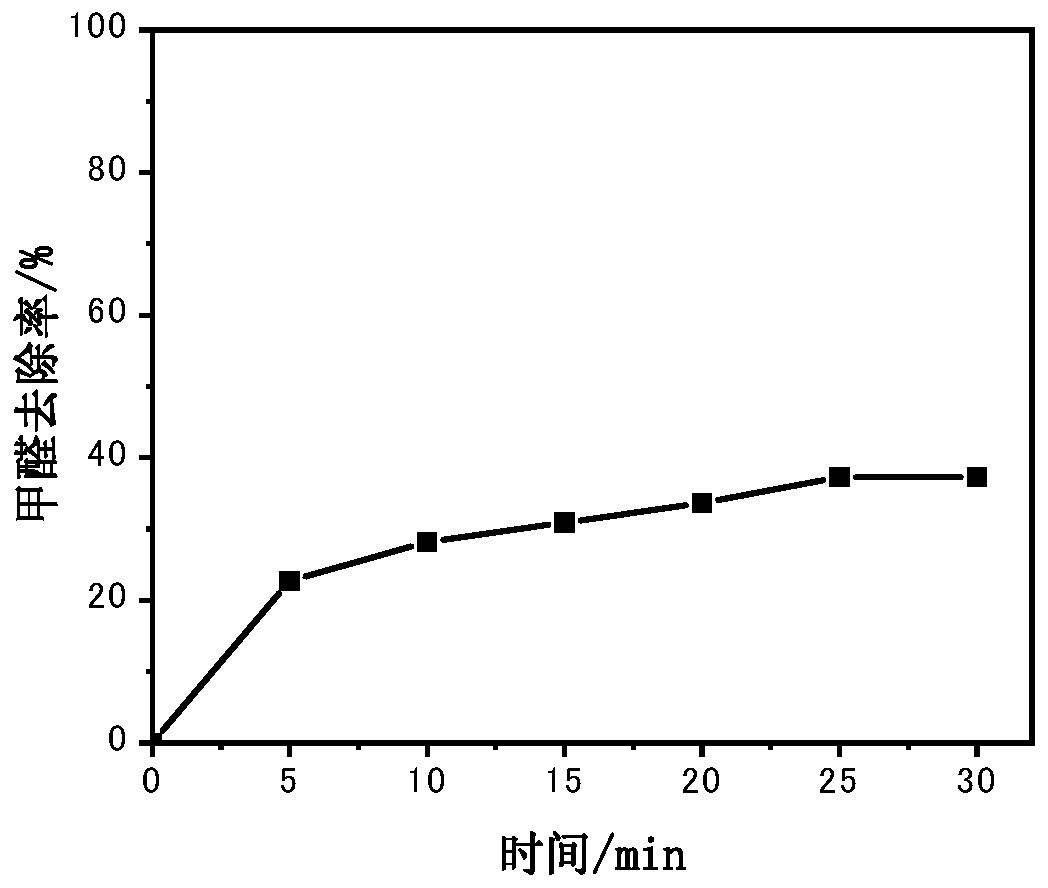

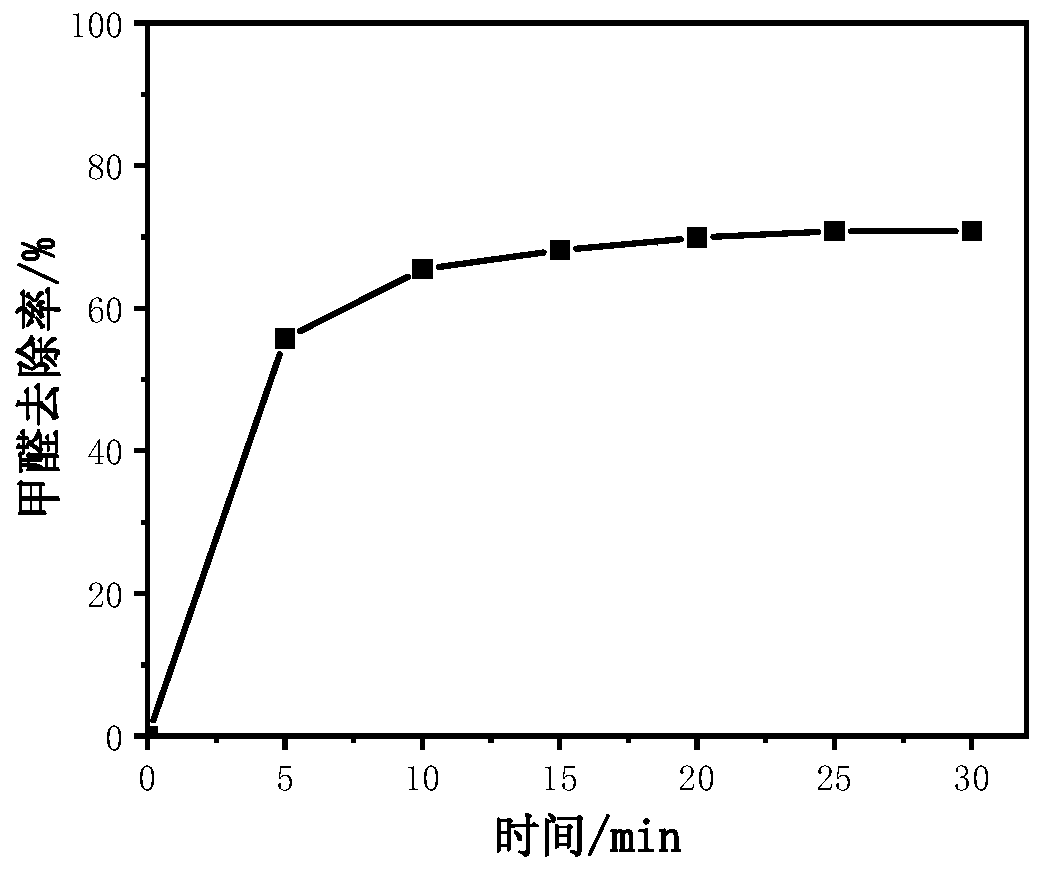

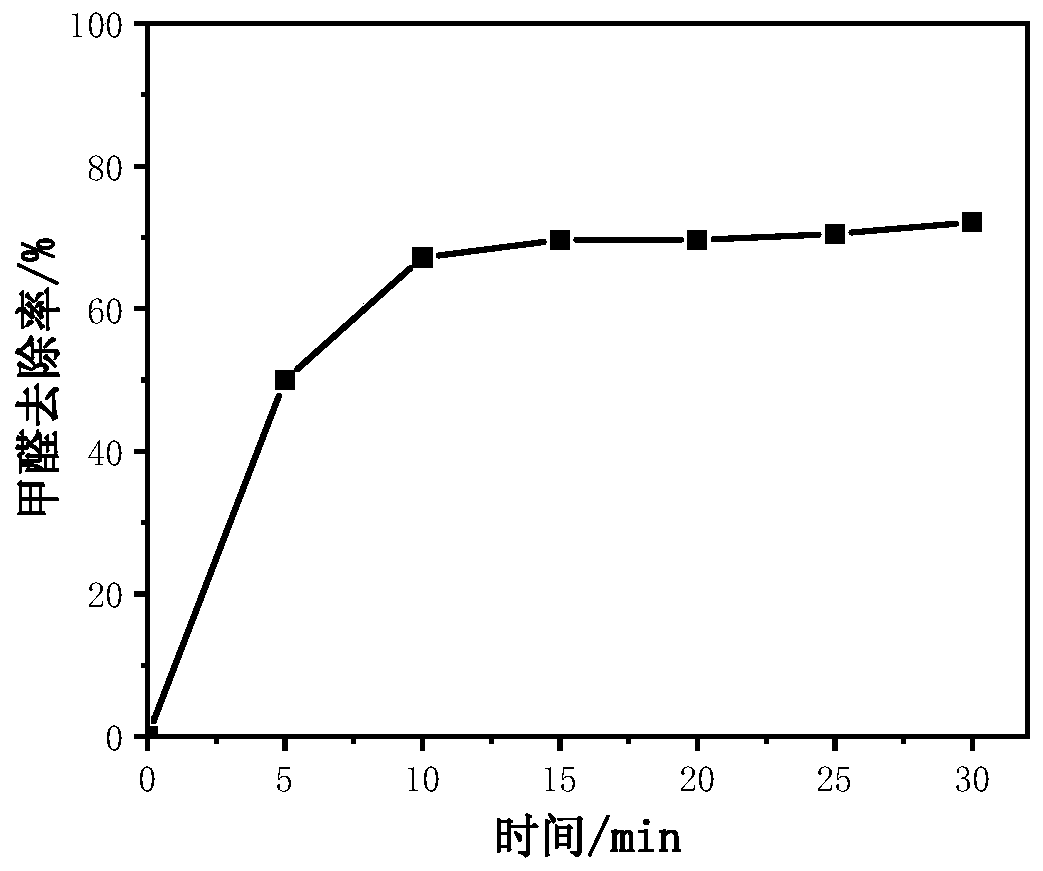

Formaldehyde degradation catalyst

ActiveCN105665021AGentle synthesis methodMild reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationTreatment effectSynthesis methods

Relating to the technical field of treatment of organic pollutants in air and water, the invention discloses a formaldehyde degradation catalyst. The catalyst is a heteropolyoxometallate catalyst containing vanadium and molybdenum, and the general formula of the polyoxometallate is AgxH5-x[PMo10V2O40]. The invention also discloses a synthesis method of the catalyst and a method of catalytic oxidation of formaldehyde with the catalyst. The polyoxometallate based treatment technology for air degradation of formaldehyde has the characteristics of mild conditions, short treatment time and low operation cost, can reach a formaldehyde degradation rate up to 60%-95%, and can be used for treatment of formaldehyde in water and free formaldehyde gas, can achieve good treatment effect, is simple to operate, and does not cause secondary pollution. The polyoxometalate catalyst has the advantages of simple synthesis method, high catalytic activity and mild reaction conditions, overcomes the disadvantage of using precious metals as the catalyst at present, and is easy to operate.

Owner:吉林省东成环保工程有限公司

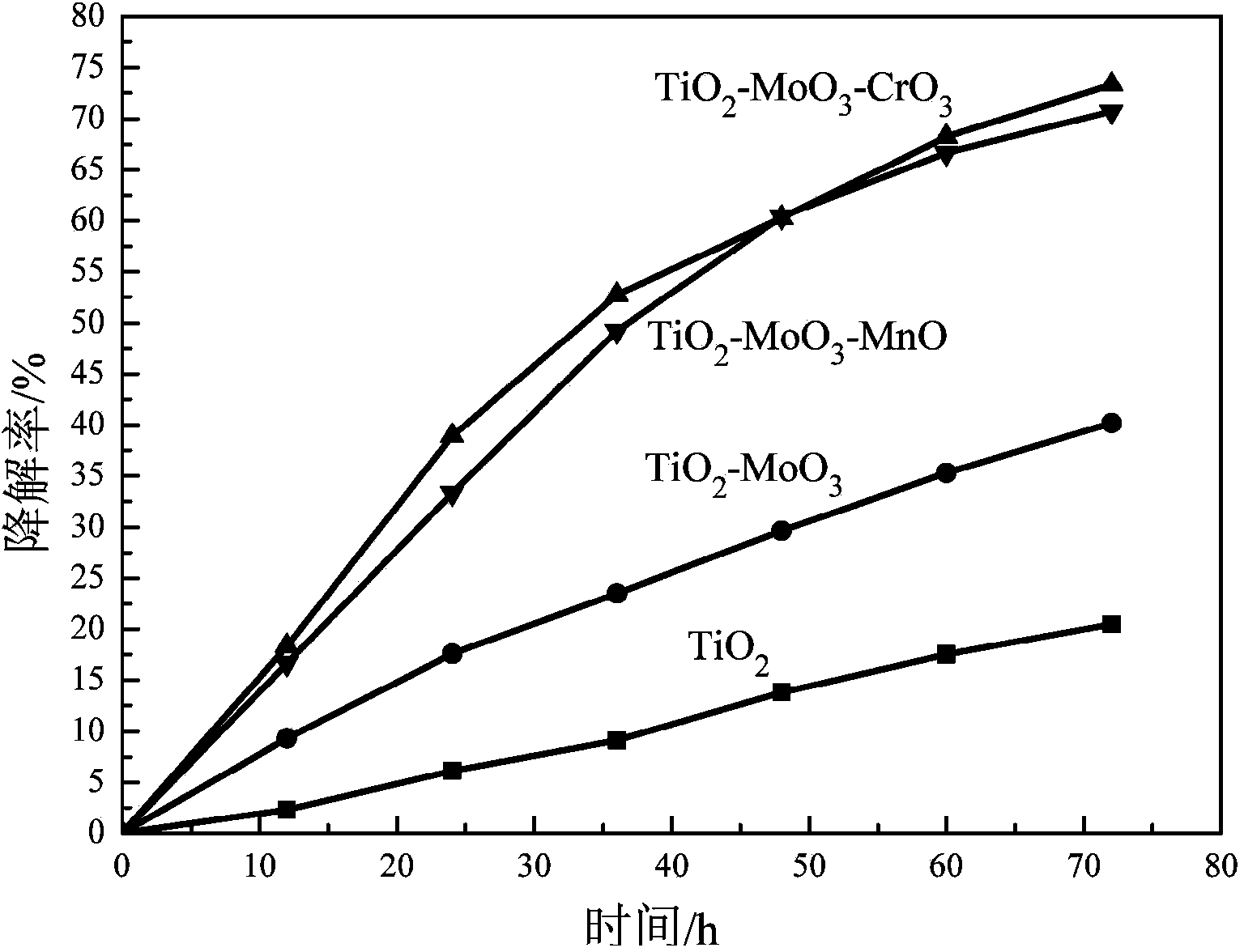

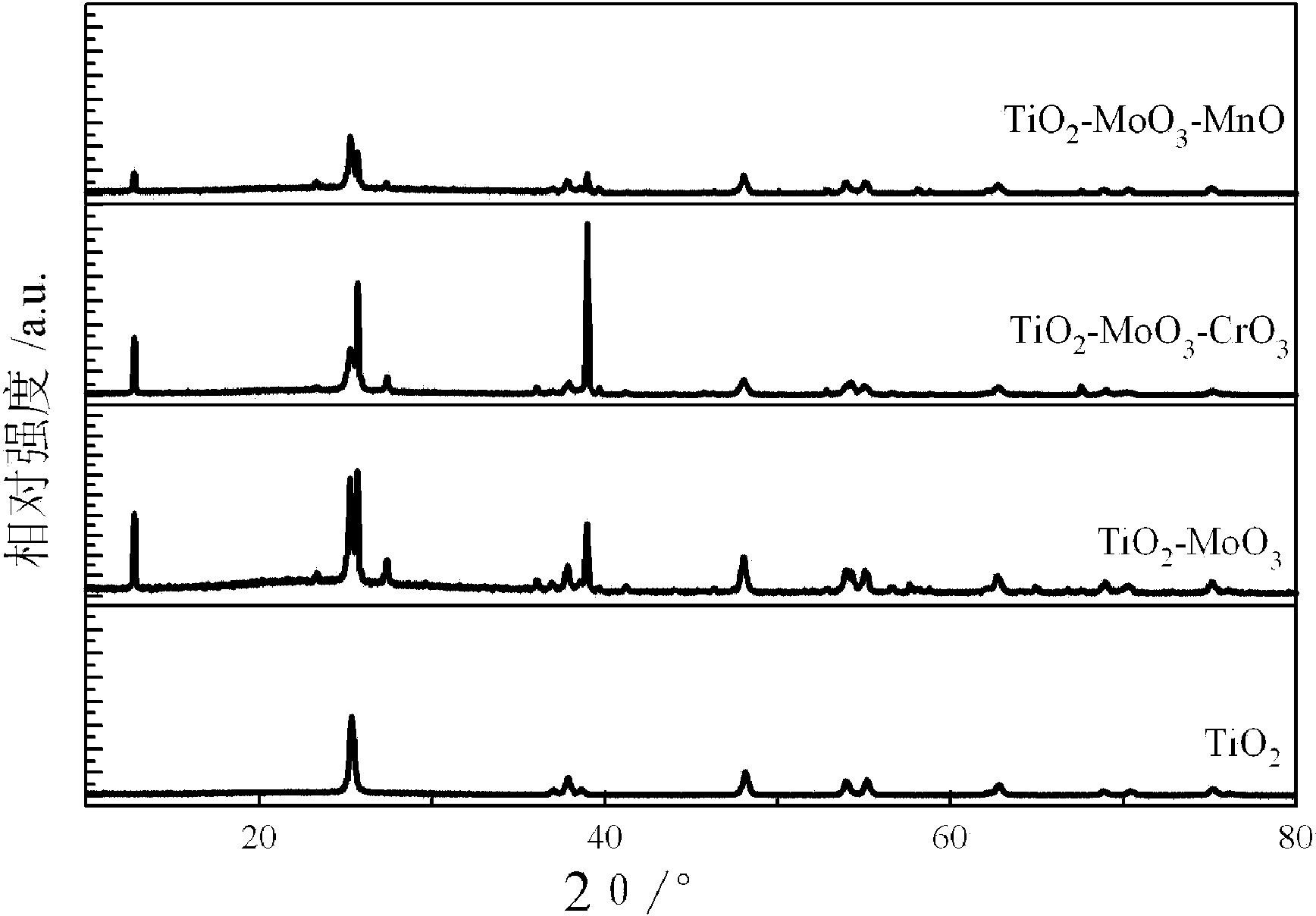

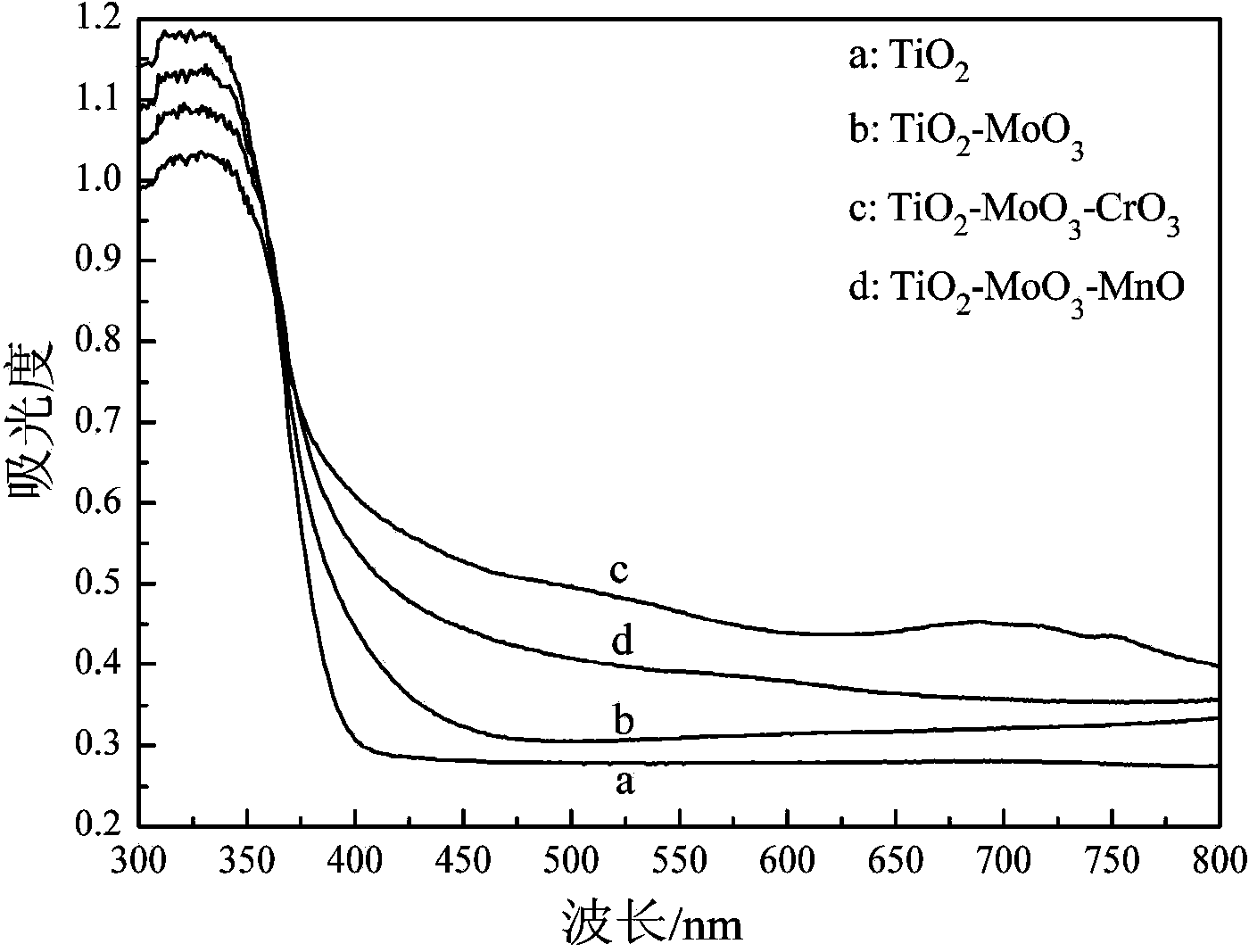

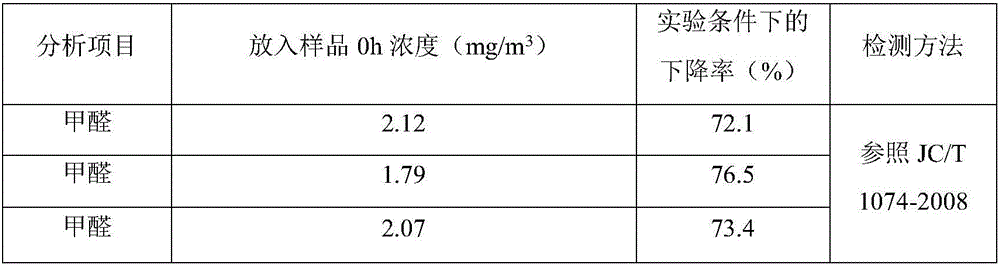

Preparation method of environment-friendly interior wall top coating for preforming catalytic degradation on formaldehyde in air during photocatalysis and chemical oxidation

InactiveCN103756467AEfficient degradationIncrease profitCoatingsCatalytic oxidationMolybdenum trioxide

The invention provides a preparation method of an environment-friendly interior wall top coating for preforming catalytic degradation on formaldehyde in air during photocatalysis and chemical oxidation. The environment-friendly interior wall top coating comprises a formaldehyde degrading agent capable of performing catalytic degradation on formaldehyde, wherein the formaldehyde degrading agent is prepared by using a precipitation method. The formaldehyde degrading agent is a titanium dioxide powder body which has a certain crystal form and contains molybdenum trioxide and other metal oxides on the surface. The environment-friendly interior wall top coating is higher in acid catalytic activity, is used in acid catalysis reaction, and is also suitable for catalytic oxidation degradation of the formaldehyde. The powder body is safe, non-volatile and pollution-free. The environment-friendly interior wall top coating provided by the invention is environment-friendly and free from pollution; the degradation rate to the formaldehyde in indoor air can reach 73.3 percent.

Owner:DALIAN POLYTECHNIC UNIVERSITY

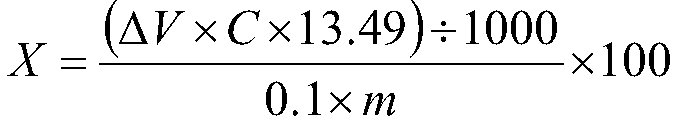

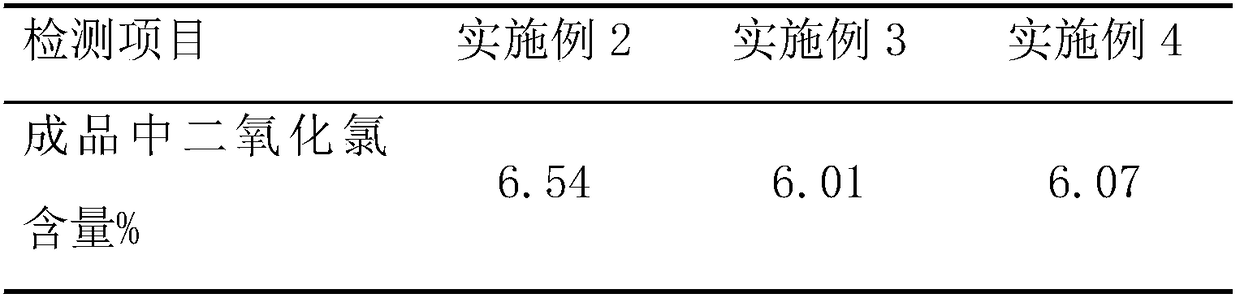

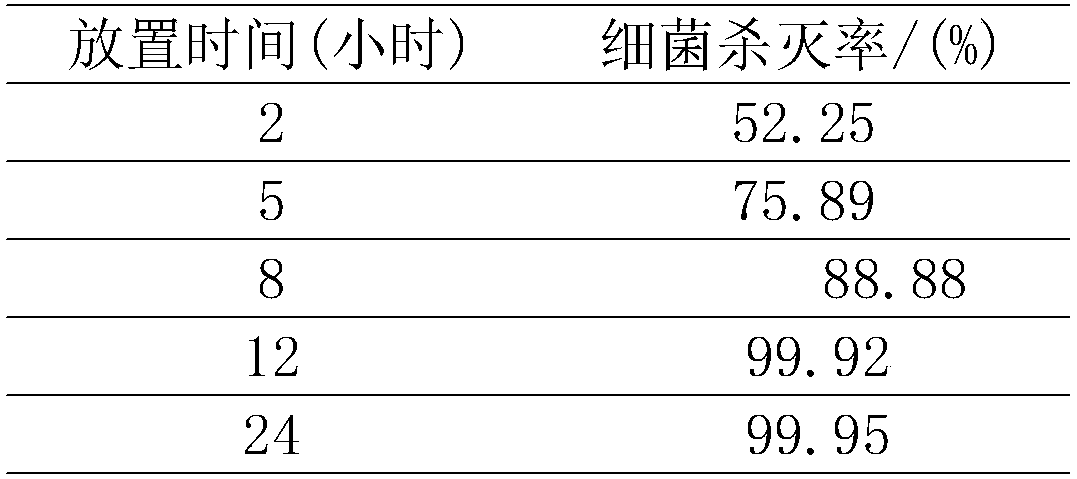

Slow-release immobilized chlorine dioxide particles and preparation method of particles

The invention discloses slow-release immobilized chlorine dioxide particles and a preparation method of the particles. The method comprises the following steps that S1, a surfactant is added to an acid solution, natural zeolite particles are immersed into the acid solution, and then modified natural zeolite particles are obtained through solid-liquid separation; S2, the modified natural zeolite particles are soaked in a transition metal salt solution, and then through solid-liquid separation and calcination, load transition metal zeolite particles are obtained; S3, sodium chlorite powder, silica gel powder and diatomite are mixed according to a proportion, and a covering agent is obtained; S4, the covering agent and the load transition metal zeolite particles are mixed, put into a pelletizer and sprayed with a binding agent, and after covering, pelletizing and drying are conducted, the slow-release immobilized chlorine dioxide particles are obtained; S5, the slow-release immobilized chlorine dioxide particles are placed in a ventilation bag. The slow-release immobilized chlorine dioxide particles release chlorine dioxide gas slowly, the preservation and application period is long,and the particles have the functions such as sterilization and formaldehyde degradation.

Owner:张志 +1

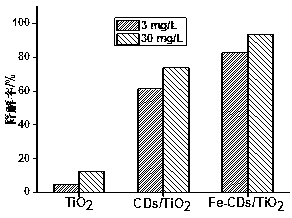

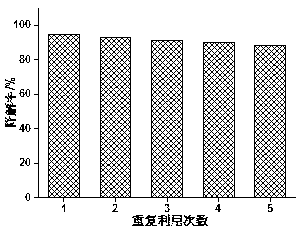

Preparation method of iron doped carbon quantum dot/titanium dioxide composite photocatalyst and formaldehyde degradation method

PendingCN108212159AImprove photocatalytic performanceGood catalytic degradation effectMetal/metal-oxides/metal-hydroxide catalystsWork contentIrradiation

The invention discloses a preparation method of an iron doped carbon quantum dot / titanium dioxide composite photocatalyst and a formaldehyde degradation method. The preparation method comprises following steps: (1) preparing iron doped carbon quantum dots; and (2) preparing the iron doped carbon quantum dot / titanium dioxide composite photocatalyst. The prepared iron doped carbon quantum dot / titanium dioxide composite photocatalyst can be used to catalytically degrade formaldehyde in the presence of visible light. An interface charge transfer effect is utilized to construct iron doped carbon quantum dots; iron doping can enhance the photocatalytic activity of the composite photocatalyst, because the work content of carbon quantum dots is reduced by the iron doping, a great potential barrieris formed between iron doped carbon quantum dots and titanium dioxide, and the photocatalytic performance of iron doped carbon quantum dots / titanium dioxide is enhanced. The introduction of iron doped carbon quantum dots greatly strengthens the catalytic performance of titanium dioxide in the presence of visible light. After 180 minutes of irradiation of visible light, the degradation rate of formaldehyde (3-30 mg / L) is increased to 85% or more, compared with 40% (titanium dioxide is taken as the catalyst).

Owner:云南健牛环境监测有限公司

Waterproof putty paste capable of removing formaldehyde

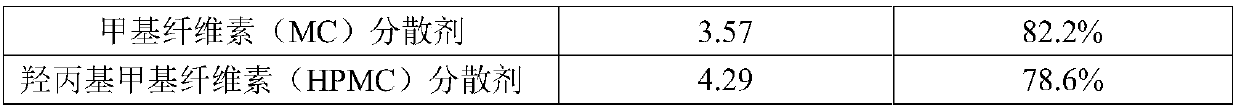

InactiveCN105315754AReduce dosageImprove waterproof performanceFilling pastesEmulsionMethyl cellulose

The invention discloses waterproof putty paste capable of removing formaldehyde. The waterproof putty paste is prepared from, by mass, 0.3-0.7 parts of hydroxypropyl methyl cellulose, 12-16 parts of water, 18-32 parts of ash calcium powder, 12-35 parts of 325-mesh talcum powder, 15-22 parts of 325-mesh calcium carbonate, 10-18 parts of ground calcium carbonate, 2-4 parts of kieselguhr and 4-8 parts of nanometer TiO2 / kieselguhr photocatalytic composite material. The waterproof putty paste is low in consumption, lowers coating consumption, improves the coating effect, is suitable for cement mortar walls, and is the optimal preferred material for diatom ooze, emulsion paint and wall paper, and particularly the cost of putty for two or more times of decorating can be saved. Under the illumination conditions, nanometer TiO2 / kieselguhr photocatalytic composite material conducts adsorption, capture, photocatalysis and degradation, indoor gas-state pollutants such as formaldehyde and methylbenzene are removed, and the formaldehyde degradation rate within 72 hours reaches up to 80% or higher.

Owner:孙全

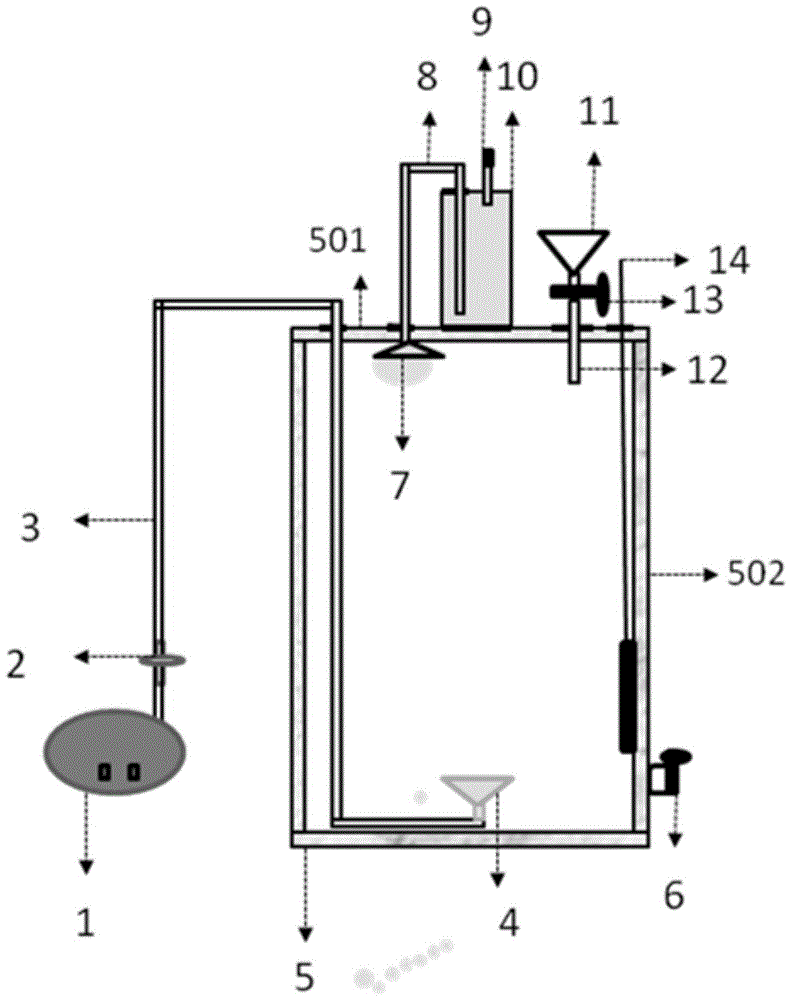

Culturing device for formaldehyde degradation bacteria

InactiveCN104946527AControl internal temperatureAvoid secondary pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringBiological filter

The invention belongs to the technical field of air purification equipment and particularly relates to a culturing device for formaldehyde degradation bacteria. A reaction tank which is of a box-type structure consists of a tank cover and a tank body; an air inlet pipeline reaches the bottom of the reaction tank through the tank cover; an aeration pump is arranged at the outer end of the air inlet pipeline; a swirl-mixing aerator is arranged at the inner end of the air inlet pipeline; a micro-porous biological filtering membrane is arranged at the end, close to the aeration pump, inside the air inlet pipeline; a temperature controller is arranged at the lower right part inside the tank body; a sampling hole is formed at the lower right part outside the tank body; a tail gas absorbing bottle is arranged in a central line at the top outside the tank cover; a tail gas pipeline is led out from the tail gas absorbing bottle, penetrates through the tank cover and then is provided with a tail gas collecting opening; a supplementing pipeline penetrates through the tank cover and then is provided with a valve and a supplementing opening in sequence. The culturing device is simple in structure, safe to use, convenient in preparation method, reliable in principle and low in cost, is capable of reducing the risk of exposure to surrounding people, and is applicable to screening, acclimatization and batch culture of formaldehyde degradation bacteria.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

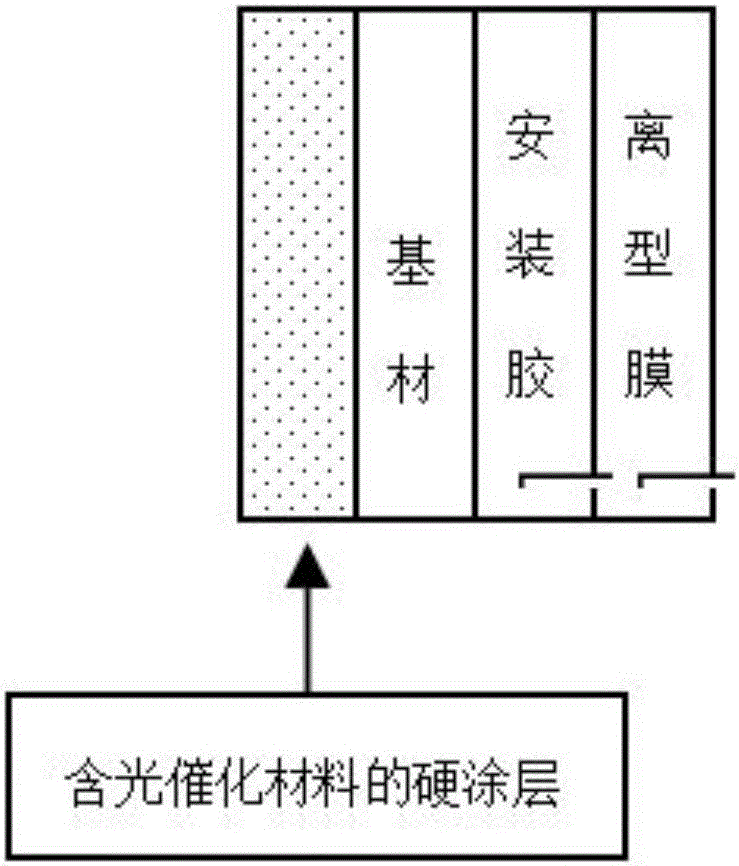

Formaldehyde film degraded by photocatalytic mechanism

ActiveCN106390740AChange hardnessNo change in scratch resistancePhysical/chemical process catalystsDispersed particle separationEngineeringHardness

The invention discloses a formaldehyde film degraded by photocatalytic mechanism. The film belongs to the field of film technology. The film combines the photocatalysis technology with the automobile film, construction film and decoration film; by integrating the nanometer photocatalytic material TiO2 into the automobile film, construction film and decoration film coating layer to ensure the preservation of the original properties of the products, namely the in-alteration of the hardness, anti-scraping performance and light permeability of the original film, and at the same time enhances the function of formaldehyde degradation. Compared with the short lived photocatalyst spraying agent the film enjoys a service life as long as over 2 years, thereby prolonging the use period of the product.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

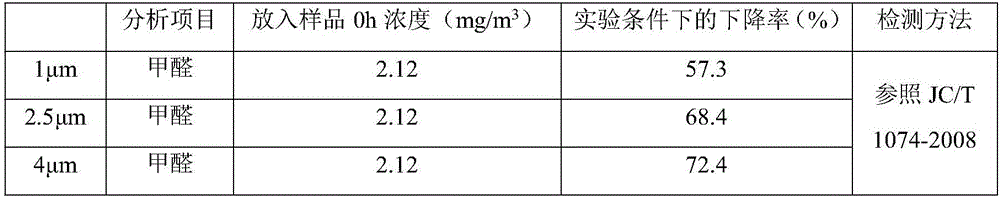

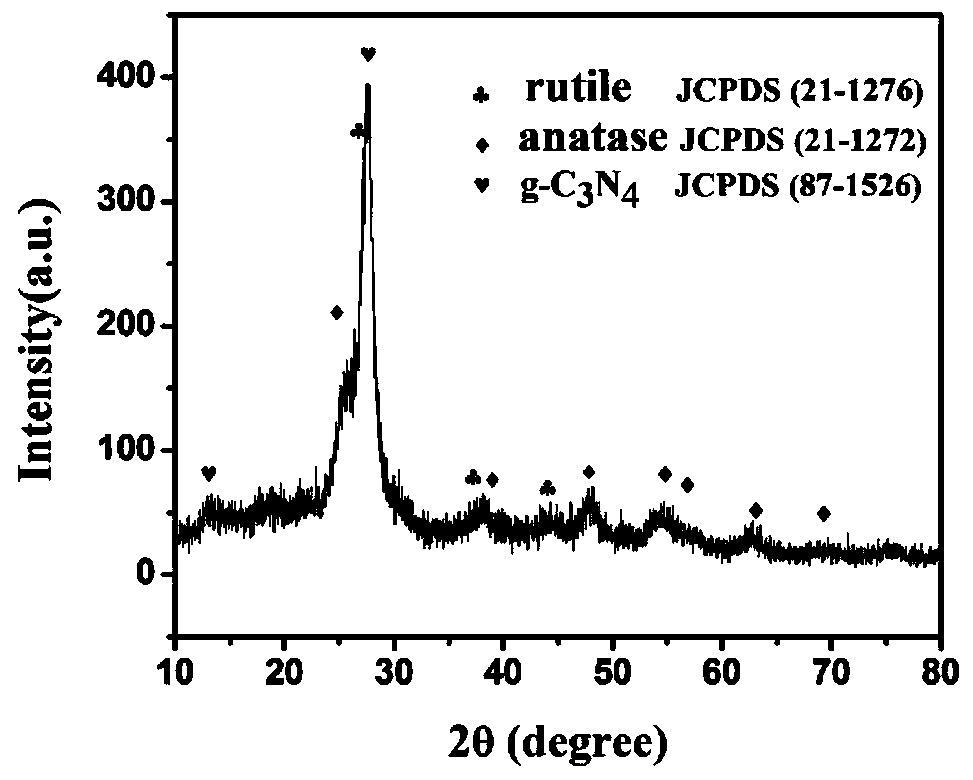

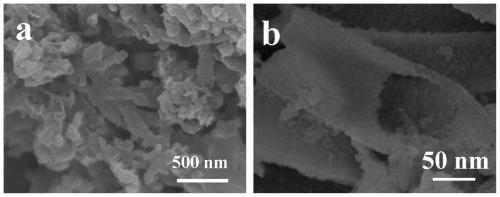

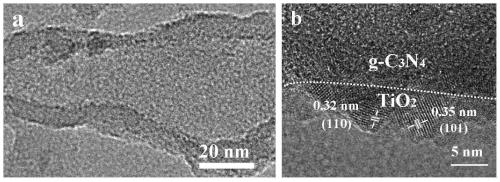

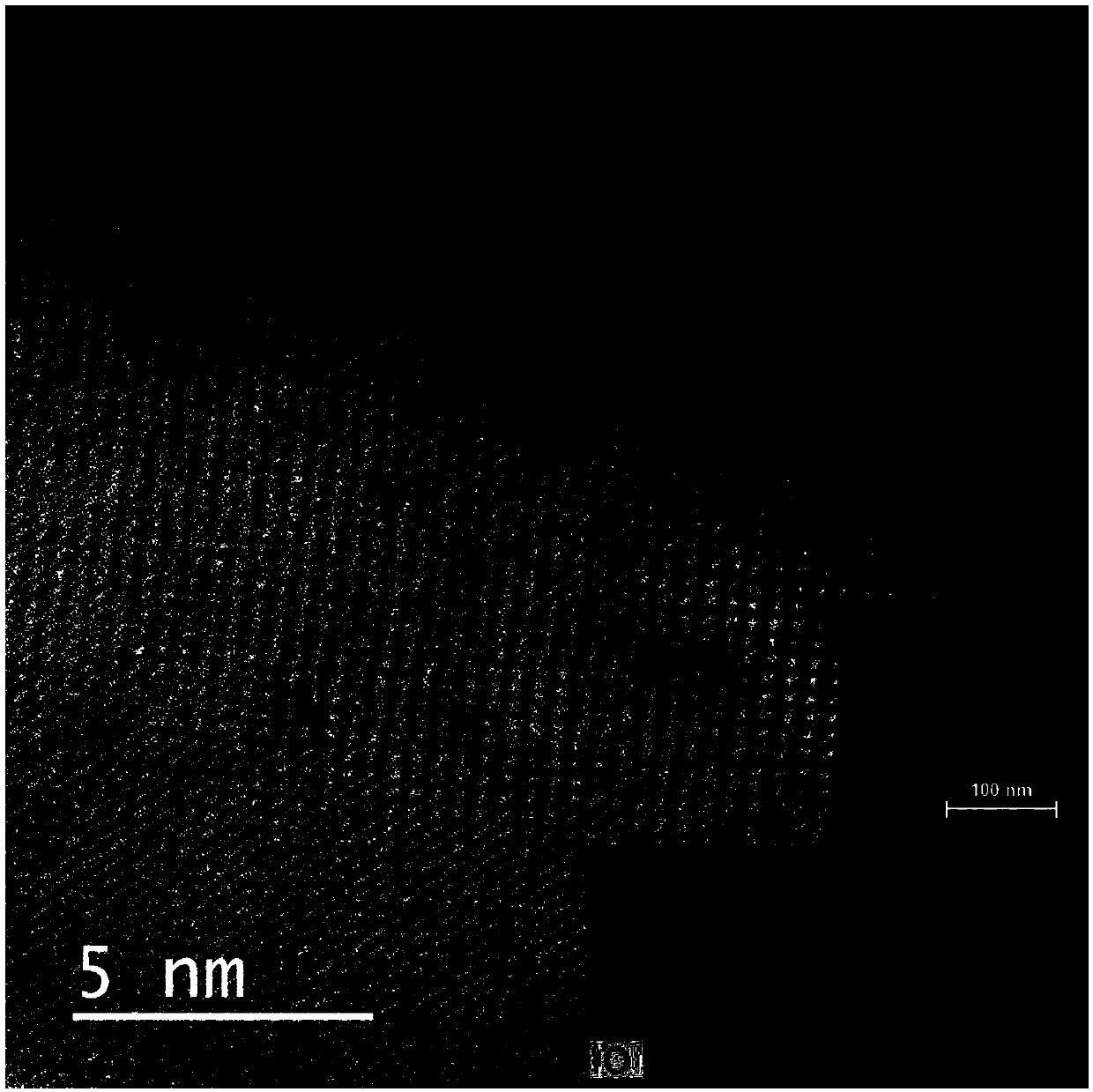

Mixed crystal TiO2/g-C3N4 nano hollow tube composite material and preparation method thereof

ActiveCN111250139AImprove photocatalytic efficiencySimple preparation processGas treatmentPhysical/chemical process catalystsTitanium chlorideHexamethylenetetramine

The invention discloses a mixed crystal TiO2 / g-C3N4 nano hollow tube composite material and a preparation method thereof. The TiO2 mixed crystal / g-C3N4 nano hollow tube composite material disclosed bythe invention can be used as an efficient photocatalyst. Urea, titanium tetrachloride and hexamethylenetetramine are used as raw materials, g-C3N4 nano hollow tubes are obtained through a secondary roasting reaction, then the rutile and anatase type TiO2 mixed crystal / g-C3N4 nano hollow tube composite material is obtained through a hydrothermal reaction, and preparation and loading of the rutileand anatase type TiO2 mixed crystal are completed in one step. The preparation method has the advantages that the used precursors are cheap urea and inorganic salt titanium tetrachloride, the preparation process is simple, and the cost is low; and the rutile and anatase type mixed crystal TiO2 / g-C3N4 nano hollow tube photocatalyst prepared by the method has good photocatalytic activity in the aspects of hydrogen production by photolysis of water, degradation of organic pollutants in water, degradation of formaldehyde in air, bacteriostasis, antibiosis and the like.

Owner:重庆郎岭新材料科技有限公司

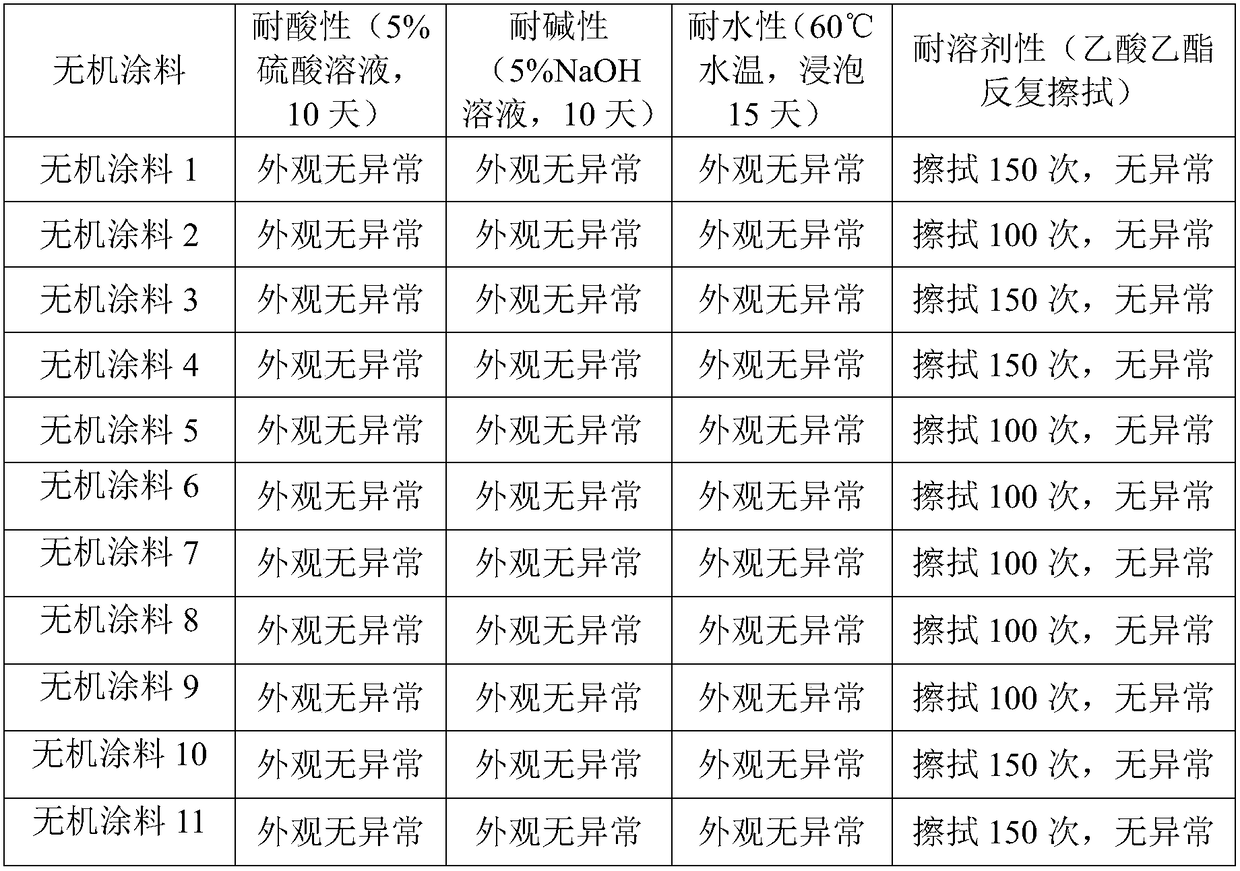

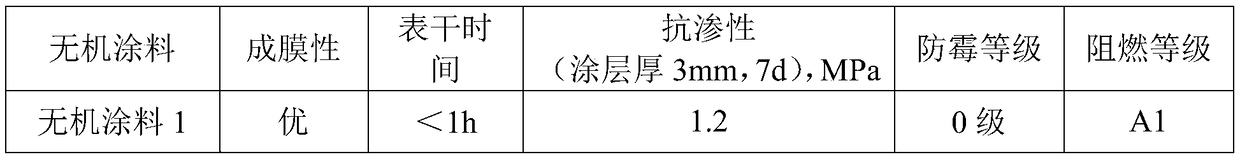

Environmental-friendly inorganic coating and preparation method thereof

InactiveCN109233376APromote degradationPrevent the occurrenceFireproof paintsAntifouling/underwater paintsEnvironmental resistanceCellulose

The invention discloses an environmental-friendly inorganic coating and a preparation method thereof. The environmental-friendly inorganic coating comprises the following raw materials in parts by weight: 40-50 parts of potassium silicate, 30-40 parts of packing, 0.5-5 parts of silicon dioxide, 5-10 parts of modified shell powder, 0.1-0.2 part of cellulose, 0.1-0.2 part of a defoaming agent, 0.1-0.3 part of a dispersant, 5-10 parts of a pigment, 1-5 parts of a pure acrylic emulsion and 20-30 parts of water. The inorganic coating disclosed by the invention has a formaldehyde degradation function which lasts for 8 months or longer, the purification performance and the effect lasting of the inorganic coating disclosed by the invention upon formaldehyde meet technical requirements of JC1074-2008 Purificatory Performance of Coatings with Air Purification type I, the inorganic coating disclosed by the invention can both meet national standards, and maintains characteristics of energy conservation, economy, environment protection, low carbon, flame retardancy, quick dry, good adhesion, water resistance, acid resistance, alkali resistance, and the like.

Owner:珠海陶氏无机涂料有限公司

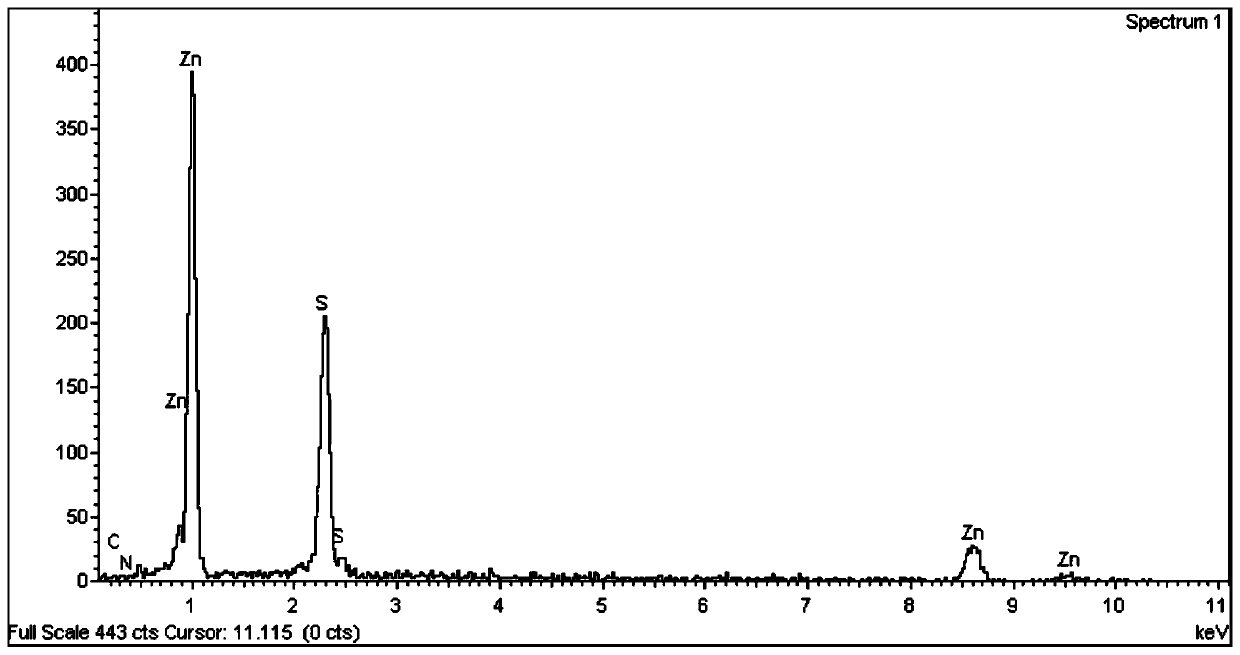

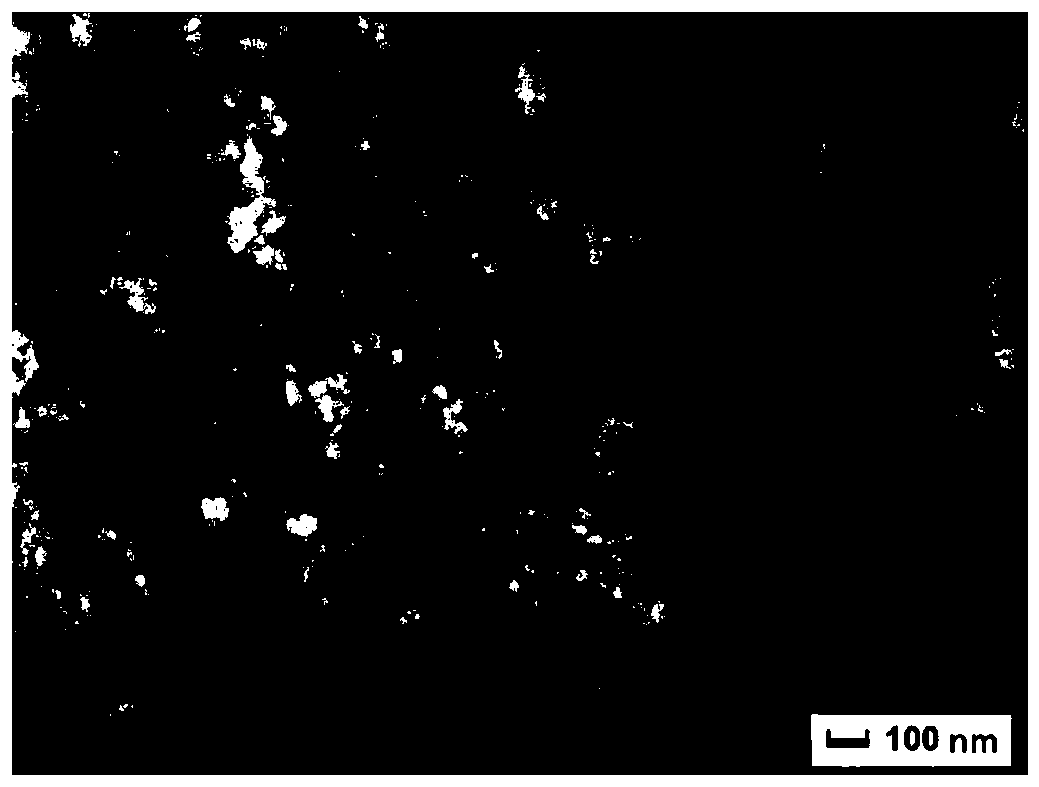

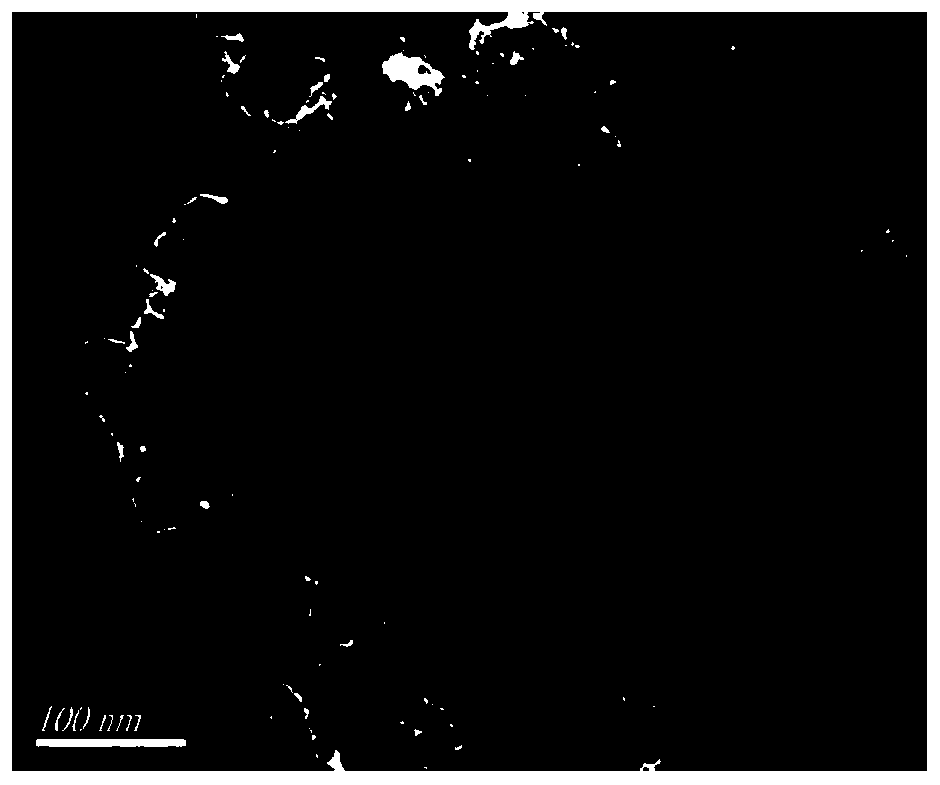

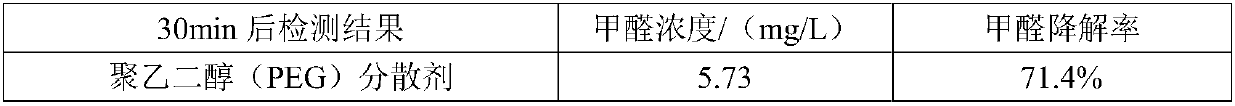

G-C3N4-ZnS composite nanomaterial as well as preparation method and application thereof

InactiveCN110075895APromote degradationImprove stabilityMaterial nanotechnologyGas treatmentAdhesiveAqueous ethanol

The invention discloses a g-C3N4-ZnS composite nanomaterial as well as a preparation method and an application thereof. The particle size of the material is 30-100 nm, and the material contains 5wt%-25wt% of g-C3N4 and the balance of ZnS. The method comprises steps as follows: a Zn source, g-C3N4 nanosheets, a surfactant and an S source are added to aqueous ethanol solution successively, the solution is ultrasonically dispersed and subjected to a hydrothermal reaction and then is separated, washed and dried, and the composite nanomaterial can be obtained. The composite nanomaterial is subjected to ball milling with a curing agent and filler, an inorganic adhesive is added, all materials are stirred uniformly, spray slurry is obtained and sprayed to the surface of a base material at a rateof 0.4-0.6 m / s under 0.45-0.55 MPa, cleaning and air-drying are performed after multi-stage heat treatment, and a g-C3N4-ZnS composite photocatalytic coating is obtained. The preparation technology issimple, and the composite photocatalytic coating prepared with the technology has higher formaldehyde degradation capacity and can be greatly applied to the fields of air purification, sewage treatment and the like.

Owner:ZHENJIANG COLLEGE

Catalyst used for degrading formaldehyde wastewater, preparation method and application thereof

ActiveCN107737594AImprove stabilityHigh activityWater treatment compoundsWater contaminantsReactive siteRoom temperature

The invention discloses a catalyst used for degrading formaldehyde wastewater, a preparation method and application thereof. The catalyst is expressed by a general formula M / HMO, wherein M is an active ingredient, HMO is a novel porous manganese dioxide carrier, and the mass ratio of the mole number of M to HMO is (1 to 5): 100. The novel porous MnO2 carrier which is large in specific surface areaand high in active sites and is capable of playing a synergistic effect with the active ingredient to catalytically oxidizing and degrading formaldehyde wastewater and an efficient catalyst capable of stably degrading formaldehyde wastewater at a room temperature condition are developed, the operating conditions are further optimized while relatively high formaldehyde degradation rate is maintained, and the catalyst has important practical significance.

Owner:SOUTHEAST UNIV

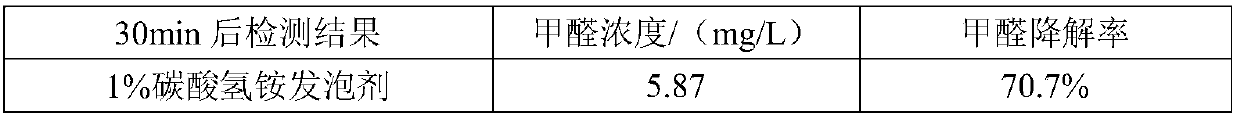

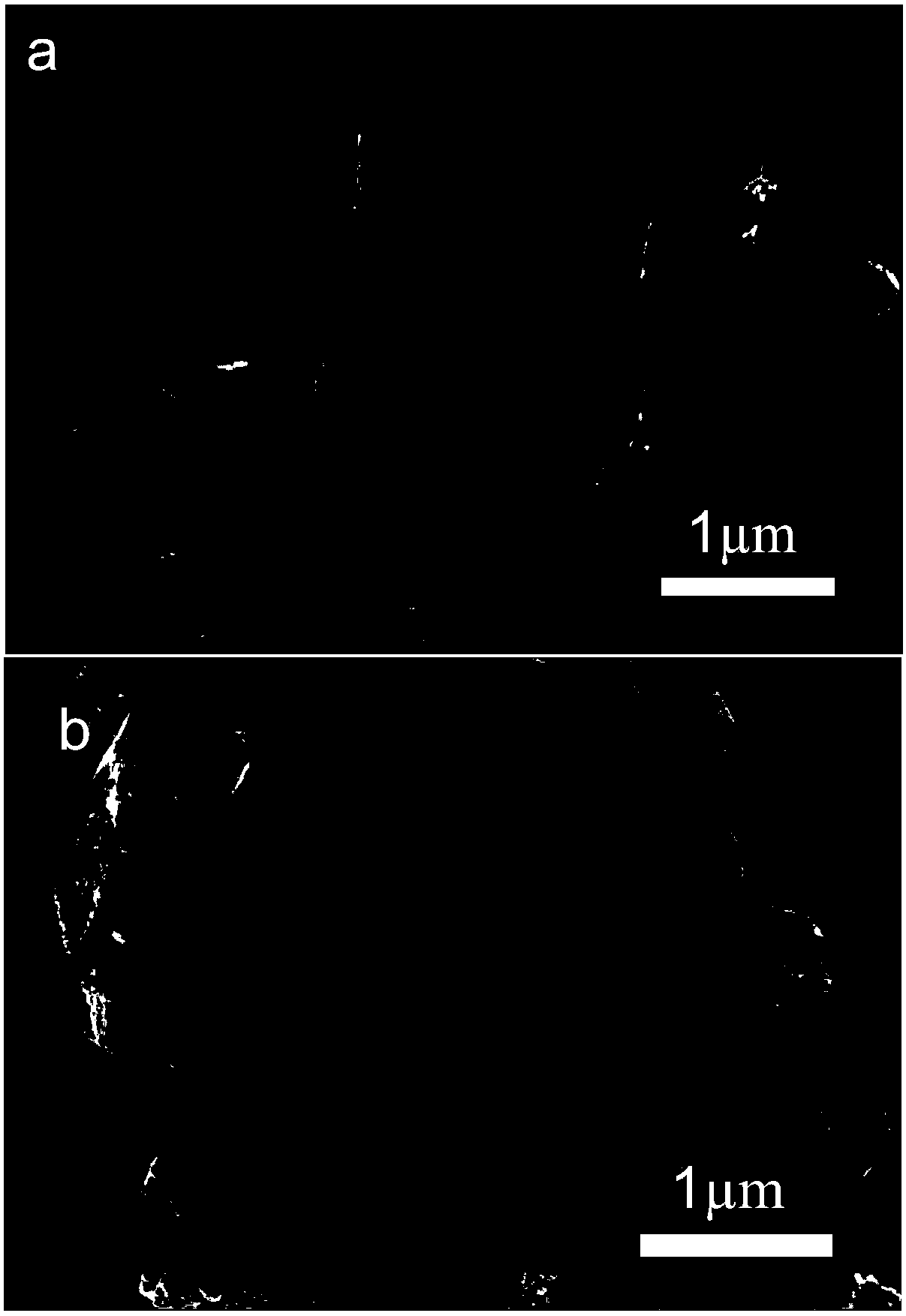

Zinc oxide composite photocatalyst, preparation method and application thereof

ActiveCN108479774ALarge specific surface areaImprove photocatalytic reactivityWater/sewage treatment by irradiationWater contaminantsPhotocatalytic reactionOxide composite

Belonging to the chemical field, chemical engineering field and environmental engineering field, the invention relates to a zinc oxide composite photocatalyst, a preparation method and application thereof. The method includes: firstly, preparing a three-dimensional micron flower-like zinc-based precursor by liquid-phase coprecipitation technique, conducting high temperature calcinations to prepareporous zinc oxide microflowers, then taking silver nitrate as the precursor, further reducing silver ions adsorbed on the porous zinc oxide surface into nano-silver particles by ultraviolet irradiation technique so as to prepare an Ag / ZnO composite material, thus obtaining the zinc oxide composite photocatalyst. The invention also provides the zinc oxide composite photocatalyst prepared by the preparation method and application of the zinc oxide composite photocatalyst to formaldehyde degradation in water under ultraviolet irradiation condition. The Ag / ZnO composite material prepared by the method provided by the invention has the advantages of large specific surface area, high photocatalytic reaction active site and the like, and can be used for photocatalytic degradation of formaldehydeliquid under ultraviolet light.

Owner:FUJIAN AGRI & FORESTRY UNIV

Catalyst and material for formaldehyde decomposition

InactiveCN102019189AImprove durabilityImprove ventilationOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationDecompositionPlatinum oxide

The present invention provides a catalyst and a material for formaldehyde decomposition. The catalyst comprises manganese dioxide, alumina, silica, copper oxide, platinum oxide and magnesia, wherein the weight ratio is: manganese dioxide: alumina: silica: copper oxide: platinum oxide: magnesia = 100:9-15:5-7:3-7:0.5-2:1-3. The material for formaldehyde decomposition comprises the catalyst and a carrier. The doped manganese dioxide catalyst of the present invention can significantly improve the persistence of the manganese dioxide during the formaldehyde decomposition and absorb part of the resultant carbon dioxide. In addition, by adopting a unique non-adhesive agglutination process, the invention can load the doped manganese dioxide catalyst on a carrier, and prepare the material with a formaldehyde degradation rate of above 90% in a short period under natural environment of normal temperature and normal pressure; achieves the advantages of high efficiency and stable degradation efficiency; and can be utilized circularly.

Owner:BEIJING NAWEIDASI TECH

Preparation method and application of dark light catalytic non-photo-catalyst/activated carbon fiber composite material

InactiveCN104437452AUninterrupted adsorptionUninterrupted adsorption degradationBiocidePhysical/chemical process catalystsActivated carbonAdhesive

The invention belongs to the field of novel materials and photocatalysis and particularly relates to a preparation method and application of a dark light catalytic non-photo-catalyst / activated carbon fiber composite material. The dark light catalytic non-photo-catalyst / activated carbon fiber composite material is characterized by comprising a non-photo-catalyst, an activated carbon fiber raw material, an adhesive and water. The preparation method comprises the following steps: cutting the activated carbon fiber to required size and perforating; weighing the non-photo-catalyst, and adding water to form a non-photo-catalyst solution; preparing a chitin powder adhesive; spray coating the non-photo-catalyst solution onto the surface of the activated carbon fiber, drying, spray coating the adhesive onto the surface of the coated non-photo-catalyst solution to fix the adhesive on the surface of the activated carbon fiber, and drying. The dark light catalytic non-photo-catalyst / activated carbon fiber composite material can purify pollutants through adsorption and catalysis functions under dark light or sufficient light, the formaldehyde degradation efficiency within 1 hour reaches 99.9%, the load is firm, the specific surface area is high, and the composite material can be regenerated in situ under sunlight exposure or at low temperature of 60 DEG C.

Owner:SICHUAN AGRI UNIV

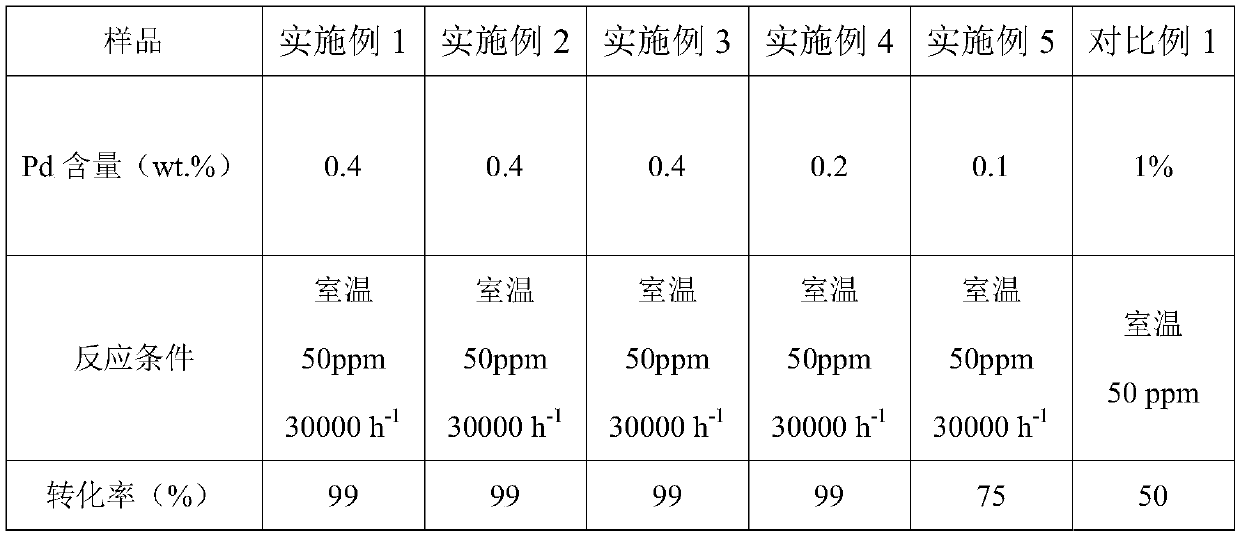

Palladium-based catalyst for thermocatalytic formaldehyde degradation

ActiveCN109529821AReduce loadGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsReduction treatmentAnatase

The invention discloses a palladium-based catalyst for thermocatalytic formaldehyde degradation. In the Pd / TiO2 catalyst, mass fraction of Pd is 0.1%-0.4%, on the basis of the weight of catalyst being100%. A preparation method comprises the following steps: 1) performing reduction treatment on a TiO2 carrier; 2) adding a defined amount of TiO2 into a palladium nitrate solution; 3) regulating pH of the solution and reducing; 4) drying the acquired mixture, thereby acquiring the required Pd / TiO2 catalyst for formaldehyde oxidation. The preparation method disclosed by the invention is simple; the prepared Pd / TiO2 catalyst has an anatase (ATiO2) phase structure; the formed Pd / TiO2 shows an excellent catalytic performance for formaldehyde oxidation.

Owner:SUN YAT SEN UNIV

Formaldehyde degradation spray for Chinese herbal components

InactiveCN105920998AReduce concentrationReduced responseGas treatmentDispersed particle separationAdditive ingredientMedicine

The invention discloses formaldehyde degradation spray for Chinese herbal components, and belongs to the technical field of air purifying. The formaldehyde degradation spray for the Chinese herbal components comprises wormwood, radix aristolochiae, dogwood, longan, cassia seed, madder, pseudo-ginseng, lithospermum, aloe, seed of Chinese dodder, honeysuckle, eupatorium, dried tangerine or orange peel and fructus forsythia. The formaldehyde degradation spray for the Chinese herbal components not only can effectively degreade formaldehyde in air, but also can enable air to be fresh and fragrant, so that the environment is improved, the fatigue is relieved, physical and mental pleasure further can be realized, the working and learning efficiency is improved, and the use is convenient.

Owner:浙江维度环保科技有限公司

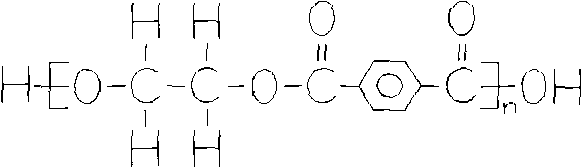

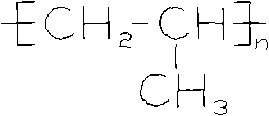

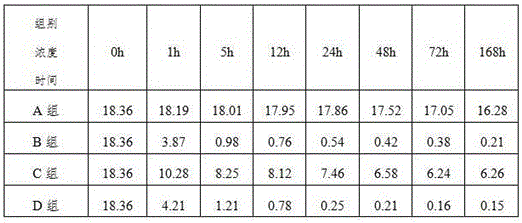

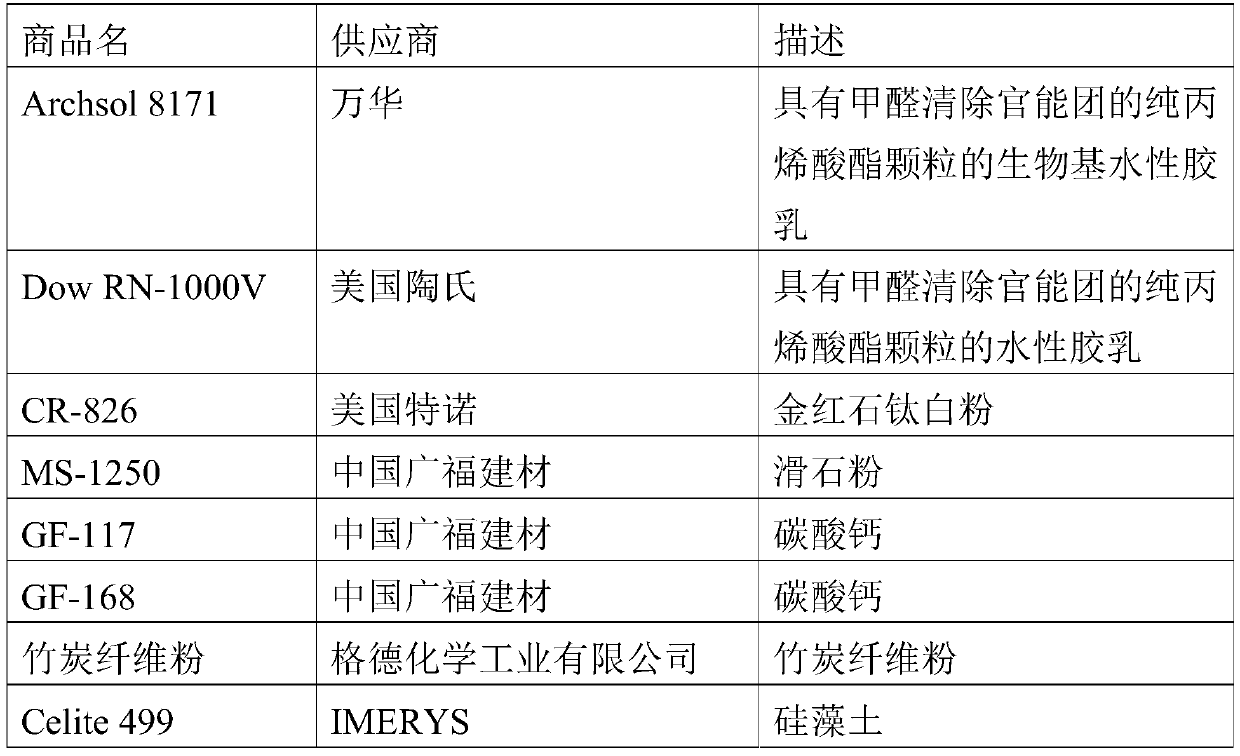

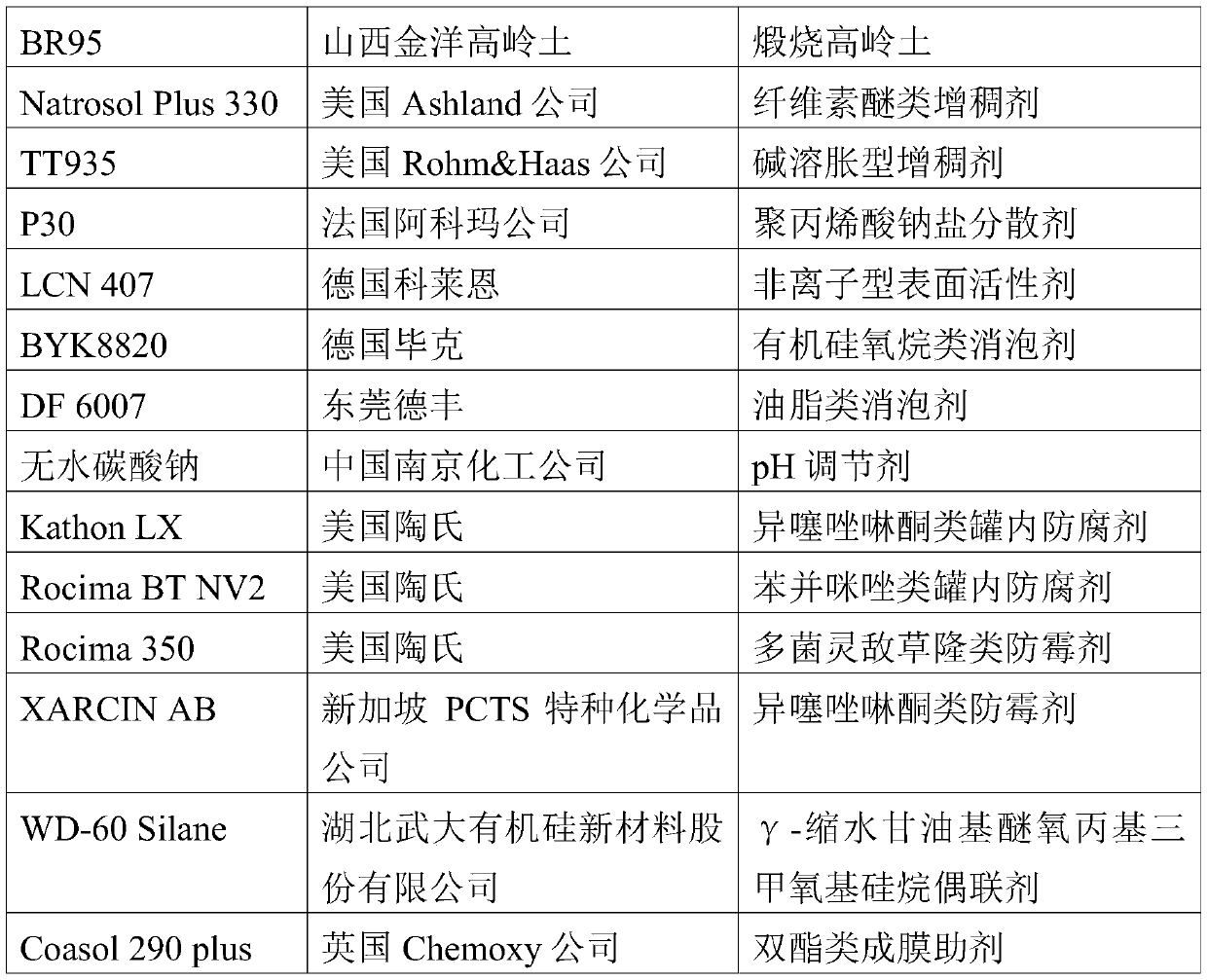

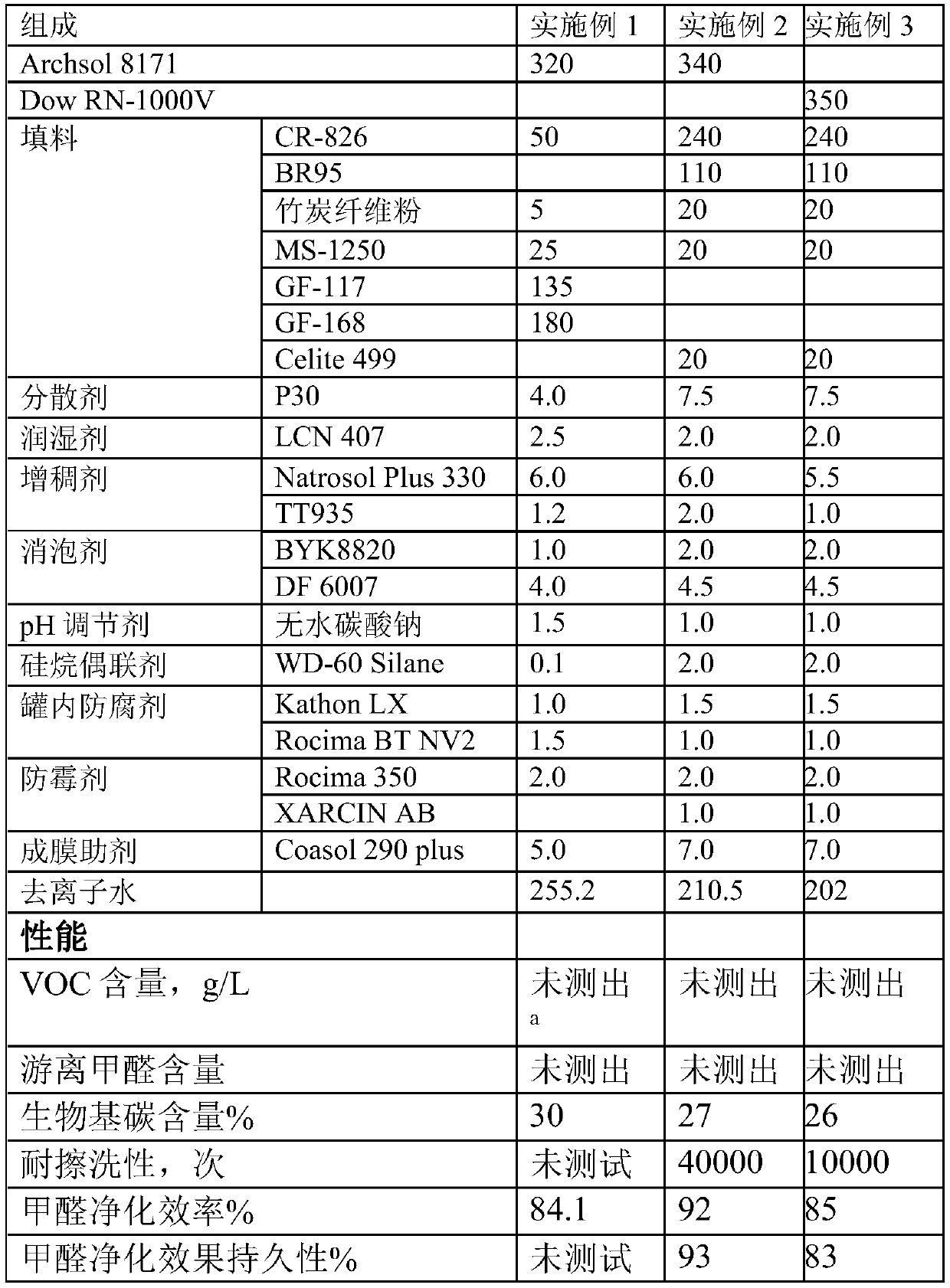

Water-based paint composition and coating formed by water-based paint composition

The invention relates to a water-based paint composition and a coating formed by the water-based paint composition. Bases on the total weight of the water-based paint composition, the water-based paint composition comprises, by weight, 20-70% of biologic water-based latex, 20-70% of filler and 0-10% of an additive, wherein the biologic water-based latex contains particles of an acrylic polymer containing formaldehyde degradation functional groups and at least 26wt% of biochar; due to the content of the formaldehyde degradation functional groups, the air formaldehyde purifying efficiency of thecoating formed by the water-based paint composition is 80% or above during the test of JC / T 1074-2008. The water-based paint composition little contains volatile organic compounds.

Owner:GUANGDONG HUARUN PAINT CO LTD

Preparation method of graphene oxide/bioenzyme nanometer composite material

InactiveCN106914226AEffective filteringStrong ability to degrade formaldehydeOther chemical processesCarbon compoundsAir purifiersAir conditioning

The invention relates to a graphene oxide / bioenzyme nanometer composite material for preventing haze and degrading formaldehyde. A preparation method of the graphene oxide / bioenzyme nanometer composite material comprises 1, preparing a bioenzyme by an acid method and dispersing the prepared bioenzyme into deionized water, 2, preparing porous sponge-like three-dimensional graphene oxide and 3, immersing the porous sponge-like three-dimensional graphene oxide in the bioenzyme solution, and drying the sponge-like three-dimensional graphene oxide carrying the bioenzyme in a drying tank at a temperature of 50 DEG C to obtain the graphene oxide / bioenzyme nanometer composite material for preventing haze and degrading formaldehyde. The graphene oxide / bioenzyme nanometer composite material can effectively filter PM2.5 and other dust particles, has strong formaldehyde degradation effects, has stable and lasting effects, can be used as a filter material of a gauze mask, an air purifier and an air conditioning device and can also be used as a sewage treatment filter material.

Owner:刘宇

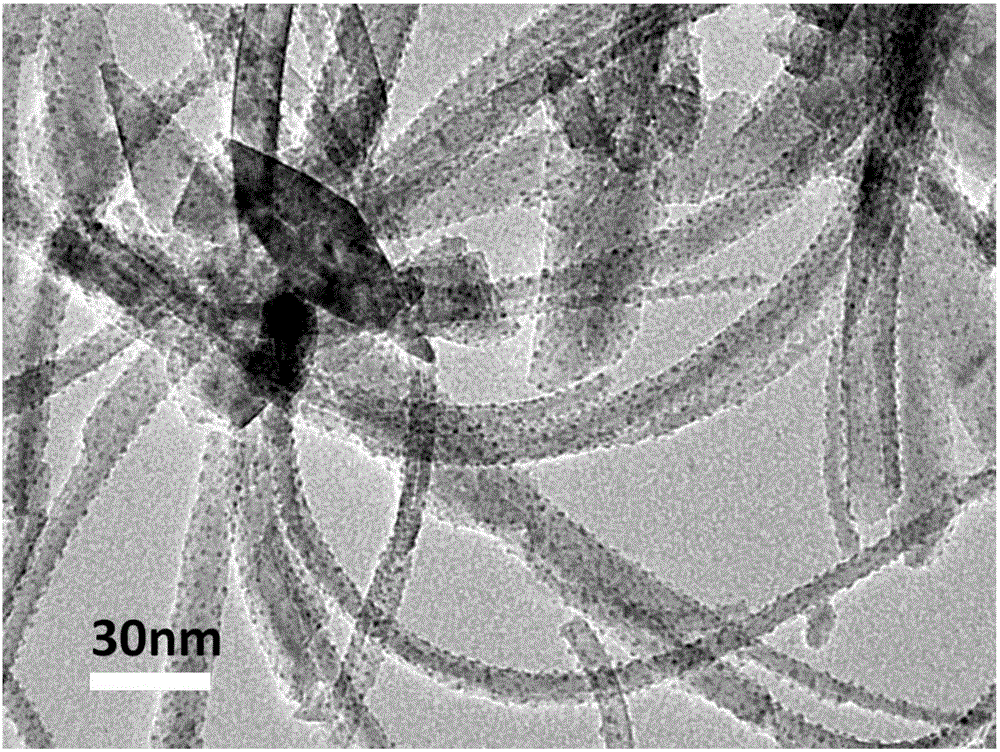

Room-temperature formaldehyde decomposing agent suitable for air purifier and preparation method thereof

InactiveCN105289192AAchieve room temperature catalysisEfficient captureDispersed particle separationAir purifiersRoom temperature

The invention discloses a room-temperature formaldehyde decomposing agent suitable for an air purifier. Diatomite powder particles are used as nucleuses, ultrafine TiO2 nanobelts grow on the surfaces of the nucleuses, and nano Pt particles are loaded on the TiO2 nanobelts, so as to prepare the room-temperature formaldehyde decomposing agent. The room-temperature formaldehyde decomposing agent is characterized in that the room-temperature formaldehyde decomposing agent is a composite material which is prepared by using the diatomite powder particles as carriers and loading the ultrafine TiO2 nanobelts, wherein the ultrafine TiO2 nanobelts and the nano Pt particles form Pt / TiO2 heterostructures, and the loading capacity of the nano Pt particles is 1% to 5% of the total mass of the Pt / TiO2 heterostructures. The formaldehyde decomposing agent can be used for integrating various types of formaldehyde pollution treatment, i.e. the diatomite powder particles with strong adsorbability are used as the nuclei, so as to efficiently capture formaldehyde molecules, the ultrafine TiO2 nanobelts grow on the surfaces of the nucleuses, so that the formaldehyde decomposing agent has a photocatalyst formaldehyde degradation function, and the tiny Pt particles are loaded on the TiO2 nanobelts, so that the formaldehyde molecules are catalyzed at room temperature, and the stable efficient long-term purification of indoor formaldehyde air is really realized.

Owner:SHANDONG UNIV

Indoor special environment-friendly purifying agent and preparation method thereof

InactiveCN104474865ANice smellEfficient purificationBiocideDispersed particle separationDioxyethylene EtherNephrolepis exaltata

The invention relates to an indoor special environment-friendly purifying agent and a preparation method thereof, belonging to the field of purifying agents. The indoor special environment-friendly purifying agent comprises the following materials in mass part: 12-19 parts of nephrolepis exaltata, 5-14 parts of grapefruit peel, 2-10 parts of cellulase, 2-8 parts of pinene, 5-10 parts of nanometer titanium dioxide, 2-9 parts of octaphenyl polyoxyethyiene, 16-27 parts of alcohol and 20-30 parts of water. The indoor purifying agent disclosed by the invention can effectively purify air and kill bacteria in air, and has pleasant smell, and the formaldehyde degradation absorption rate of the indoor purifying agent can reach up to 90 percent above; the indoor purifying agent has stable properties, still can effectively purify air when being stored for a long term, has no side and toxic effect, and is environmentally friendly; and the preparation method disclosed by the invention is simple and easily implemented, and can be popularized and applied in a larger range.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

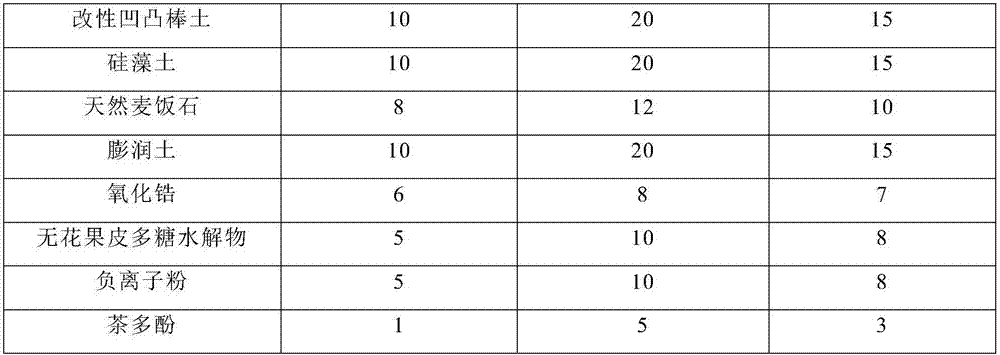

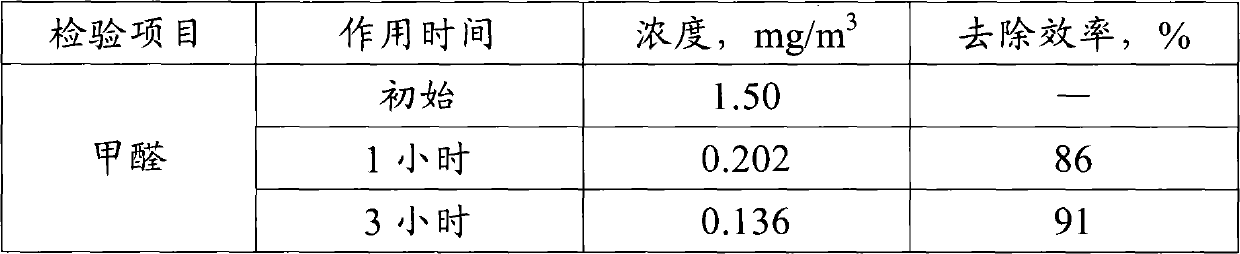

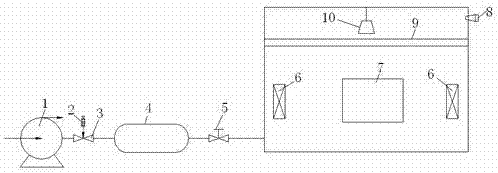

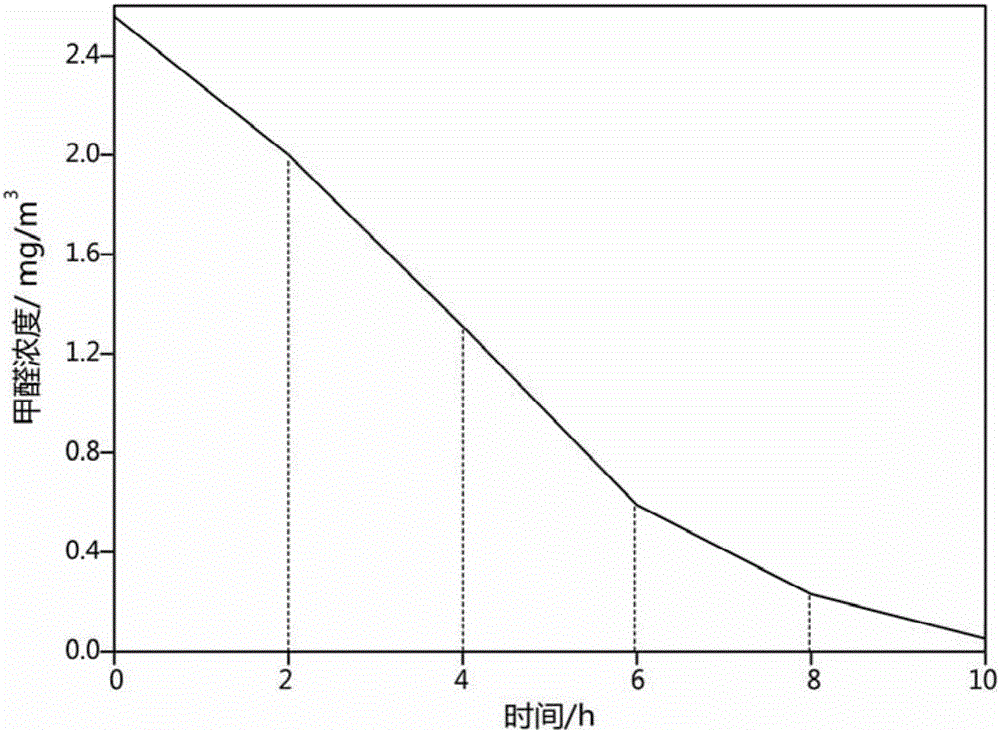

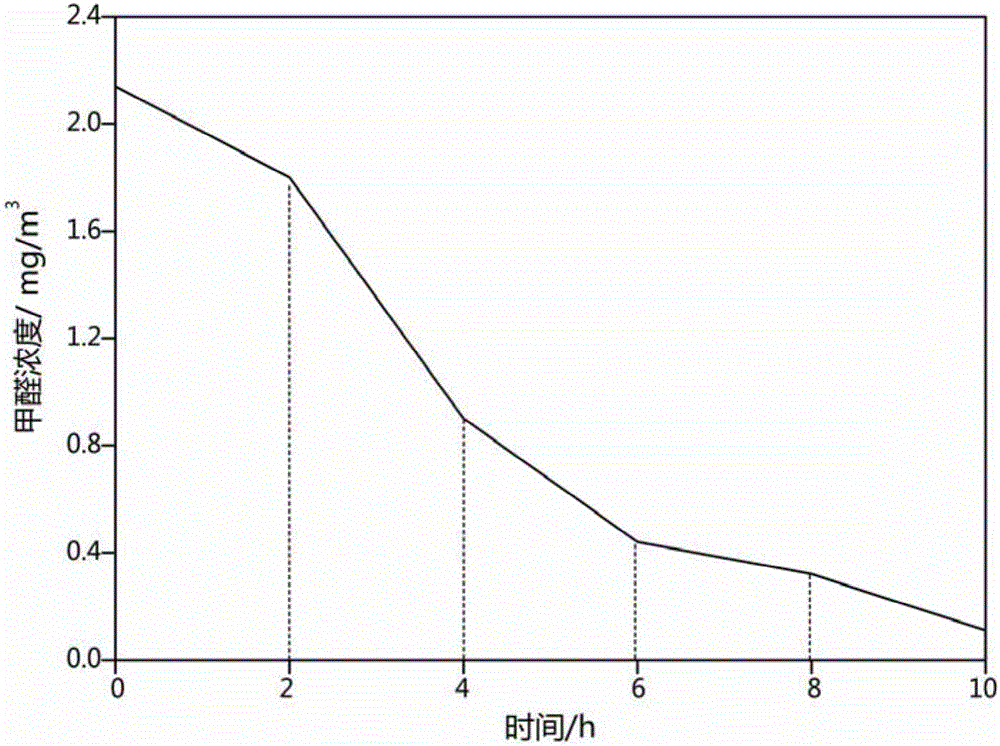

Formaldehyde degradation experiment chamber, experimental method and application for degrading formaldehyde by using photocatalyst

InactiveCN106984188ASimple structureSimple processGas treatmentAir-pressure/air-lock chambersPhysical chemistryPhoto catalysis

The invention relates to a formaldehyde degradation experiment chamber, an experimental method and an application for degrading formaldehyde by using a photocatalyst and belongs to the technical field of environmental protection. The formaldehyde degradation experiment chamber comprises an experiment chamber, an air pump, a needle valve and a buffer container; a small-size fan, an exhaust port, a fluorescent tube and a carrier are arranged in the experiment chamber; the air pump is connected with the needle valve, the buffer container, the control valve and the experiment chamber in turn through a pipeline. The experiment chamber has a simple structure and is convenient for an application experiment of degrading formaldehyde by using the photocatalyst. In an airtight space, the initial value of formaldehyde is not above 1.5mg / m<3>, the concentration of the photocatalyst is controlled within 0.1-0.5mg / m<3>, the temperature and humidity in the airtight space are identical to each other, a fluorescent tube is used as a light source for irradiating, the degradation rate of formaldehyde within 2h under the existence of Cu-TiO2 photocatalyst is 57.3%, the degradation rate of formaldehyde within 2h under the existence of SO4-modified Co-TiO2 photocatalyst is 58.7% and the degradation rate of formaldehyde within 2h under the existence of CdxMn1-xS photocatalyst is 57.8%; the degradation rate of formaldehyde within 10h is above 95%; the preparation method for the photocatalyst is simple in process, high in doping efficiency, low in cost and suitable for indoor air treatment.

Owner:DALIAN UNIV OF TECH

Preparation method of aqueous paint for degradation of formaldehyde gas and toluene gas

ActiveCN103275543AEfficient degradationActive removalPhysical/chemical process catalystsDispersed particle separationHydrolysisRaw material

A preparation method of an aqueous paint for degradation of a formaldehyde gas and a toluene gas is provided, and comprises: using a natural micropore nonmetal mineral as raw material; purifying the mineral by means of scrubbing, acid leaching, calcining and the like; using the purified micropore nonmetal mineral as a carrier, using an inorganic titanium salt as a precursor, and preparing a nano titanium dioxide composite photocatalytic material by neutralization, hydrolysis and precipitation at a low temperature; and using the prepared nano titanium dioxide composite photocatalytic material as a filler, and preparing the aqueous paint for degradation of the formaldehyde gas and the toluene gas. Harmful substances such as volatile organic compounds, formaldehyde, toluene and the like are not contained in the paint, and the formaldehyde gas and the toluene gas can be effectively degraded, with the formaldehyde degradation rate of up to 80% or more and the toluene degradation rate of up to 35% or more.

Owner:LUOYANG INST OF SCI & TECH

Sliver-titanium composite film loaded wood base material capable of degrading formaldehyde under visible light irradiation, and preparation method of sliver-titanium composite film loaded wood base material

InactiveCN105126923AHigh catalytic efficiencyHigh formaldehyde degradation efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationComposite filmPhotocatalytic degradation

The invention discloses a sliver-titanium composite film loaded wood base material for degrading formaldehyde under visible light irradiation, and a preparation method of the sliver-titanium composite film loaded wood base material, and relates to a wood base material capable of degrading formaldehyde under visible-light photocatalysis, and a preparation method of the wood base material. The sliver-titanium composite film loaded wood base material solves the problems that the conventional photocatalytic formaldehyde degradation method using single catalyst has the defects of small light-absorbing wavelength range, low catalytic efficiency and difficulty in recycle. The material is capable of degrading formaldehyde under the irradiation of visible light with wavelength of 400nm-800nm to reduce the concentration of formaldehyde to below 0.12mg / m3. Titanium dioxide loaded wood is firstly soaked in a Tollens' reagent to react; after the reaction, wood A is taken out of the Tollens' reagent, and the residual Tollens' reagent is obtained; the wood A is soaked in a glucose aqueous solution to react, and then the residual Tollens' reagent is added into the glucose aqueous solution in which the wood A is soaked to continue the reaction; and finally, performing washing and drying to obtain the sliver-titanium composite film loaded wood base material. The preparation method comprises: 1, preparing the titanium dioxide loaded wood; and 2, carrying out an impregnation reaction.

Owner:NORTHEAST FORESTRY UNIVERSITY

Antibacterial formaldehyde-removing catalytic material, and preparation method and application thereof

ActiveCN110639550AImprove transfer efficiencyRapid catalytic degradationGas treatmentAntifouling/underwater paintsPermanganate saltIron salts

The invention belongs to the technical field of catalytic materials and coatings, and discloses an antibacterial formaldehyde-removing catalytic material, and a preparation method and an application thereof. The preparation method comprises the following steps: adding a permanganate, an iron salt, an oxalate and silver nitrate into water, performing stirring for uniform mixing, carrying out a hydrothermal reaction at 70-120 DEG C, naturally cooling the obtained solution to room temperature after the reaction is finished, and separating, washing and drying the obtained solid product to obtain the powdery antibacterial formaldehyde-removing catalytic material. The antibacterial formaldehyde-removing catalytic material, titanium dioxide, a styrene-acrylic emulsion and water are stirred and mixed, assistants are added, and stirring is performed for uniform mixing to obtain an antibacterial formaldehyde-removing coating. The obtained catalytic material can be used for carrying out efficientcatalytic oxidation on formaldehyde under the condition of no light at room temperature, so that formaldehyde is degraded into harmless carbon dioxide and water. The obtained antibacterial formaldehyde-removing coating can be well smeared on artificial boards, plastic wallpaper and walls, and is safe, nontoxic and odorless. The catalytic material can quickly and safely degrade formaldehyde for along time.

Owner:SOUTH CHINA UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com