Preparation method and application of photocatalytic functional fabric

A functional fabric and photocatalytic technology, which is applied in the field of preparation of photocatalytic functional fabrics, can solve the problems of reduced photocatalytic activity, difficulty in recycling, easy precipitation of photocatalytic materials, etc., and achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

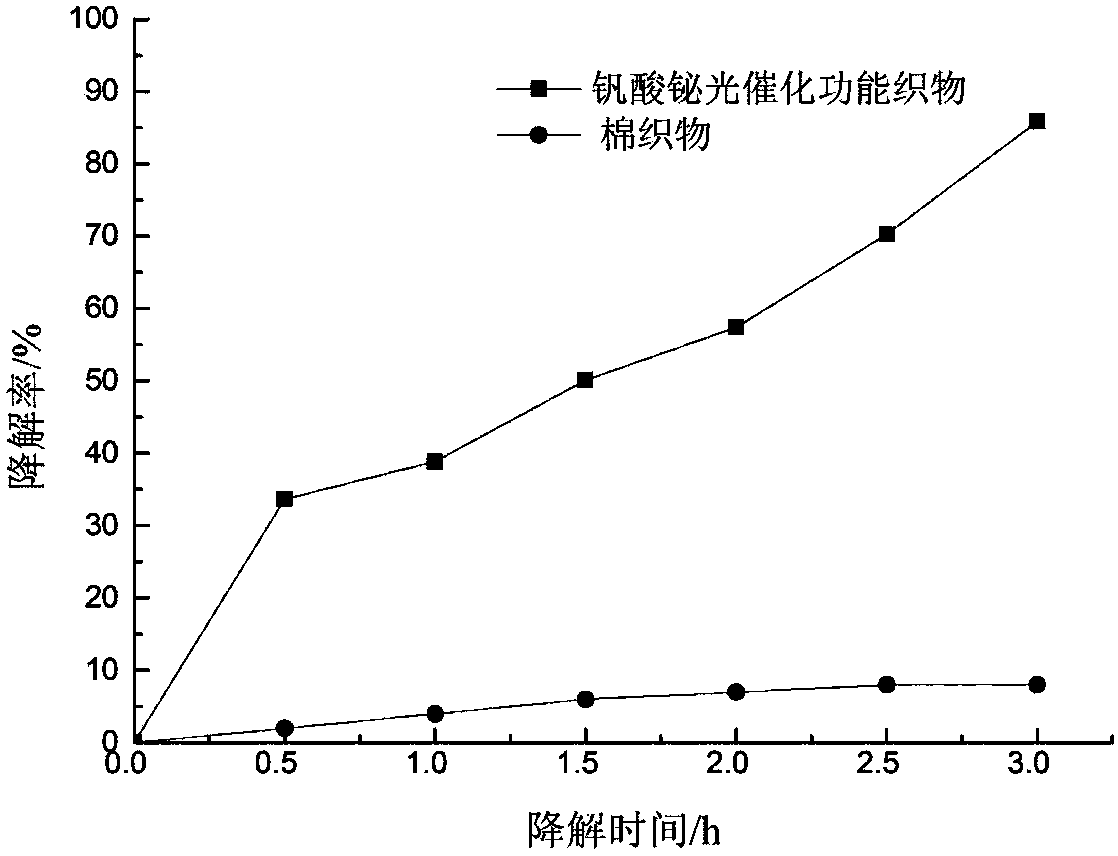

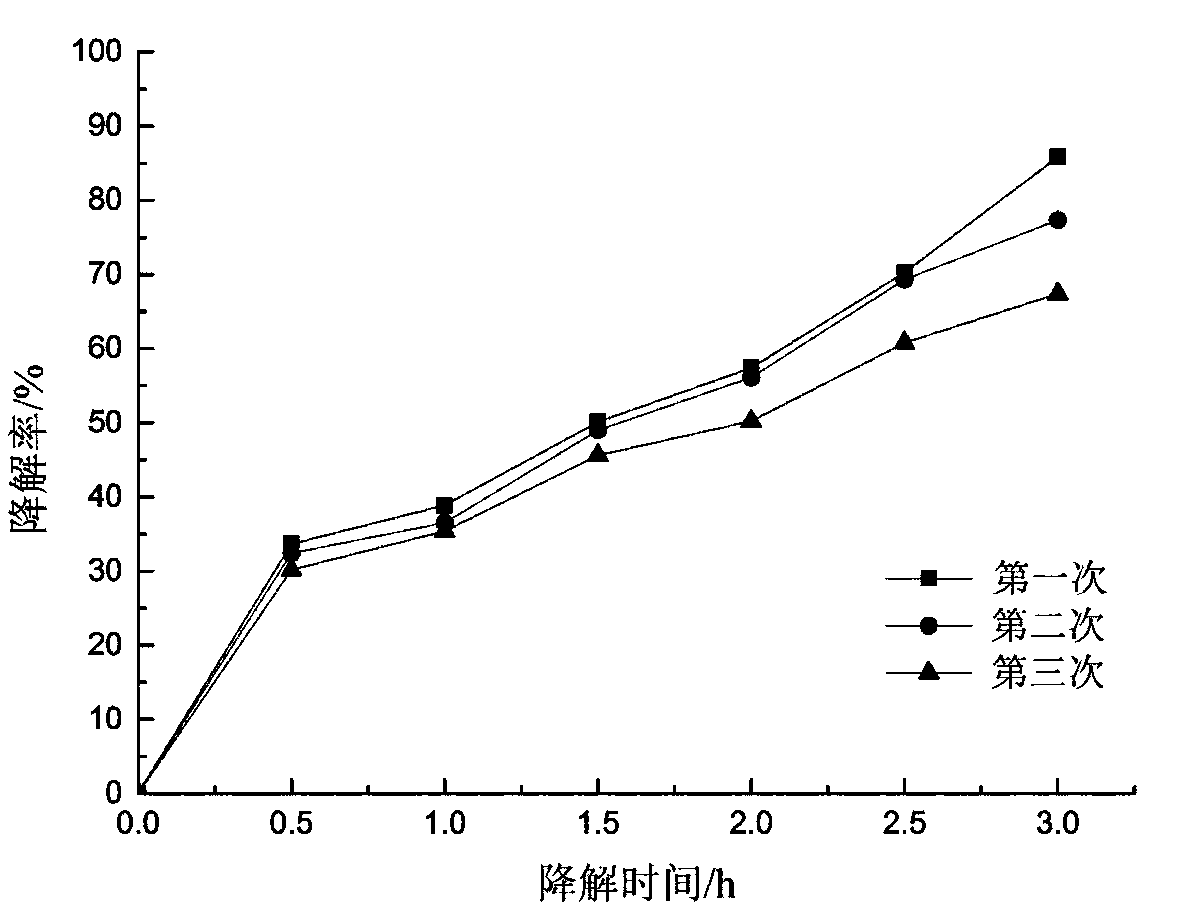

[0017] A method for preparing a photocatalytic functional fabric, comprising the following steps:

[0018] (1) Fabric pretreatment: boil the deboiled and bleached cotton fabric in hot water at 90°C for 10 minutes to remove the remaining water-soluble impurities on the fabric, take it out and dry it, immerse the fabric in acetone and ultrasonically for 30 minutes to further remove the surface of the fabric. Residual impurities were washed with distilled water for 3 times, and dried for later use.

[0019] (2) In situ growth of ZIF-8 on the fabric: 2.05 g of 2-methylimidazole was placed in 250 mL of methanol solution, and treated with ultrasound for 10 min to obtain A solution. Put 3.67g of zinc nitrate hexahydrate in 250mL of methanol solution, and use ultrasonic treatment for 10min to obtain B solution. Then soak 0.5g cotton fabric in solution A, treat with ultrasonic waves for 30min, then slowly add solution B dropwise to solution A soaked in cotton fabric, stir with magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com