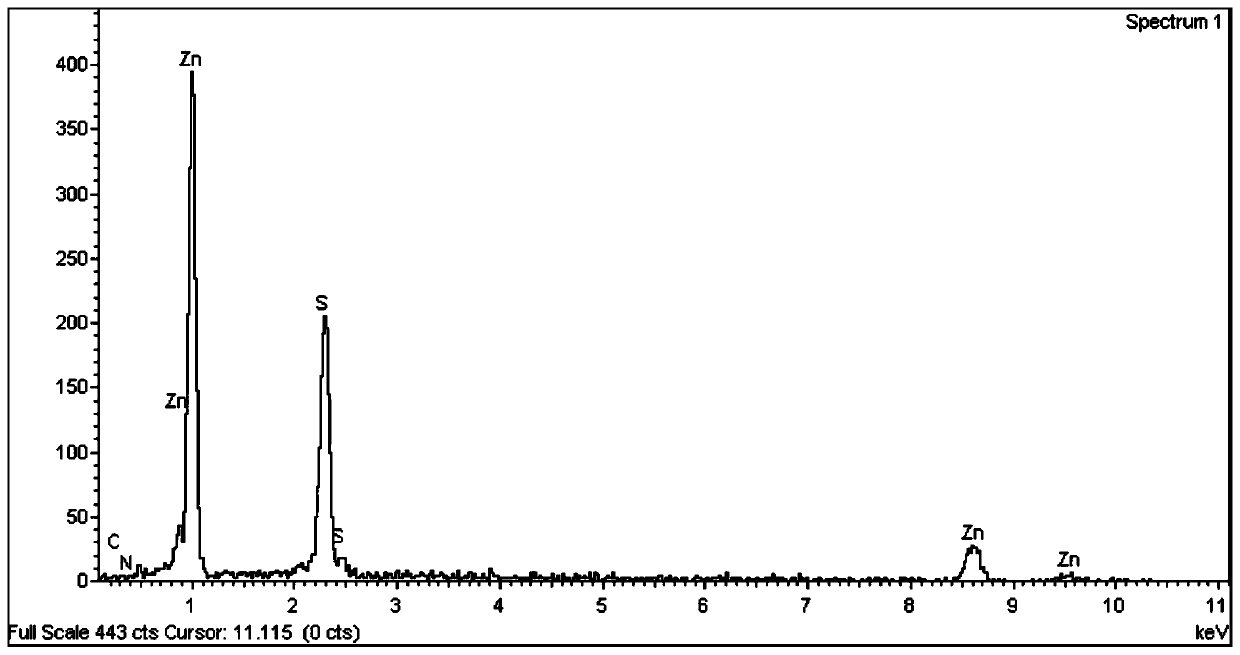

G-C3N4-ZnS composite nanomaterial as well as preparation method and application thereof

A composite nanomaterial, zinc sulfide technology, applied in chemical instruments and methods, catalyst activation/preparation, nanotechnology, etc., can solve the problems of low quantum efficiency, high coincidence rate of photogenerated electron holes, limited application, etc., and achieve strong formaldehyde Degradation ability, the effect of improving the photocatalytic degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

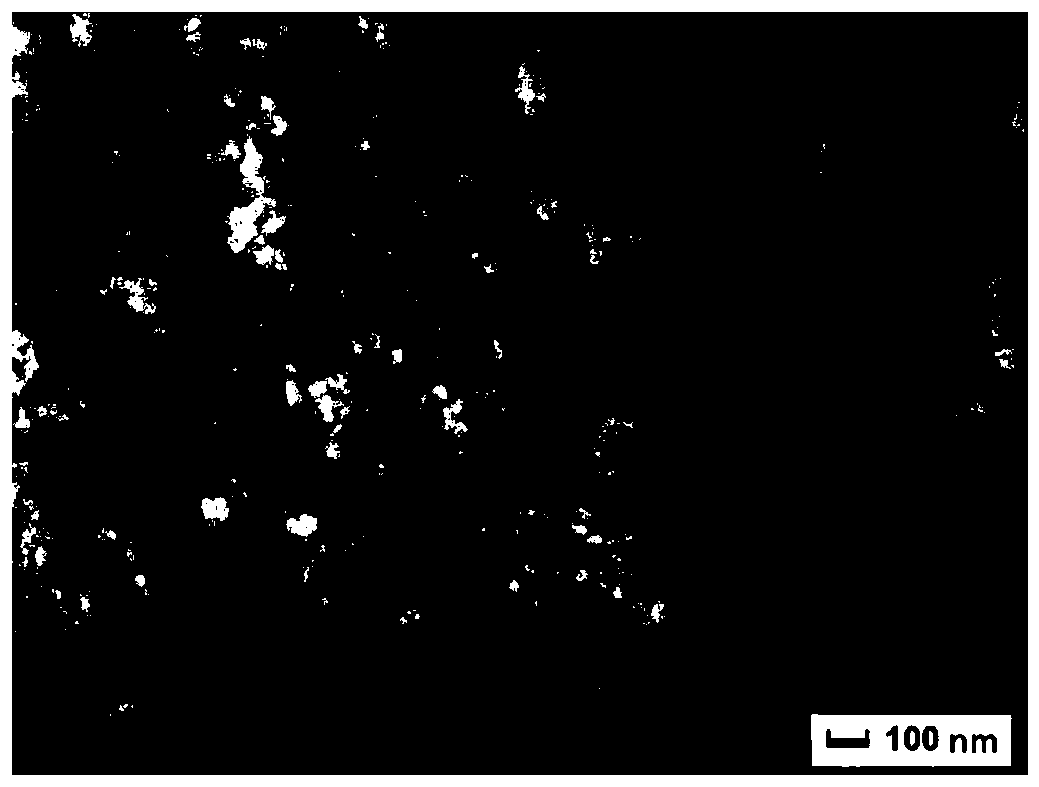

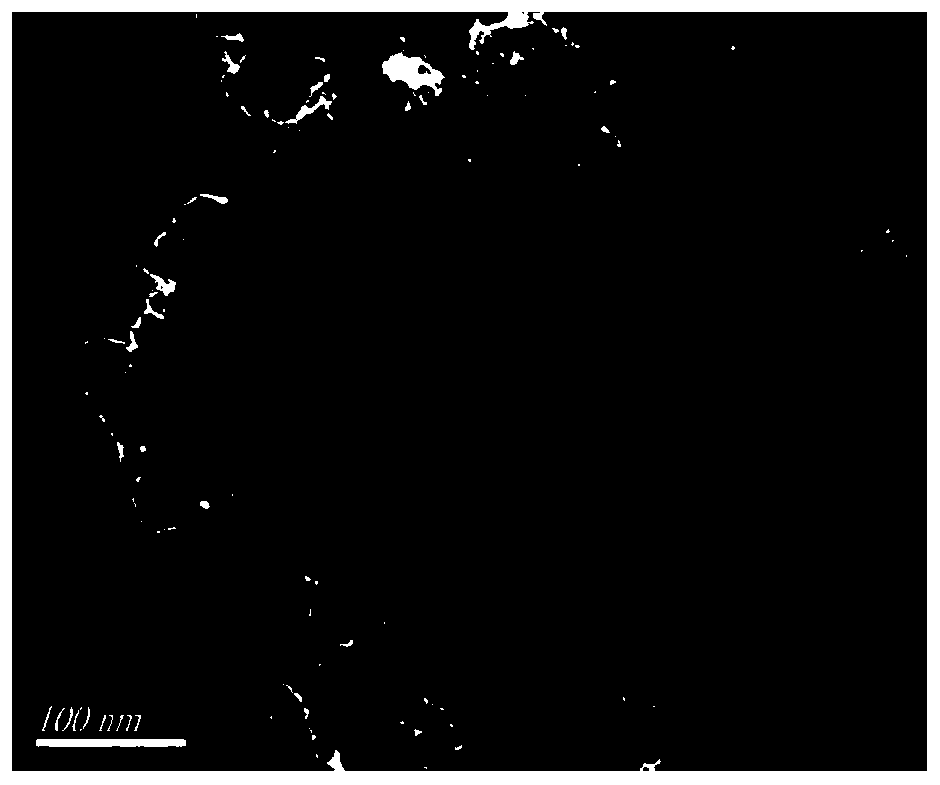

[0024] 1. Preparation of carbon nitrogen-zinc sulfide composite nanomaterials

[0025] 1.78g Zn(AC) 2 Dissolve in 50mL ethanol aqueous solution (according to volume ratio V 乙醇 :V 去离子水 =1:0.5~2), and then 0.05g of g-C prepared by solid phase method 3 N 4 Nanosheets and 0.02 g of hexadecyl diethylammonium bromide were added to the above solution, and after ultrasonic dispersion for 2 h, sodium sulfide solution (25 mL, 0.1 mol / L) was added dropwise until the precipitation was complete, and the mixture was transferred to a 100 ml In a stainless steel reaction kettle, place it in a vacuum drying oven at 160°C for 24 hours, and cool to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly three times with deionized water and absolute ethanol, and finally dried under vacuum at 80°C for 10 h to obtain g-C 3 N 4 / ZnS composite nanomaterials.

[0026] 2. Preparation of carbon nitrogen-zinc sulfide composite photocatalytic coating ...

Embodiment 2

[0029] 1. Preparation of carbon nitrogen-zinc sulfide composite nanomaterials

[0030] 2.75g Zn(NO 3 ) 2 Dissolve in 50mL ethanol aqueous solution (according to volume ratio V 乙醇 :V 去离子水 =1:0.5~2), and then 0.1g of g-C prepared by solid phase method 3 N 4 Nanosheets and 0.04 g of polyethylene glycol were added to the above solution, and after ultrasonic dispersion for 1 h, ammonium sulfide solution (25 mL, 0.1 mol / L) was added dropwise until the precipitation was complete, and the mixed solution was transferred to a 100 ml stainless steel reaction kettle, and placed Insulate at 160° C. for 24 hours in a vacuum oven, and cool to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly three times with deionized water and absolute ethanol, and finally dried under vacuum at 80°C for 10 h to obtain g-C 3 N 4 / ZnS composite nanomaterials.

[0031] 2. Preparation of carbon nitrogen-zinc sulfide composite photocatalytic coating

...

Embodiment 3

[0034] 1. Preparation of carbon nitrogen-zinc sulfide composite nanomaterials

[0035] 1.24g Zn(SO 4 ) 2 Dissolve in 50mL ethanol aqueous solution (according to the volume ratio V 乙醇 :V 去离子水 =1:0.5~2), and then 0.25g of g-C prepared by solid phase method 3 N 4 Nanosheets and 0.06 g of sodium lauryl sulfate were added to the above solution, and after ultrasonic dispersion for 2 h, thiourea aqueous solution [CS(NH 2 ) 2 ] (10mL, 0.5mol / L) until the precipitation was complete, the mixture was transferred to a 100ml stainless steel reaction kettle, placed in a vacuum oven at 180°C for 16h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly three times with deionized water and absolute ethanol, and finally dried under vacuum at 80°C for 10 h to obtain g-C 3 N 4 / ZnS composite nanomaterials.

[0036] 2. Preparation of carbon nitrogen-zinc sulfide composite photocatalytic coating

[0037] 0.1 g of g-C 3 N 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com