Preparation method of adsorption-photocatalysis compound type formaldehyde removing coating

A composite, photocatalytic technology, applied in the direction of coating, etc., can solve the problems of low efficiency of formaldehyde degradation and inability to enrich formaldehyde, and achieve the effect of extensive and long-lasting energy sources, no secondary pollution, and wide pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

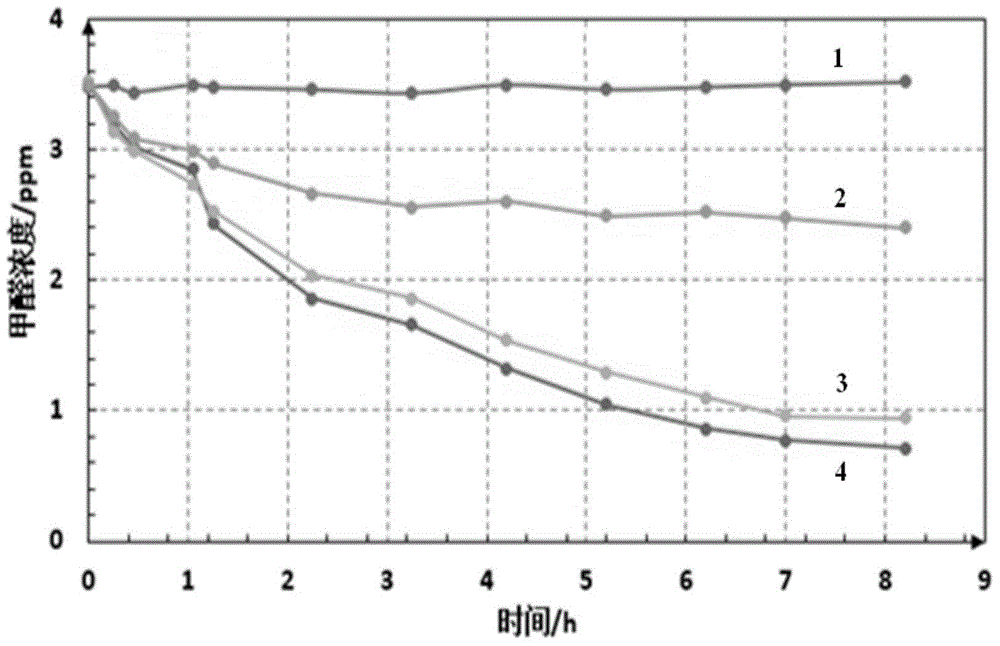

Image

Examples

specific Embodiment approach 1

[0022] Embodiment 1: In this embodiment, a method for preparing an adsorption-photocatalytic compound formaldehyde-removing coating is specifically carried out according to the following steps:

[0023] 1. Wash the activated carbon fiber with deionized water, then control the temperature at 80°C to 120°C, dry it for 2 hours, then dry it at room temperature for 24 hours, then put it in concentrated nitric acid, keep it at room temperature for 2 hours, and then use deionized water Rinse until the pH of the washing solution is 7, then keep it in the air at room temperature for 24 hours, and dry to prepare concentrated nitric acid-modified ACF;

[0024] 2. Under stirring conditions, add butyl titanate to the mixed solution of absolute ethanol and glacial acetic acid to obtain liquid A. The volume ratio of butyl titanate to the mixed solution of absolute ethanol and glacial acetic acid is 1:4.5-5.5 , the volume ratio of absolute ethanol and glacial acetic acid in the mixed solution...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass concentration of concentrated nitric acid in step one is 65%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the volume ratio of butyl titanate to the mixed solution of absolute ethanol and glacial acetic acid in step 2 is 1:5. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com