Sliver-titanium composite film loaded wood base material capable of degrading formaldehyde under visible light irradiation, and preparation method of sliver-titanium composite film loaded wood base material

A composite film and visible light technology, which is applied in separation methods, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as low catalytic efficiency, small wavelength range of light absorption, and difficult recycling. Achieve the effects of improving catalytic efficiency, easy process control, and expanding the absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

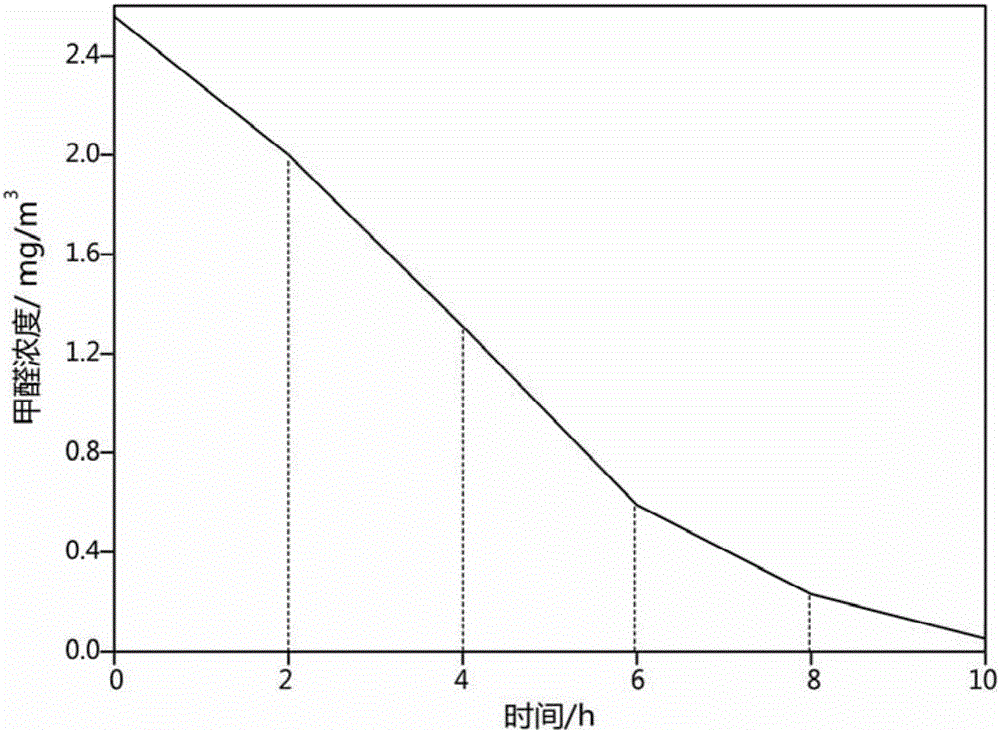

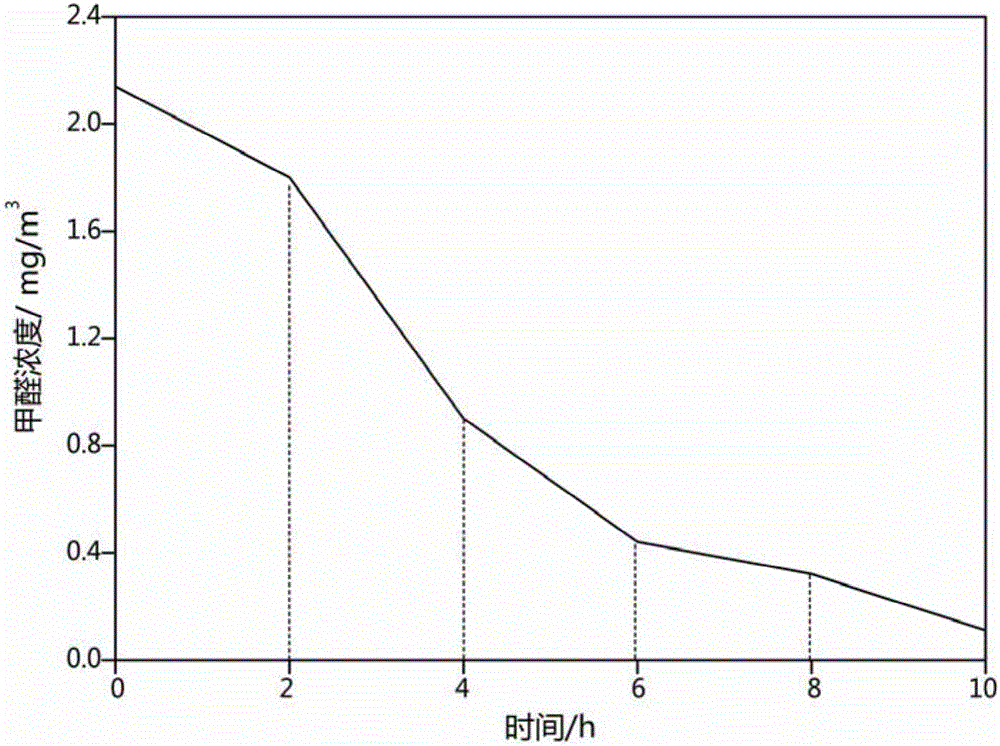

[0023] Specific Embodiment 1: The silver-titanium composite film-loaded wood-based material described in this embodiment can degrade formaldehyde to a concentration of 0.12 mg / m under visible light with a wavelength of 400 nm to 800 nm. 3 within;

[0024] The wood-based material supported by the silver-titanium composite film that degrades formaldehyde under visible light irradiation is first dipped into the silver-ammonia solution to react with the wood loaded with titanium dioxide. After the reaction, the wood A is taken out to obtain the remaining silver-ammonia solution, and then the wood A is Immersing in an aqueous glucose solution for reaction, then adding the remaining silver ammonia solution to the aqueous glucose solution impregnated with wood A to continue the reaction to obtain wood B, and finally washing and drying wood B to obtain;

[0025] The concentration of the aqueous glucose solution is 0.001mol / L˜10mol / L.

[0026] In this embodiment, the concentration of ...

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the titanium dioxide-loaded wood is prepared according to the following steps: mix boric acid, ammonium fluorotitanate and distilled water, stir evenly to obtain a mixed solution, and then Add a hydrochloric acid solution with a concentration of 0.001 mol / L to 10 mol / L dropwise into the mixed solution until the pH of the mixed solution is 3, and then immerse the wood in the mixed solution with a pH of 3. Hydrothermal reaction in a vacuum oven for 5h to 20h. After the reaction, wash the reacted wood with deionized water and dry it in an oven to obtain titanium dioxide-loaded wood;

[0033] The concentration of the boric acid in the mixed solution is 0.5mol / L-2mol / L; the concentration of the ammonium fluorotitanate in the mixed solution is 0.2mol / L-1.8mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the described silver ammonia solution is prepared according to the following steps: under stirring conditions, the mass percentage is 20%~40% ammoniacal liquor Add it dropwise to silver nitrate aqueous solution with a concentration of 0.1mol / L-2mol / L until clear and transparent to obtain silver ammonia solution. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com